Fiber-reinforced ceramic tile with high impact resistance

An impact-resistant, high-resistance technology, applied in the field of tiles, can solve problems such as insufficient toughness, and achieve the effect of not being easy to crack and increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

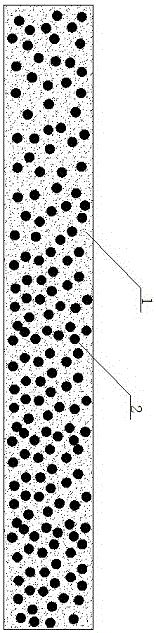

[0028] Specific embodiment 1: as figure 1 As shown, this embodiment discloses a carbon fiber reinforced high impact resistance ceramic tile, characterized in that, the carbon fiber reinforced high impact resistance ceramic tile includes a ceramic matrix 1 and a reinforced carbon fiber 2, and the reinforced carbon fiber is a carbon fiber reinforced nylon Fiber, the mass ratio of carbon fiber and nylon is 1:1, the carbon fiber of the carbon fiber reinforced nylon fiber is chopped carbon fiber, nylon adopts nylon 6.

[0029] The preparation method of the carbon fiber reinforced high impact resistance ceramic tile disclosed in this embodiment is as follows:

[0030] Step 1: The principles of the following parts by weight are mixed and prepared and fully mixed in a mixer:

[0031] 20 parts of quartz, 10 parts of nepheline syenite, 40 parts of albite, 5 parts of tin oxide, 20 parts of pyrophyllite, 5 parts of barium titanate, and 5 parts of magnesium carbonate form a mixture. The ...

specific Embodiment 2

[0035] Specific embodiment 2: as figure 1 As shown, this embodiment discloses a carbon fiber reinforced high impact resistance ceramic tile, characterized in that, the carbon fiber reinforced high impact resistance ceramic tile includes a ceramic matrix 1 and a reinforced carbon fiber 2, and the reinforced carbon fiber is a carbon fiber reinforced nylon Fiber, the mass ratio of carbon fiber and nylon is 1:1, the carbon fiber of the carbon fiber reinforced nylon fiber is chopped carbon fiber, nylon adopts nylon 6.

[0036] The preparation method of the carbon fiber reinforced high impact resistance ceramic tile disclosed in this embodiment is as follows:

[0037] Step 1: The principles of the following parts by weight are mixed and prepared and fully mixed in a mixer:

[0038] 20 parts of quartz, 10 parts of nepheline syenite, 40 parts of albite, 5 parts of tin oxide, 20 parts of pyrophyllite, 5 parts of barium titanate, and 5 parts of magnesium carbonate form a mixture. The ...

specific Embodiment 3

[0041] Specific embodiment 3: as figure 1 As shown, this embodiment discloses a carbon fiber reinforced high impact resistance ceramic tile, characterized in that, the carbon fiber reinforced high impact resistance ceramic tile includes a ceramic matrix 1 and a reinforced carbon fiber 2, and the reinforced carbon fiber is a carbon fiber reinforced nylon Fiber, the mass ratio of carbon fiber and nylon is 1:3, the carbon fiber of the carbon fiber reinforced nylon fiber is chopped carbon fiber, and nylon adopts nylon 6.

[0042] The preparation method of the carbon fiber reinforced high impact resistance ceramic tile disclosed in this embodiment is as follows:

[0043] Step 1: The principles of the following parts by weight are mixed and prepared and fully mixed in a mixer:

[0044]20 parts of quartz, 10 parts of nepheline syenite, 40 parts of albite, 5 parts of tin oxide, 20 parts of pyrophyllite, 5 parts of barium titanate, and 5 parts of magnesium carbonate form a mixture. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com