Patents

Literature

40results about How to "Prevent reaggregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

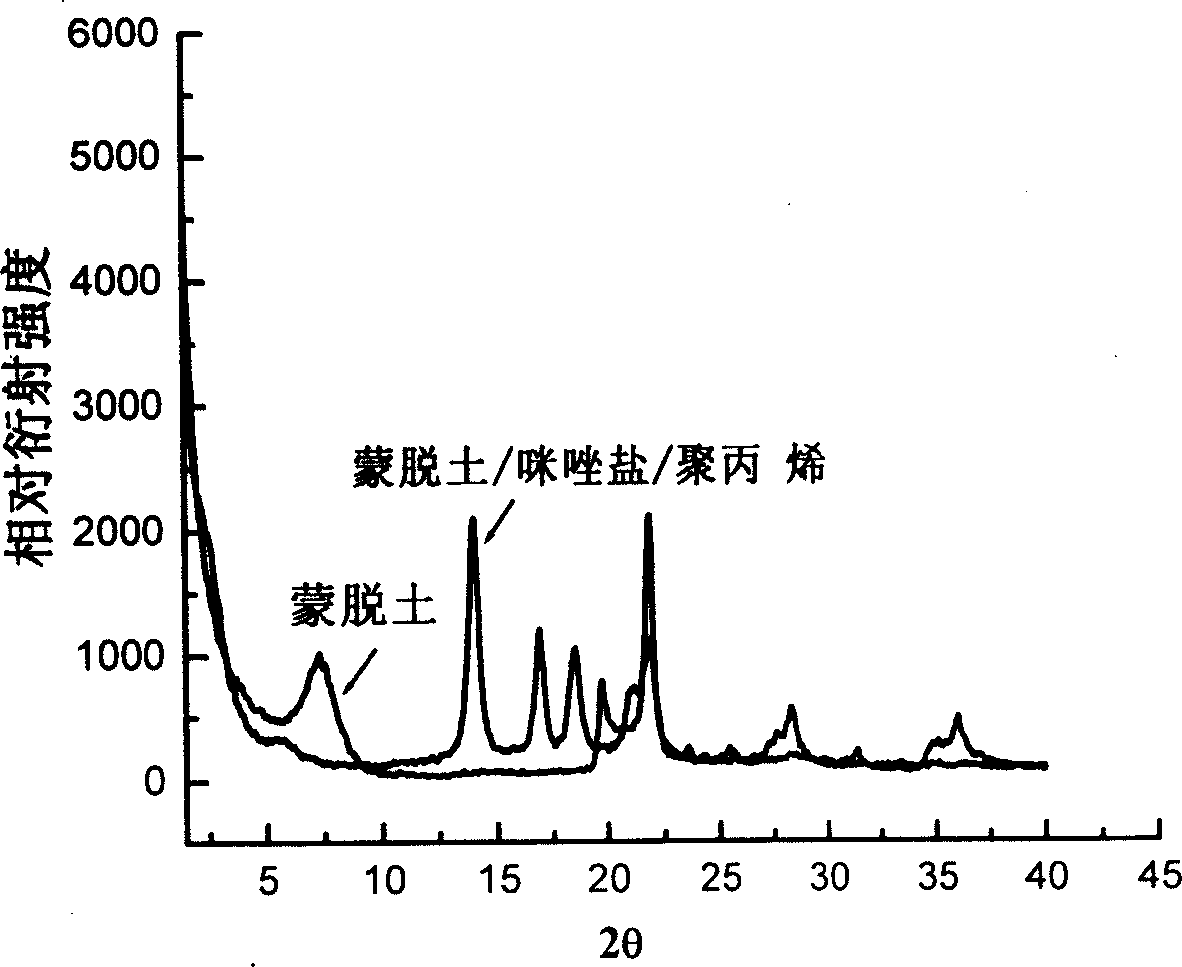

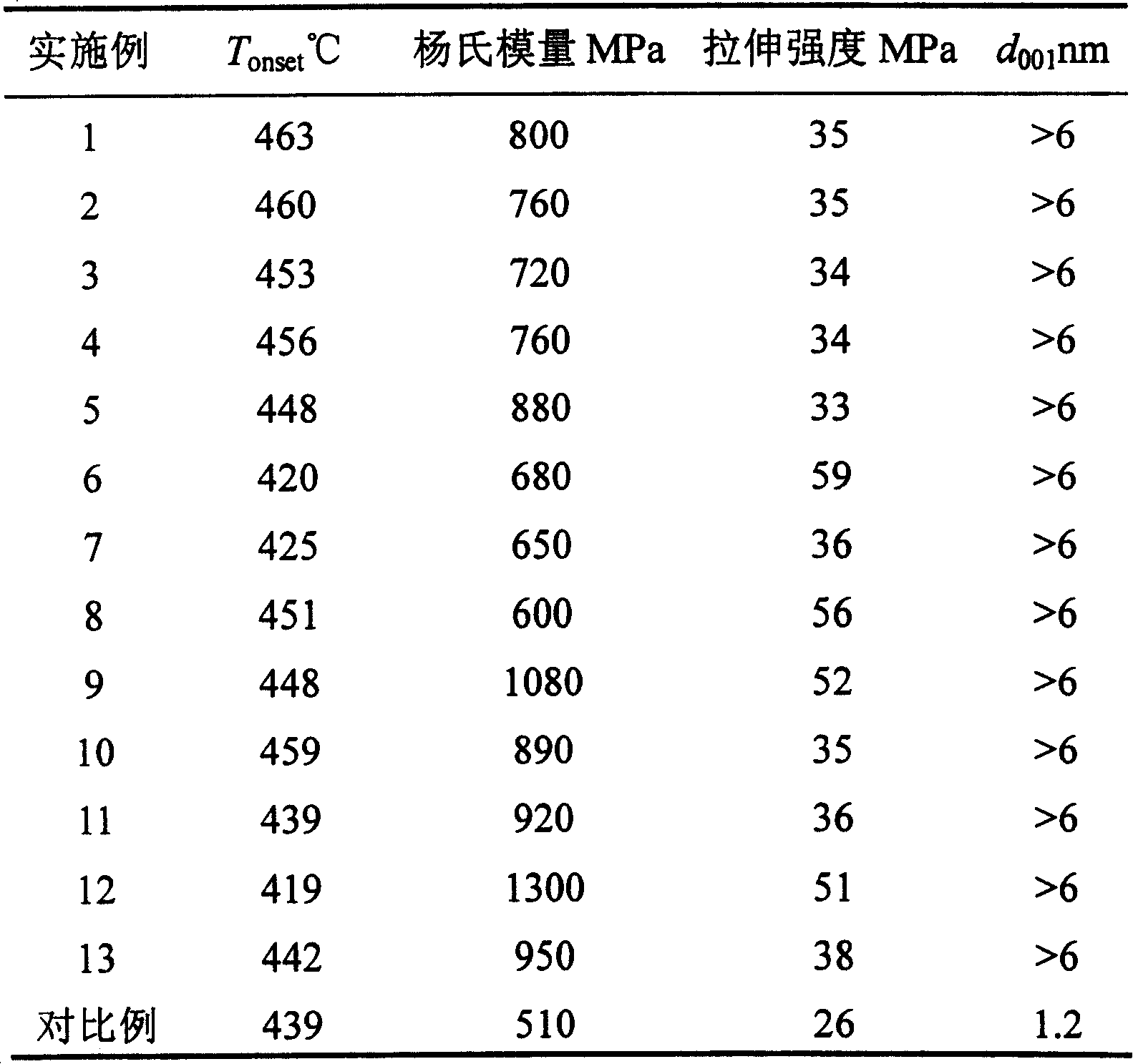

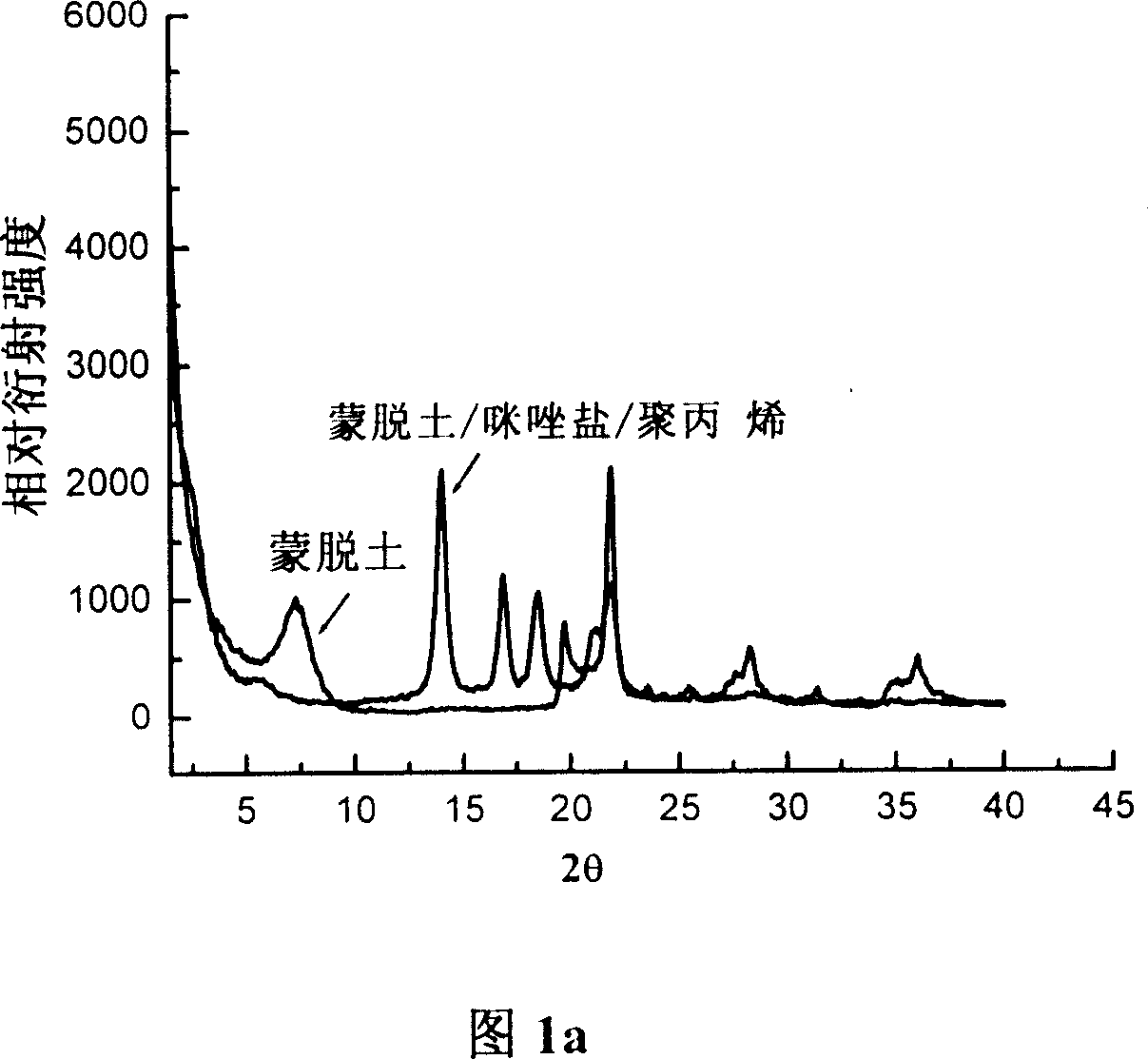

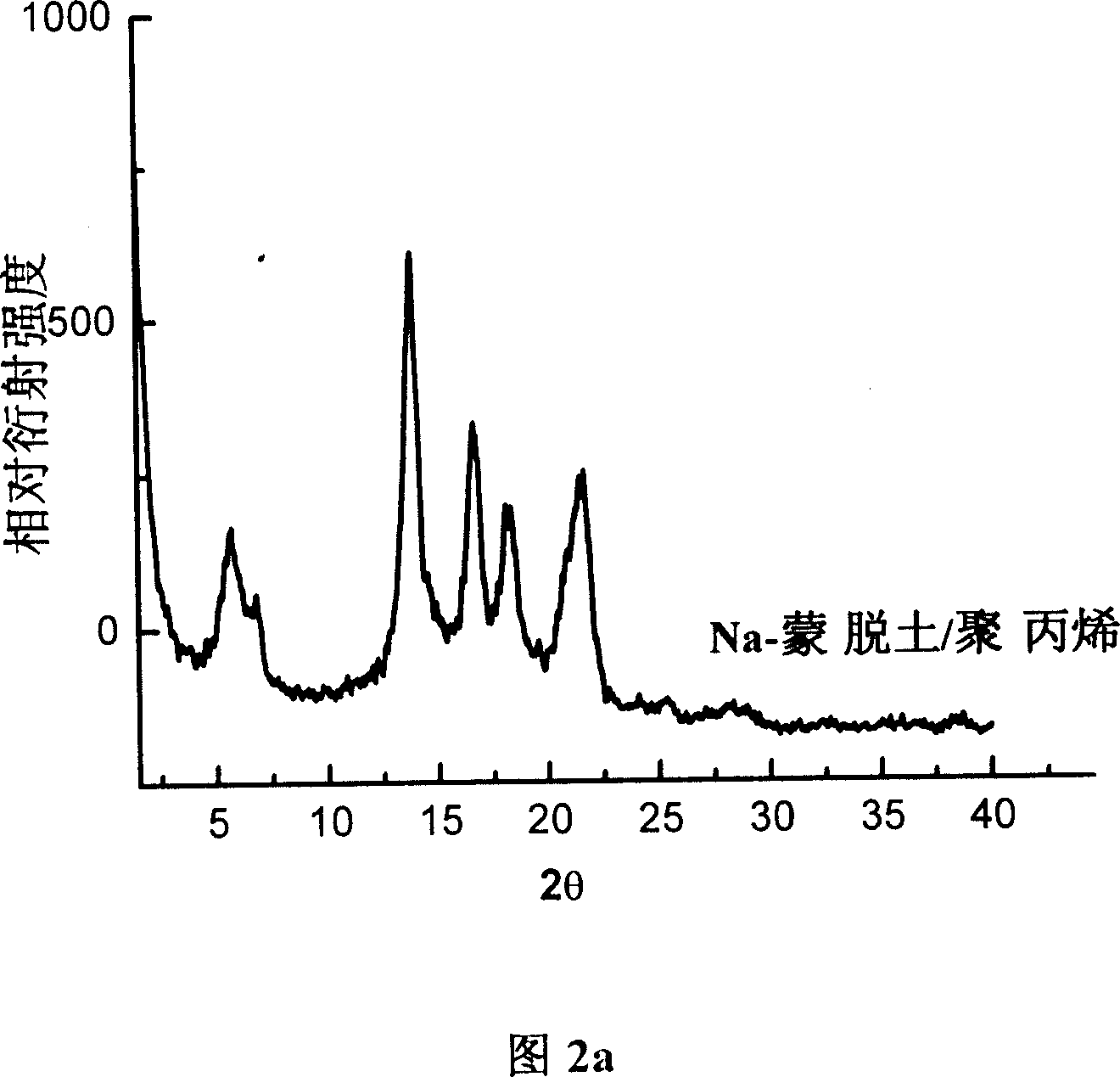

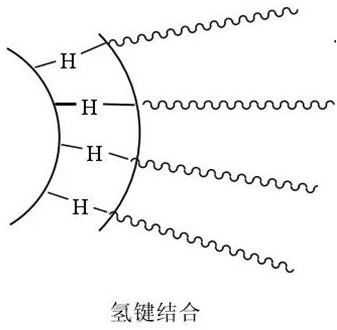

Method of preparing polymer/montmorillonid nano-composite material by montmorillonoid in-situ organization

A process for preparing composite polymer / montmorillonite nanoparticles by in-situ organizing of montmorillonite features that the imidazole-type or pyridine-type organic salt is used in non-water solvent to obtain organic modifier for organizing and dispersing the montmorillonite, resulting in the colloidal solution of its nanoparticles. The solvents with different properties and the organic salts with different molecular structures can be chosen for preparing the nanoparticles with relative performance. Its advantages are high thermal stability and high compatibility.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-toughness concrete and preparation method thereof

The invention discloses high-toughness concrete and a preparation method thereof. The formula of the high-toughness concrete comprises 0.2-0.5kg / <m>3 of modified graphene, 150-175kg / <m>3 of water, 395-415kg / <m>3 of cement, 45-60kg / <m>3 of coal ash, 20-35kg / <m>3 of slag powder, 1000-1100 kg / <m>3 of broken stone, 600-700 kg / <m>3 of fine aggregate and 4.5-7 kg / <m>3 of a water reducing agent, wherein the modified graphene is water-soluble grapheme of which the surface has hydroxide radicals; the content of the hydroxide radicals is 0.005-0.012 percent. When the modified grapheme is used for preparing high-toughness concrete, first, the modified grapheme can be dissolved in water to form a graphene water solution; then, the graphene water solution and other concrete preparation materials are uniformly mixed, novel high-toughness concrete obtained after curing can show obvious strain hardening or deformation hardening characteristic under the action of direct tensile load or bending load, and can be applied to bridge floors of high-speed rail viaducts and long-span sea-crossing and river-crossing bridges, and various tunnel arches such as subways. The high-toughness concrete is high in technological content and has relatively good application prospect.

