Efficient electromagnetic pulse valve and working method thereof

An electromagnetic pulse valve, high-efficiency technology, applied in the direction of the valve operation/release device, valve details, diaphragm valve, etc., can solve the problems of the dust removal effect of the dust collector, the air supply time becomes longer, the diaphragm cracks and fails, etc., to achieve enhanced reliability Performance and service life, improved circulation efficiency, and fast pulse action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

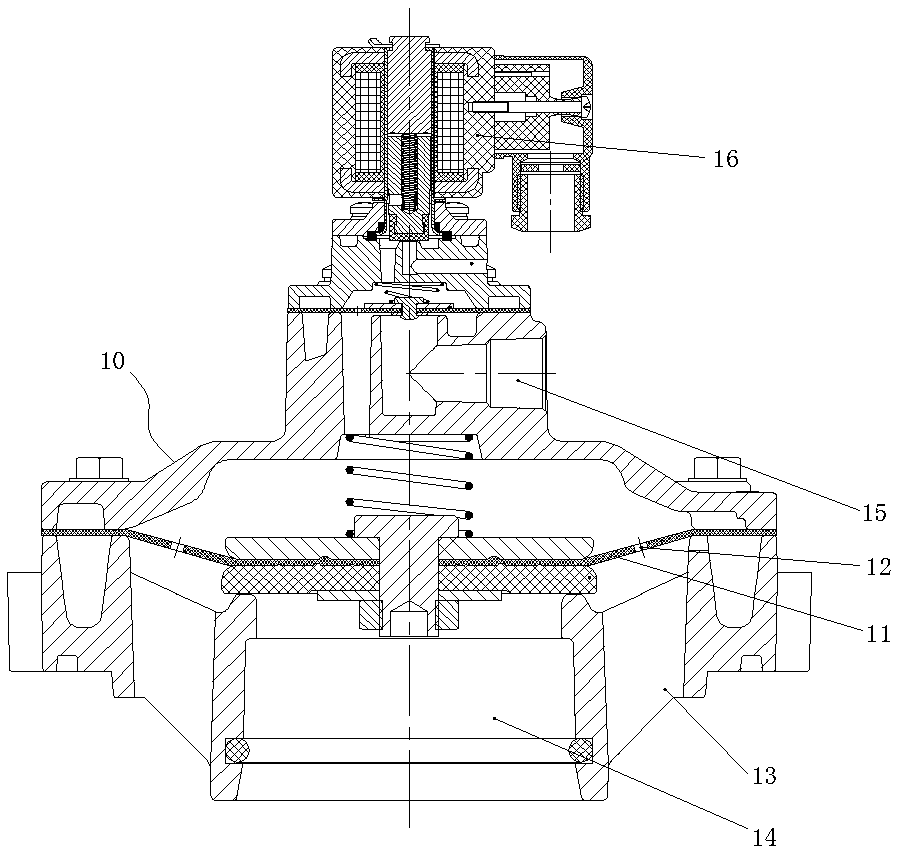

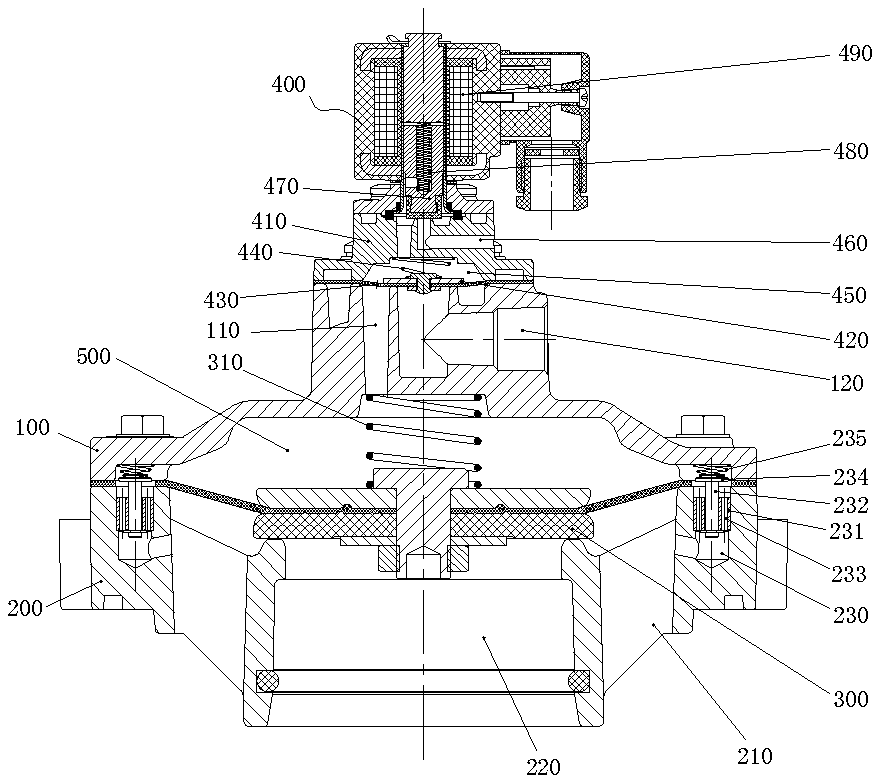

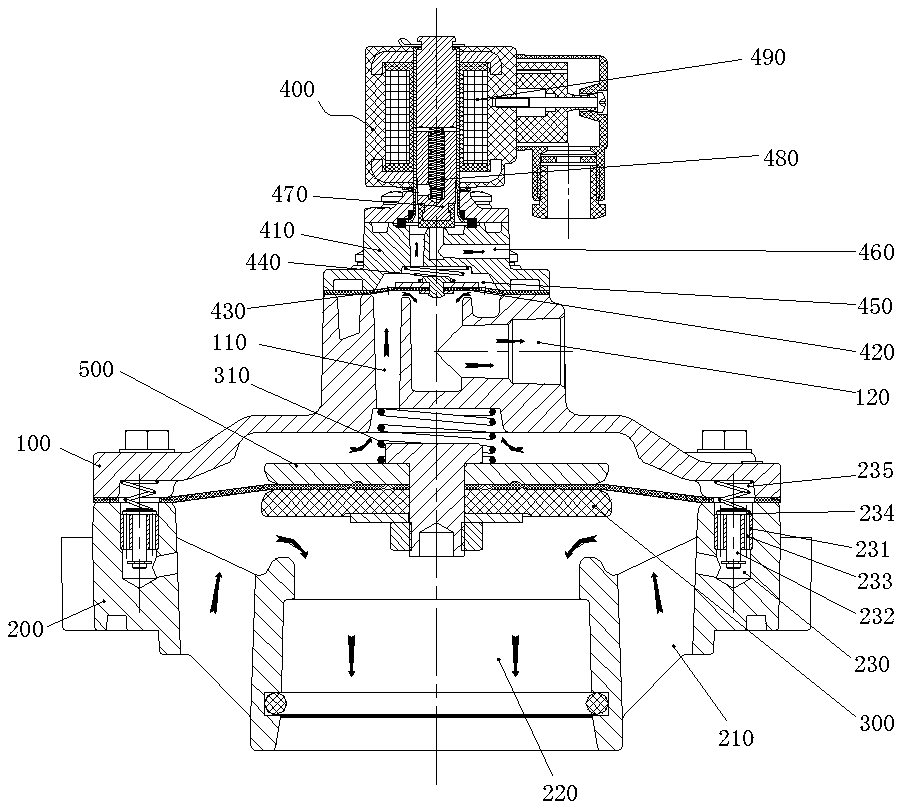

[0019] Such as Figure 2~6 As shown, a high-efficiency electromagnetic pulse valve includes an upper valve seat 100 and a lower valve seat 200, an inlet passage 210 is arranged on the edge of the lower valve seat 200, an air outlet passage 220 is arranged at the center of the lower valve seat 200, and an air outlet passage 220 is arranged on the upper valve seat 100 and the lower valve seat 200. A first diaphragm assembly 300 is arranged between the lower valve seat 200 to block the inlet passage 210 and the outlet passage 220, a first spring 310 is arranged between the first diaphragm assembly 300 and the upper valve seat 100, and the upper valve The upper end of the seat 100 is also provided with a control valve 400 capable of attracting the first diaphragm assembly 300 to move upwards, and a first air chamber 500 is provided between the first diaphragm assembly 300 and the upper valve seat 100, which is characterized in that: the lower valve seat On 200, along the central a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com