Cement grinding aid

A cement grinding aid and modification technology, applied in the field of cement grinding aids, can solve the problems of safety hazards of cement and concrete durability, unstable quality of grinding aids, fluctuation of cement quality, etc., to achieve less pollution and lower free energy. , the effect of low total alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A cement grinding aid, the composition of the cement grinding aid in mass parts is as follows: 10 parts of modified triethanolamine, 0.3 part of polypropylene oxide ethylene oxide ether, 6 parts of fatty acid sodium, 12 parts of sodium acetate, glycerin distillation 2 parts of residue, 2 parts of sodium thiosulfate, 0.2 parts of Tween, 1 part of ammonium nitrate, 2 parts of sodium gluconate, 20 parts of deionized water.

[0021] Wherein, the modified triethanolamine is triethanolamine sulfate compound.

[0022] Wherein, the molecular weight of the polypropylene oxide ethylene oxide ether is 240, and the content of ethylene oxide is 15%.

[0023] Wherein, the mass fraction of the glycerol distillation residue is 42%.

Embodiment 2

[0025] A cement grinding aid, the mass parts of the cement grinding aid are composed as follows: the mass parts of the cement grinding aid are composed as follows: 12 parts of modified triethanolamine, 0.4 parts of polypropylene oxide ethylene oxide ether, 8 parts of sodium fatty acid, 15 parts of sodium acetate, 3 parts of glycerin distillation residue, 3.5 parts of sodium thiosulfate, 0.3 parts of Tween, 2 parts of ammonium nitrate, 3 parts of sodium gluconate, 25 parts of deionized water.

[0026] Wherein, the modified triethanolamine is a mixture of triethanolamine sulfate compound and triethanolamine acetate compound, and its mass ratio is 1:0.2

[0027] Wherein, the molecular weight of described polypropylene oxide ethylene oxide ether is 280 and the content of ethylene oxide is 30

[0028] Wherein, the mass fraction of the glycerol distillation residue is 45

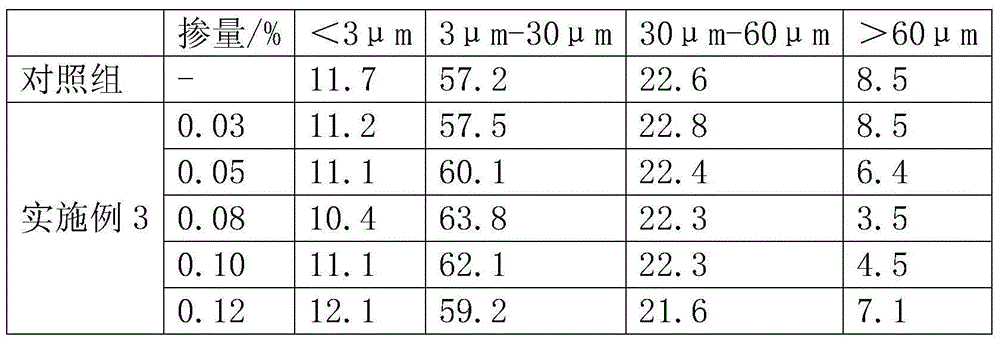

Embodiment 3

[0030] A cement grinding aid, the mass parts of the cement grinding aid are composed as follows: 15 parts of modified triethanolamine, 0.5 part of polypropylene oxide ethylene oxide ether, 15 parts of fatty acid sodium, 24 parts of sodium acetate, glycerin distillation 4 parts of residue, 5 parts of sodium thiosulfate, 0.4 parts of Tween, 3 parts of ammonium nitrate, 5 parts of sodium gluconate, and 40 parts of deionized water.

[0031] Wherein, the modified triethanolamine is a mixture of triethanolamine sulfate compound and triethanolamine acetate compound, the mass ratio of which is 1:0.4.

[0032] Wherein, the molecular weight of the polypropylene oxide ethylene oxide ether is 350, and the content of ethylene oxide is 78%.

[0033] Wherein, the mass fraction of the glycerol distillation residue is 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com