A seal line adhesive for a sanitary napkin single-sheet package film and a preparing method thereof

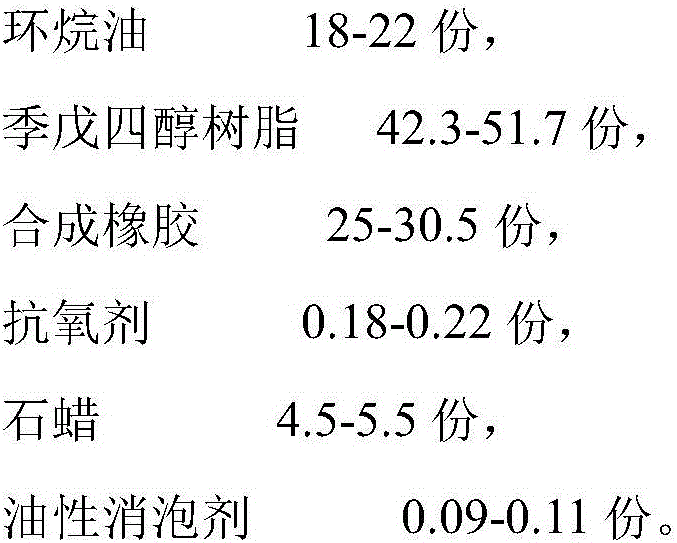

A technology for packaging films and sanitary napkins, which is applied in the field of single-piece packaging film sealing glue for sanitary napkins and its preparation, and can solve the problems of improved adhesion, easy tearing of packaging films, and inconvenience in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

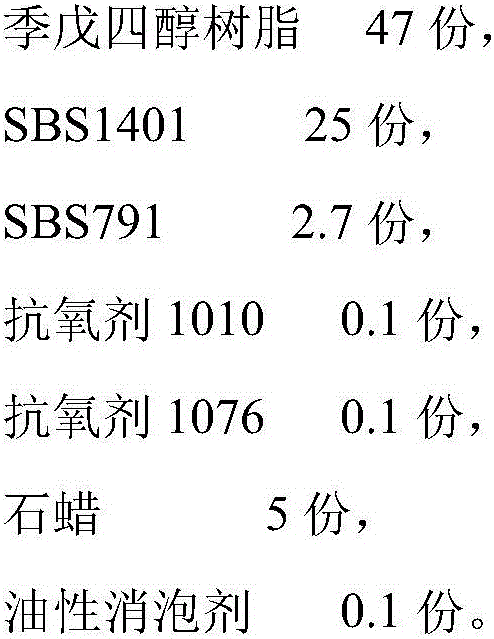

Embodiment 1

[0041] The specific process of preparing the sealing line glue for single-piece packaging of sanitary napkins is as follows:

[0042] Step 1: Set the temperature of the reactor to 100° C., then add 20 g of naphthenic oil and stir for 10 min at a speed of 100 rpm.

[0043] Step 2: Continue to heat up the reaction kettle to 120°C, add 25g of SBS1401, 2.7g of SBS791 and 5g of paraffin, and continue to stir for 90min at a speed of 100 rpm.

[0044] Step 3: Continue heating the reactor to 140°C, add 47g of pentaerythritol resin, 0.1g of antioxidant 1010, 0.1g of antioxidant 1076 and 0.1g of oily defoamer, and stir for 20 minutes at a speed of 200 rpm.

[0045] Step 4: The product obtained in step 3 is discharged after being vacuumed for 10 minutes, and filtered twice through a filter cover with a pore size of 1 cm and a filter cloth bag of 300 mesh respectively, and then placed in a container to cool to room temperature before encapsulation.

[0046] The appearance of the sealing li...

Embodiment 2-7

[0048] The process flow in each of the following examples is similar to Example 1, the only difference lies in the proportioning of components and process parameters. The quality of each component in Example 1 and the following examples is shown in Table 2. The process parameters involved in Example 1 and the following examples are shown in Table 3.

[0049] The quality of each component in table 2 embodiment 1 to embodiment 7

[0050]

[0051]

[0052] The process parameters involved in table 3 embodiment 1 to embodiment 7

[0053]

[0054] The performance test result comparison of the sealing line glue that table 4 embodiment 1 to embodiment 7 prepares

[0055]

[0056]

[0057] Based on the above test results, Example 1 has better performance. When heated to 150°C and 160°C, the viscosity is moderate, that is, the packaging film can be sealed, and it is easy to tear when the user peels it off. And reduce the processing and use temperature of sealing line g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com