Owner:HONGFENG GRP FUJIAN

High-density polyethylene/graphene/polyaniline composite material and synthetic method thereof

The invention discloses a high-density polyethylene / graphene / polyaniline composite material and a synthetic method thereof. According to the high-density polyethylene / graphene / polyaniline composite material, the surface of graphene is coated with polyaniline to form a polyaniline / graphene blend, and the polyaniline / graphene blend is dispersed in a high-density polyethylene substrate. As the polyaniline (PANI) coats the graphene (CB) to be blended with the high-density polyethylene (HDPE) substrate, the dispersity of the graphene is improved, the degree of crystallinity of the high-density polyethylene is reduced, therefore, the PTC intensity and the stability of the polyethylene / graphene / polyaniline composite material are improved.

Owner:TAICANG JINKAI SPECIAL TYPE CABLE

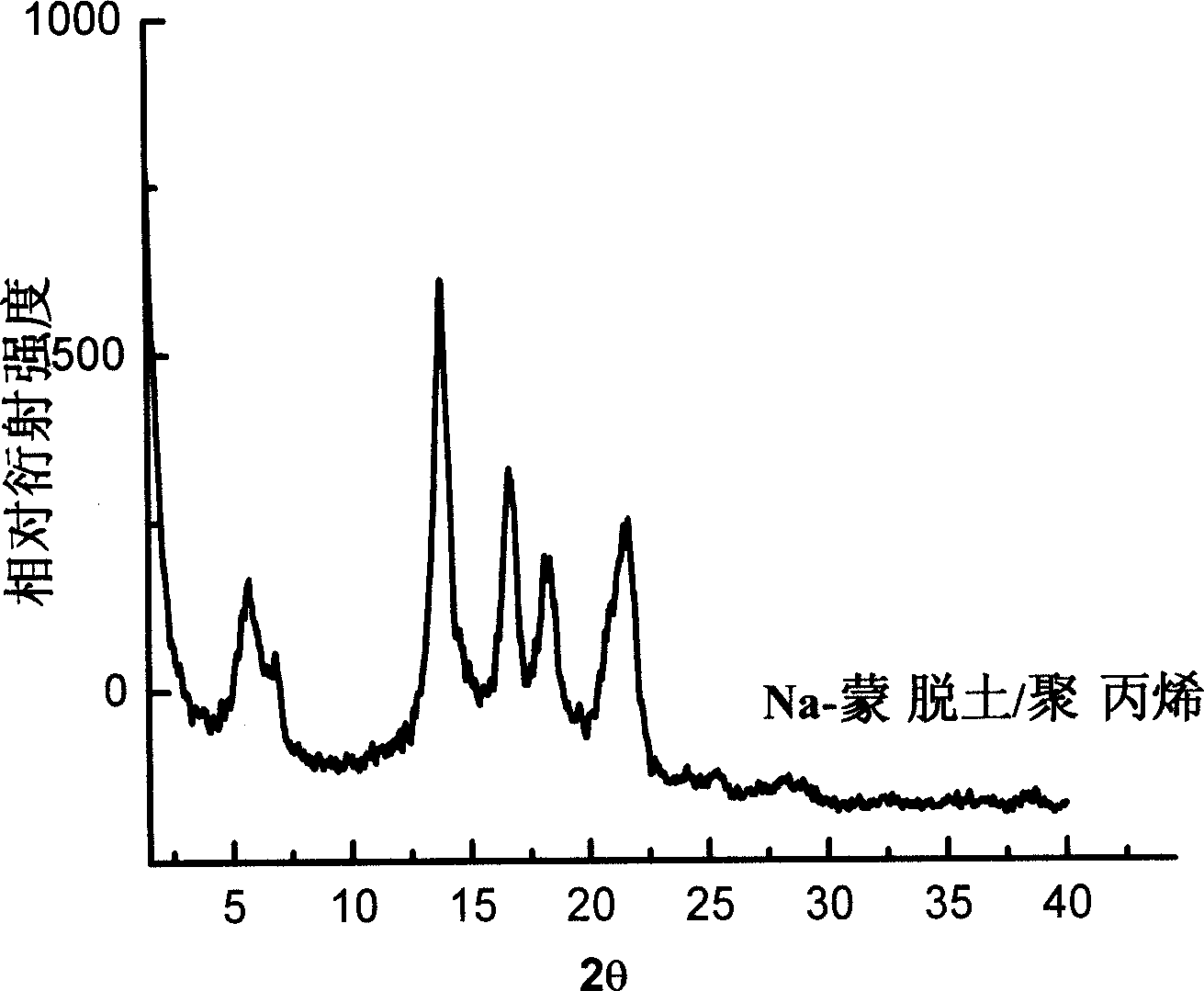

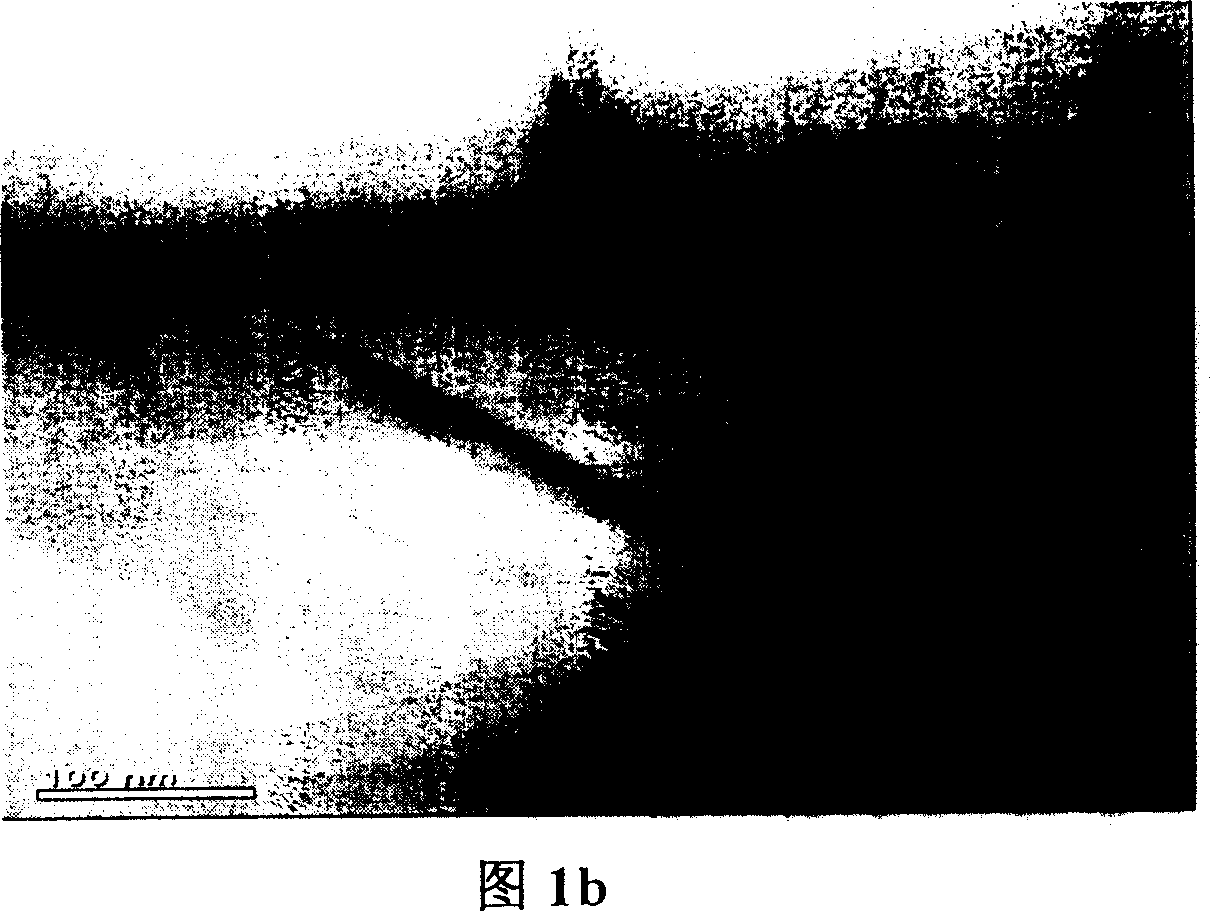

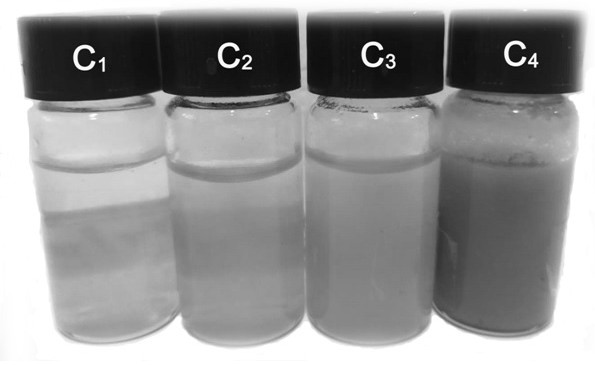

Preparation method of polyolefin/montmorillonite nano-composite material

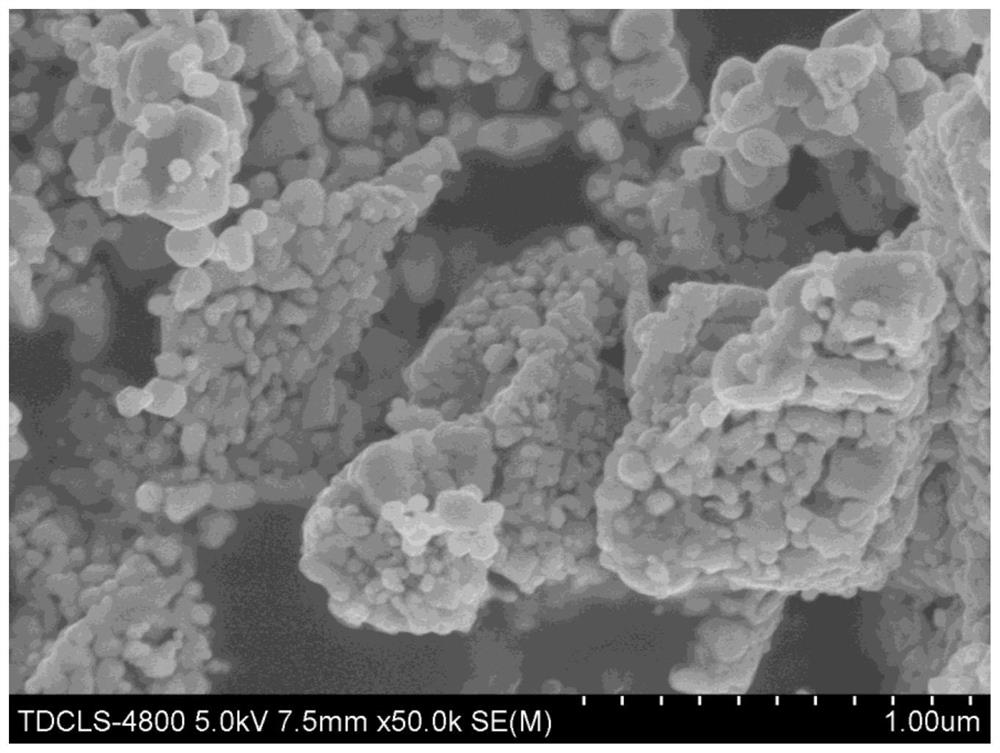

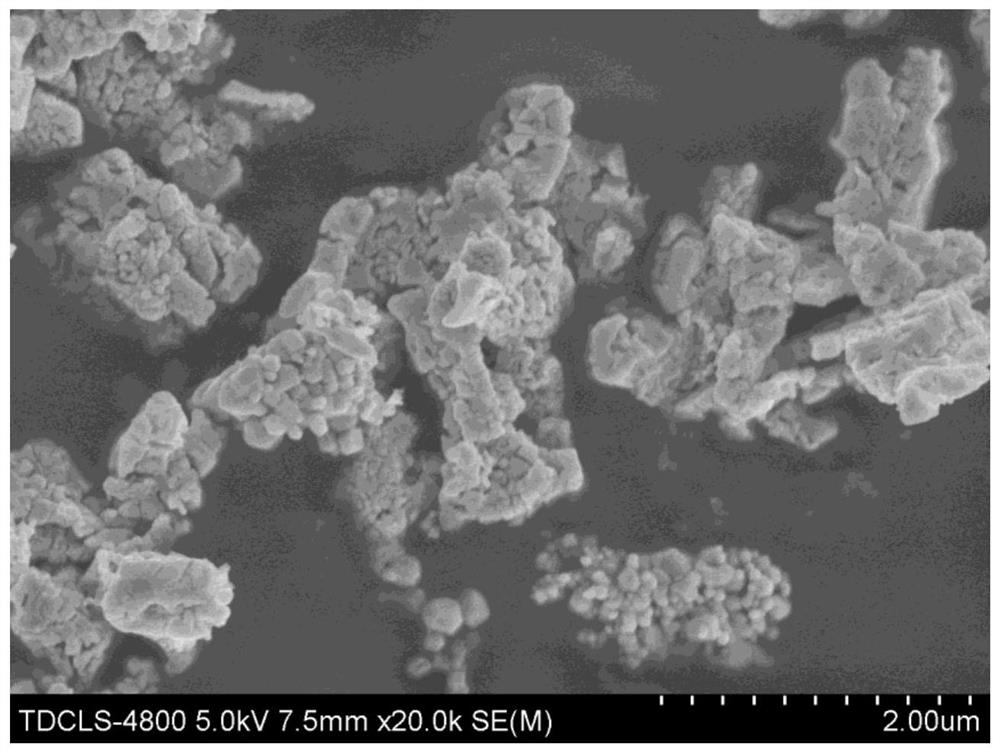

The present invention discloses a preparation method of polyolefine / montmorillonite nano composite material. Under the condition of having no need of any solvent said invention adopts the following steps: using imidazole salt or pyridine salt ionic liquid as organic modifying agent, grinding said organic modifying agent and montmorillonite at room temperature to implement organization of the montmorillonite and form nano organic montmorillonite particles with ionic liquid intercalation, then melting and mixing the polyolefine and organic montmorillonite so as to form the invented polyolefine / montmorillonite nano composite material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Waterborne titanium white paste and preparation method thereof

The invention relates to the technical field of coating preparation, in particular to waterborne titanium white paste and a preparation method thereof. The waterborne titanium white paste comprises the following raw material components in parts by weight: 12-18 parts of deionized water, 2-6 parts of a humectant, 8-12 parts of a dispersing agent, 0.1-0.5 part of a defoaming agent, 70-76 parts of rutile type titanium dioxide, 0.3-1.0 part of an anti-settling agent, 0.1-0.2 parts of a bactericide and 0.1-0.3 part of a pH adjuster. The waterborne titanium white paste provided by the invention hasgood compatibility with a two-component polyurethane system, and the color paste itself is high in stability, suitable not only for the two-component polyurethane system, but also for an one-componentpolyurethane system, an acrylic acid system and other systems, low in VOC (volatile organic compounds) content, safe, environmentally-friendly, simple in preparation method, easy to operate, and suitable for large production operations.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Method of preparing tungsten-doped superfine yttrium oxide compound powder by freeze drying

