Fast-fired composite-phase microcrystal matt surface glaze slip and application thereof

A technology of smooth glaze and glaze slurry, which is applied in the field of glaze on ceramic surfaces, and can solve problems such as matte, strong refractive index of glazed light, and insufficient fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of high temperature zirconium white matt frit:

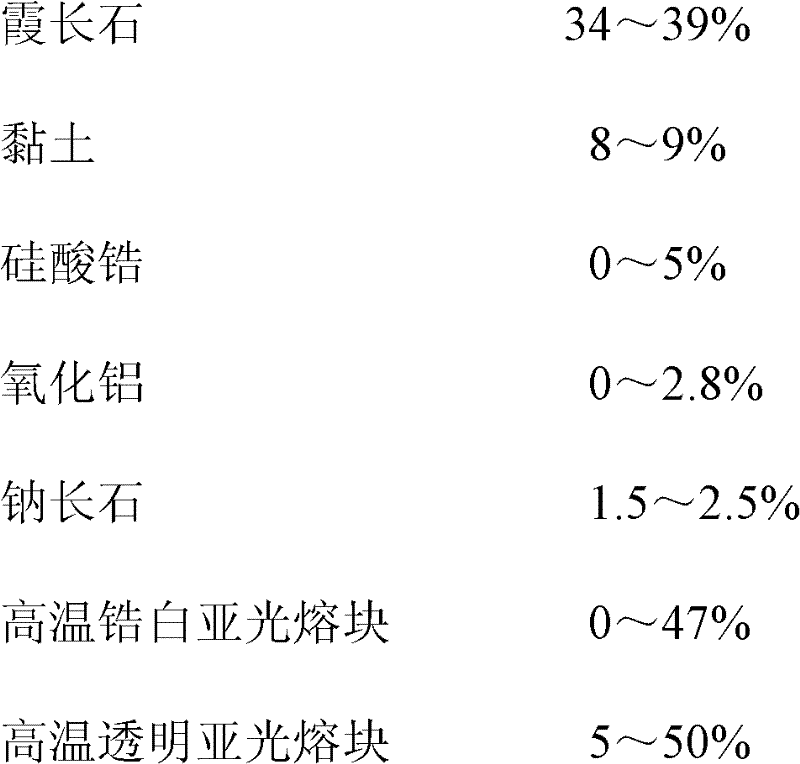

[0042] (1) According to the following weight percentages, each raw material is pulverized into 200-250 mesh particles respectively, and then mixed;

[0043]

[0044] (2) The mixture in step (1) was fired at 1570° C. for 2 hours to obtain a glassy molten slurry, which was quenched in water to obtain the high-temperature zirconium white matte frit; wherein, the weight percentage of each component is:

[0045] Mg: 6, Ca: 15, Al: 12.3, Si: 58, K: 0.5, Na: 0.2, Zr: 6.5, B: 1.0, Zn: 0.5;

[0046] Preparation of high temperature transparent matt frit:

[0047] (1) According to the following weight percentages, each raw material is pulverized into 200-250 mesh particles respectively, and then mixed;

[0048]

[0049] (2) The mixture in step (1) is fired at 1560-1580°C for 1.5-2 hours to obtain a glassy molten slurry, which is water-quenched to obtain the high-temperature transparent matte frit, wherein each co...

Embodiment 2

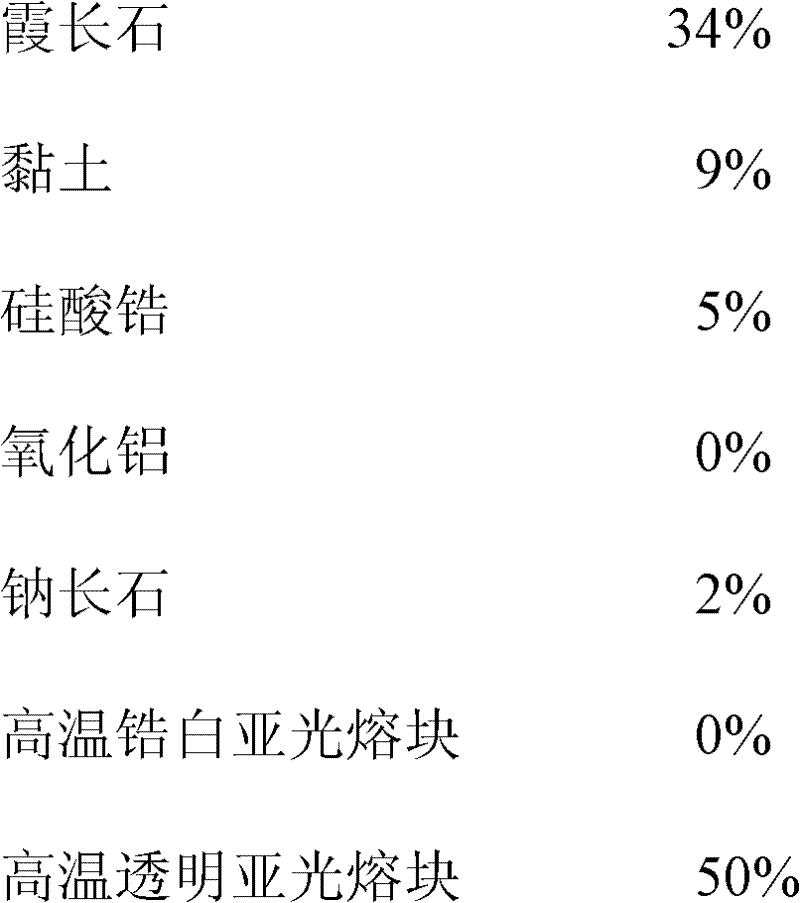

[0052] Described raw material mixture is made up of the component of following percentage by weight:

[0053]

[0054]

[0055] The high-temperature transparent matt frit was prepared by the method in Example 1.

[0056] The concrete steps that above-mentioned mixture is prepared into glaze slurry are:

[0057] Put the raw material mixture into the ball mill tank according to the usage amount, and then add water, sodium methylcellulose and sodium tripolyphosphate. The ratio of parts by weight of material mixture, sodium methylcellulose, sodium tripolyphosphate and water is:

[0058]

[0059] Ball milling to a particle size of 300-325 meshes to obtain a fast-firing multi-phase microcrystalline matte glaze glaze slurry; the specific steps for turning the glaze slurry into a multi-phase microcrystalline matte glaze are:

[0060] Apply the glaze slurry to the base glazed body, and then sinter it in a high-temperature gas roller kiln at 1195°C for a period of 50 minutes....

Embodiment 3

[0064] Customers who are using this product: Jiangxi Sun Ceramics and Mengtexiang Ceramics

[0065] Described raw material mixture is made up of the component of following percentage by weight:

[0066]

[0067]The high-temperature zirconium white matt frit and the high-temperature transparent matt frit were prepared by the preparation method in Example 1. The concrete steps that above-mentioned mixture is prepared into glaze slurry are:

[0068] Put the raw material mixture into the ball mill tank according to the usage amount, and then add water, sodium methylcellulose and sodium tripolyphosphate. The ratio of parts by weight of material mixture, sodium methylcellulose, sodium tripolyphosphate and water is:

[0069]

[0070]

[0071] Ball milling to a particle size of 300-325 meshes to obtain a fast-firing multi-phase microcrystalline matte glaze glaze slurry; the specific steps for turning the glaze slurry into a multi-phase microcrystalline matte glaze are:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com