Oil-displacing agent for binary oil displacement and binary oil displacement mining method of oil field

The technology of oil displacement agent and auxiliary agent is applied in the field of oil displacement agent for binary oil displacement and oil field binary oil displacement, and can solve the problem of high cost of oil displacement agent, and achieves good effect, obvious effect and simple and easy-to-obtain raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a kind of oil displacement agent for binary oil displacement, which is prepared through the following steps:

[0040] 0.3g sodium polyacrylate, 0.08g polyoxyethylene sorbitan monooleate, microdispersant (ATMP, 0.001g) are dissolved with appropriate amount of Daqing oil field water to obtain a solution, and it is the NaCl aqueous solution of 20wt% to adjust the mineral content of the solution. Then dilute it with Daqing oilfield water to a total weight of 100g to obtain four oil displacement agent solutions with salinity of 5630mg / L, 10630mg / L, 15630mg / L and 25630mg / L respectively.

[0041] Oil sand deoiling experiment:

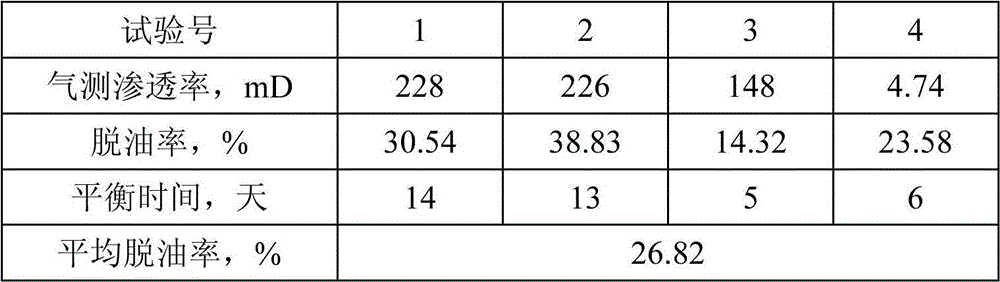

[0042] Viscosity at 45°C is 10mPa·s, d=0.8294g / cm 3 The oil sand (40-80 mesh) prepared from crude oil in Daqing Oilfield, the specific preparation steps of oil sand: mix the mass ratio of quartz sand and crude oil according to the mass ratio of 8:2, then put it into an oven and age it at a formation temperature of 45°C 192 hou...

Embodiment 2

[0044] This embodiment provides a kind of oil displacement agent for binary oil displacement, which is prepared through the following steps:

[0045] 0.3g sodium polyacrylate, 0.05g polyoxyethylene sorbitan monooleate, and microdispersant (TH904, 0.002g) were dissolved with an appropriate amount of Daqing oilfield water to obtain a solution, and the concentration was 20wt% NaCl aqueous solution to adjust the mineral content of the solution. Then dilute it with Daqing oilfield water to a total weight of 100g to obtain four oil displacement agent solutions with salinity of 5200mg / L, 10200mg / L, 15200mg / L and 25200mg / L respectively.

[0046] Oil sand deoiling experiment:

[0047] Viscosity at 45°C is 10mPa·s, d=0.8294g / cm 3 The oil sands (80-100 mesh, aged at 45°C for 192 hours) prepared from crude oil from the Daqing Oilfield were subjected to atmospheric pressure static deoiling experiments on the above four oil displacement agent solutions, and the experiments were carried out...

Embodiment 3

[0050] This embodiment provides a kind of oil displacement agent for binary oil displacement, which is prepared through the following steps:

[0051] 0.3g sodium polyacrylate, 0.05g polyoxyethylene sorbitan monooleate, microdispersant (TH904, 0.002g) are dissolved with an appropriate amount of Dagang oil field water to obtain a solution, and the concentration is 20wt% NaCl aqueous solution to adjust the mineral content of the solution. Then dilute it with Dagang oilfield water to a total weight of 100g to obtain four oil displacement agent solutions with salinity of 8700mg / L, 13700mg / L, 18700mg / L and 28700mg / L respectively.

[0052] Oil sand deoiling experiment:

[0053] At 53.6°C, the viscosity is 9.9mPa·s, d=0.8603g / cm 3 The oil sands (100-160 mesh, aged at 53.6°C for 192 hours) prepared from crude oil in the Dagang Oilfield were subjected to atmospheric pressure static deoiling experiments on the above four oil displacement agent solutions, and the experiments were carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com