ActiveCN108356275ANarrow size distributionNo particle size bimodal distribution phenomenonFreeze-dryingAmmonium metatungstate

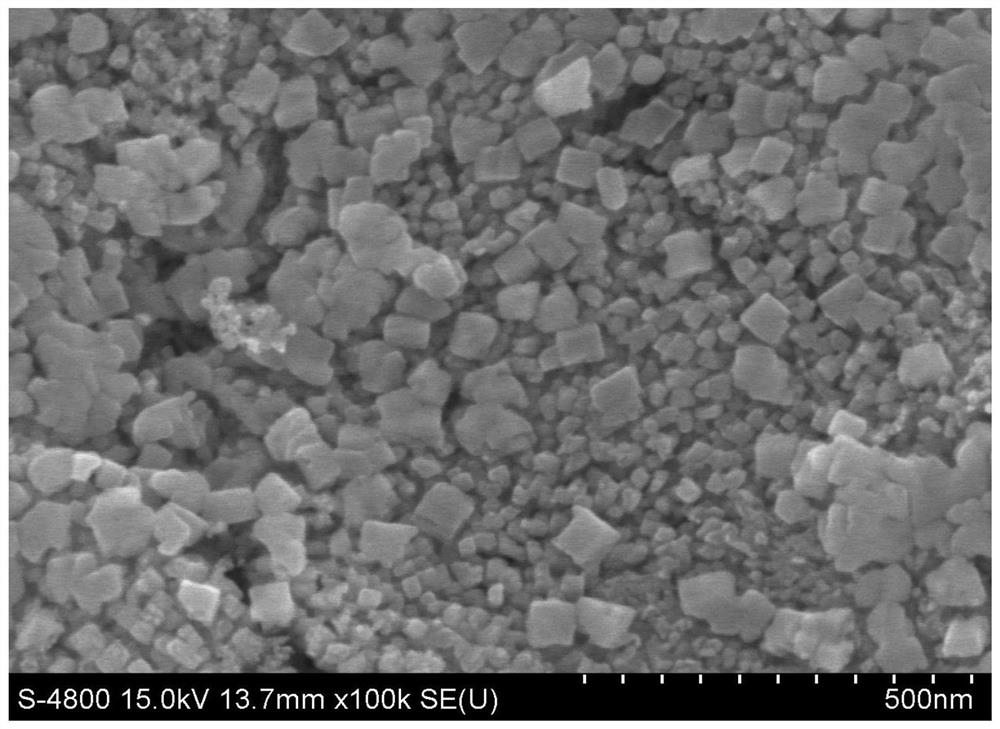

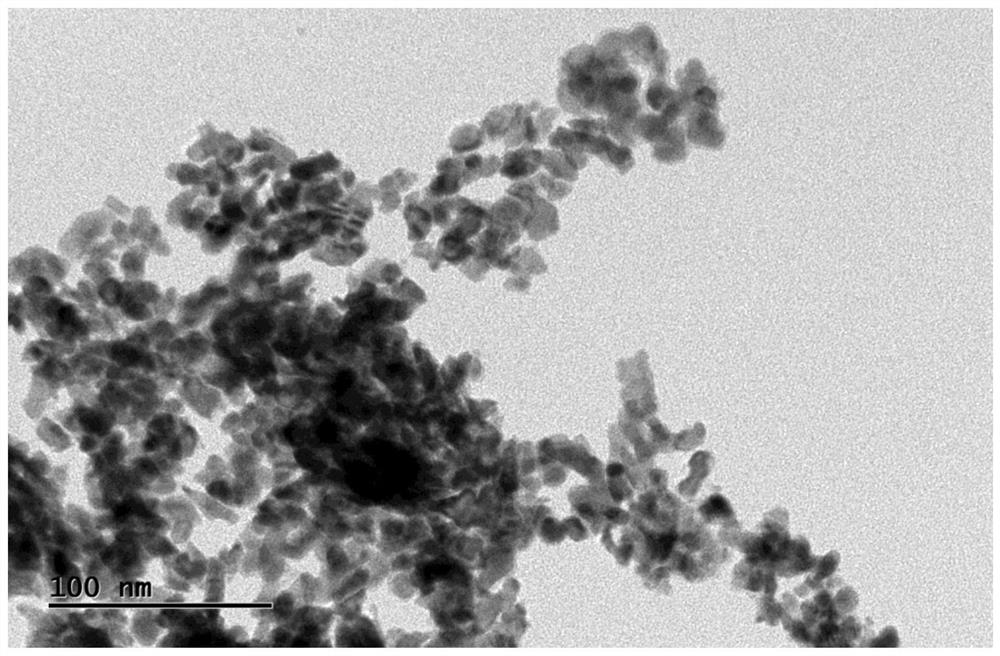

The invention provides a method of preparing tungsten-doped superfine yttrium oxide compound powder by freeze drying. The method comprises the following steps: dissolving ammonium metatungstate and ayttrium nitrate hexahydrate in deionized water or distilled water, and carrying out ultrasonic treatment to disperse and dissolve the mixture to prepare a solution; pouring the solution into a surfacevessel or other containers large in surface areas, putting the surface vessel or other containers in a refrigerator, and pre-freezing the same at 40 DEG C below zero and 10 DEG C below zero; openingrefrigeration and a vacuum meter of a freeze drier in advance, and after the temperature of the freeze drier is reduced to the freezing temperature of 58 DEG C below zero and 20 DEG C below zero and is stabilized, putting the pre-frozen surface vessel in the freezer dryer, and opening a vacuum pump to maintain the vacuum degree and carry out freeze drying; putting the freeze-dried compound powderin a tubular furnace, and calculating the compound powder in a nitrogen or an argon air flow to obtain WO3-Y2O3 compound oxide powder; and carrying out two-step reduction with pure hydrogen in the tubular furnace to obtain the tungsten-doped superfine yttrium oxide compound powder. The average grain size is about 10nm, the grain size distribution is extremely narrow, and a bimodal distribution phenomenon is avoided.

Owner:TIANJIN UNIV

Method for preparing polyurethane macromolecule dispersing agent for pigment printing paste of fabric

The invention relates to a method for preparing a polyurethane macromolecule dispersing agent for pigment printing paste of a fabric, which comprises the following steps of: dissolving diisocyanate and hydrophilic carboxyl diatomic alcohol into an organic solvent and heating to 75 DEG C for reacting for 60 minutes; then dropwise adding a micromolecule diatomic alcohol solution in batch and carrying out multi-chain extension reaction for 60 minutes; after the chain extension reaction is finished, carrying out end sealing reaction for 120 minutes; cooling to 50 DEG C, dropwise adding a Na2CO3 solution and emulsifying during neutralization; and after the dropwise addition is finished and adding water for heating to 60 DEG C, continuously stirring and dissolving for 30 minutes to prepare the polyurethane macromolecule dispersing agent. The macromolecule dispersing agent has stronger affinity on the surface of pigment particles, difficult desorption, good flocculation resistance, simple preparation method, low cost and environmental protection; and the pigment paste prepared by the dispersing agent has high stability and can obtain high printing dry and wet friction fastness by being used for the printing processing of the fabric.

