Environment friendly industrial oil stain cleaning agent and preparing method thereof

An industrial oil-stained, environmentally friendly technology, applied in detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve problems such as cleaning and environmental pollution, reduce usage, improve cleaning effect, and heavy metal content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

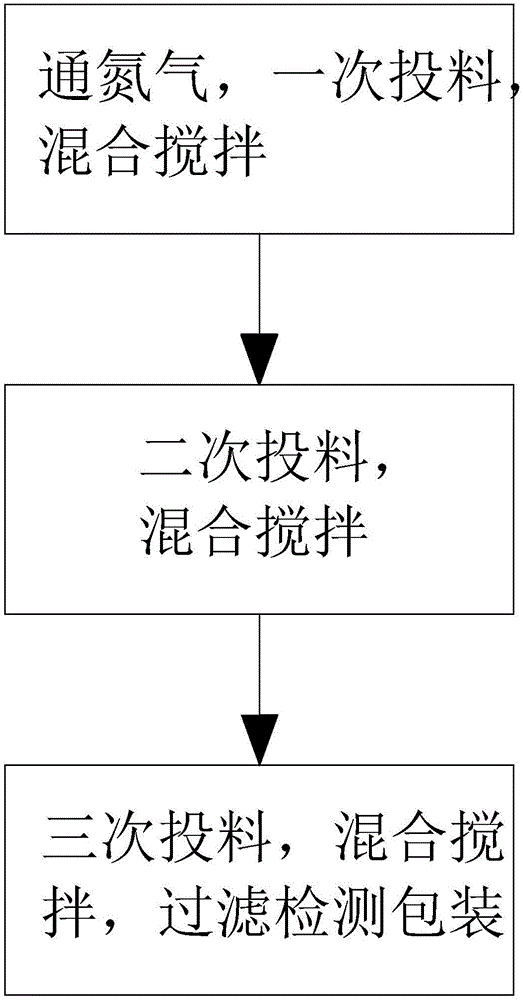

Method used

Image

Examples

Embodiment 1

[0043] Step 1: Introduce nitrogen into the reaction kettle for evacuation treatment, add 75kg of water, 2kg of polyethylene glycol, and 2kg of isopropanol into the reaction kettle, and then add 1kg of sodium citrate and 5kg of ethylenediaminetetraacetic acid Add sodium and 5kg fatty alcohol polyoxyethylene ether sodium sulfate into the reaction kettle in turn and mix and stir, the stirring temperature is 25-35°C, the stirring speed is 60-100rpm, until the stirring is uniform;

[0044]Step 2: Slowly add 2kg of sodium carbonate and 1kg of sodium dodecylbenzenesulfonate into the reaction kettle, and mix and stir until the stirring is even, the stirring speed is 50-80rpm, and the stirring temperature is 30-40°C;

[0045] Step 3: 3kg amine oxide, 0.7kg dimethyldiallyl ammonium chloride-acrylamide copolymer, 0.3kg polydimethyldiallyl ammonium chloride, 0.8kg sulfonated lignin, 0.4kg poly Aspartic acid, 0.8kg tallow amine, 0.7kg THIX-578 sewage treatment defoamer and 0.3kg THIX-108 s...

Embodiment 2

[0047] Step 1: Introduce nitrogen into the reaction kettle for evacuation treatment, add 45kg of water, 5kg of polyethylene glycol, and 5kg of isopropanol into the reaction kettle, and then add 5kg of sodium citrate and 10kg of ethylenediaminetetraacetic acid Add sodium and 10kg fatty alcohol polyoxyethylene ether sodium sulfate into the reaction kettle in turn and mix and stir, the stirring temperature is 25-35°C, the stirring speed is 60-100rpm, until the stirring is uniform;

[0048] Step 2: Slowly add 5kg of sodium carbonate and 3kg of sodium dodecylbenzenesulfonate into the reaction kettle, and mix and stir until the stirring is even, the stirring speed is 50-80rpm, and the stirring temperature is 30-40°C;

[0049] Step 3: 5kg amine oxide, 0.7kg dimethyldiallylammonium chloride-acrylamide copolymer, 1.3kg polydimethyldiallylammonium chloride, 0.75kg sulfonated lignin, 0.75kg poly Add aspartic acid, 1.5kg tallow amine, 0.8kg THIX-578 sewage treatment defoamer and 1.2kg THI...

Embodiment 3

[0051] Step 1: Introduce nitrogen into the reaction kettle for evacuation treatment, add 60kg of water, 3.4kg of polyethylene glycol, and 3.6kg of isopropanol into the reaction kettle, and then add 3kg of sodium citrate and 7.6kg of ethylenediamine Disodium tetraacetate and 7.5 kg of fatty alcohol polyoxyethylene ether sodium sulfate were sequentially added to the reaction kettle for mixing and stirring, the stirring temperature was 25-35°C, the stirring speed was 60-100 rpm, until the stirring was uniform;

[0052] Step 2: Slowly add 3.5kg of sodium carbonate and 2kg of sodium dodecylbenzenesulfonate into the reaction kettle, and mix and stir until it is evenly stirred. The stirring speed is 50-80rpm, and the stirring temperature is 30-40°C;

[0053] Step 3: 4kg amine oxide, 0.63kg dimethyldiallyl ammonium chloride-acrylamide copolymer, 0.77kg polydimethyldiallyl ammonium chloride, 0.75kg sulfonated lignin, 0.52kg poly Add aspartic acid, 1.13kg tallow amine, 0.75kgHIX-578 def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com