Scratch-resistant photocuring odorless matte white finish paint

A light-curing, white topcoat technology, applied in the field of coatings, can solve the problems of leaving lead marks, strong odor, and no scratch resistance, and achieve the effect of improving wear resistance, good flexibility, and easy curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

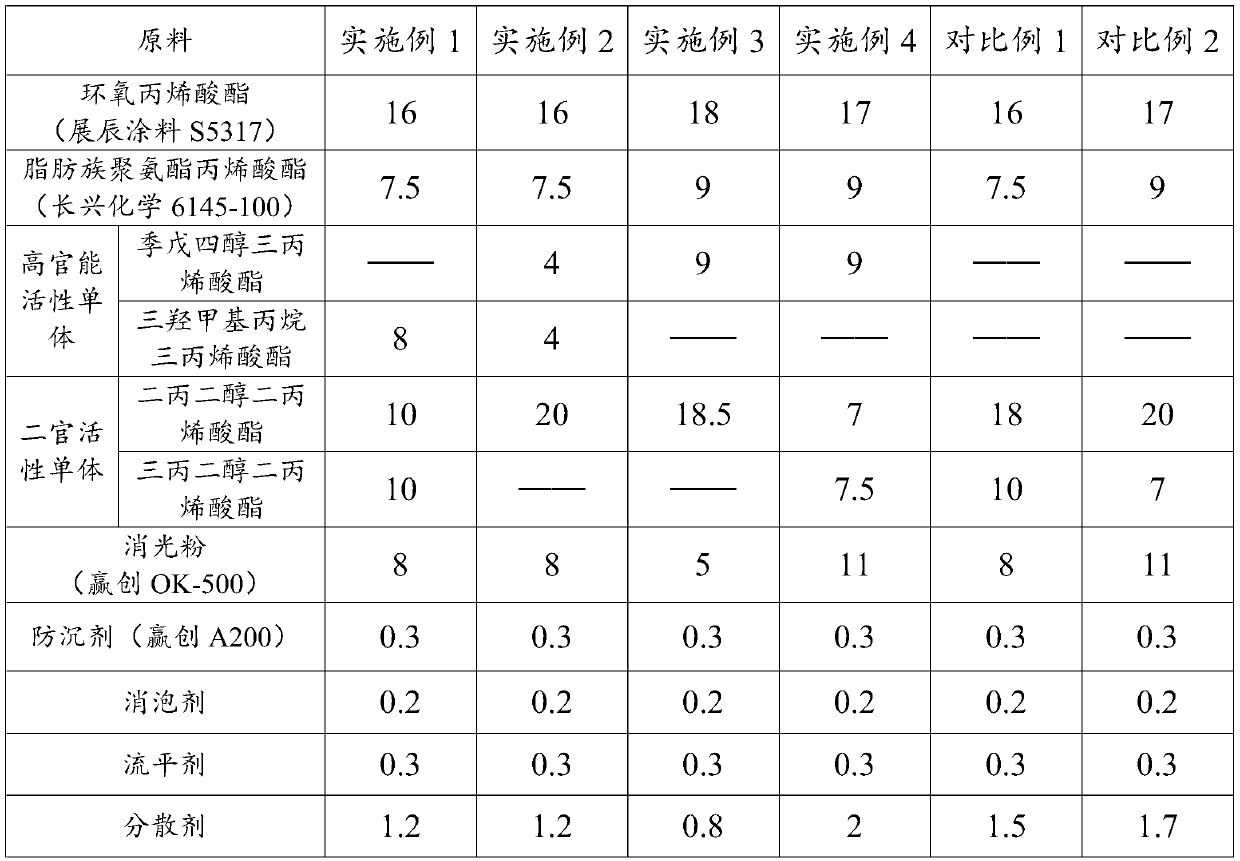

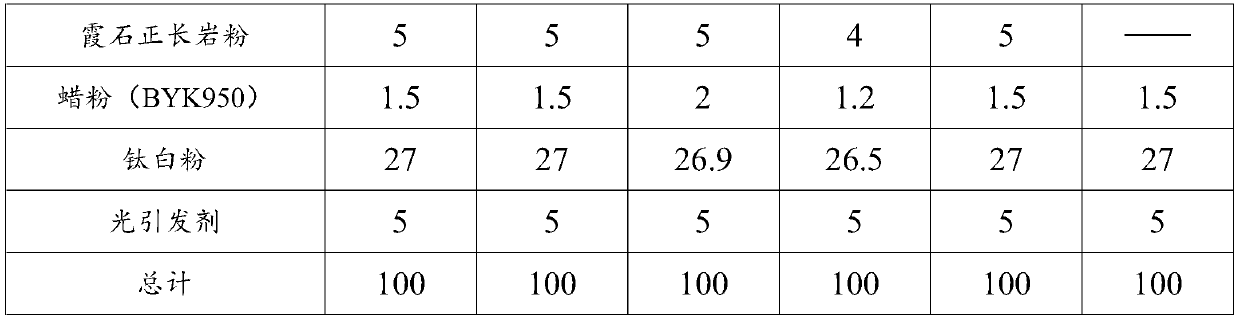

[0044] The raw materials of Examples 1-4 are listed in Table 1. Put the epoxy acrylate, aliphatic urethane acrylate, high-functional active monomer, difunctional active monomer, and photoinitiator into the reaction kettle, and disperse