Viscosity reducer for heavy oil recovery and preparation method thereof

A technology of viscosity reducer and heavy oil, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as unsatisfactory viscosity reduction effect, and achieve the advantages of reducing flow resistance, reducing viscosity of heavy oil, and fast penetration speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

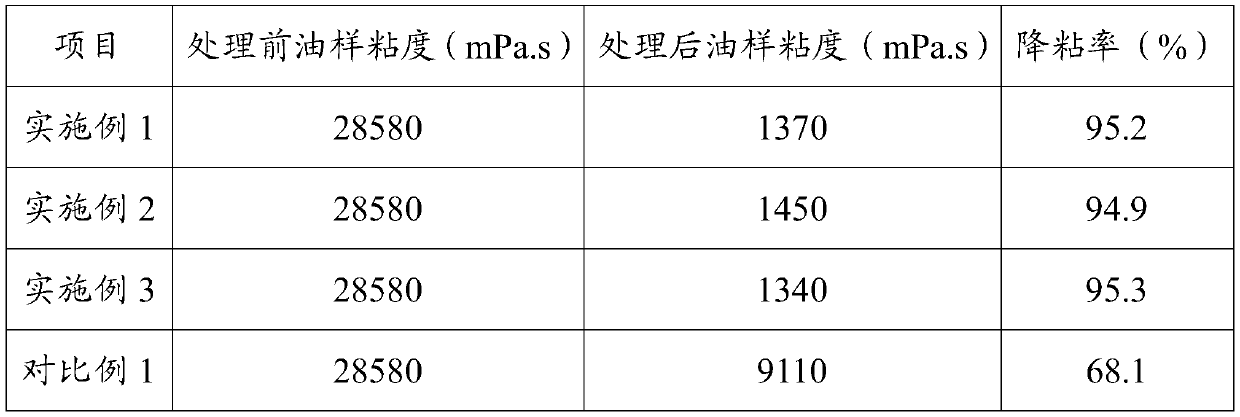

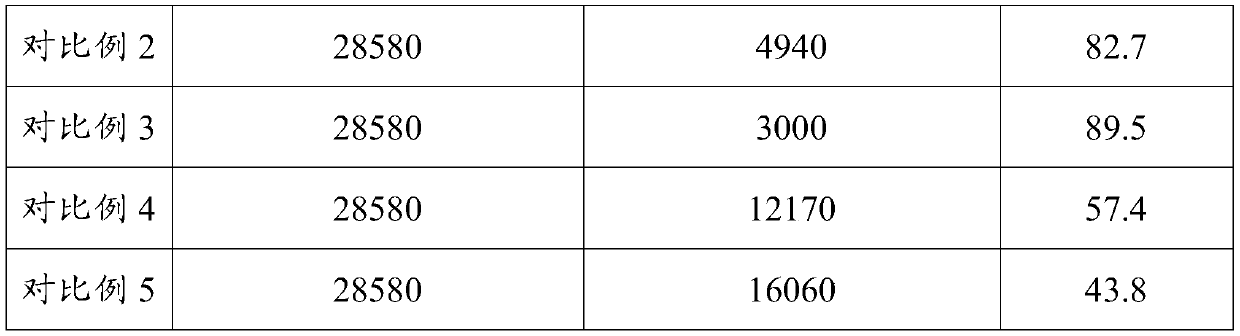

Examples

Embodiment 1

[0031] A viscosity reducer for heavy oil recovery, consisting of the following components: 200 g of lauryl imidazoline betaine, 50 g of bis(2-ethylhexyl) phthalate, sodium chitosan maleic anhydride acylate 40g, 20g of polycaprolactone grafted starch nanocrystals with a particle size of 50nm, 2g of EDTA-2Na, and 688g of water.

[0032] The specific preparation method is as follows:

[0033] Step 1, take lauryl imidazoline betaine 200g, bis(2-ethylhexyl) phthalate 50g, maleic anhydride acylated chitosan sodium 40g, polycaprolactone grafted starch nano crystal 20g, EDTA-2Na 2g, water 688g;

[0034] Step 2, the maleic anhydride acylated chitosan sodium and EDTA-2Na taken in step 1 are dissolved in the water taken in step 1 to obtain a mixed aqueous solution;

[0035] Step 3, lauryl imidazoline betaine, bis(2-ethylhexyl) phthalate, polycaprolactone grafted starch nanocrystals weighed in step 1 are added in the mixed aqueous solution of step 2, Disperse at a high speed for 30 min...

Embodiment 2

[0037] A viscosity reducer for heavy oil recovery, consisting of the following components: 150 g of dodecyl dimethyl betaine, 80 g of bis(2-ethylhexyl) phthalate, maleic anhydride acylated shell 30 g of polysaccharide sodium, 10 g of polycaprolactone grafted starch nanocrystals with a particle size of 80 nm, 1 g of EDTA-2Na, and 729 g of water.

[0038] The specific preparation method is as follows:

[0039] Step 1, take by weighing lauryl dimethyl betaine 150g, bis(2-ethylhexyl) phthalate 80g, maleic anhydride acylated chitosan sodium 30g, polycaprolactone grafted Amylopectin nanocrystal 10g, EDTA-2Na 1g, water 729g;

[0040] Step 2, the maleic anhydride acylated chitosan sodium and EDTA-2Na taken in step 1 are dissolved in the water taken in step 1 to obtain a mixed aqueous solution;

[0041] Step 3, adding dodecyl dimethyl betaine, bis(2-ethylhexyl) phthalate, and polycaprolactone grafted starch nanocrystals to the mixed aqueous solution of step 2 in step 1 In the proces...

Embodiment 3

[0043] A viscosity reducer for heavy oil recovery, consisting of the following components: 180g of decanyl hydroxypropyl sulfobetaine, 100g of bis(2-ethylhexyl) phthalate, acylated maleic anhydride 50g of sodium chitosan, 30g of polycaprolactone grafted starch nanocrystals with a particle size of 100nm, 3g of EDTA-2Na, and 637g of water.

[0044] The specific preparation method is as follows:

[0045] Step 1, take by weight respectively decanyl hydroxypropyl sulfobetaine 180g, bis(2-ethylhexyl) phthalate 100g, maleic anhydride acylated chitosan sodium 50g, polycaprolactone Grafted starch nanocrystals 30g, EDTA-2Na 3g, water 637g;

[0046] Step 2, the maleic anhydride acylated chitosan sodium and EDTA-2Na taken in step 1 are dissolved in the water taken in step 1 to obtain a mixed aqueous solution;

[0047] Step 3, the decanyl hydroxypropyl sulfobetaine, bis(2-ethylhexyl) phthalate, polycaprolactone grafted starch nanocrystals weighed in step 1 are added to the mixing mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com