Preparation method of environment-friendly hydrotalcite-like nanosheets

An environmentally friendly, hydrotalcite technology, applied in the fields of hydrotalcite, chemical instruments and methods, oxide/hydroxide preparation, etc., can solve the problems of complex process and difficult recovery of organic solvents, and achieve simple process, environmental friendliness, prevent The effect of re-aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Will [Mg 2+ 0.8 Al 3+ 0.2 (OH) 2 ][CO 3 2- 0.1 ] Hydrotalcite-like 1g, sodium lauryl sulfate 0.01mol, dispersed in 100mL of absolute ethanol; the above mixed solution was added to a supercritical reactor, and the temperature was adjusted to 240°C to keep the mixed solution in the supercritical state of ethanol Under 4 hours; return to normal temperature and normal pressure, take the supernatant in the mixed solution and centrifuge, dry to obtain hydrotalcite-like nanosheets; recycle the ethanol obtained after centrifugation into the remaining mixed solution, and add it to the supercritical reactor. Adjust the temperature to 240°C, keep the mixed solution in the supercritical state of ethanol for 4 hours; return to normal temperature and normal pressure, take the supernatant in the mixed solution, centrifuge, dry, and obtain hydrotalcite-like nanosheets again. The yield of hydrotalcite-like nanosheets collected twice was 32%.

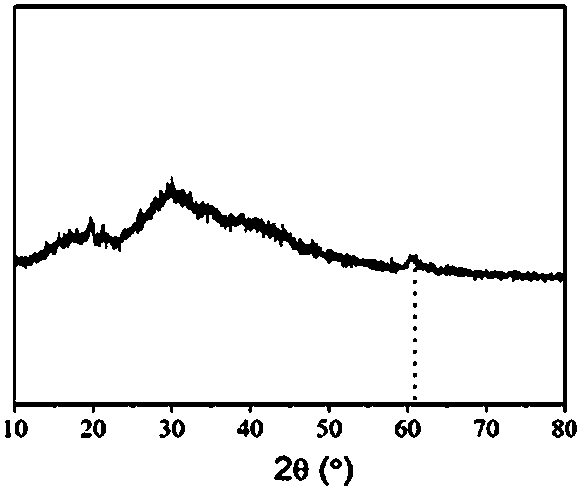

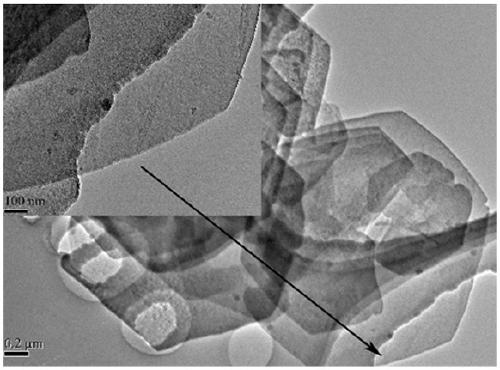

[0020] From figure 1 It can be see...

Embodiment 2

[0023] Will [Co 2+ 0.66 Al 3+ 0.34 (OH) 2 ][CO 3 2- 0.17 ] Hydrotalcite-like 0.1g, sodium oleate 0.001mol, dispersed in 100mL of absolute ethanol; the above mixed solution was added to a supercritical reactor, and the temperature was adjusted to 270°C to keep the mixed solution in the supercritical state of ethanol for 2 Hours; return to normal temperature and normal pressure, take the supernatant in the mixed solution and centrifuge and dry to obtain hydrotalcite-like nanosheets; recycle the ethanol obtained after centrifugation into the remaining mixed solution, and add it to a supercritical reactor to adjust the temperature To 270°C, keep the mixed solution in the supercritical state of ethanol for 2 hours; return to normal temperature and normal pressure, take the supernatant in the mixed solution, centrifuge, dry, and obtain hydrotalcite-like nanosheets again. The yield of hydrotalcite-like nanosheets collected twice was 41%.

Embodiment 3

[0025] Will [Cu 2+ 0.13 Zn 2+ 0.51 Fe 3+ 0.36 (OH) 2 ][CO 3 2- 0.18 ] Hydrotalcite-like 0.1g, sodium oleate 0.001mol, dispersed in 100mL of absolute ethanol; the above mixed solution was added to a supercritical reaction kettle, the temperature was adjusted to 280°C, and the mixed solution was kept in the supercritical state of ethanol for 1 Hours; return to normal temperature and normal pressure, take the supernatant in the mixed solution and centrifuge and dry to obtain hydrotalcite-like nanosheets; recycle the ethanol obtained after centrifugation into the remaining mixed solution, and add it to a supercritical reactor to adjust the temperature To 280°C, keep the mixed solution in the supercritical state of ethanol for 1 hour; return to normal temperature and normal pressure, take the supernatant in the mixed solution, centrifuge, dry, and obtain hydrotalcite-like nanosheets again. The yield of hydrotalcite-like nanosheets collected twice was 33%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com