Owner:DONGHUA UNIV

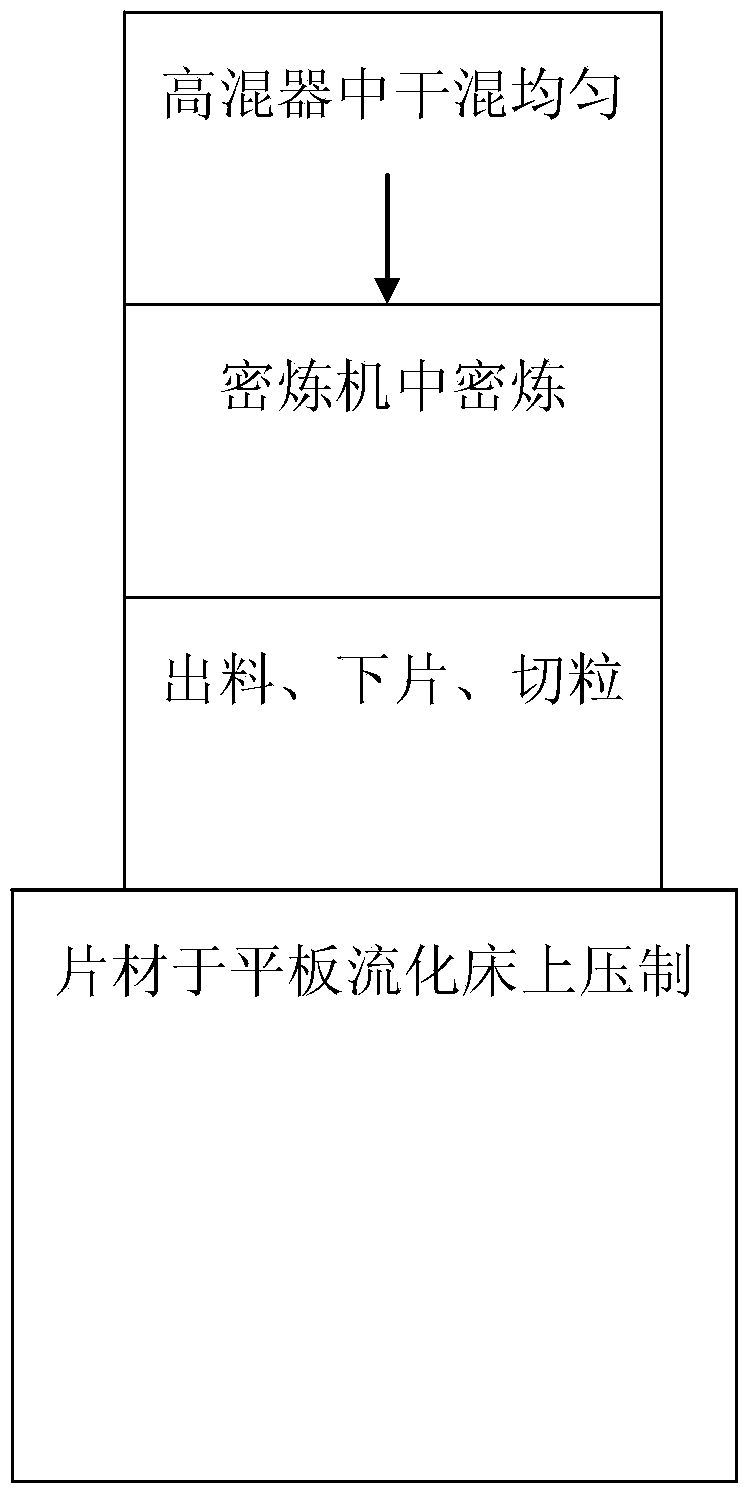

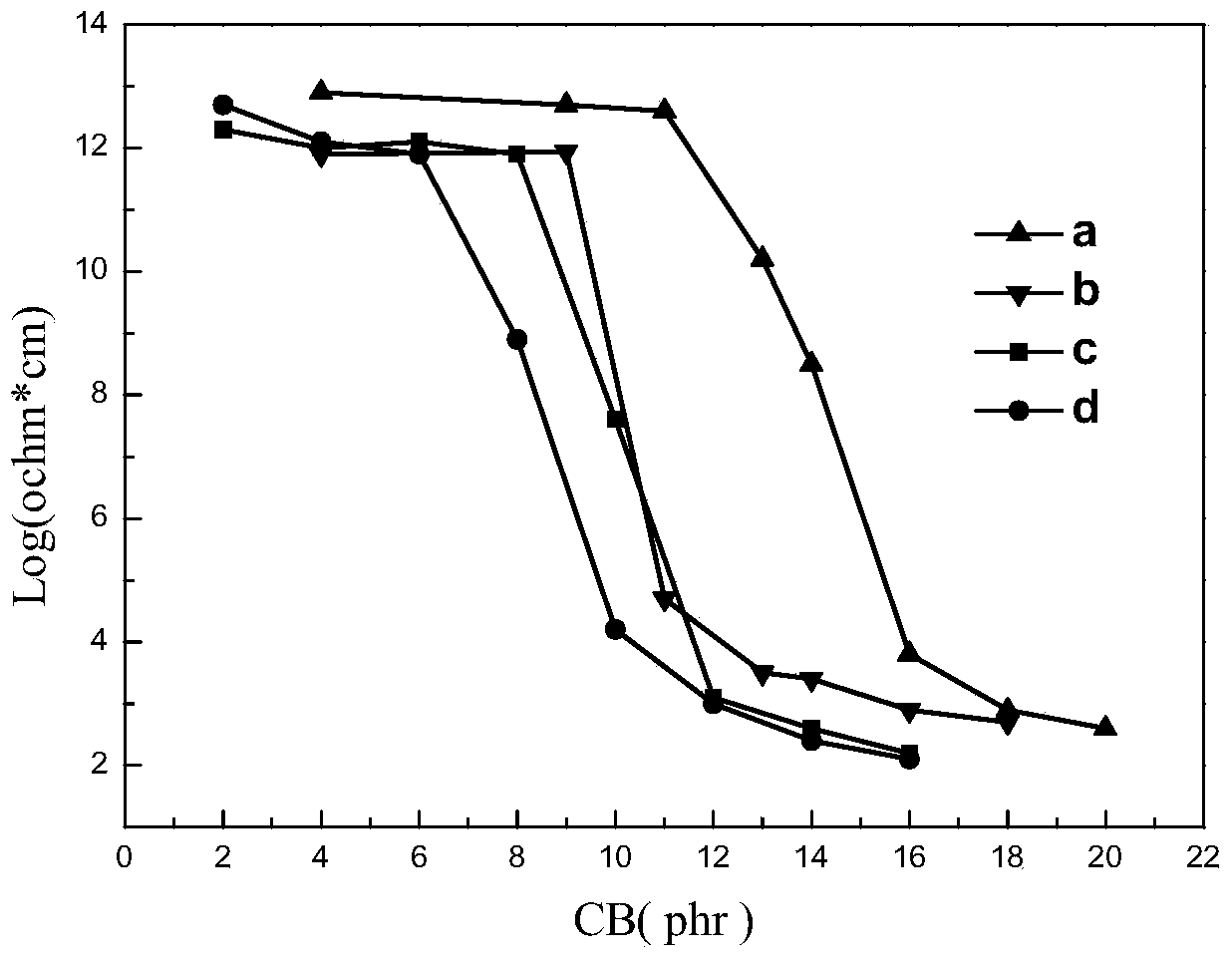

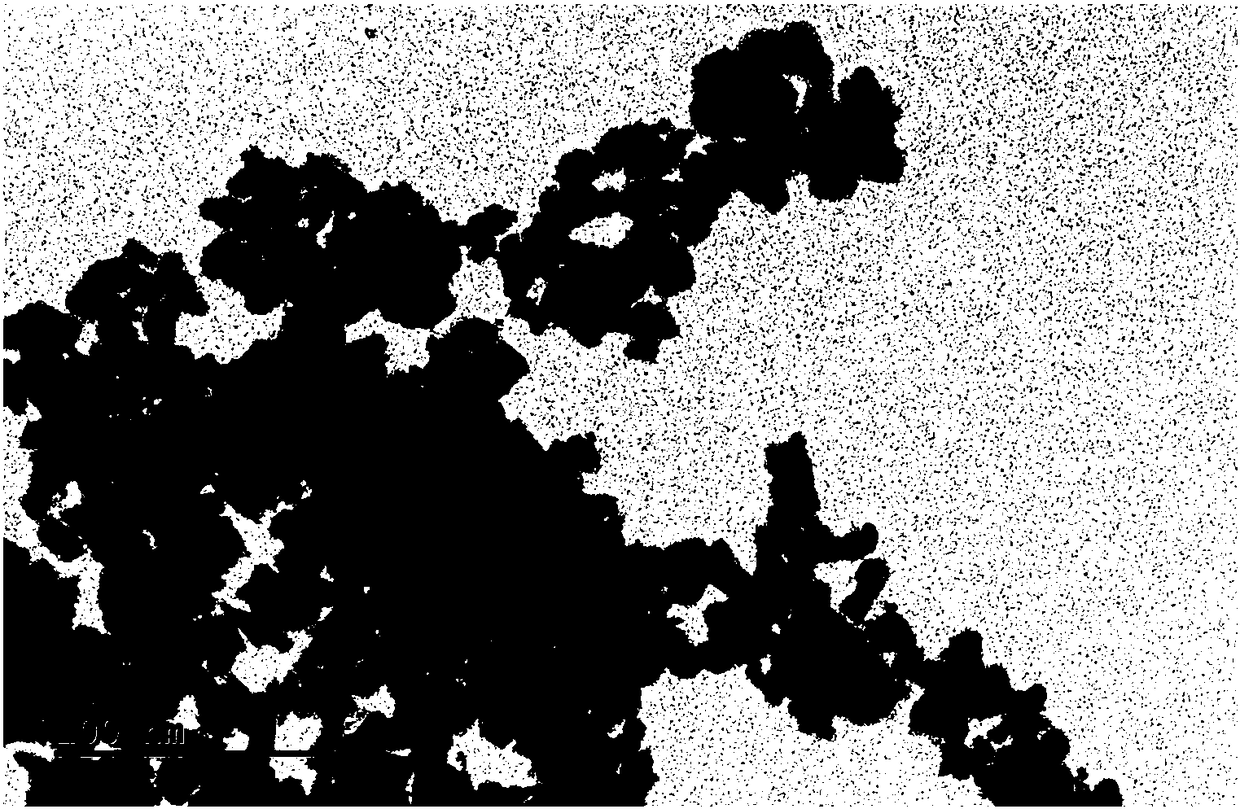

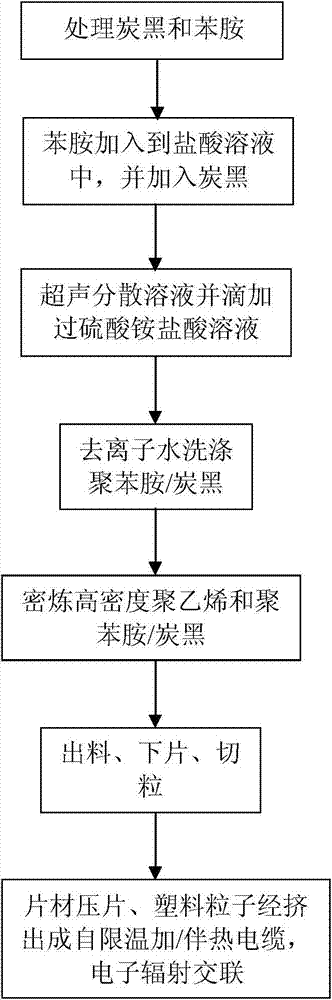

Method for preparing PTC (positive temperature coefficient) material by compounding polyaniline/carbon black/polyolefin

InactiveCN103483666AGood compatibilityPrevent reaggregationCable/conductor manufacturePolyolefinVulcanization

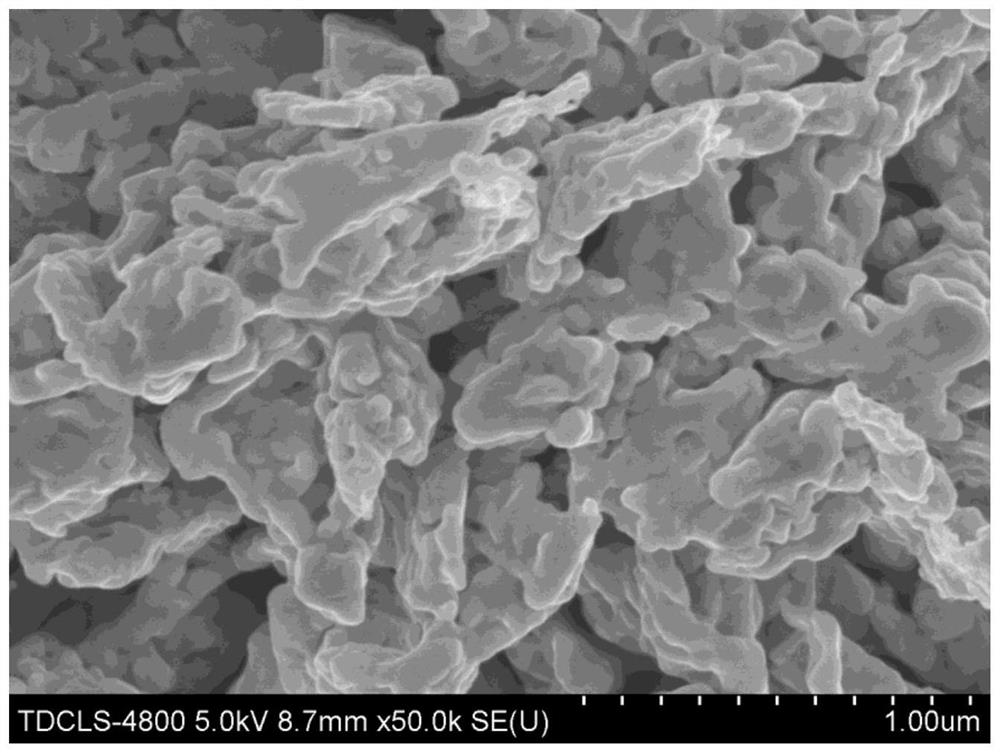

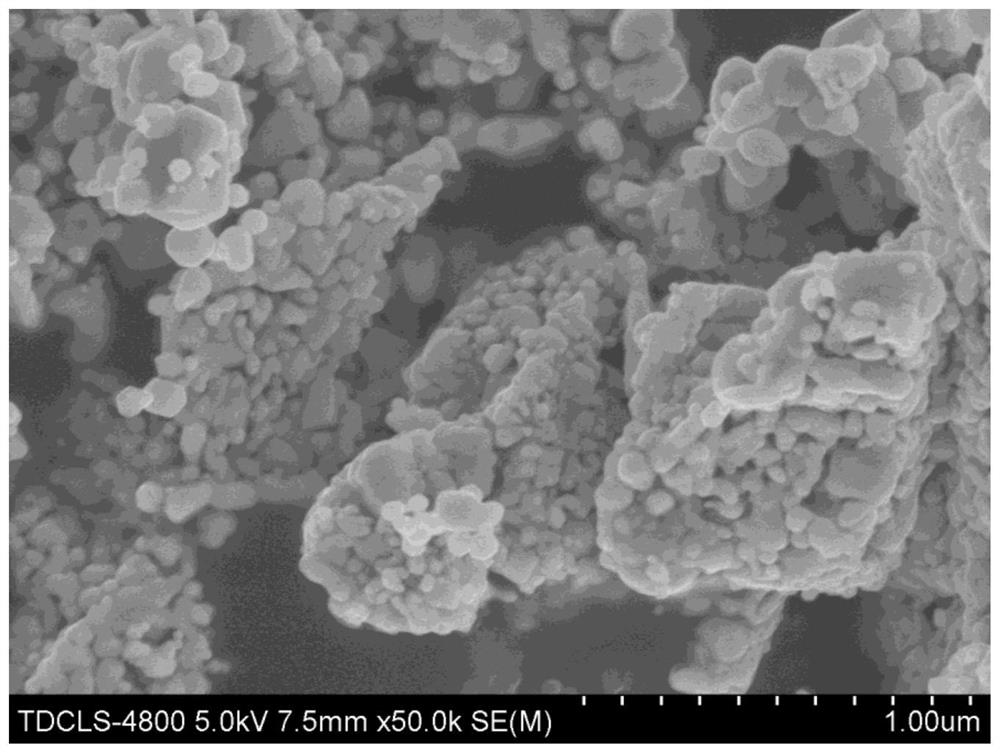

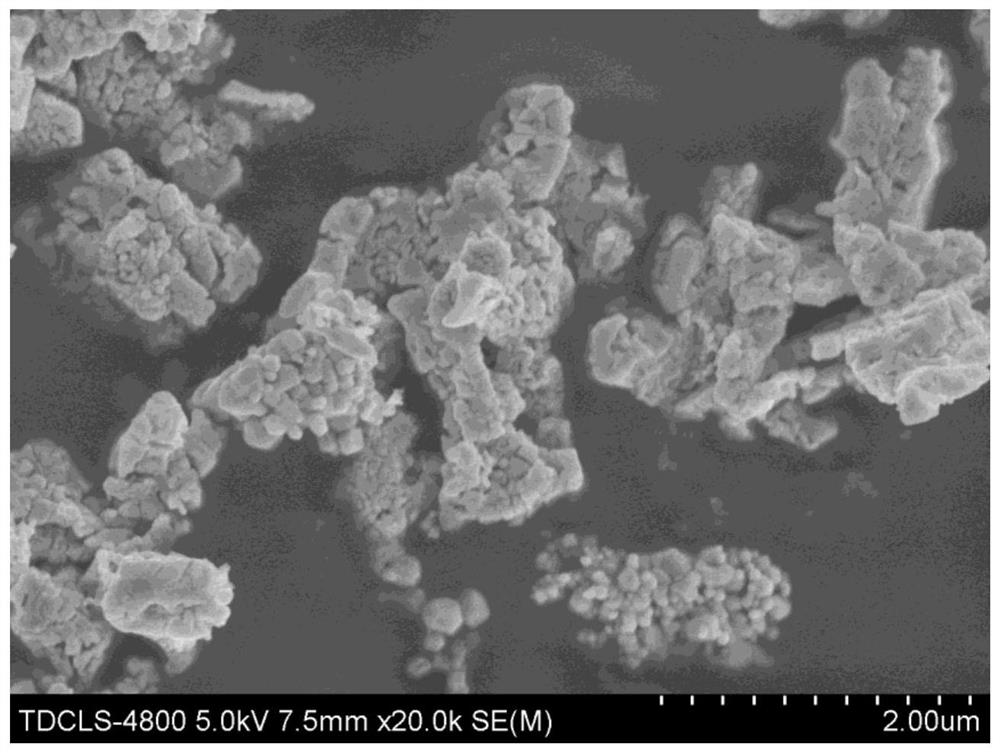

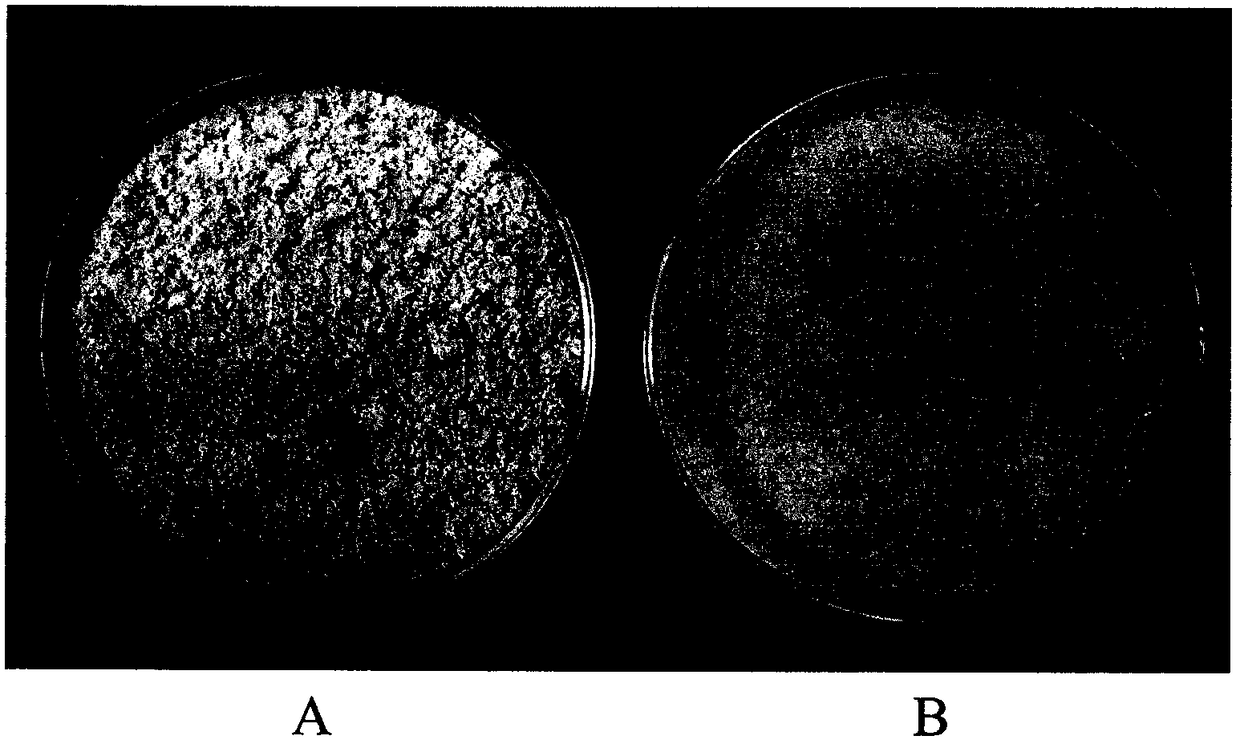

A method for preparing a PTC material by compounding polyaniline / carbon black / polyolefin comprises the steps as follows: step one, the carbon black and aniline are processed; step two: the aniline is added to a hydrochloric acid solution, and then the carbon black is added; step three: the formed solution is subjected to ultrasonic dispersion, and a ammonium persulfate hydrochloric acid solution is dropwise added into the solution; step four: a formed polyaniline / carbon black product is washed and leached repeatedly with deionized water; step five: high-density polyethylene and polyaniline / carbon black are uniformly refined in a banbury mixer; step six: a product is discharged, batched-off and subjected to grain-sized dicing; and step seven: sheet materials are sheeted on a slab vulcanization machine tool, and plastic particles are extruded to form self-temperature-limiting heating / heat tracing cables, and then electronic radiation crosslinking is realized; and in the step one, the carbon black is placed in a vacuum drying oven and dried to the constant weight, and the aniline is processed through pressure reduction distillation. According to the method, reaggregation of carbon black particles is prevented, so that particles are uniformly distributed, and the performance of the PTC material is remarkably improved.

Owner:TAICANG JINKAI SPECIAL TYPE CABLE

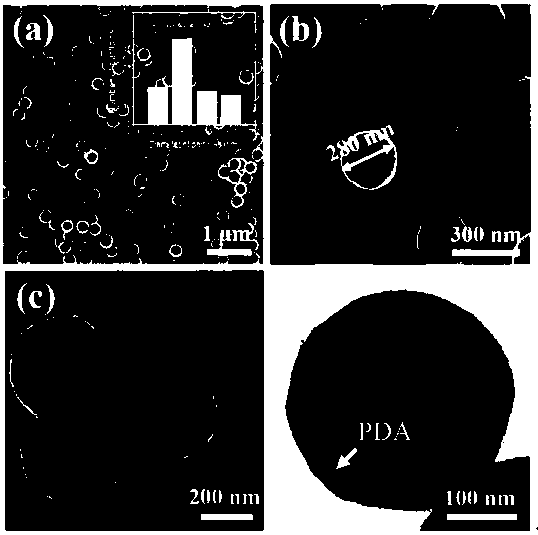

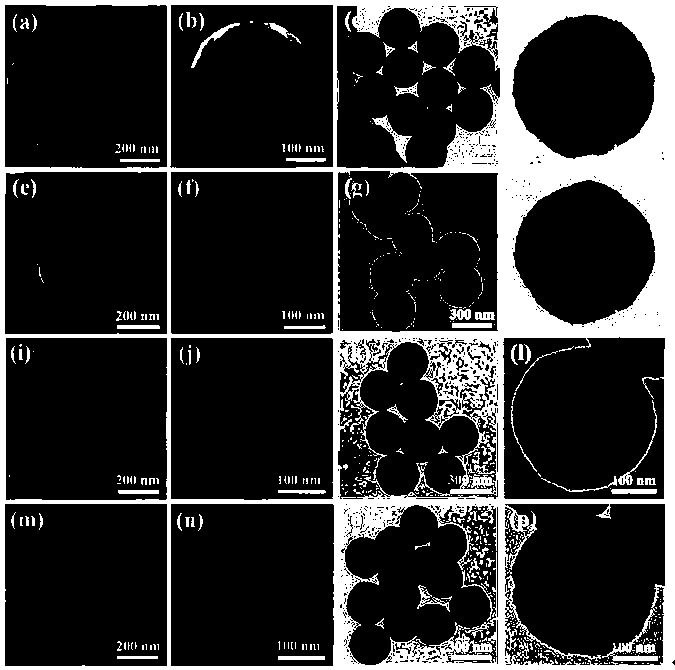

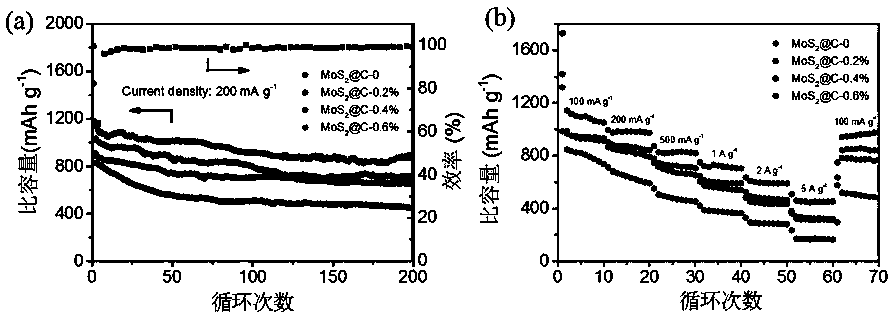

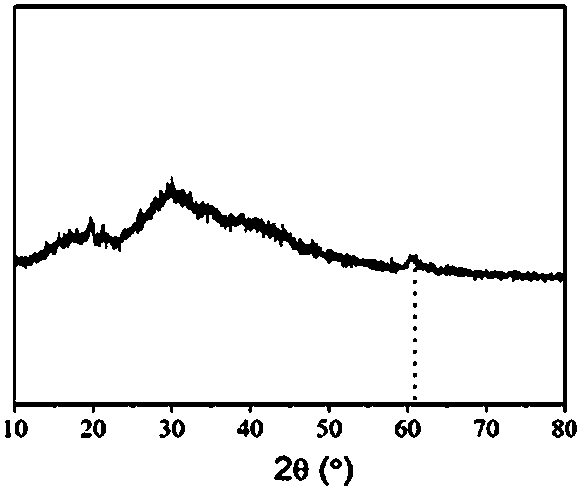

Preparation method of yolk-shell structure molybdenum disulfide@ carbon electrode material

