Truncated polyhedron-shaped MOFs (at) rGO material as well as preparation method and application thereof

A polyhedron and truncated angle technology, applied in chemical instruments and methods, refined hydrocarbon oil, other chemical processes, etc., can solve the problems of harsh reaction conditions, high production cost, small sulfur capacity, etc., to improve desulfurization performance and save material costs. and time cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Weigh 50 mg of graphite oxide and 50 mg of sodium benzenesulfonate and disperse them into 100 mL of ethanol, and ultrasonically peel them off for 8 hours to obtain a uniform graphene oxide dispersion A.

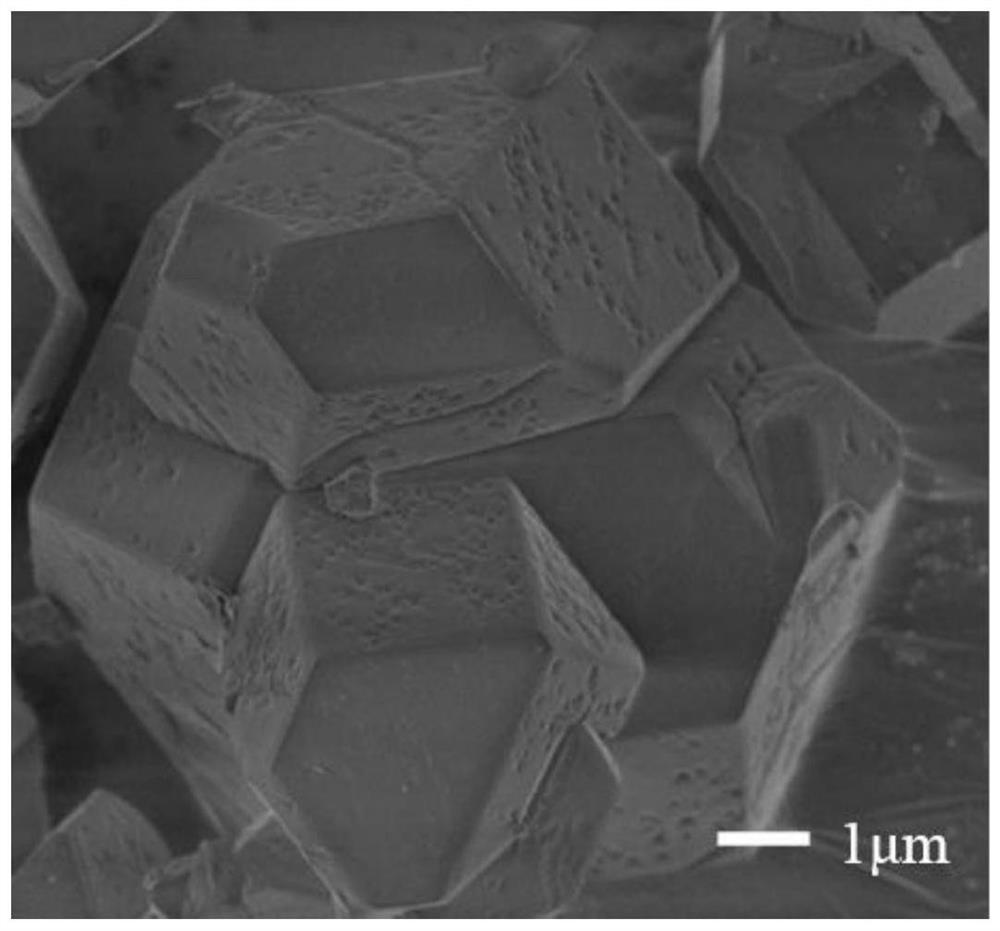

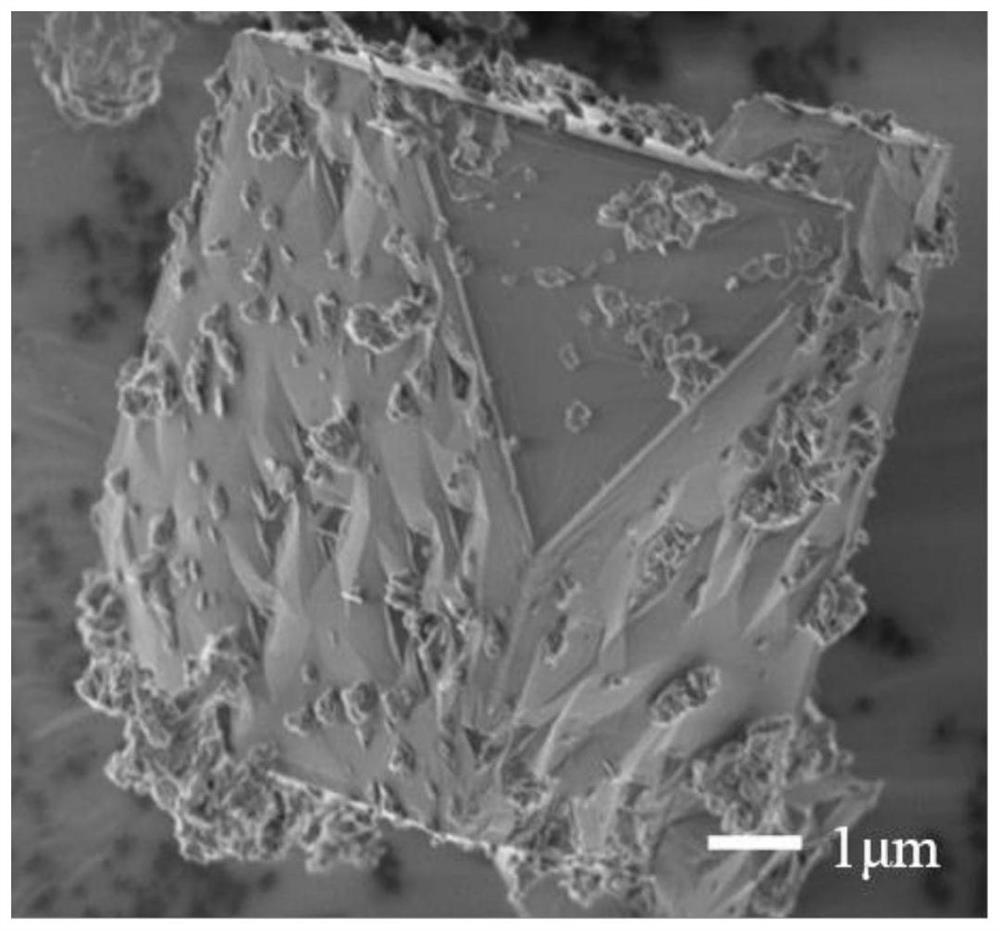

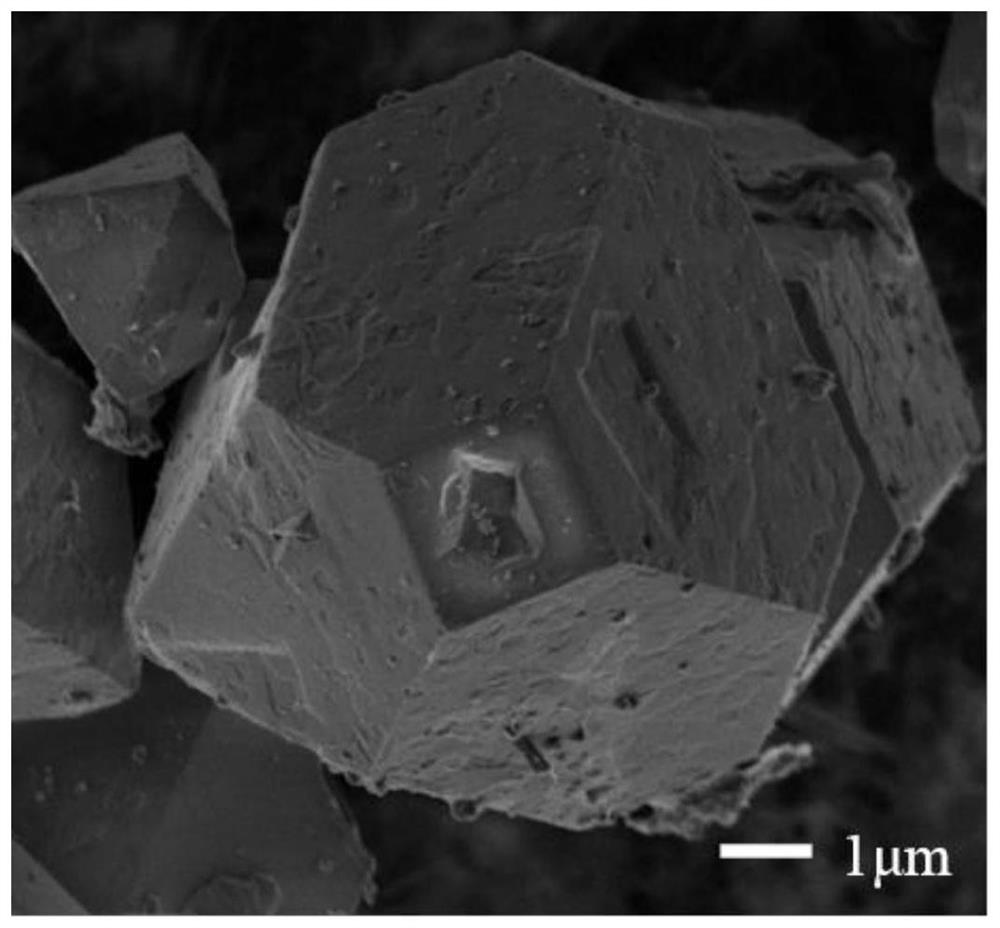

[0061] Weigh 700 mg of trimesic acid and add it into a mixture of 40 mL of absolute ethanol and 20 mL of N,N-dimethylformamide, and stir thoroughly for 30 min. Weigh 1400mg of copper nitrate trihydrate and dissolve it in 20mL of deionized water, then fully stir the two solutions for 60min to obtain MOF-199 mother liquor. Slowly add the graphene oxide dispersion A into the MOF-199 mother liquor, and