Inorganic microparticle-dispersed paste composition

A technology of inorganic particles and compositions, applied in luminescent materials, pigment pastes, chemical instruments and methods, etc., can solve the problems of difficulty in adjusting the molecular weight of acrylic resins, deterioration of thermal decomposition properties of acrylic resins, poor thermal decomposition properties, etc. High efficacy, improved dispersion stability, and the effect of preventing re-aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

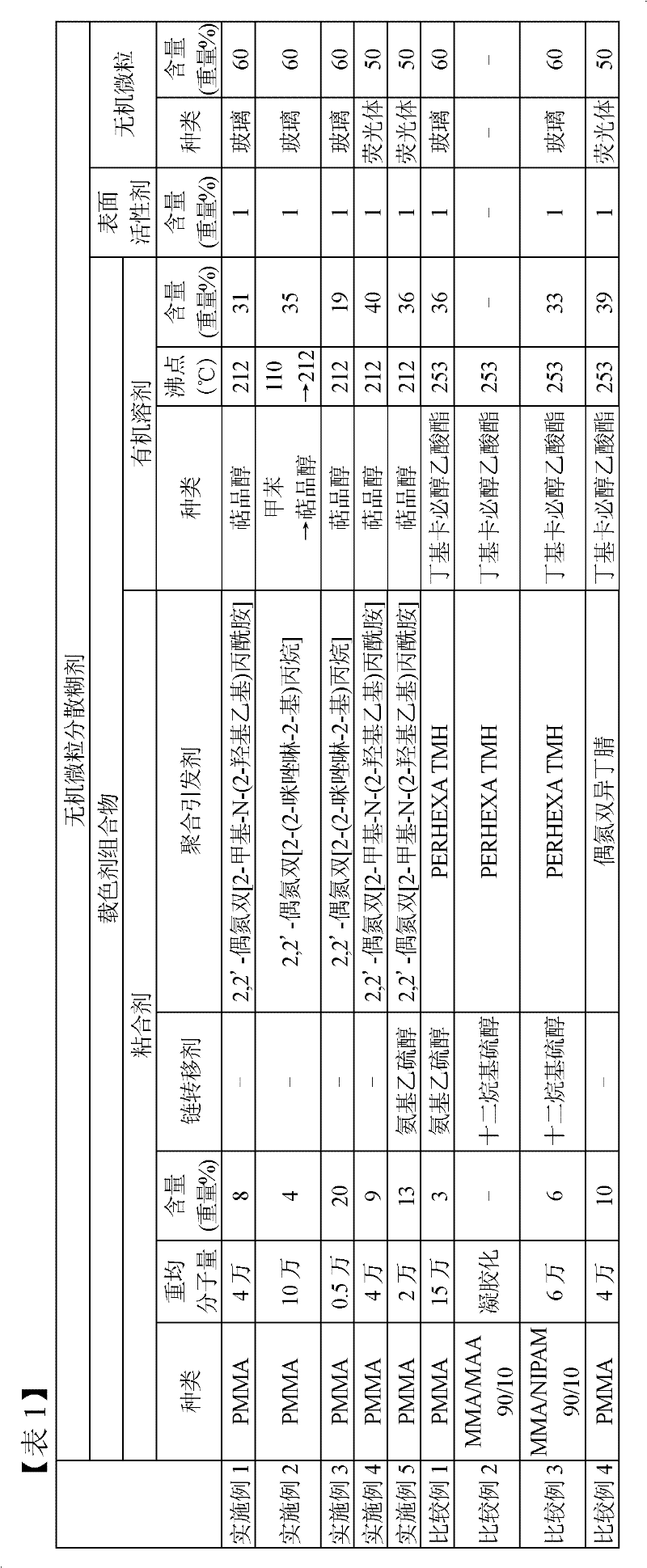

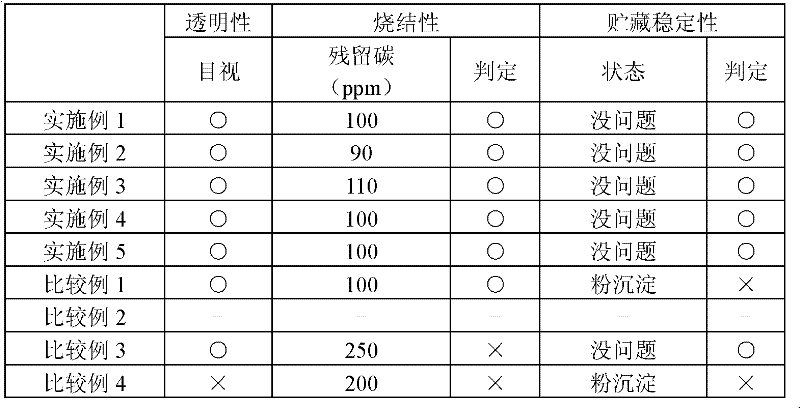

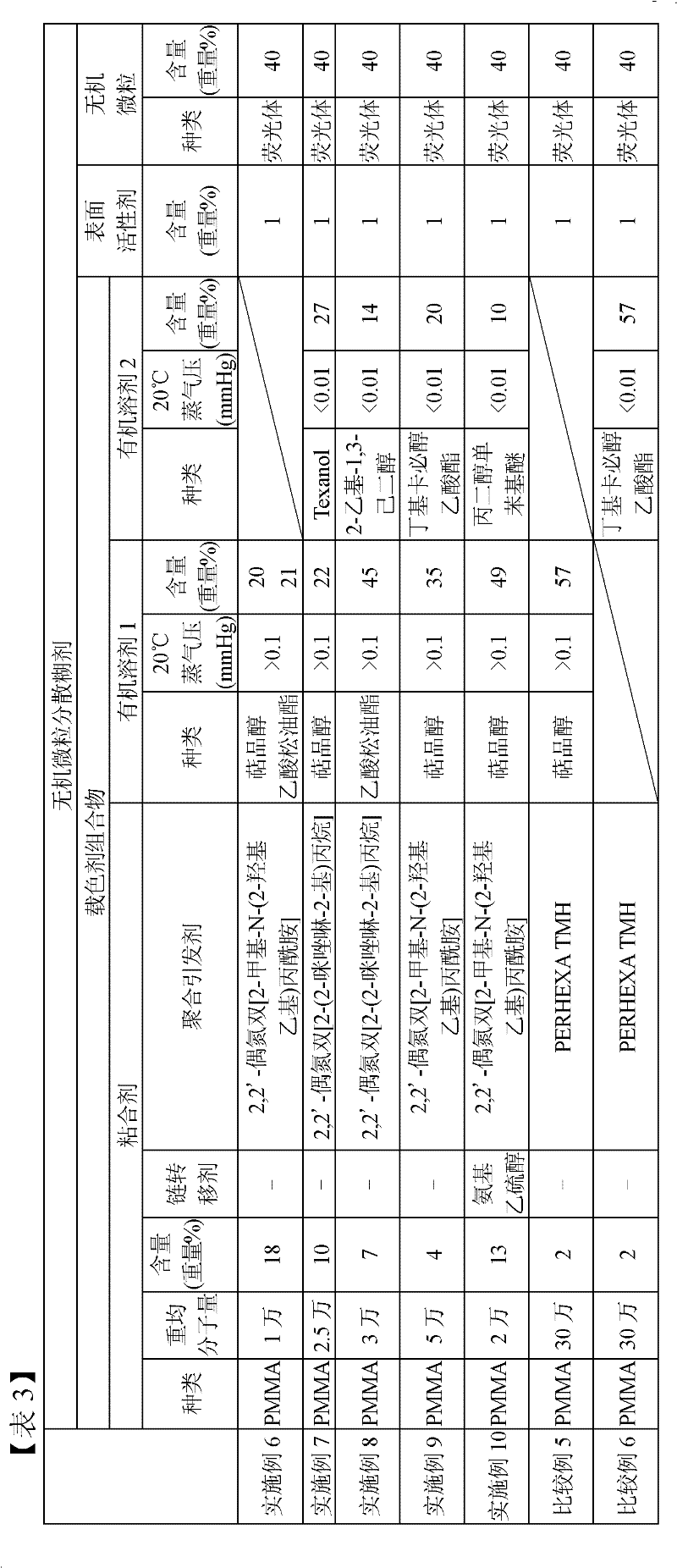

Examples

Embodiment 1

[0107] Mix 100 parts by weight of methyl methacrylate (MMA) and 100 parts by weight of terpineol as an organic solvent in a 2L detachable flask with a stirrer, a cooler, a thermometer, a hot water bath, and a nitrogen gas inlet to obtain a single body mixture.

[0108] After removing dissolved oxygen by bubbling the obtained monomer mixed liquid with nitrogen gas for 20 minutes, the inside of the separable flask was replaced with nitrogen gas, and the temperature of the oil tank was raised to 130° C. while stirring. A solution obtained by diluting 2,2'-azobis[2-methyl-N-(2-hydroxyethyl)propionamide] as a polymerization initiator with terpineol was added. Moreover, the terpineol solution containing a polymerization initiator was added several times during polymerization, and 1.5 weight part of polymerization initiators were added in total with respect to 100 weight part of monomers.

[0109] After 7 hours from the start of the polymerization, it was cooled to room temperature ...

Embodiment 2

[0113] 100 parts by weight of methyl methacrylate (MMA) and 100 parts by weight of toluene as an organic solvent were mixed in a 2L detachable flask with a stirrer, a cooler, a thermometer, a hot water bath, and a nitrogen inlet to obtain a monomer mixture. liquid.

