Self-feedback two-phase system drilling fluid mixing system and method of mixing drilling fluid

A hybrid system, self-feedback technology, applied in wellbore/well components, earthmoving, flushing wellbore, etc., can solve the problems of well kill failure, small safety margin, damage to the network structure, etc., to protect work safety , increase reliability, mix high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

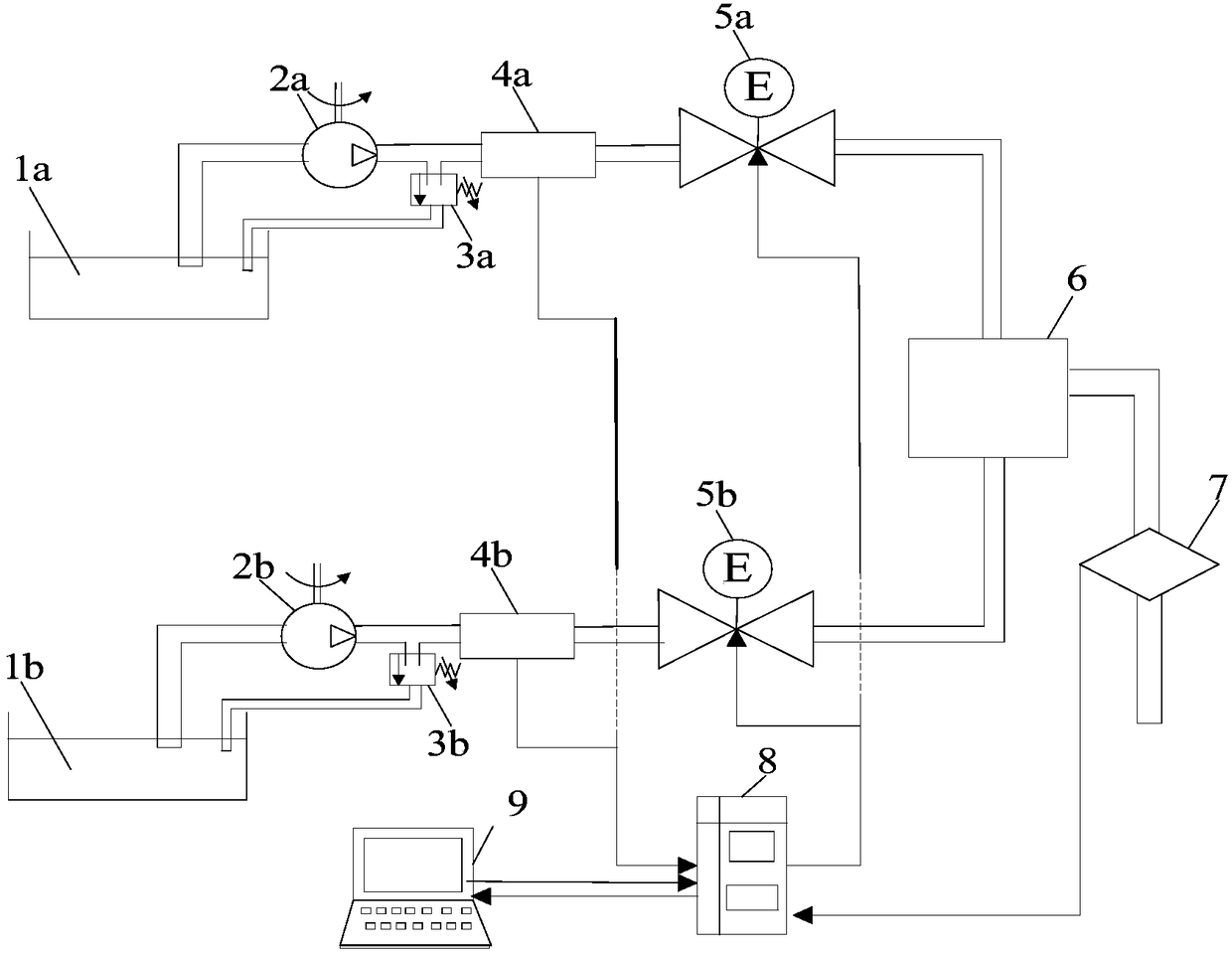

[0023] like figure 1 As shown, the self-feedback two-phase system drilling fluid mixing system includes: a mixer 6, a seawater pool 1a, and a base slurry pool 1b; the seawater pool 1a is connected to the mixer 6 through a first pipeline, and the base slurry pool 1b is connected through a second pipe The road is connected with the mixer 6; wherein, the seawater tank 1a holds seawater, and is used to provide seawater raw materials for the first pipeline; the base slurry tank 1b holds the base slurry, and is used to provide the base slurry raw materials for the second pipeline; After entering the mixer 6 and mixing, it enters the mud pool or the mud pump manifold through the density feedback module 7.

[0024] The mortar pump 2a, the first flowmeter 4a and the first control valve 5a are sequentially installed on the first pipeline from the seawater pool 1a to the mixer 6; wherein, an overflow return bypass is provided between the mortar pump 2a and the first flowmeter 4a , the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com