ultrasonicate for 60 minutes. Then put it in a 95°C reactor for 20h. After the reaction was completed, it was naturally cooled to room temperature, centrifuged, washed three times with absolute ethanol, dried at 60 °C for 6 h, and dried at 130 °C for 8 h to obtain MOFs@rGO-1 materials. Among them, the mass ratio of metal to reduced graphene oxide in the MOF is about 25:1. ...

Embodiment 2

[0065] Weigh 50 mg of graphite oxide and 50 mg of sodium dodecylbenzene sulfonate and disperse them into 100 mL of ethanol, and ultrasonically peel them off for 8 hours to obtain a uniform graphene oxide dispersion A.

[0066] Weigh 700 mg of trimesic acid and add it into a mixture of 40 mL of absolute ethanol and 20 mL of N,N-dimethylformamide, and stir thoroughly for 30 min. Weigh 1400mg of copper nitrate trihydrate and dissolve it in 20mL of deionized water, then fully stir the two solutions for 60min to obtain MOF-199 mother liquor. Slowly add the graphene oxide dispersion A into the MOF-199 mother liquor, and ultrasonicate for 60 minutes. Then put it in a 95°C reactor for 20h. After the reaction was completed, it was naturally cooled to room temperature, centrifuged, washed three times with absolute ethanol, dried at 60 °C for 6 h, and dried at 130 °C for 8 h to obtain MOFs@rGO-2 materials. Among them, the mass ratio of metal to reduced graphene oxide in the MOF is abou...

Embodiment 3

[0070] Weigh 140 mg of graphite oxide and 50 mg of sodium benzenesulfonate and disperse them into 100 mL of ethanol, and ultrasonically peel them off for 8 hours to obtain a uniform graphene oxide dispersion A.

[0071] Weigh 700 mg of trimesic acid and add it into a mixture of 40 mL of absolute ethanol and 20 mL of N,N-dimethylformamide, and stir thoroughly for 30 min. Weigh 1400mg of copper nitrate trihydrate and dissolve it in 20mL of deionized water, then fully stir the two solutions for 60min to obtain MOF-199 mother liquor. Slowly add the graphene oxide dispersion A into the MOF-199 mother liquor, and ultrasonicate for 60 minutes. Then put it in a 95°C reactor for 20h. After the reaction was completed, it was naturally cooled to room temperature, centrifuged, washed three times with absolute ethanol, dried at 60 °C for 6 h, and dried at 130 °C for 8 h to obtain MOFs@rGO-3 materials. Among them, the mass ratio of metal to reduced graphene oxide in the MOF is about 16:1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com