[0114] After removing dissolved oxygen by bubbling nitrogen gas into the obtained monomer mixed liquid for 20 minutes, the inside of the separable flask was replaced with nitrogen gas, and the temperature of the oil tank was raised to 130° C. while stirring. A solution obtained by diluting 2,2'-azobis[2-(2-imidazolin-2-yl)propane] as a polymerization initiator with terpineol was added. Separately, the terpineol solution containing the polymerization initiator was added several times during the polymerization, and a total of 1.5 parts by weight of the polymerization initiator was added with respect to 100 parts by weight of the monomers.

[0115] After 7 hours from the initiation of the polymerization, the polymer...

Embodiment 3

[0119] In a 2L detachable flask having a stirrer, a cooler, a thermometer, a hot water bath, and a nitrogen inlet, 100 parts by weight of methyl methacrylate (MMA) and 200 parts by weight of terpineol as an organic solvent were mixed to obtain Monomer mixture.

[0120] After removing dissolved oxygen by bubbling nitrogen gas into the obtained monomer mixed liquid for 20 minutes, the inside of the separable flask was replaced with nitrogen gas, and the temperature of the oil tank was raised to 130° C. while stirring. A solution obtained by diluting 2,2'-azobis[2-(2-imidazolin-2-yl)propane] as a polymerization initiator with terpineol was added. Moreover, the terpineol solution containing a polymerization initiator was added several times during polymerization, and 10 weight part of polymerization initiators were added in total with respect to 100 weight part of monomers.

[0121] After 7 hours from the initiation of the polymerization, the polymerization was completed by cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com