InactiveCN108039459AUniform sizePrevent reaggregationCell electrodesSecondary cellsYolkCarbonization

The invention relates to a preparation method of a yolk-shell structure molybdenum disulfide@ carbon electrode material. The preparation method includes: utilizing molybdenum disulfide precursor solvothermal ethylene glycol to obtain monodisperse molybdenum disulfide nanospheres; allowing dopamine to self-polymerize on the interfaces of molybdenum disulfide particles to obtain a molybdenum disulfide@ polydopamine core-shell structure, and performing high-temperature carbonization on molybdenum disulfide@ polydopamine to obtain core-shell structure molybdenum disulfide@ carbon nanoparticles; dispersing molybdenum disulfide@ carbon in a hydrogen peroxide solution for hydrogen peroxide etching to obtain the yolk-shell structure molybdenum disulfide@ carbon material. A gap between molybdenum disulfide and a carbon shell can be well regulated by adjusting concentration of hydrogen peroxide. When the concentration of hydrogen peroxide is 0.4vol%, discharging specific capacity of a prepared yolk-shell structure molybdenum disulfide@ carbon lithium ion battery cathode in the second circle is up to 1167mAh g-1, discharging specific capacity after being circulated for 200 circles is 880mAh g-1, capacity retaining rate is 75.4%, and rate performance is outstanding.

Owner:FUDAN UNIV

Preparation method of environment-friendly hydrotalcite-like nanosheets

ActiveCN109607488AOvercome electrostatic forcesPrevent reaggregationOxide/hydroxide preparationIron compoundsAnhydrous ethanolOrganic solvent

The invention relates to a preparation method of environment-friendly hydrotalcite-like nanosheets, and belongs to the technical field of preparation of two-dimensional nano materials. Through the preparation method, complexity of the process, difficult recovery of organic solvents and other problems are solved in an existing process of nanosheet preparation by using a hydrotalcite-like compound as a precursor. The preparation method comprises the steps: dispersing the hydrotalcite-like compound and a stabilizer in anhydrous ethanol, adjusting the temperature and pressure so as to keep ethanolat a supercritical state for a period of time, and returning to the state of normal temperature and normal pressure so as to obtain the hydrotalcite-like nanosheets. Through conversion of ethanol between a supercritical state and a conventional state, the hydrotalcite-like compound is stripped effectively, and recycling use of ethanol is achieved. The disadvantages that multiple times of ion exchange are needed in the conventional method, and use of formamide and other organic solvents is needed are avoided, and the preparation method has the characteristics of environmental friendliness, a simple process and low cost.

Owner:SHANXI UNIV

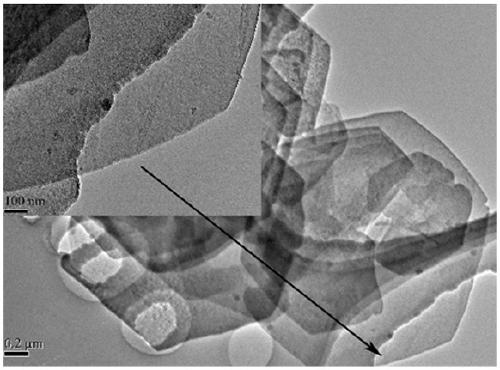

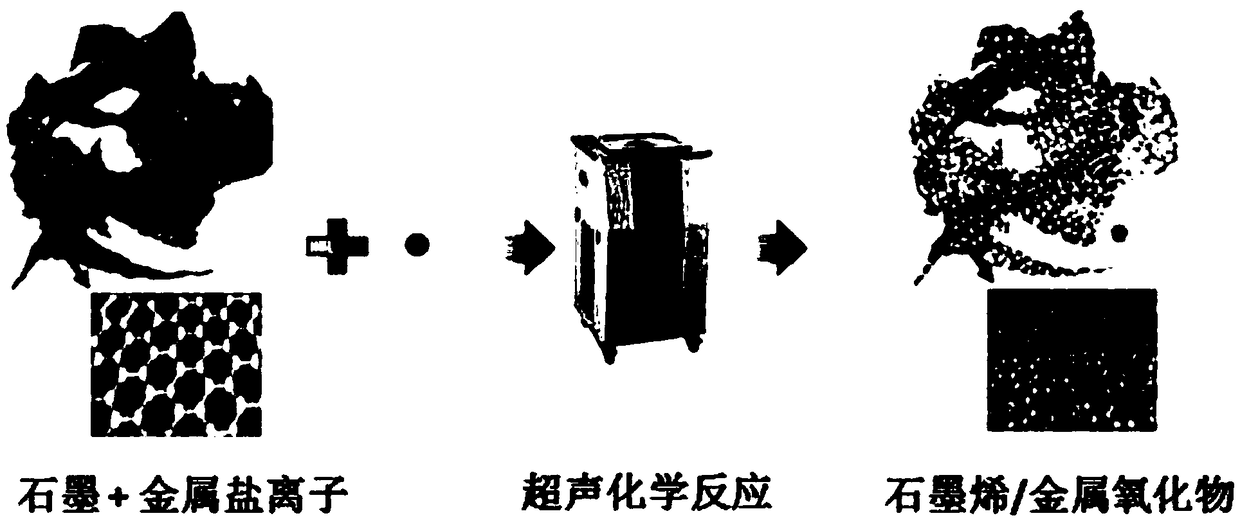

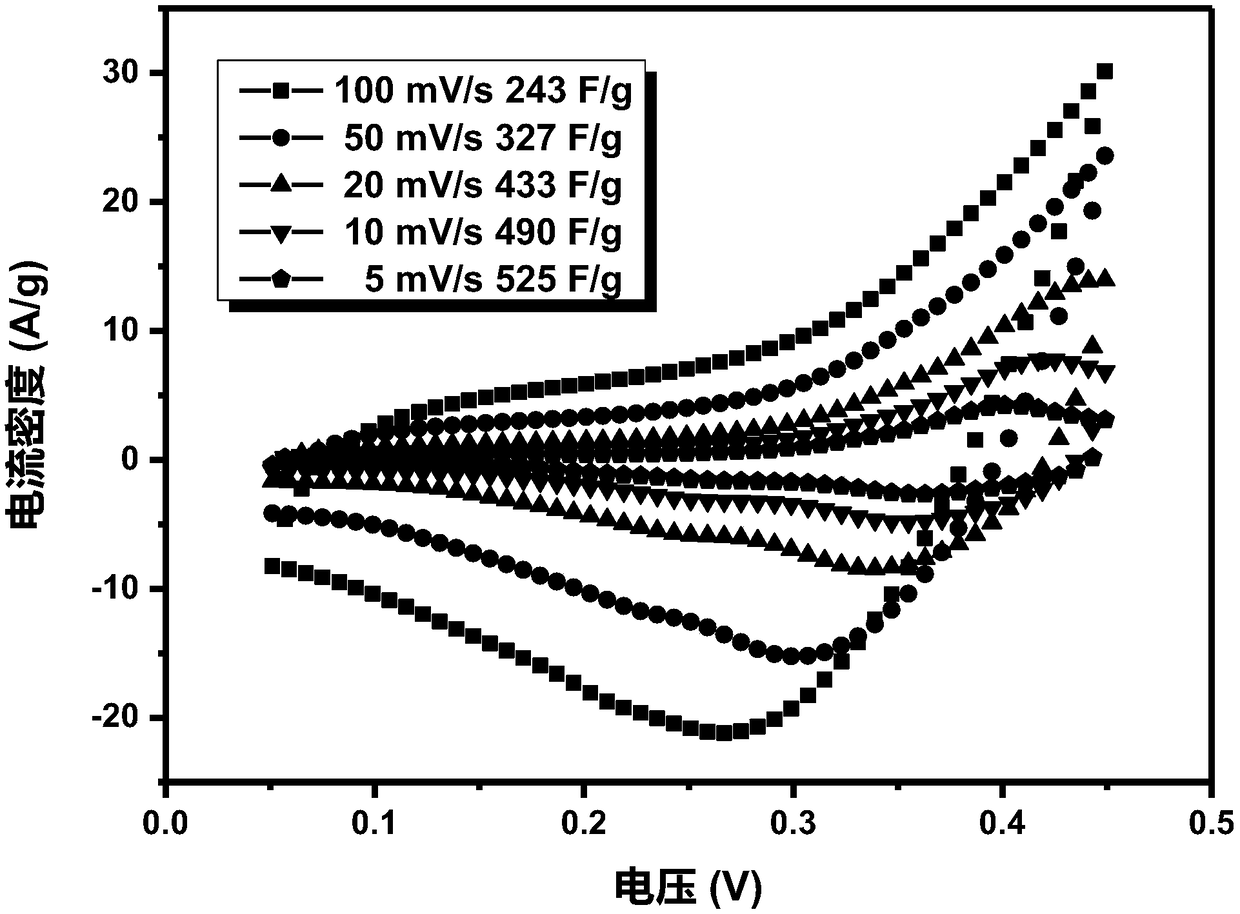

In-situ preparation of graphene composite electrode materials by ultrasonic chemical method

ActiveCN109087820AIncrease the effective specific surface areaIncrease transfer rateHybrid capacitor electrodesCell electrodesCapacitanceChemical reaction

The invention provides an in-situ preparation of graphene composite electrode materials by a ultrasonic chemical method. Graphene composite electrode materials with high specific capacitance, fast charge / discharge rate and good cycle stability can be obtained by effectively peeling graphite into graphene through a simple ultrasonic chemical reaction process and generating metal oxides and conductive polymer on the surface of graphene in situ. The method comprises the following steps in particular: adding graphite, metal salt or conductive polymer monomer and auxiliary agents into a solvent tocarry out ultrasonic chemical reaction, wherein the ultrasonic frequency is 20 kHz to 10 MHz, the ultrasonic power is 150 to 1000 W, and the reaction time is more than 1 hour; then performing washingand drying to obtain the graphene composite electrode material, wherein the prepared graphene composite electrode material is graphene / metal oxide composite electrode material, or graphene / conductivepolymer composite material, or graphene / metal oxide / conductive polymer composite material.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES +1

Method for initiating polymer grafting treatment on carbon black surface by utilizing gamma ray radiation

InactiveCN101665560AImprove dispersion stabilityPrevent reaggregationPigment treatment with macromolecular organic compoundsDispersion stabilityChemical treatment

The invention relates to a method for initiating polymer grafting treatment on carbon black surface by utilizing gamma ray radiation, belonging to the technical field of high molecule polymer graftingchemical treatment. The method mainly comprises the following process: first, preparing carbon black dispersed liquid sizing agent which contains a certain quantity of carbon black powder particles and is evenly dispersed inside distilled water, and then adding polymer monomer butyl methacrylate, styrene and acrylonitrile mixed monomer emulsion into the sizing agent. The mixed monomer emulsion isprepared by mixed monomer which is prepared by the polymer monomer butyl methacrylate, the styrene and the acrylonitrile mixed monomer emulsion according to the mixture ration of 7:2:1, emulsifier sodium dodecyl sulfate or / and alkylphenol polyethenoxy ether and a certain amount of distilled water, and the weight ratio among the mixed polymer monomer, the emulsifier and the distilled water is 5:1:14, placing the mixed liquid containing the carbon black sizing agent and the monomer emulsion under gamma ray radiation for irradiation treatment, the irradiation dose of the gamma ray is 3-10KGy, and finally, the radiation initiation polymer grafting treatment is carried out on the carbon black surface by gamma ray. After being treated, the carbon black particles have good dispersion stability and uniformity.

Owner:SHANGHAI UNIV

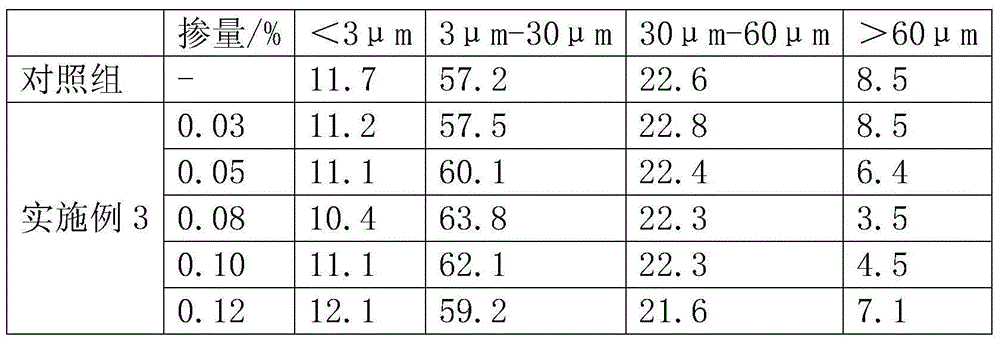

Cement grinding aid

The invention relates to the technical field of cement additives, in particular to a cement grinding aid. The cement grinding aid is composed of, by mass, the following components of 10-20 parts of modified triethanolamine, 0.3-0.8 part of polypropylene oxide ethylene oxide ether, 6-18 parts of sodium aliphatate, 12-28 parts of sodium acetate, 2-6 parts of glycerin distilling residues, 2-6 parts of sodium thiosulfate, 0.2-0.5 part of tween, 1-5 parts of ammonium nitrate, 2-6 parts of sodium gluconate and 20-50 parts of deionized water. According to the cement grinding aid, free energy on the surface of powder and surfactants which can prevent the powder from regathering are significantly reduced. By testing the influence of the cement grinding aid on the grinding effect and the cement particle size distribution and testing the macroscopic and microscopic influence of the cement grinding aid on the cement and concrete properties, it is discovered that the cement grinding aid has the advantages of being small in total alkaloid content, low in energy consumption, little in pollution, excellent in property and the like, and an environment-friendly standard is achieved.

