Recycled asphalt mixture and preparation method thereof

A technology of recycled asphalt and mixture, applied in the field of recycled asphalt mixture and its preparation, can solve the problems of insufficient use of asphalt mixture, increased processing costs, and a large amount of construction waste, so as to improve regeneration effect, reduce waste, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

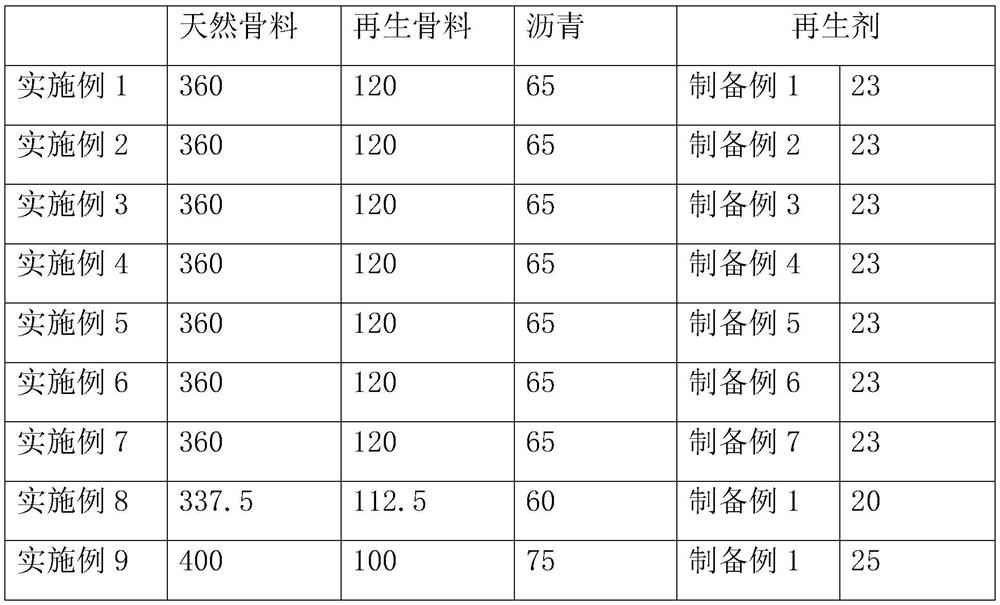

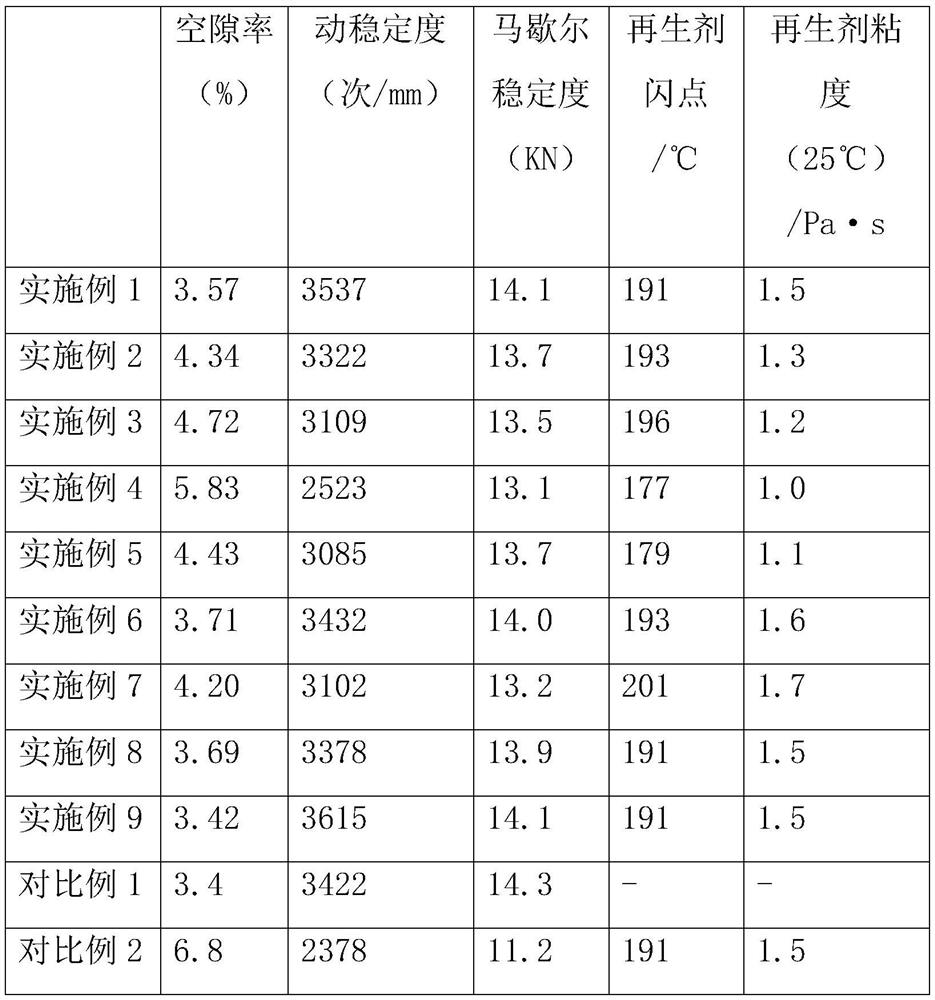

preparation example 1-3

Comparative example 1 10kg 20kg 30kg 1.5kg 6kg 1.5kg 1.5kg Comparative example 2 10kg 20kg 40kg 1.4kg 8kg 2kg 2kg Comparative example 3 10kg 30kg 40kg 1.34kg 8kg 4kg 4kg

[0041] A preparation method of a regeneration agent for regenerated asphalt mixture, comprising the following steps

[0042] S1: Mix heavy oil and ethanol in proportion to obtain stable heavy oil components;

[0043] S2: Adding Al to the stable heavy oil component 2 o 3 Powder, AlCl 3 Powder, mixed evenly to obtain oil phase and solid phase mixture;

[0044] S3: Finally, add glycerin and palm oil to the oil phase and solid phase mixture, and mix evenly in an 80°C ambient water bath;

[0045] S4: Add plasticizer and stir at 80°C for 20 minutes.

[0046] AlCl used 3 、Al 2 o 3 The average particle size is 2mm.

preparation example 4

[0048] The difference with Preparation Example 1 is that no ethanol, Al 2 o 3 Particles, AlCl 3 particles.

[0049] The preparation method of this preparation example regeneration agent, comprises the following steps:

[0050] S1 Mix heavy oil, glycerin and palm oil in proportion in a water bath at 80°C;

[0051] Add plasticizer to S2 and stir at 80°C for 20 minutes.

preparation example 5

[0053] The difference with Preparation Example 1 is that Al is not added in this preparation example 2 o3 , AlCl 3 .

[0054] The preparation method of this preparation example regeneration agent, comprises the following steps:

[0055] S1, mixing heavy oil and ethanol in proportion to obtain a stable heavy oil component;

[0056] S2, adding glycerin and palm oil to the stable heavy oil component, and mixing evenly under a water bath at 80°C;

[0057] S3, add plasticizer, and stir at 80°C for 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com