A kind of freeze-drying preparation method of second-phase particle dispersed molybdenum composite powder

A technology for compounding powders and granules, applied in the field of powder preparation engineering, can solve the problems of hard agglomeration of crystal grains, high hydrothermal temperature, poor doping uniformity, etc., and achieve the effect of small agglomeration, easy agglomeration, and improved particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) 5g of ammonium molybdate tetrahydrate and 0.05g of yttrium nitrate hexahydrate were dissolved in 50mL of deionized water, then 0.25g of PVPk-12 was dissolved in it, and finally added to 100ml with deionized water, and ultrasonically treated (ultrasonic treatment) The power is 50W, and the ultrasonic time is 2h) to fully dissolve and disperse to obtain a mixed solution.

[0026] (2) Then pour the mixture into liquid nitrogen to pre-freeze the mixture.

[0027] (3) After the temperature of the freeze dryer is lowered to the freezing temperature of -60°C and stabilized, put the pre-frozen watch glass into the freeze dryer, turn on the vacuum pump and keep the vacuum below 50Pa, and freeze-dry for 36 hours.

[0028] (4) The lyophilized powder was calcined in air at 450°C for 1.5 h to obtain composite oxide powder.

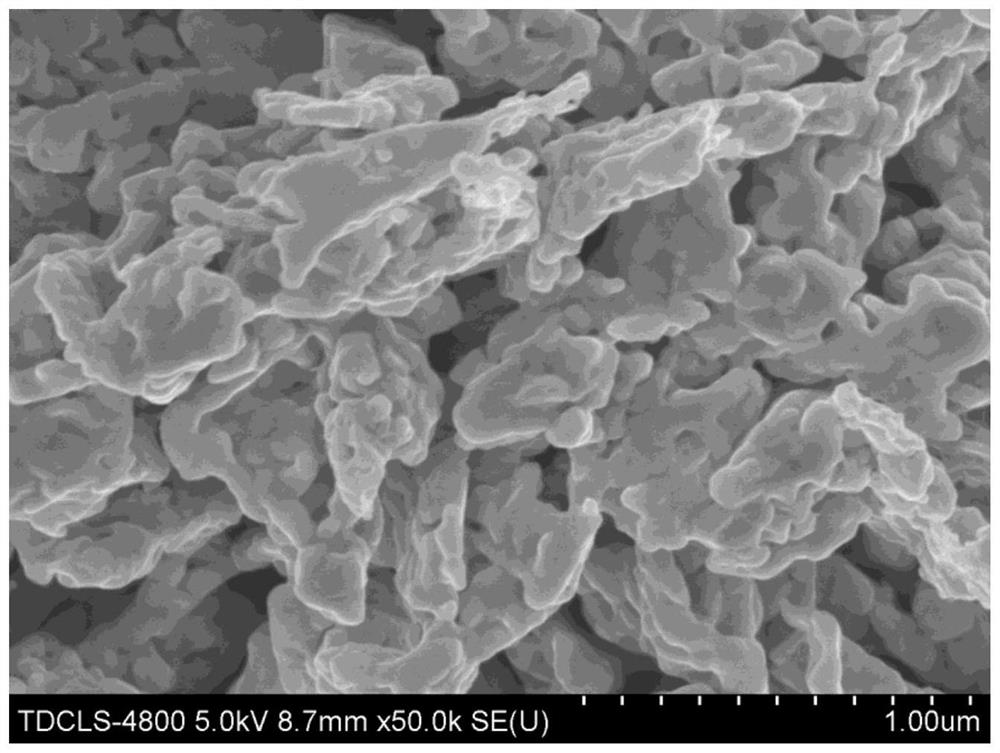

[0029] (5) The composite oxide powder is subjected to two-step reduction in a hydrogen stream (600° C. for 1.5 h, and 750° C. for 1.5 h) to obtain a compos...

Embodiment 2

[0031] (1) Dissolve 1 g of ammonium molybdate tetrahydrate and 0.001 g of lanthanum nitrate hexahydrate in 50 mL of deionized water, then dissolve 0.02 g of PEG-6000 in it, and finally add it to 100 mL with deionized water, and use ultrasonic treatment (ultrasonic treatment) The power is 150W, and the ultrasonic time is 0.1h) to be fully dissolved and dispersed to obtain a mixed solution.

[0032] (2) Then pour the mixture into dry ice to pre-freeze the mixture.

[0033] (3) After the temperature of the freeze dryer is lowered to the freezing temperature of -80°C and stabilized, put the pre-frozen watch glass into the freeze dryer, turn on the vacuum pump and keep the vacuum below 50Pa, and freeze-dry for 5 hours.

[0034] (4) The lyophilized powder was calcined in air at 450° C. for 0.5 h to obtain composite oxide powder.

