Quantitative rule-based automatic batching assembly line for prefabricated dishes and batching method

A technology of automatic batching and prefabricated dishes, which is applied in the direction of chemical instruments and methods, mixer accessories, mixers, etc., can solve the problems of unfeeding, affecting the uniformity of ingredients, and uneven content, so as to ensure uniformity and increase the effect of ingredients , to ensure the effect of the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

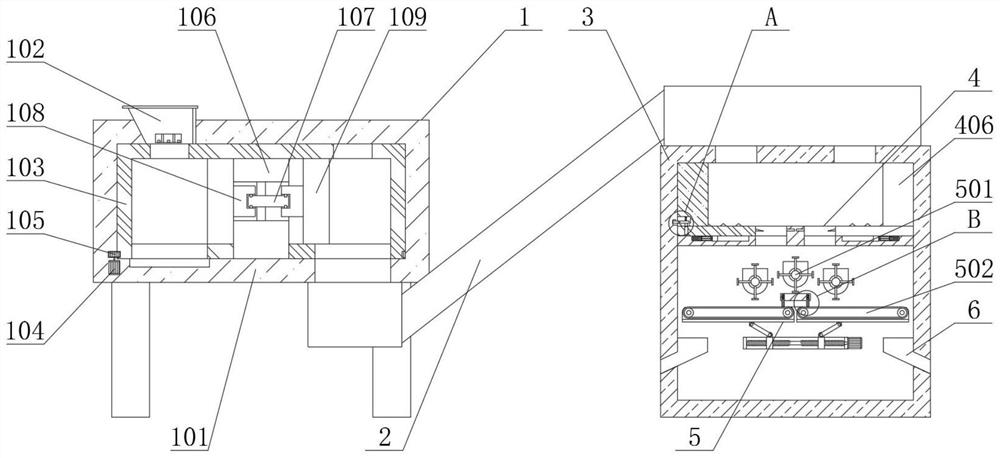

[0029] see Figure 1-6 , the present invention provides a technical solution:

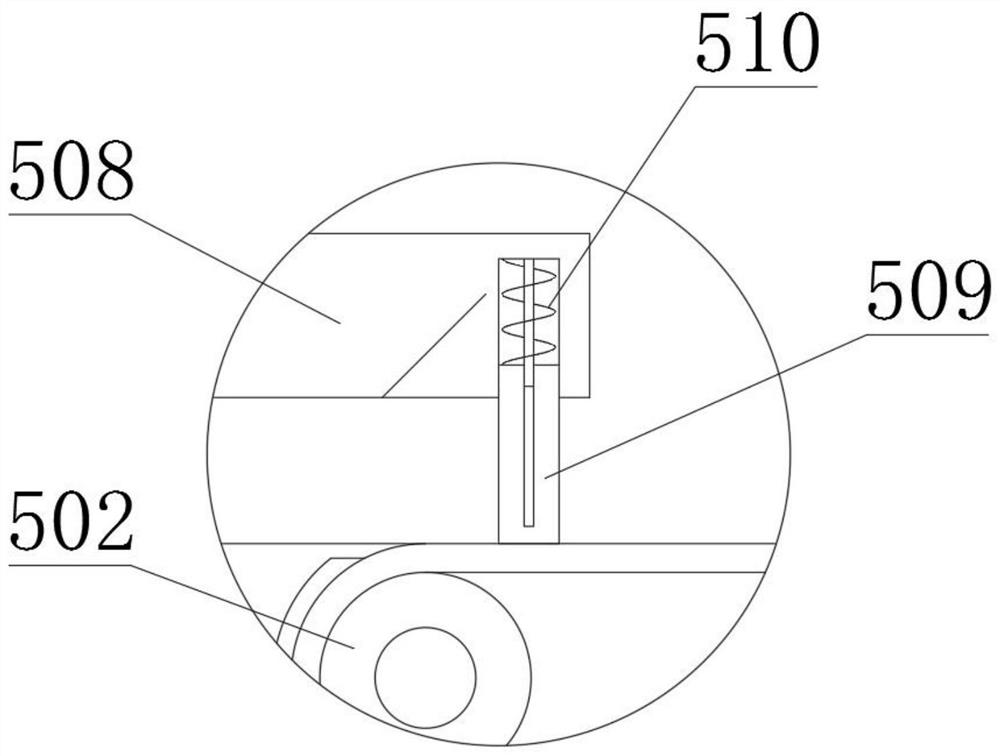

[0030] An automatic batching assembly line and batching method for prefabricated dishes based on quantitative rules, including a quantitative classification device 1 for prefabricated dishes, a conveyor 2 and a batching box 3, the top of the batching box 3 is connected to a conveyor 2, and the left end of the conveyor 2 is provided with a prefabricated dish Quantitative sorting device 1 for dishes, which connects the quantitative sorting device 1 for prepared dishes with the batching box 3 through the conveyor 2 to realize the delivery of the prepared dishes. The quantitative sorting device 1 for prepared dishes includes a sorting box 101, a hopper 102, and a round basin for pushing 103, the first motor 104, the transmission gear 105, the fixed cylinder 106, the eccentric wheel 107, the sliding seat 108 and the push plate 109, the bottom end of the sorting box 101 communicates with the conveyor 2, ...

Embodiment 2

[0034] see Figure 1-6 , the present invention provides a technical solution:

[0035] An automatic batching line and batching method for prefabricated dishes based on quantitative rules, the same parts as in Embodiment 1 in Embodiment 2 will not be repeated in the present invention, and the difference lies in the work flow.

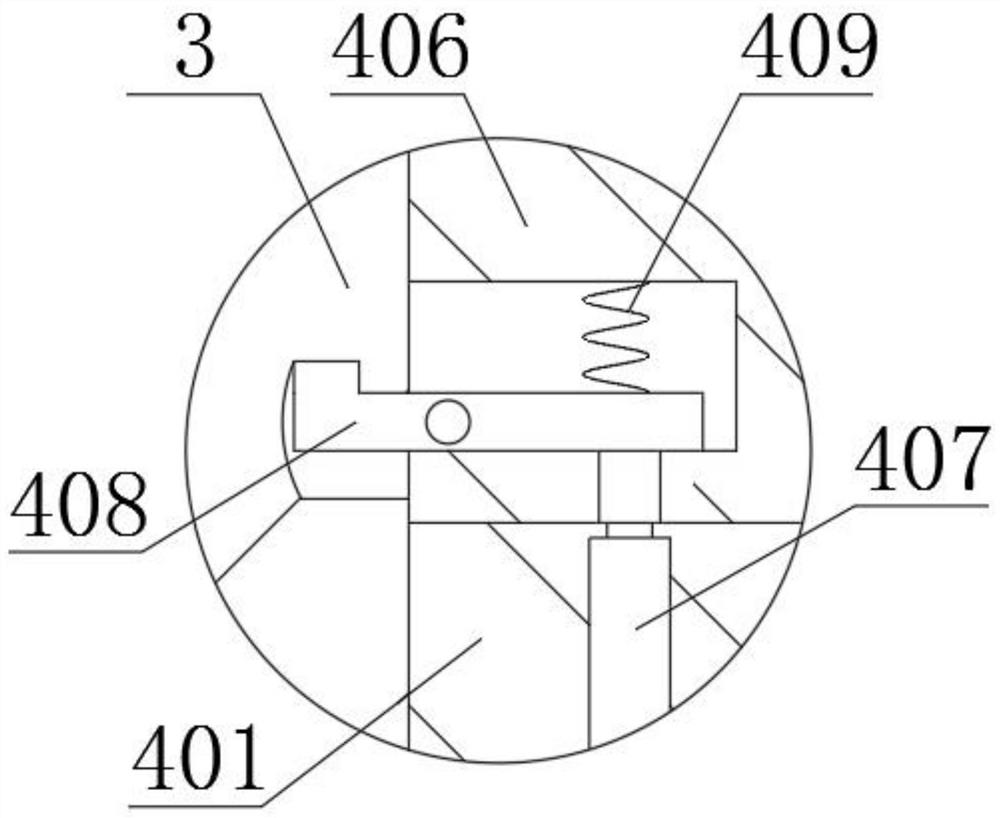

[0036] Workflow: When some prefabricated dishes cannot be driven by the shaking plate 402 due to their large mass or being attached to the surface, the electric telescopic rod 407 can be activated when the electric telescopic rod 407 is corresponding to the bottom of the L-shaped clip 408 Make the electric telescopic rod 407 stretch until the electric telescopic rod 407 limits the L-shaped clip 408, so that the L-shaped clip 408 is no longer engaged with the batching box 3, and at this time the movement of the shaking plate 402 will drive the push block 406 Move together, and push the prefabricated dishes with larger quality, or scrape and push the dish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com