Owner:汤海涛

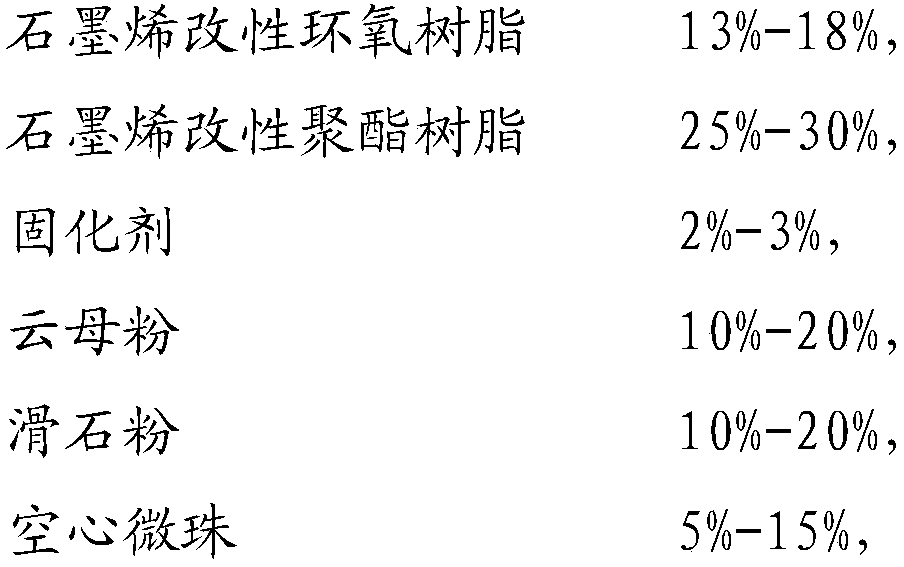

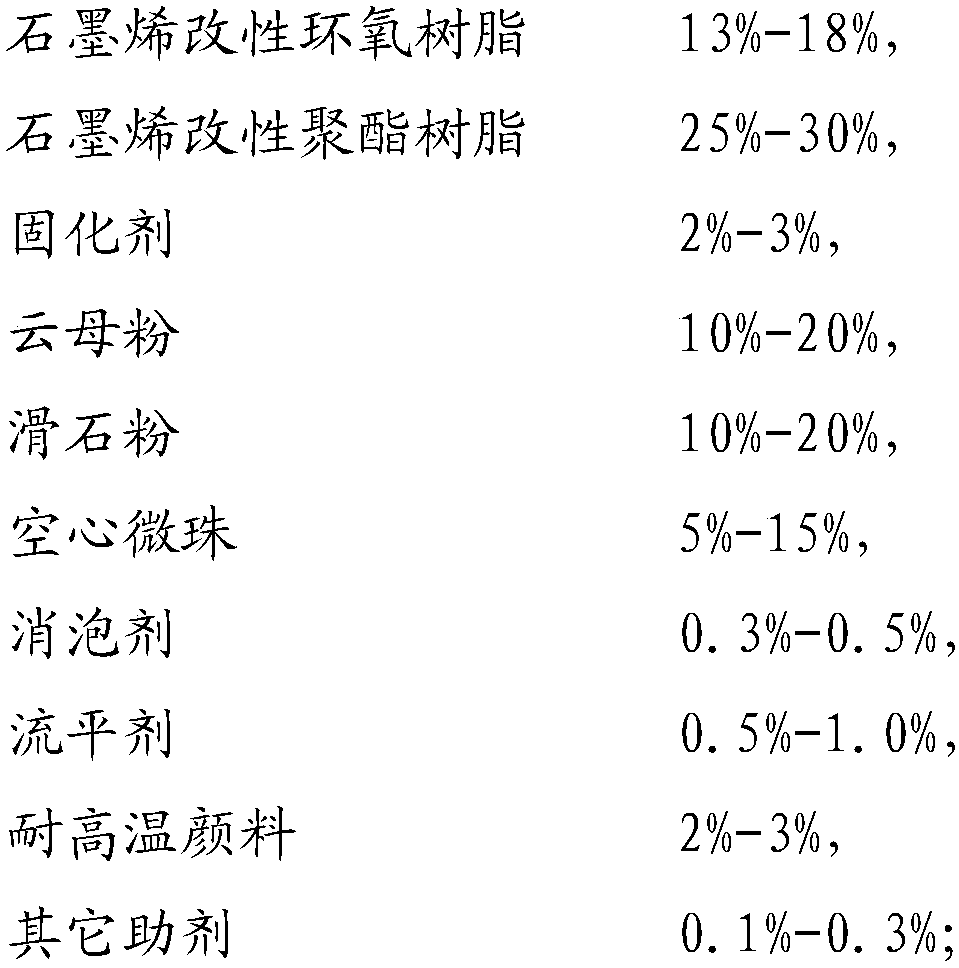

High temperature-resistant powder coating and preparation method thereof

The invention relates to high temperature-resistant powder coating and a preparation method thereof. The high temperature-resistant powder coating comprises graphene modified epoxy resin, graphene modified polyester resin, a curing agent, a mica powder, a talc powder, hollow microbeads, a defoamer, a leveling agent, a high temperature-resistant pigment and other auxiliary agents. According to thetechnical scheme, through the addition of the hollow microbeads in the coating, by virtue of the characteristic of good fluidity of the hollow microbeads, the high temperature resistance of the powdercoating is effectively improved; the film forming hardness of the powder coating is adjusted through different hardness of the graphene modified epoxy resin and the graphene modified polyester resin,and through different contents of graphene in the epoxy resin and the polyester resin, after mixing, a bonding force inside the material can prevent reaggregation of the graphene because of capability of forming a disordered structure in a coating layer of the coating and increases the resistance of permeability factors permeating to the surface of a substrate, so that the corrosion resistance ofthe coating is greatly improved.

Owner:宁波派特勒新材料股份有限公司

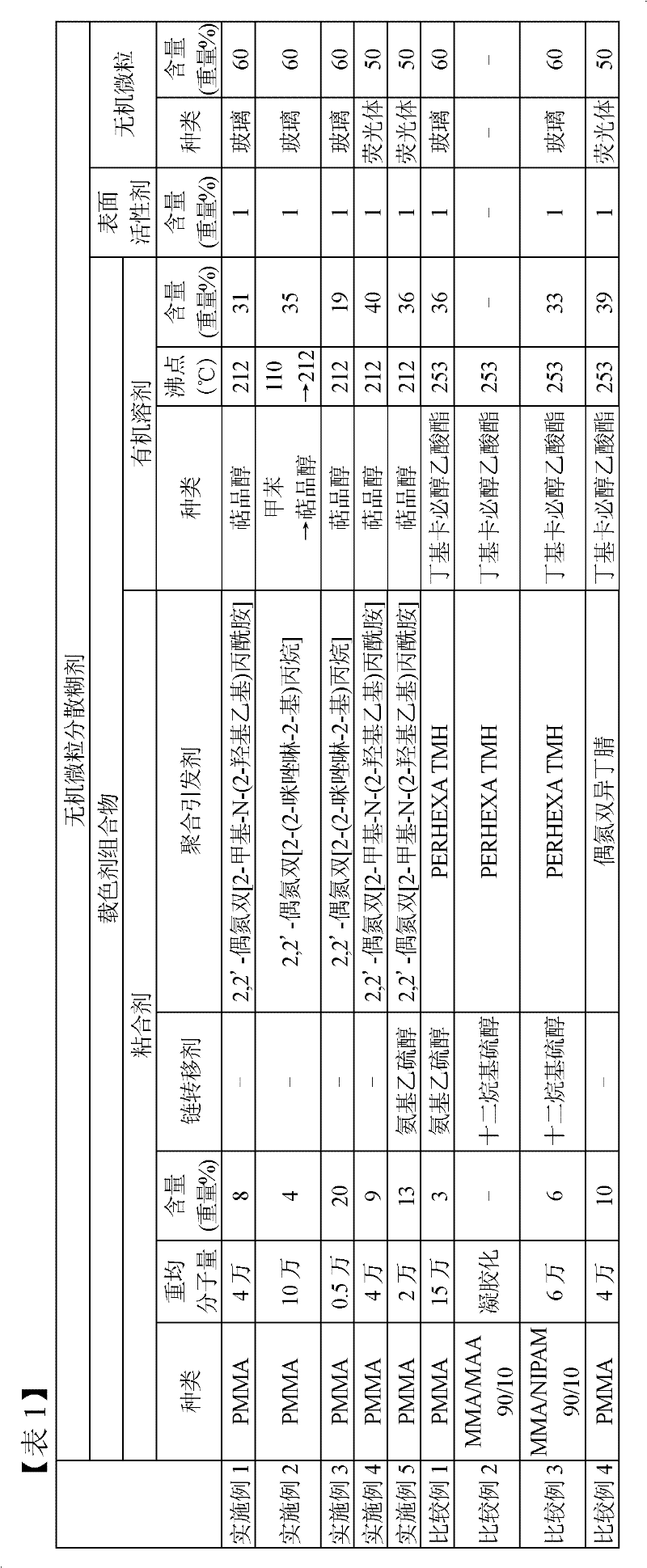

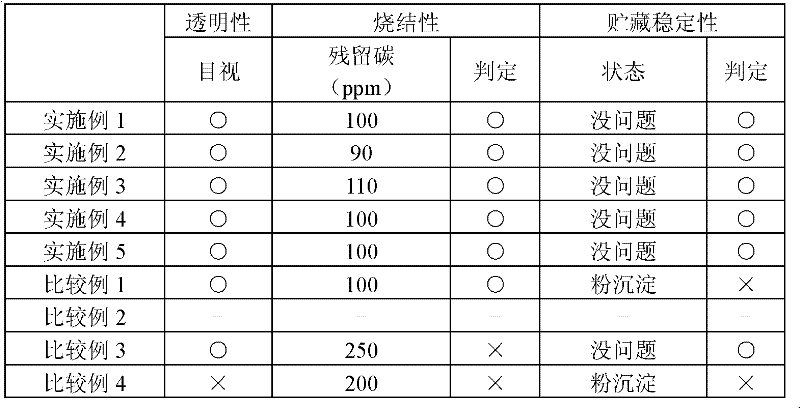

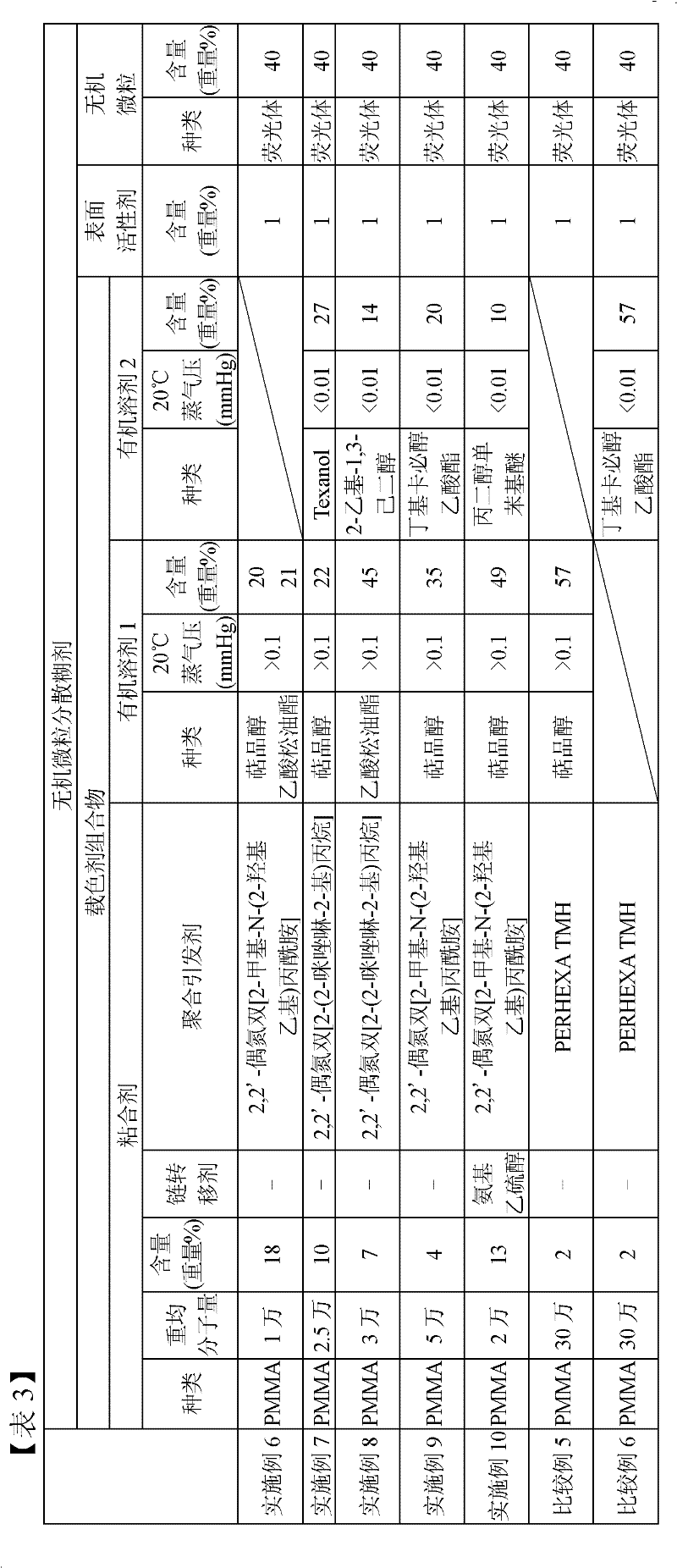

Inorganic microparticle-dispersed paste composition

InactiveCN102333818AHigh interactionPrevent reaggregationLuminescent compositionsPigment pastesPolystyreneAcrylic resin

Disclosed is an inorganic microparticle-dispersed paste composition which can be defatted at low temperature and has excellent dispersibility and storage stability. The inorganic microparticle-dispersed paste composition comprises a (meth)acrylic resin, inorganic microparticles, and an organic solvent. The (meth)acrylic resin has an amino group or an amide group at a molecular end and has a weight average molecular weight in terms of polystyrene of 5000 to 100000.

Owner:SEKISUI CHEM CO LTD

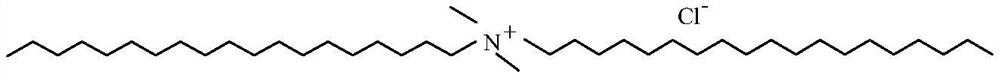

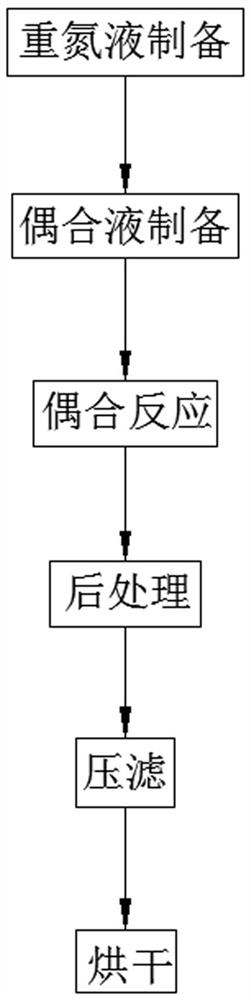

Application of quaternary ammonium salt derivative in preparation of red pigment, red pigment and preparation method of red pigment

In order to solve the problems that pigments are poor in wettability and dispersity, high in viscosity and poor in storage stability, a quaternary ammonium salt derivative is applied to preparation of an azo red pigment for water-based UV ink. The invention also relates to the red pigment and a preparation method thereof and further provides the water-based UV red ink using the red pigment. The preparation method of the red pigment comprises the processes of diazotization reaction, coupling liquid preparation, coupling reaction, post-treatment and the like, wherein a quaternary ammonium salt derivative solution is added in the preparation process of coupling liquid, and compound liquid of an anionic surfactant and a nonionic surfactant is added in a post-treatment process. Thus, the pigment has good wettability, high dispersibility, high coloring strength, low viscosity and good storage stability in a water-based UV system.

Owner:LONGKOU UNION CHEM

Freeze-drying preparation method of second-phase particle dispersion molybdenum composite powder

The invention provides a freeze-drying preparation method of second-phase particle dispersion molybdenum composite powder. The method comprises the following steps that rare-earth nitrate or carbide particles, molybdate and a surfactant are added to deionized water together and are subjected to ultrasonic treatment, and a solution or turbid liquid is prepared; pre-freezing is performed on the solution or the turbid liquid by the aid of liquid nitrogen or dry ice, or pre-freezing is performed for 4-12 hours in a low-temperature environment such as a refrigerator and the like at subzero 60-subzero 10 DEG C, then freeze-drying is performed, that is, the pre-frozen solution or turbid liquid is placed into a stable freeze-drying machine of which the freeze-drying temperature reaches a preset temperature of subzero 80-subzero 20 DEG C, a vacuum pump is started, the vacuum degree is kept below 50 Pa, and freeze-drying is performed for 5-48 hours; and the freeze-dried precursor powder is calcined, and then two-step reduction is performed in a reducing atmosphere, and the superfine second-phase particle dispersed molybdenum composite powder is obtained finally. According to the method, preparation of the superfine nano powder can be realized, and meanwhile, the method is very suitable for single-batch large-scale preparation of the composite powder.

