Method for dyeing meta-aramid fabric particle flow

A dyeing method and particle flow technology, applied in the field of textile printing and dyeing, can solve problems such as toxicity, affecting fabric air permeability and hand feeling, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

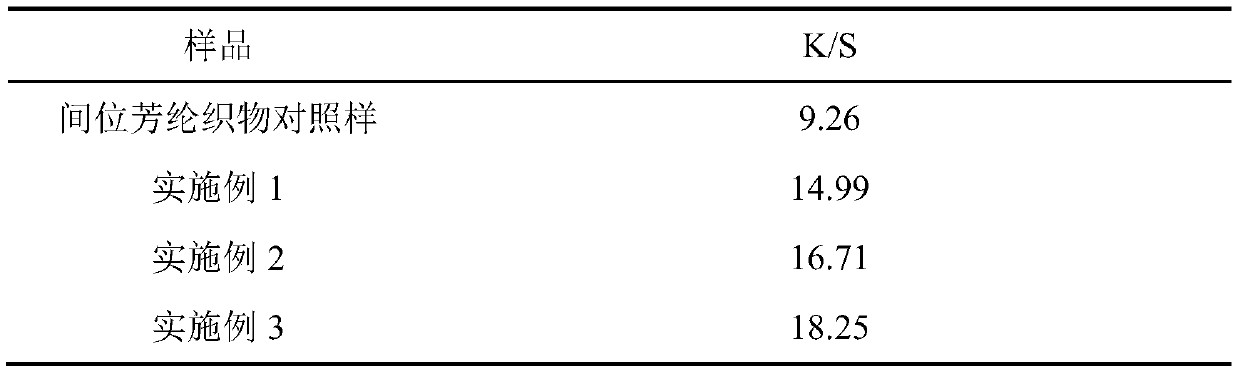

[0028] Take a meta-aramid fabric with a size of 10cm×15cm, use disperse scarlet GS as the disperse dye, and prepare a dye solution in proportion. The mass percentage of N,N-dimethylacetamide in the dye solution is 98%, and the mass percentage of ethanol is 1%. The mass percentage of disperse dyes is 1%. After the dyeing solution is prepared, it is stirred at 200 rpm for 3 minutes at a temperature of 30°C to form a dyeing solution, and meta-aramid is added to the dyeing solution according to a bath ratio of 1:5. Soak the fabric for 5 minutes, then take out the meta-aramid fabric soaked in the dye solution, control its liquid retention rate to 100%, and place the meta-aramid fiber fabric with a liquid retention rate of 100% on a flat vulcanizing machine at a temperature of 165°C , within 5 seconds, increase the pressure of the flat vulcanizing machine to 5Mpa, and keep it for 10 minutes, then take out the dyed fabric, wash and dry it to obtain a dyed meta-aramid fabric. The effe...

Embodiment 2

[0030] Take a meta-aramid fiber fabric with a size of 10cm×15cm, use disperse scarlet GS as the disperse dye, and prepare a dye liquor in proportion. The mass percentage of N,N-dimethylacetamide in the dye liquor is 89%, and the mass percentage of ethanol is 10%. The mass percentage of disperse dye is 5%. After the dye liquor is prepared, it is stirred at 200 rpm for 3 minutes at a temperature of 30°C to form a dye liquor, and meta-aramid fiber is added to the dye liquor according to the bath ratio of 1:5. Soak the fabric for 10 minutes, then take out the meta-aramid fabric soaked in the dye solution, control its liquid retention rate to 150%, and place the meta-aramid fiber fabric with a liquid retention rate of 150% on a flat vulcanizing machine at a temperature of 180°C , within 10 seconds, add the pressure of the flat vulcanizer to 8Mpa, and keep it for 12 minutes, then take out the dyed fabric, wash and dry it to obtain the dyed meta-aramid fabric. The effect is shown in ...

Embodiment 3

[0032] Take a meta-aramid fabric with a size of 10cm×15cm, use disperse scarlet GS as the disperse dye, and prepare a dyeing solution in proportion. The mass percentage of N,N-dimethylacetamide in the dyeing solution is 60%, and the mass percentage of ethanol is 30%. The mass percentage of disperse dye is 10%. After the dye liquor is prepared, it is stirred at 200 rpm for 3 minutes at a temperature of 30°C to form a dye liquor, and meta-aramid fiber is added to the dye liquor according to the bath ratio of 1:5. Soak the fabric for 30 minutes, then take out the meta-aramid fabric soaked in the dye solution, control its liquid retention rate to 200%, and place the meta-aramid fiber fabric with a liquid retention rate of 200% on a flat vulcanizing machine at a temperature of 205°C , within 15 seconds, increase the pressure of the flat vulcanizing machine to 10Mpa, and keep it for 15 minutes, then take out the dyed fabric, wash and dry it to obtain a dyed meta-aramid fabric. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com