High temperature-resistant powder coating and preparation method thereof

A powder coating, high temperature resistant technology, applied in powder coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problem of low corrosion resistance, and achieve the effect of increasing anti-corrosion performance, reducing the amount of matting agent, and improving flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

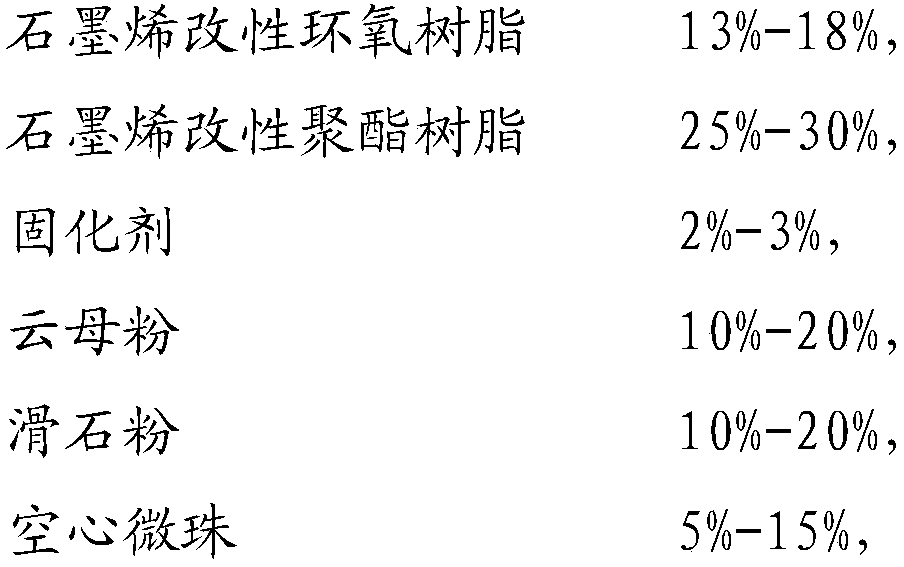

[0042] A high-temperature-resistant powder coating consists of the following components by weight percentage:

[0043]

[0044] The above-mentioned components are blended after stirring to ensure uniform mixing, and then the preparation process of powder coatings is carried out. First, blending and extrusion are carried out according to the above ratio, and then tableting, fine separation, inspection, measurement, packaging and other processes are obtained. Finished graphene powder coating.

Embodiment 2

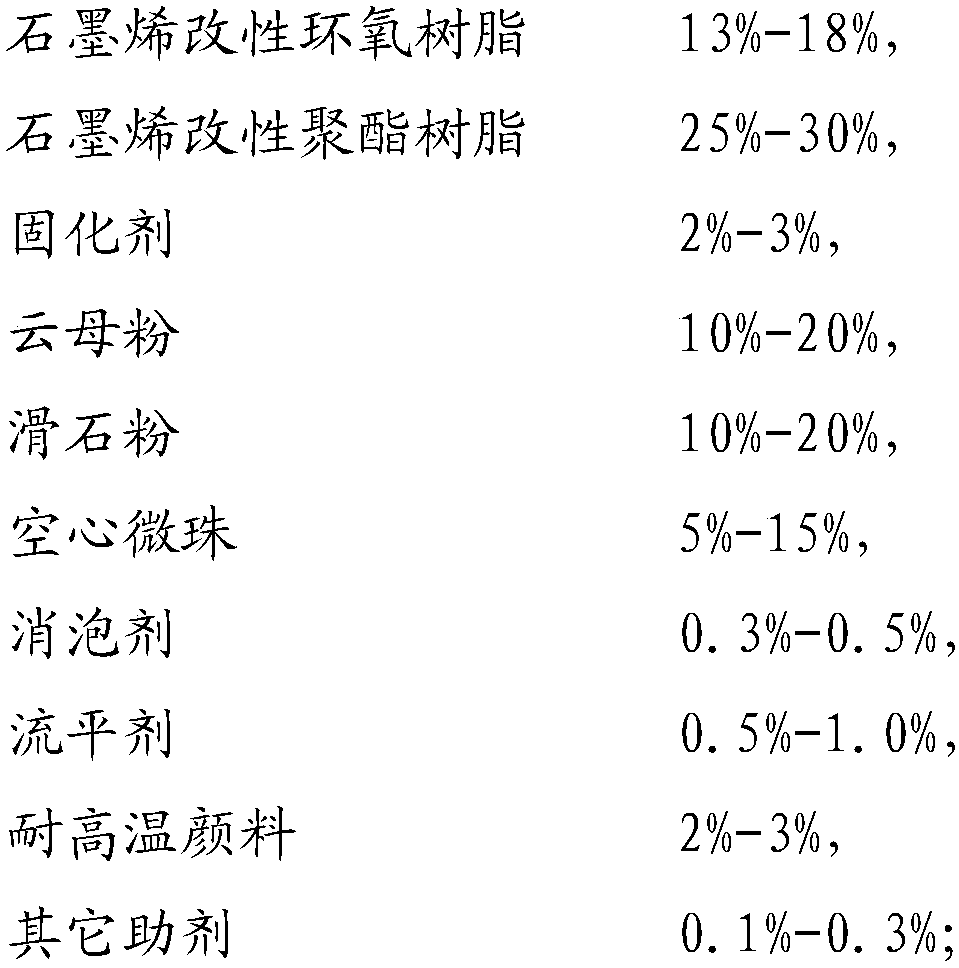

[0046] A high-temperature-resistant powder coating consists of the following components by weight percentage:

[0047]

[0048] The above-mentioned components are blended after stirring to ensure uniform mixing, and then the preparation process of powder coatings is carried out. First, blending and extrusion are carried out according to the above ratio, and then tableting, fine separation, inspection, measurement, packaging and other processes are obtained. Finished graphene powder coating.

Embodiment 3

[0050] A high-temperature-resistant powder coating consists of the following components by weight percentage:

[0051]

[0052] The above-mentioned components are blended after stirring to ensure uniform mixing, and then the preparation process of powder coatings is carried out. First, blending and extrusion are carried out according to the above ratio, and then tableting, fine separation, inspection, measurement, packaging and other processes are obtained. Finished graphene powder coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com