Owner:TIANJIN UNIV

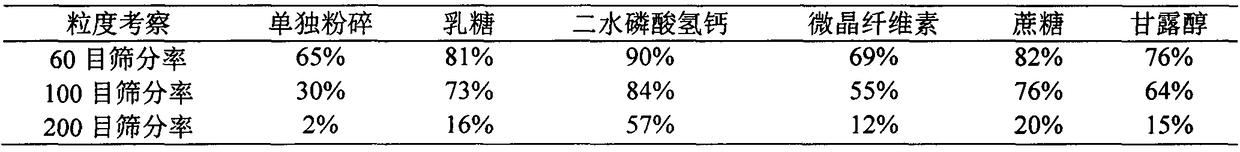

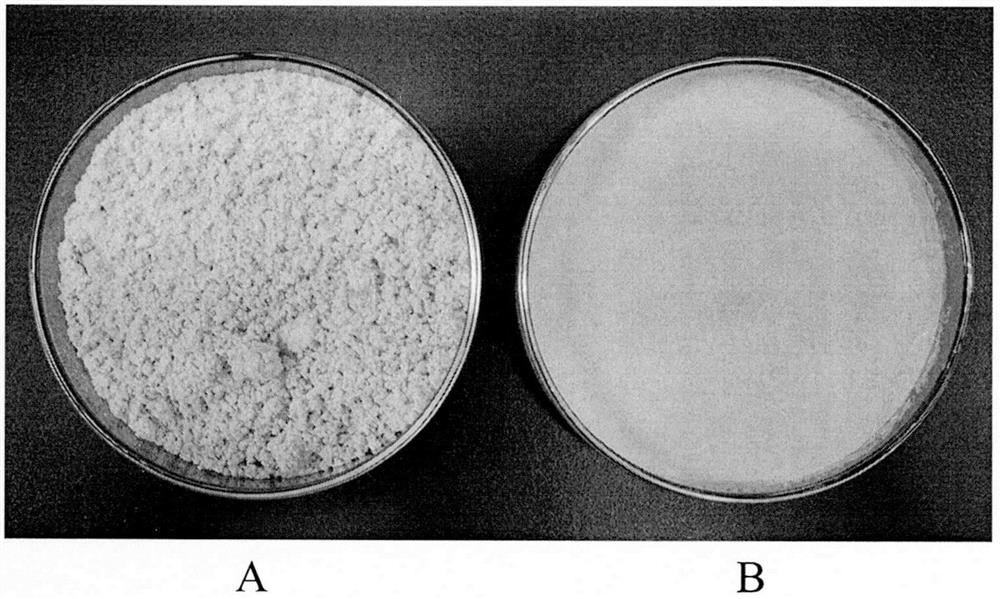

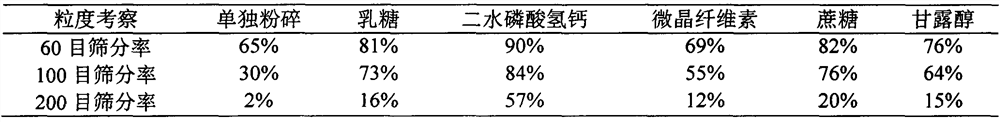

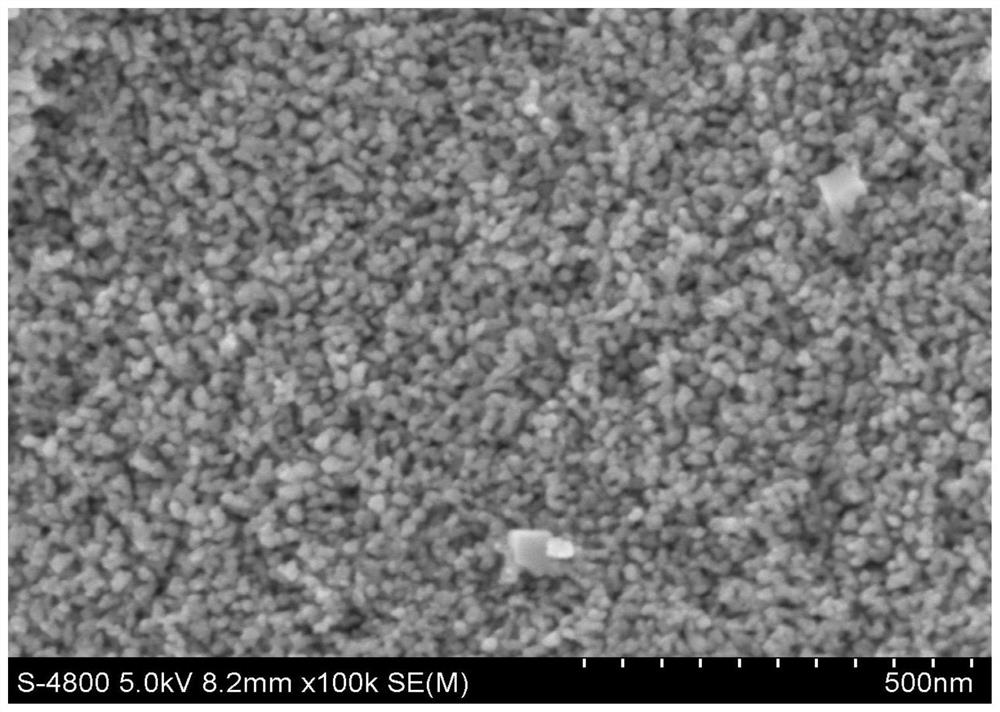

Thyroid tablets produced by direct whole-powder tabletting and preparation process thereof

ActiveCN109464411AHigh densityLow densityPowder deliveryInorganic non-active ingredientsHydrogen phosphateMedicine

The invention belongs to the technical field of pharmaceutical preparations, and relates to thyroid tablets produced by direct whole-powder tabletting and a preparation process of the thyroid tabletsproduced by the direct whole-powder tabletting, in particular to synergetic application of calcium hydrogen phosphate-assisted optimization of powder properties of thyroid raw materials and freeze-drying assisted grinding technology. More than 98% of the particle sizes of thyroid mixed ground materials prepared by the invention are smaller than 250 microns, and the thyroid mixed ground materials are difficultly reaggregated, and uniformly mixed with other auxiliary materials; RSD of the T3 and T4 contents in thyroid powder is not greater than 4%; the angle of repose of the mixed powder is smaller than 35 degrees, so that requirements of powder direct tabletting are met; the content uniformity (A+2.2S) of T3 and T4 in the thyroid tablets is not greater than 20, each tablet is disintegratedwithin 15min, and the disintegration time limit difference is small (RSD is not greater than 5%). The thyroid tablets produced by the direct whole-powder tabletting and the preparation process of thethyroid tablets produced by the direct whole-powder tabletting disclosed by the invention effectively solve the problems that the thyroid raw materials are not easily ground, and not uniformly mixed with the auxiliary materials and the like, optimize the grinding effect of the thyroid raw materials, improve the powder properties of the thyroid raw materials, and greatly enhance the content uniformity of T3 and T4 in the thyroid tablets.

Owner:CHINA PHARM UNIV

A kind of thyroid tablet produced by full powder direct compression and its preparation process

ActiveCN109464411BHigh densityLow densityPowder deliveryInorganic non-active ingredientsMetallurgyFreeze-drying

Owner:CHINA PHARM UNIV

A method for preparing ultrafine yttrium oxide-doped tungsten composite powder by freeze-drying

The invention provides a method of preparing tungsten-doped superfine yttrium oxide compound powder by freeze drying. The method comprises the following steps: dissolving ammonium metatungstate and ayttrium nitrate hexahydrate in deionized water or distilled water, and carrying out ultrasonic treatment to disperse and dissolve the mixture to prepare a solution; pouring the solution into a surfacevessel or other containers large in surface areas, putting the surface vessel or other containers in a refrigerator, and pre-freezing the same at 40 DEG C below zero and 10 DEG C below zero; openingrefrigeration and a vacuum meter of a freeze drier in advance, and after the temperature of the freeze drier is reduced to the freezing temperature of 58 DEG C below zero and 20 DEG C below zero and is stabilized, putting the pre-frozen surface vessel in the freezer dryer, and opening a vacuum pump to maintain the vacuum degree and carry out freeze drying; putting the freeze-dried compound powderin a tubular furnace, and calculating the compound powder in a nitrogen or an argon air flow to obtain WO3-Y2O3 compound oxide powder; and carrying out two-step reduction with pure hydrogen in the tubular furnace to obtain the tungsten-doped superfine yttrium oxide compound powder. The average grain size is about 10nm, the grain size distribution is extremely narrow, and a bimodal distribution phenomenon is avoided.

Owner:TIANJIN UNIV

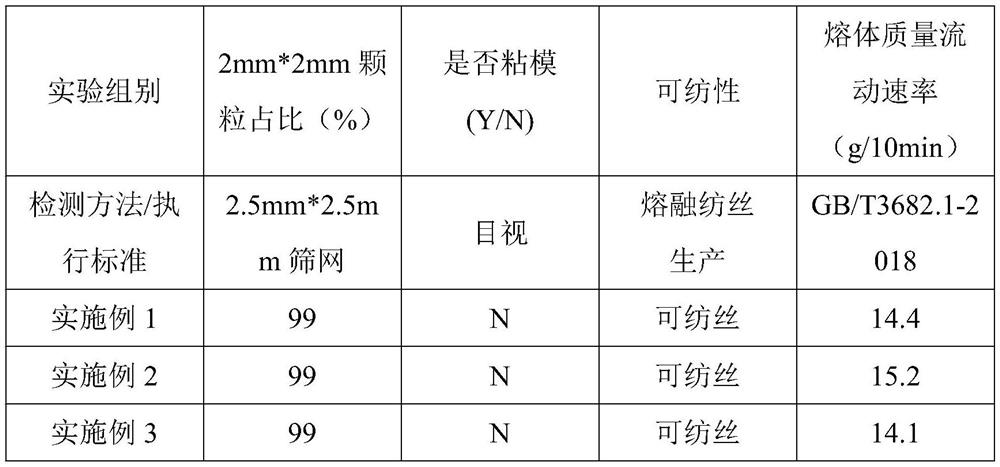

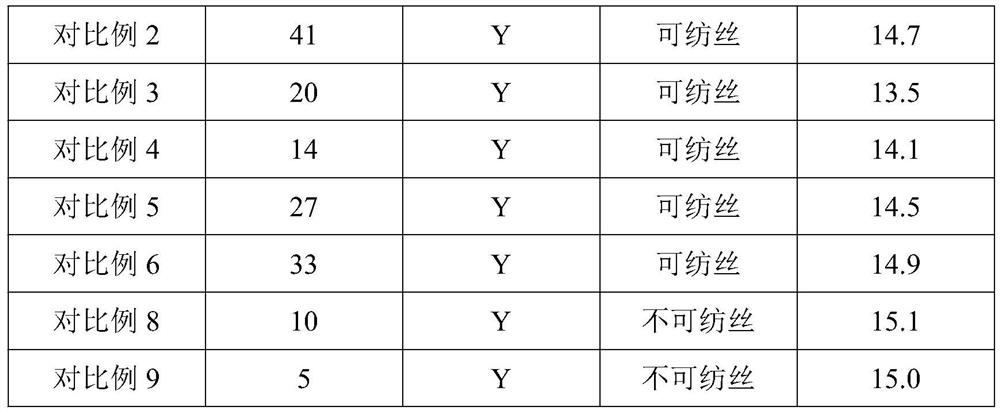

Antimony oxide master batch special for flame-retardant non-woven fabric and preparation method of antimony oxide master batch

ActiveCN113024952AHigh melt mass flow rateSolve the problem of pelletizing not formingFlame-proof filament manufactureGlutaric acidNonwoven fabric

The invention discloses an antimony oxide master batch special for flame-retardant non-woven fabric, which comprises the following raw materials by weight: 75%-93% of antimony oxide, 4%-15% of polypropylene resin, 1%-1.5% of a hyperdispersant, 0.4%-0.7% of trimethyl octadecyl ammonium bromide, 0.5%-3% of stearate, 0.3%-5% of a novel toughening auxiliary agent, and 0.1%-2% of zinc glutarate. The antimony oxide master batch is prepared through the steps of raw material weighing, premixing, re-stirring, melting, plasticizing, granulating, drying and the like. By implementing the innovative formula and the processing technology, the molding problem of the high melt mass flow rate type polypropylene resin applied to preparation of the antimony oxide master batch taking the polypropylene resin as the carrier can be effectively solved, and the production quality problems of mold sticking, particle breaking, particle connection and the like in particle cutting are solved.