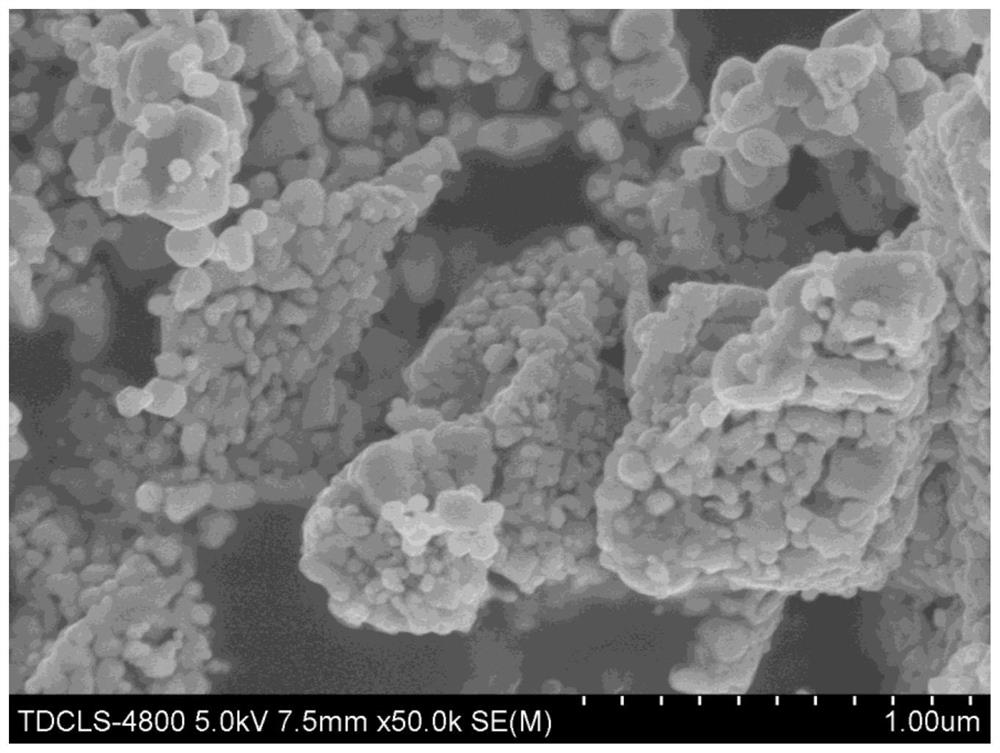

[0035](5) The composite oxide powder is subjected to two-step reduction in a hydrogen stream (550° C. for 0.5 h, and 700° C. for 0.5 h) to obtain a compo...

Embodiment 3

[0037] (1) Dissolve 20 g of ammonium molybdate heptahydrate, 0.5 g of yttrium nitrate hexahydrate, and 0.5 g of zirconium nitrate pentahydrate in 50 mL of deionized water, then dissolve 1 g of PVP K12 and 1 g of PEG-6000 in it, and finally use deionized water. Water was added to 100ml, fully dissolved and dispersed by ultrasonic treatment (ultrasonic treatment power was 250W, ultrasonic time 1.5h) to obtain a mixed solution.

[0038] (2) Then pour the mixture into liquid nitrogen to pre-freeze the mixture.

[0039] (3) After the temperature of the freeze dryer is lowered to the freezing temperature of -60°C and stabilized, put the pre-frozen watch glass into the freeze dryer, turn on the vacuum pump and keep the vacuum below 50Pa, and freeze-dry for 48h.

[0040] (4) The lyophilized powder was calcined in air at 450° C. for 2 h to obtain composite oxide powder.

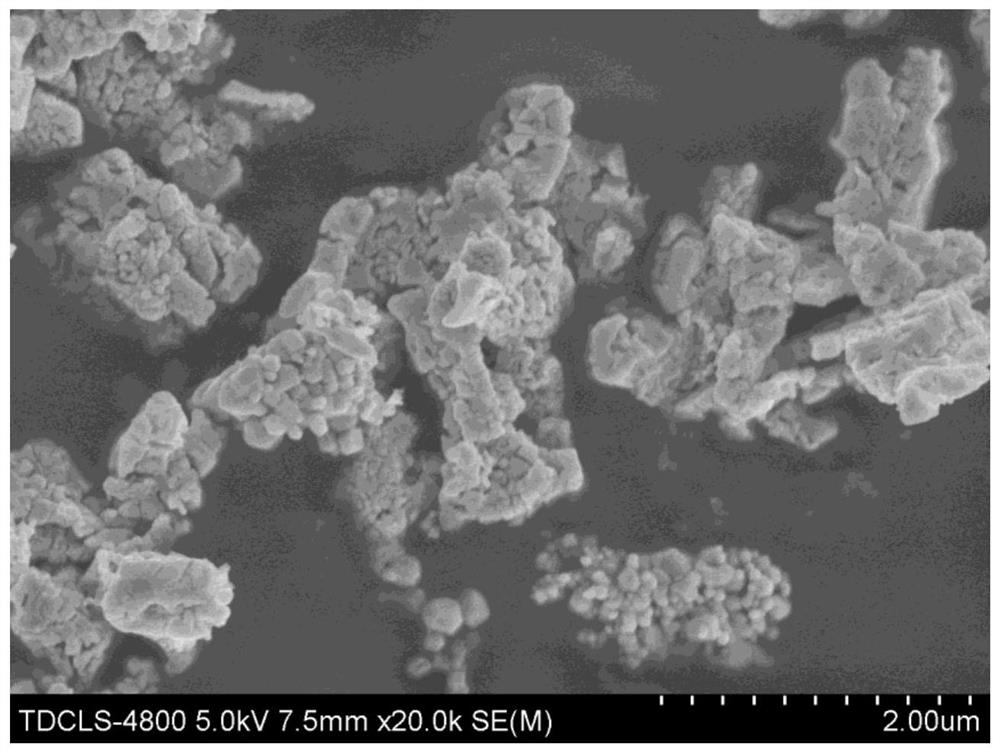

[0041] (5) The composite oxide powder is subjected to two-step reduction in a hydrogen stream (700° C. for 3 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com