Transparent hardening composition, TAC glasses film and preparation method of TAC glasses film

A composition and transparent technology, applied in coatings, instruments, optics, etc., can solve problems such as poor wear resistance, and achieve the effects of improved coating properties, extended service life, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

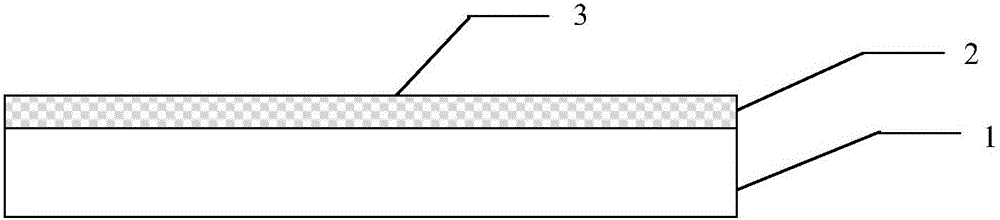

Image

Examples

Embodiment 1

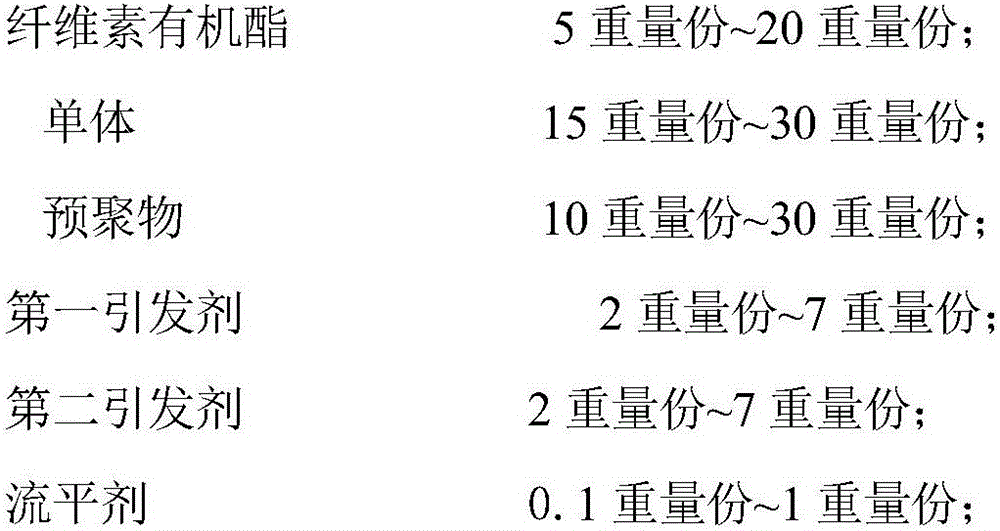

[0048] 1. Preparation of cellulose organic ester reaction solution:

[0049] Cellulose acetate butyrate 5g

[0050] Monomer triethylene glycol diacrylate 15g

[0051] The first initiator 2g

[0052] Mix 5g of cellulose acetate butyrate [Eastman, CAB-550-5, acetyl 4%, butyryl 51%, hydroxyl 1%] and 15 g of triethylene glycol diacrylate monomer [Sartomer TEGDA , SR272, functionality 2] mixed, stirred on a heating mixer at 30°C for 1 hour at a high speed, so that the solid cellulose organic powder particles were evenly swollen in the monomer diluent, and 2g of the first initiator [BASF, Germany, 184] Add it into the mixed solution and continue to stir at a low speed for 0.5 hour to pre-crosslink the cellulose organic ester and the monomer to form 22 g of the cellulose organic ester reaction solution.

[0053] 2. Preparation of transparent hardening solution:

[0054]

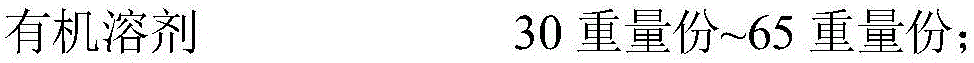

[0055] Dissolve 10g of aliphatic urethane acrylate prepolymer EB205 [Ubicil, functionality 3] into 30g of ...

Embodiment 2

[0059] 1. Preparation of cellulose organic ester reaction solution:

[0060]

[0061] 5g cellulose acetate butyrate [Eastman, CAB-550-5, acetyl 4%, butyryl 51%, hydroxyl 1%], 5g cellulose acetate [Eastman CA-398-10, acetyl Base 40%, hydroxyl 3.5%] mixed with 15g of pentaerythritol triacrylate monomer [Shanghai Yante PETA, functionality 3], stirred at a high speed of 30°C for 1 hour on a heating mixer, so that the solid cellulose organic powdery particles were evenly swollen In the monomer diluent, add 4g of the first initiator [Beijing Yingli, 1173] into the mixed solution, and continue to stir at a low speed for 0.5 hours to pre-crosslink the cellulose organic ester and the monomer to form 29g of cellulose organic ester The reaction solution.

[0062] 2. Preparation of transparent hardening solution:

[0063]

[0064] Dissolve 15g of aliphatic urethane acrylate prepolymer 6145-100 [Changxing Chemical, functionality 6] into 65g of toluene solvent, add 0.3g of polysilox...

Embodiment 3

[0068] 1. Preparation of cellulose organic ester reaction solution:

[0069]

[0070] 5g cellulose acetate butyrate [Eastman, CAB-550-5, acetyl 4%, butyryl 51%, hydroxyl 1%], 5g cellulose acetate [Eastman CA-398-10, acetyl Base 40%, hydroxyl 3.5%], 5g cellulose acetate propionate [Eastman, CPA-482-0.5, acetyl 2.5%, propionyl 45%, hydroxyl 2.6%] and 20g hydroxyethyl methacrylate [ Shanghai Cytec HEMA, functionality 1] mixed, stirred on a heating mixer at 30°C for 1 hour, so that the solid cellulose organic powder particles were uniformly swelled in the monomer diluent, and 2g of the first initiator [Beijing Yingli , 1173] was added to the mixed solution, and continued to stir at a low speed for 0.5 hours to pre-crosslink the cellulose organic ester and the monomer to form a 37g cellulose organic ester reaction solution.

[0071] 2. Preparation of transparent hardening solution:

[0072]

[0073]

[0074] Dissolve 19g of aliphatic urethane acrylate prepolymer KJ9503 [...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com