Thyroid tablets produced by direct whole-powder tabletting and preparation process thereof

A thyroid tablet and a preparation process technology, applied in the field of thyroid powder, can solve the problems of complex preparation process, inactivation, drug degradation, etc., and achieve the effects of rough particle surface, preventing re-aggregation, and increasing bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

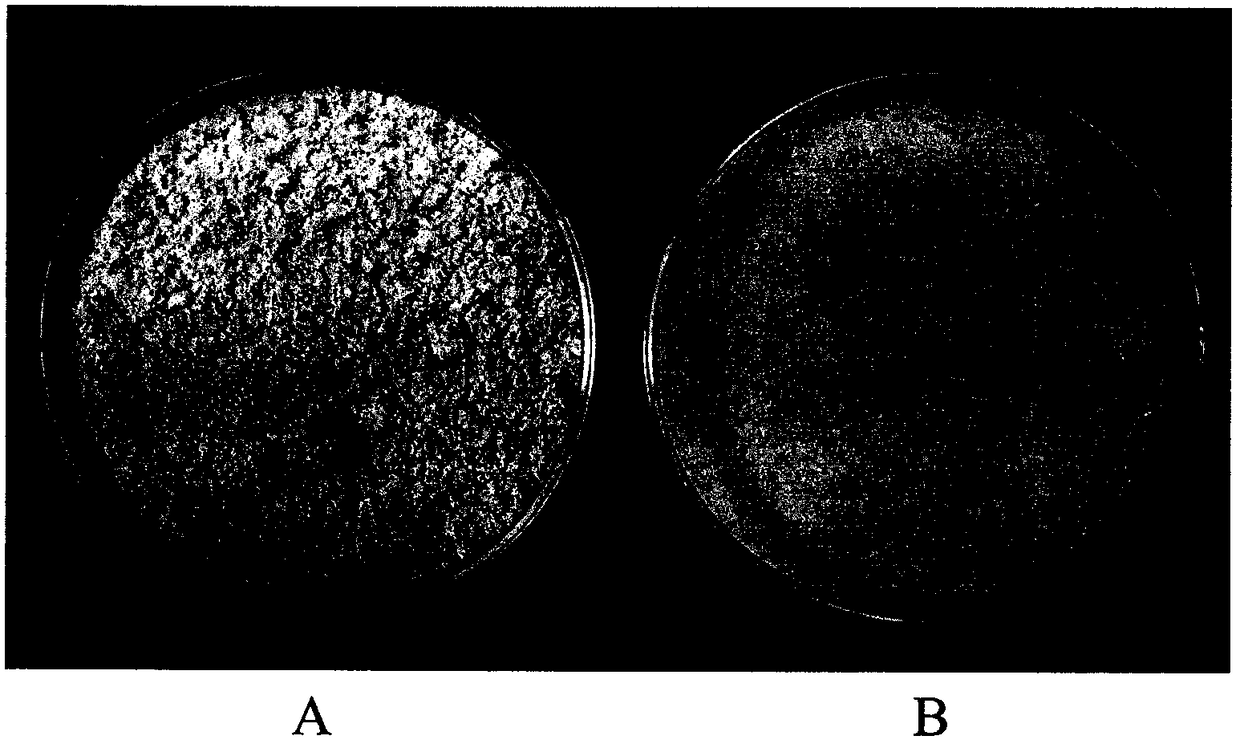

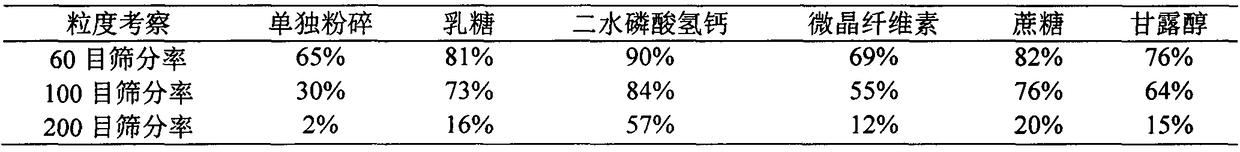

[0056] Investigate the effects of different granular substances on the auxiliary crushing of thyroid raw materials, specific examples are: the auxiliary effect of the addition of lactose, calcium hydrogen phosphate dihydrate, sucrose, mannitol, and microcrystalline cellulose on the crushing of thyroid raw materials. Specific steps are as follows:

[0057] Take 10g of thyroid raw material for each portion, add lactose, calcium hydrogen phosphate dihydrate, sucrose, mannitol, and microcrystalline cellulose in a ratio of 1:2, mix evenly, mechanically pulverize for 3 minutes, and mix with the directly mechanically pulverized material of thyroid raw material Compare.

[0058] Taking the particle size of the material and whether it is re-aggregated as the main indicators, the comparison and analysis of the assisted crushing and direct crushing of granular materials are carried out. The inspection method of the particle size of the material is: respectively inspecting the ratio (scr...

Embodiment 2

[0065] Investigate the auxiliary effect of freeze-drying technology on thyroid material auxiliary crushing, and compare with direct crushing.

[0066] Take 10 g of the processed thyroid raw material, grind it mechanically for 3 minutes, and sieve it.

[0067] Another 10 g of processed thyroid raw material was taken for freeze-drying and auxiliary pulverization. The specific steps are as follows:

[0068] (1) Preparation of lyophilized samples of thyroid raw material

[0069] Take 10g of processed thyroid material, add 50mL of water, stir, and fully infiltrate. Spread the wetted samples on a freeze-drying tray with a thickness of about 1 cm, and place them in a freeze-dryer for use.

[0070] (2) freeze-drying

[0071] Place the sample in a freeze dryer and follow the freeze-drying process below to freeze-dry.

[0072] a. Pre-freezing stage: Turn on the freeze dryer, set the pre-freezing temperature to -40°C, and keep the temperature for 2-6 hours until all thyroid raw materia...

Embodiment 3

[0085] According to embodiment 1 and embodiment 2, it is found that calcium hydrogen phosphate assisted crushing technology and freeze-drying technology have respective advantages and disadvantages, and the advantages and disadvantages of the two technologies used alone have a tendency to complement each other and synergy, thus, the two The synergistic use of these technologies further optimizes the pulverization effect of thyroid raw materials.

[0086] The specific implementation plan is: after taking 20g of calcium hydrogen phosphate and 10g of thyroid material and mixing evenly, the calcium hydrogen phosphate particles are uniformly and fully filled in the thyroid material, and after wetting with 50mL of purified water, the operation is performed according to the freeze-drying process in Table 5 .

[0087] Table 5 Freeze-drying process

[0088]

[0089] The mixture was lyophilized and pulverized. The results are shown in Table 6: the synergistic use of the two technol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| friability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com