Antimony oxide master batch special for flame-retardant non-woven fabric and preparation method of antimony oxide master batch

A technology of flame-retardant non-woven fabrics and antimony oxide, which is applied in the manufacture of fire-resistant and flame-retardant filaments to achieve the effects of improving melt strength, improving notched impact strength, and preventing re-agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of described hyperdispersant, comprises the following steps:

[0044] (1) In parts by weight, weigh 20.4 parts of diol dimethacrylate and dissolve in 35 mL of ethanol with a mass concentration of 80%, pour the resulting solution into the reactor, and pour 14.6 parts of triethanolamine into the reactor in N 2 Under protection, the microwave power is 180W, the temperature is 40°C, and the rotation speed is 400r / min, the reaction is stirred for 5.2h, and the ethanol is removed after the reaction to obtain the first reaction mixture;

[0045] (2) Add 8.6 parts of linseed oil and 0.3 part of zinc oxide in the first reaction mixture obtained in step (1), 2 Under protection, the microwave power was 230W, the temperature was 82°C, and the rotation speed was 300r / min, stirring and reacting for 3h to prepare the second reaction mixture;

[0046] (3) Add 42.5 parts of tetrahydrofuran (THF), 0.6 part of magnesium ethylate in the second reaction mixture obta...

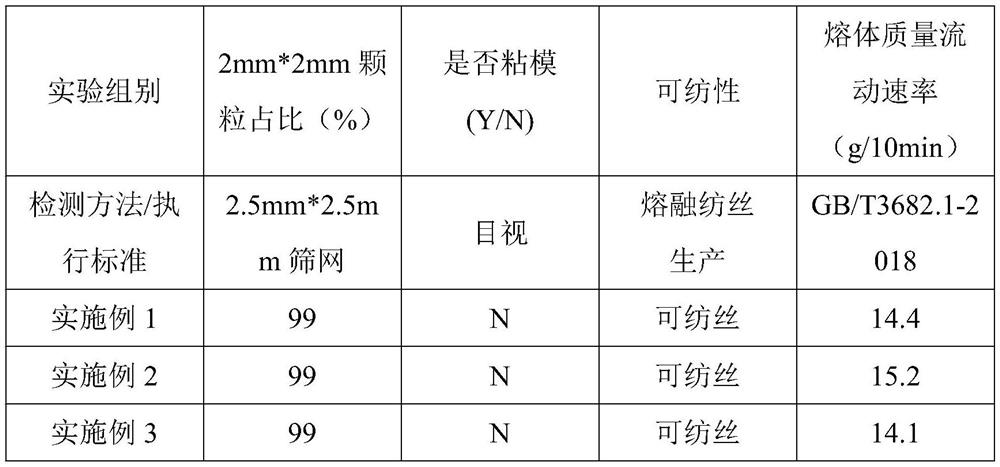

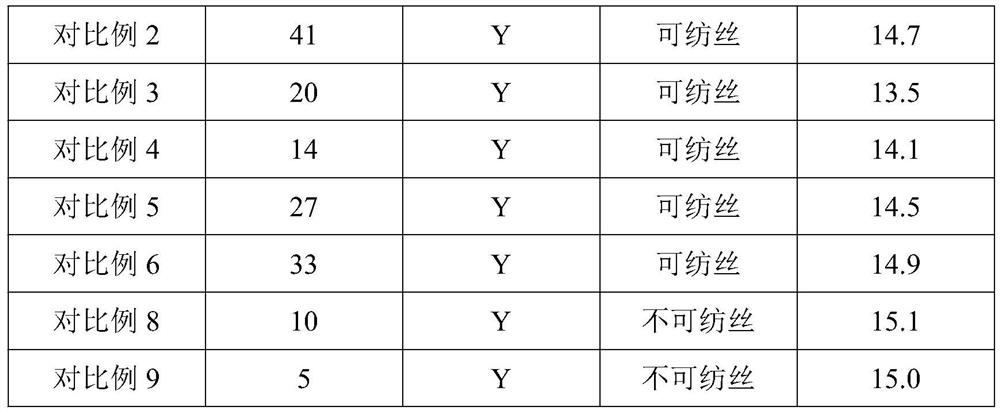

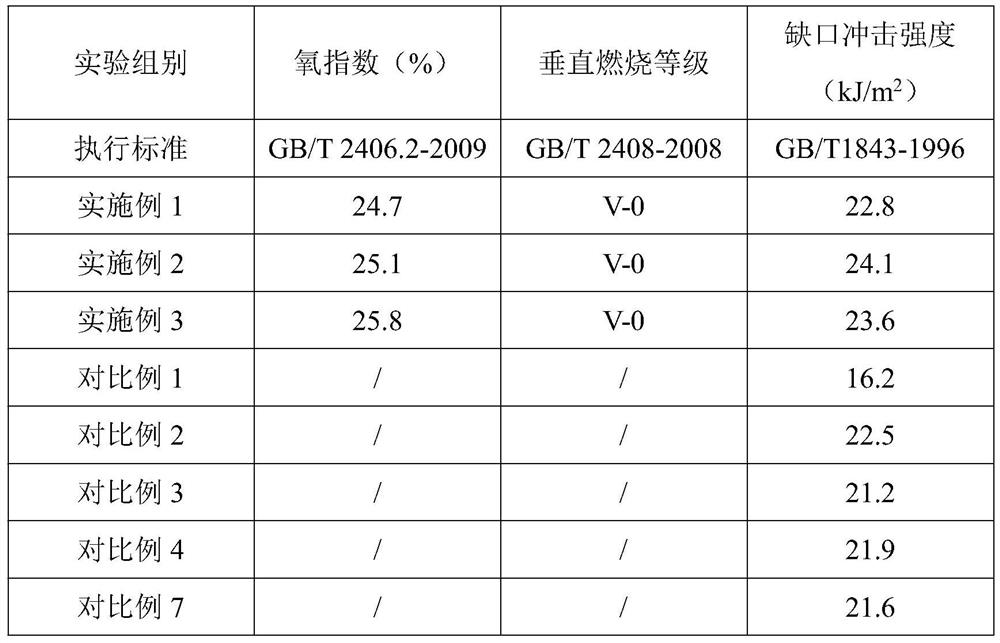

Embodiment 1

[0064] A special antimony oxide masterbatch for flame-retardant non-woven fabrics, including the following raw materials in weight percent: 75.4% antimony oxide, 15% polypropylene resin, 1% hyperdispersant, trimethyloctadecylammonium bromide 0.6%, zinc stearate 3%, new toughening additives 3%, zinc glutarate 2%;

