Easy-to-clean ceramic product and preparation method thereof

A ceramic product and easy-to-clean technology, applied in the field of ceramic products, can solve the problems that the surface is not smooth enough, not easy to clean, easy to scratch, etc., and achieves the effect of high yield, not easy to scratch, and delicate glaze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

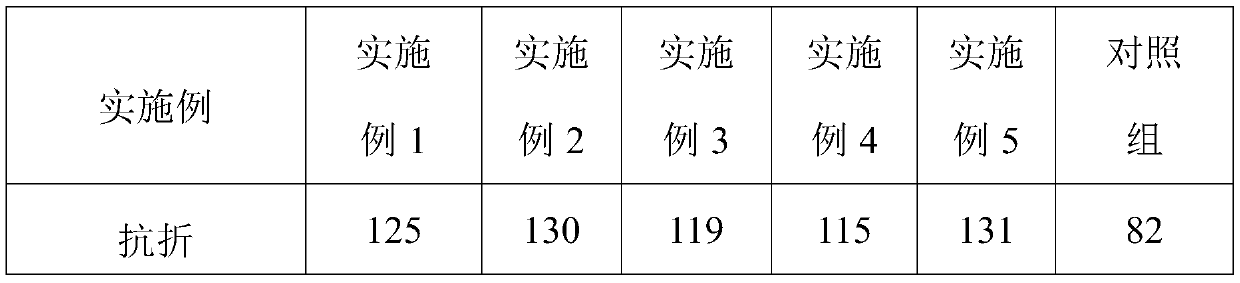

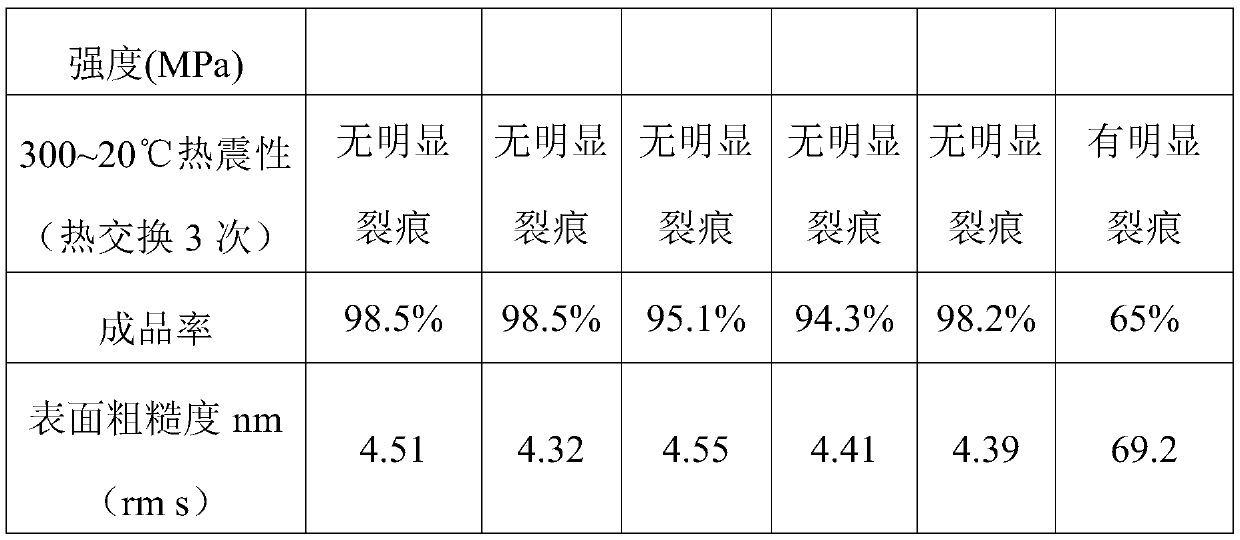

Examples

preparation example Construction

[0019] A preparation method for easy-to-clean ceramic products, comprising the following steps:

[0020] S1. Glaze production: put the above-mentioned nepheline syenite, dolomite, flint and spodumene into a pulverizer and then pass through a 100-mesh sieve to obtain a powder, and mix the powder with the above-mentioned magnesite, talc, barium carbonate Add Hongdie strontium carbonate into a ball mill for dry grinding for 8 hours to obtain the basic glaze, add 1.3 times the water of the basic glaze and Hebei Lingshou tourmaline whose weight is 8% of the basic glaze, carry out wet grinding for 10 hours, and then pass through a 200-mesh sieve , get glaze;

[0021] S2. Biscuit production: put the above clay, bentonite and quartz into a pulverizer and pulverize them, and then filter them with a 200-mesh sieve to obtain the basic powder. Put the basic powder into a ball mill for dry grinding for 8 hours, and then add 1.1 times of raw material water for wet grinding. After grinding ...

Embodiment 1

[0025] An easy-to-clean ceramic product, comprising a green body and a glaze layer applied on the surface of the green body, the green body includes the following raw materials in parts by weight: 30 parts of pottery clay, 8 parts of bentonite, and 10 parts of quartz; the glaze layer includes the following weight parts Parts of raw materials: 40 parts of nepheline syenite, 1 part of magnesite, 10 parts of flint, 4 parts of talc, 4 parts of barium carbonate, 10 parts of dolomite, 1 part of spodumene, and 1 part of strontium carbonate.

[0026] A preparation method for easy-to-clean ceramic products, comprising the following steps:

[0027] S1. Glaze production: Put the above-mentioned nepheline syenite, dolomite, flint and spodumene into a pulverizer and pulverize them, then pass through a 100-mesh sieve to obtain a powder, and put the powder into a high-temperature furnace for a heating rate of 8°C / min, 700°C heat preservation for 2.5h, anaerobic calcination at a cooling rate...

Embodiment 2

[0032] An easy-to-clean ceramic product, comprising a green body and a glaze layer applied on the surface of the green body, the green body includes the following raw materials in parts by weight: 40 parts of pottery clay, 13 parts of bentonite, and 17 parts of quartz; the glaze layer includes the following weight parts Parts of raw materials: 50 parts of nepheline syenite, 5 parts of magnesite, 18 parts of flint, 8 parts of talc, 10 parts of barium carbonate, 18 parts of dolomite, 5 parts of spodumene, and 5 parts of strontium carbonate.

[0033] A preparation method for easy-to-clean ceramic products, comprising the following steps:

[0034] S1. Glaze production: Put the above-mentioned nepheline syenite, dolomite, flint and spodumene into a pulverizer and pulverize them, then pass through a 100-mesh sieve to obtain a powder, and put the powder into a high-temperature furnace for a heating rate of 8°C / min, 900°C heat preservation for 1.5h, anaerobic calcination at a cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com