evenly at a speed of 500-800 rpm; then add the The defoamer, leveling agent, dispersant and anti-sedimentation agent are uniformly dispersed at a rotating speed of 500 to 800 rpm; then the matting powder, nepheline syenite powder, wax powder and titanium dioxide are added, and the Disperse for more than 30 minutes at 1500-2000 revolutions / min until the fineness is ≤35 microns, and then the anti-scratch light-curing odor-cleaning matte white finish of the present invention can be obtained.

[0045] The mass parts of the raw material of table 1 embodiment 1~4 and comparative example 1,2

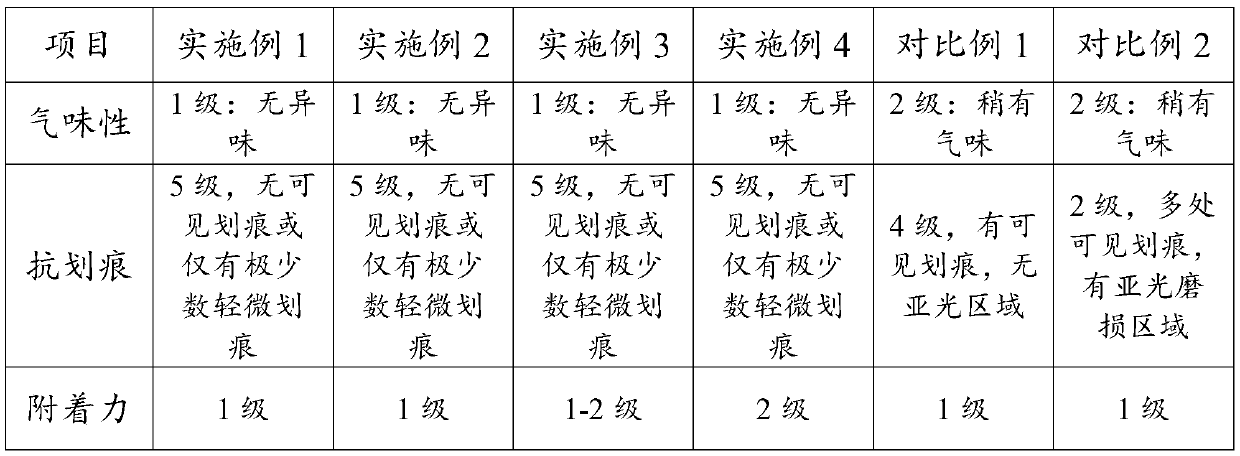

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com