[0065] The polypropylene resin is a homopolymer, and the melt mass flow rate is 54.3g / 10min;

[0066] The preparation method of described hyperdispersant, comprises the following steps:

[0067] (1) In parts by weight, weigh 20.4 parts of diol dimethacrylate and dissolve in 35 mL of ethanol with a mass concentration of 80%, pour the resulting solution into the reactor, and pour 14.6 parts of triethanolamine into the reactor in N 2 Under protection, the microwave power is 180W, the temperature is 40°C, and the rotation speed is 400r / min, the reaction is stirred for 5.2h, and the ethanol is removed after the reaction to obtain the first reaction mixture;

[0068] (2...

Embodiment 2

[0085] A special antimony oxide masterbatch for flame-retardant non-woven fabrics, which includes the following raw materials in weight percent: 83% antimony oxide, 10% polypropylene resin, 1.5% hyperdispersant, trimethyloctadecylammonium bromide 0.5%, calcium stearate 2%, new toughening additives 2%, zinc glutarate 1%;

[0086] The polypropylene resin is a homopolymer, and the melt mass flow rate is 53.4g / 10min;

[0087] The preparation method of described hyperdispersant, comprises the following steps:

[0088] (1) In parts by weight, weigh 20.4 parts of diol dimethacrylate and dissolve in 35 mL of ethanol with a mass concentration of 80%, pour the resulting solution into the reactor, and pour 14.6 parts of triethanolamine into the reactor in N 2 Under protection, the microwave power is 180W, the temperature is 40°C, and the rotation speed is 400r / min, the reaction is stirred for 5.2h, and the ethanol is removed after the reaction to obtain the first reaction mixture;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com