Owner:广西华锑科技有限公司

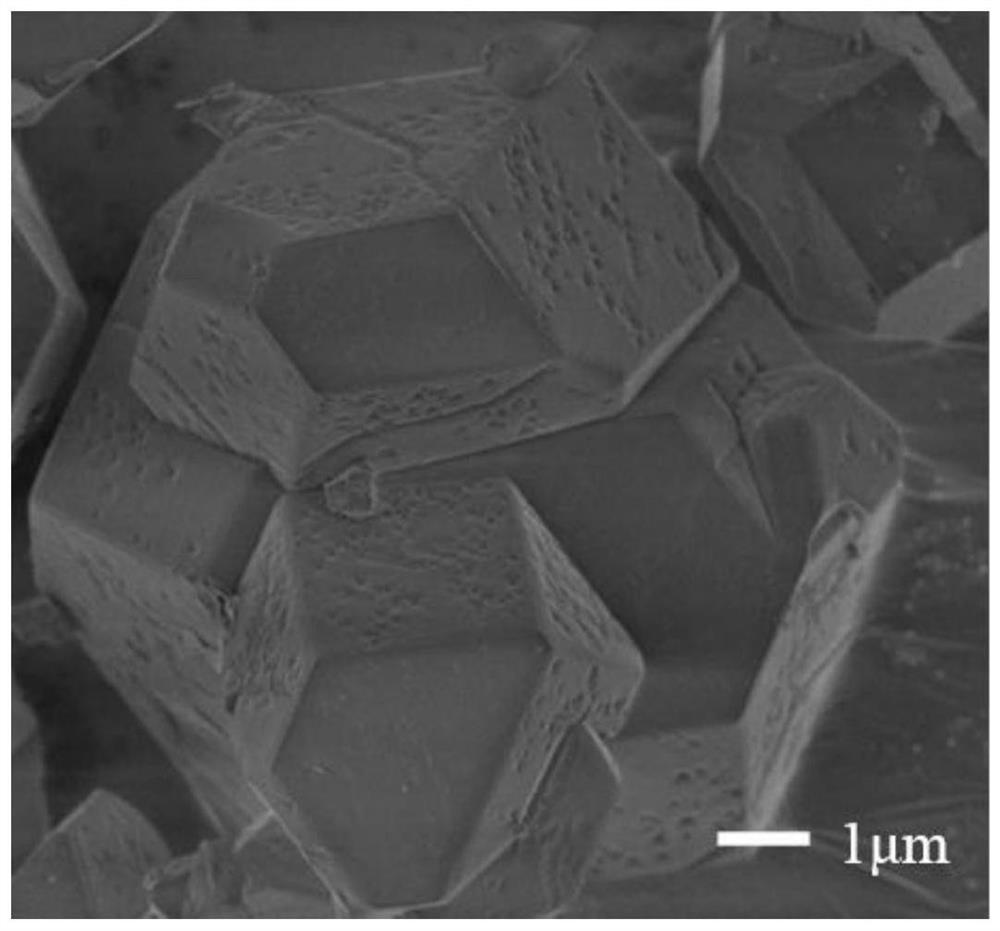

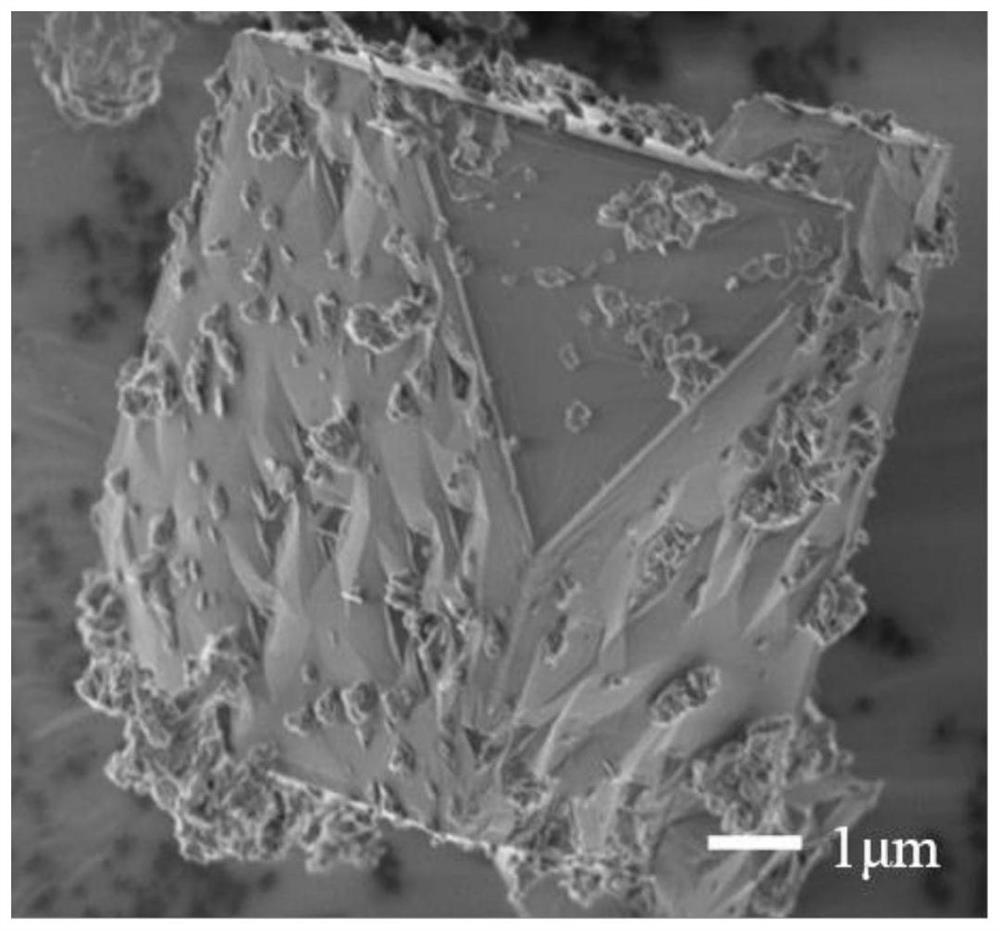

Truncated polyhedron-shaped MOFs (at) rGO material as well as preparation method and application thereof

PendingCN114471467ARich pore structureImprove adsorption capacityOther chemical processesHydrocarbon oils refiningMetal-organic frameworkSulfide compound

The invention discloses a truncated polyhedron-shaped MOFs (at) rGO material as well as a preparation method and application thereof. The chamfered polyhedron-shaped MOFs (at) rGO material provided by the invention comprises reduced graphene oxide and a metal organic framework material, and the chamfered polyhedron-shaped MOFs (at) rGO material contains a hierarchical pore structure. The truncated polyhedron-shaped MOFs (at) rGO material can be used as an adsorbent for effectively removing thiophene sulfides, has the characteristics of stable structure, high removal rate and high sulfur capacity, and is mild in reaction condition, low in production cost and low in hydrogen consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

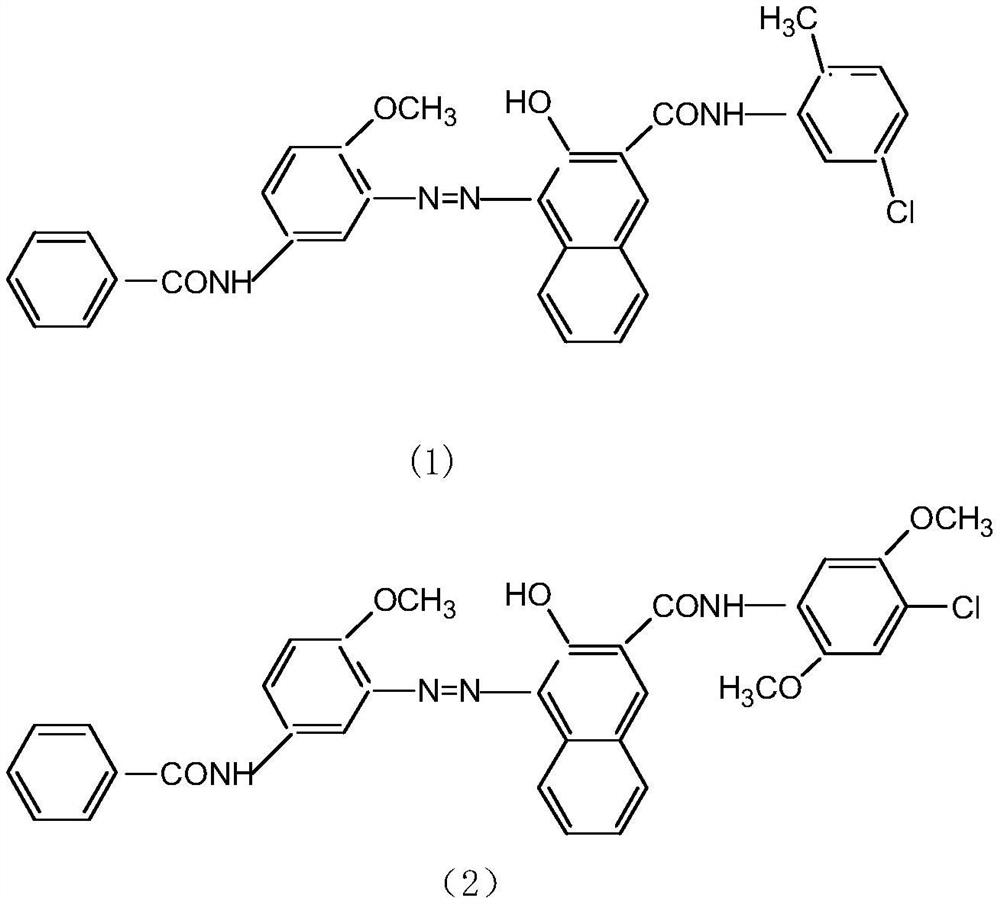

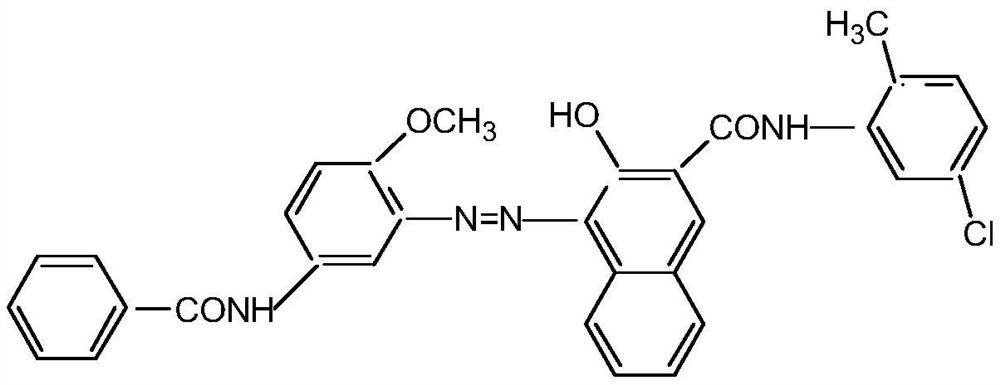

Synthesis method of high-speed, high-tinting-strength and odorless pigment yellow

PendingCN114736532AGood water solubilityImprove stabilityDisazo dyesChemical industryLiquid viscosityActive agent

The invention belongs to the field of pigment yellow synthesis, particularly relates to a high-speed, high-tinting-strength and odorless pigment yellow synthesis method, and aims to solve the problems of high material liquid viscosity, extremely low reaction efficiency, incomplete reaction and the like due to no use of auxiliaries in the existing pigment synthesis process. In order to solve the problems of high bubbling quantity and low reaction efficiency in the prior art, the invention provides the following scheme: the method comprises the following steps: S1, preparing a diazonium solution; s2, preparation of a coupling liquid: 4-chloro-2, 5-dimethoxyacetoacetanilide is subjected to clarification and acid precipitation; and S3, coupling reaction: adding the prepared diazonium liquid into the coupling liquid. The invention has good water solubility, excellent nonionic surfactant, good washing decontamination ability and strong emulsibility, can excellently improve the reaction efficiency effect, can effectively improve the reaction rate, and can shorten the coupling reaction time.

Owner:CROWN CHEMICAL CORP

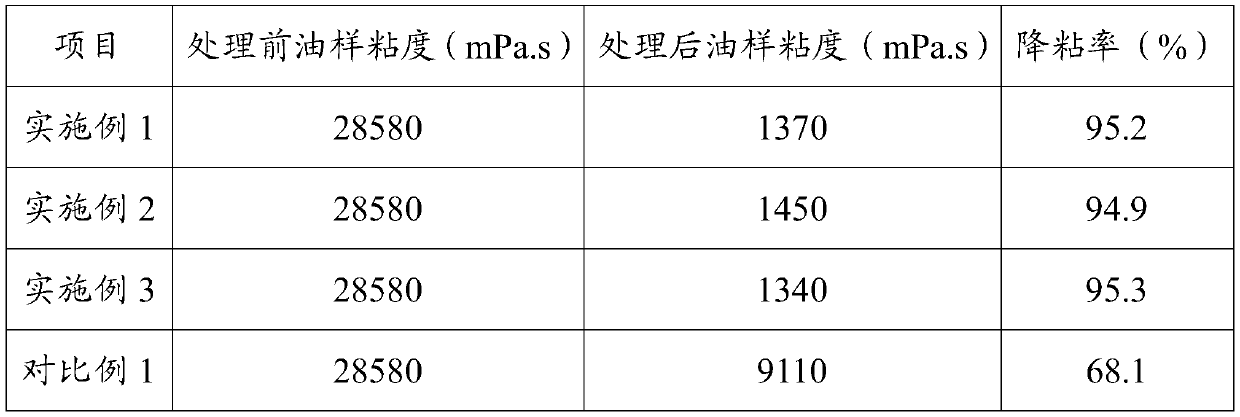

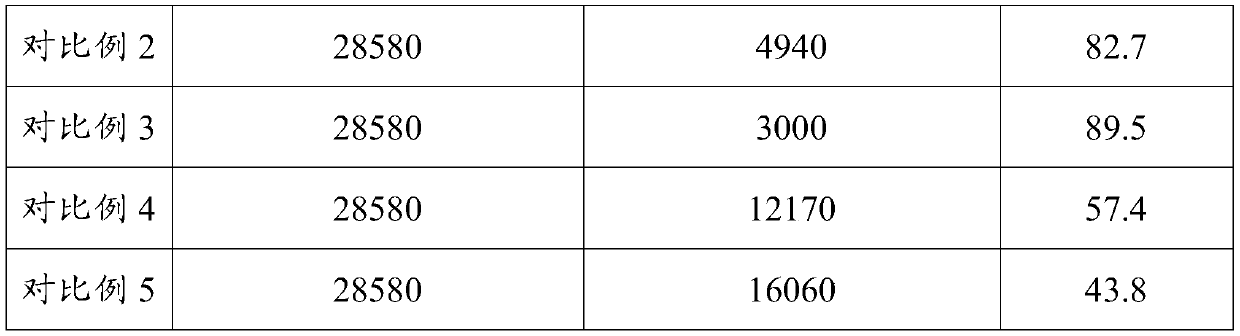

Viscosity reducer for heavy oil recovery and preparation method thereof

Owner:SHAANXI YANCHANG PETROLEUM GRP

A kind of freeze-drying preparation method of second-phase particle dispersed molybdenum composite powder

Owner:TIANJIN UNIV

Preparation method of polyolefin/montmorillonite nano-composite material

The present invention discloses a preparation method of polyolefine / montmorillonite nano composite material. Under the condition of having no need of any solvent said invention adopts the following steps: using imidazole salt or pyridine salt ionic liquid as organic modifying agent, grinding said organic modifying agent and montmorillonite at room temperature to implement organization of the montmorillonite and form nano organic montmorillonite particles with ionic liquid intercalation, then melting and mixing the polyolefine and organic montmorillonite so as to form the invented polyolefine / montmorillonite nano composite material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method of preparing polymer/montmorillonid nano-composite material by montmorillonoid in-situ organization

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of dispersing agent for polyurethane coating

InactiveCN111826068AIncrease surface adsorption capacityImprove wettabilityPolyurea/polyurethane coatingsPolymer scienceNitrogen atmosphere

The invention discloses a preparation method of a dispersing agent for a polyurethane coating, and relates to the technical field of coating additives. The preparation method comprises the following steps of: (1) acquiring an initiator solution; (2) acquiring a reaction solution; (3) acquiring a dispersion liquid preparation body; and (4) adding isodecanol and oleylamine into the obtained dispersion liquid preparation body, performing heating to 70-75DEG C under the protection of nitrogen atmosphere, carrying out heat preservation and stirring for 2h, and then performing natural cooling to room temperature to obtain the product. The invention provides a preparation method of the dispersing agent for a polyurethane coating. Compared with a conventional dispersing agent, the dispersing agentdisclosed by the invention has a stronger surface adsorption effect on pigments and fillers, the wetting effect on pigment and filler particles can be obviously improved, the grinding process is shortened, the yield per unit time is increased, an excellent anti-flocculation effect is realized, and re-aggregation of dispersed particles can be prevented, the dispersing agent provided by the invention adopts a non-polar part to provide a three-dimensional barrier among filler particles, and the stability of the filler particles in a solvent system is realized by virtue of a space entropy effect.

Owner:安徽喜宝高分子材料有限公司

Preparation method of polyurethane polymer dispersant for textile pigment printing paste

The invention relates to a preparation method of a polyurethane polymer dispersant for textile pigment printing paste, comprising: dissolving diisocyanate and hydrophilic carboxyl diol in an organic solvent, raising the temperature to 75°C for 60 minutes, and then dripping in batches Add small molecule dihydric alcohol solution, carry out multiple chain extension reactions, the reaction time is 60min, after the chain extension reaction is completed, carry out capping reaction for 120min; cool down to 50°C, add Na2CO3 solution dropwise, emulsify while neutralizing, dropwise add After completion, add water and heat up to 60°C and continue to stir and dissolve for 30 minutes to prepare a polyurethane polymer dispersant. The polymer dispersant of the present invention has strong affinity to the surface of pigment particles, is not easy to desorb, and has good anti-flocculation; and the preparation method is simple, low in cost, and environmentally friendly; the pigment paste prepared by using the dispersant is stable High, used in textile printing processing, can obtain high dry and wet rubbing fastness of printing.

Owner:DONGHUA UNIV

Holocellulose nano composite fiber and preparation method thereof

ActiveCN112030251AImprove dispersion stabilityPrevent reaggregationConjugated cellulose/protein artificial filamentsWet spinning methodsMicrocrystalline cellulosePolymer science

The invention discloses a preparation method of a holocellulose nano composite fiber. The preparation method comprises the following steps: a microcrystalline cellulose suspension is ground and centrifugally separated to obtain a cellulose nanocrystalline supernatant, the cellulose nanocrystalline supernatant is added into a cellulose fiber spinning solution to be uniformly mixed, bubbles are removed from the uniformly mixed cellulose nanocrystalline / cellulose fiber spinning solution, and then spinning is conducted, wherein the length of the cellulose nanocrystalline in the supernatant is 223+ / -100 nm to 366+ / -171 nm, and the diameter of the cellulose nanocrystalline is 29+ / -8 nm to 35+ / -9 nm. According to the preparation method, the cellulose nanocrystalline can be uniformly dispersed inthe cellulose fiber spinning solution, meanwhile, the dispersion stability of the cellulose nanocrystalline in the spinning solution is improved, reaggregation of the cellulose nanocrystalline is avoided, the cellulose nanocrystalline can be uniformly dispersed in the spinning solution, and finally the mechanical property of the composite fiber is improved.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com