Extra coarse grain WC-Co hard alloy and preparation process thereof

A cemented carbide and a preparation process technology, applied in the field of extra-coarse-grained WC-Co cemented carbide and its preparation process, can solve the problems of unsuitability for recycling, unsuitable for safe production, and highly toxic triethylamine, etc. Achieve the effect of shortening the carbonization time, promoting grain growth, and ensuring complete carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

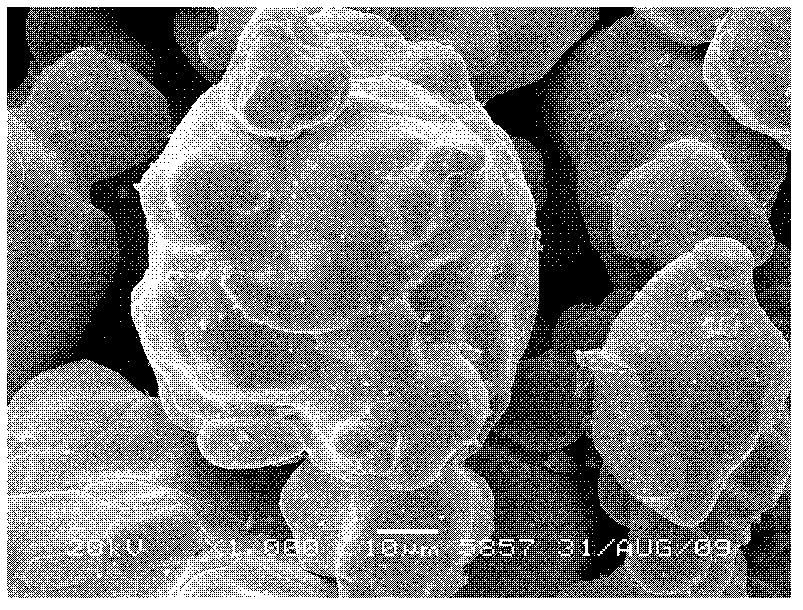

[0085] Preparation of WC-6Co cemented carbide

[0086] Step 1: Preparation of tungsten carbide pre-milled powder

[0087] Take the ultra-coarse tungsten carbide powder with a particle size of (28-29) μm and the sub-fine tungsten carbide powder with a particle size of (0.6-0.7) μm, mix them, and perform a ball mill for 12 hours to obtain a pre-milled tungsten carbide powder; The mass ratio of extra-coarse tungsten carbide powder to sub-fine tungsten carbide powder is 9:1; the technical parameters of one ball mill are: ball-material ratio: 3:1, speed: 34 rpm, ball mill medium: gasoline;

[0088] The second step: preparation of tungsten carbide-cobalt mixed powder

[0089] Mix the tungsten carbide pre-mill powder obtained in the first step with cobalt powder and forming agent, and perform secondary ball milling for 8 hours to obtain tungsten carbide-cobalt-forming agent mixed powder. 6% and 0.5% of the mass of pre-ball milling powder, the particle size of the cobalt powder is 1...

Embodiment 2

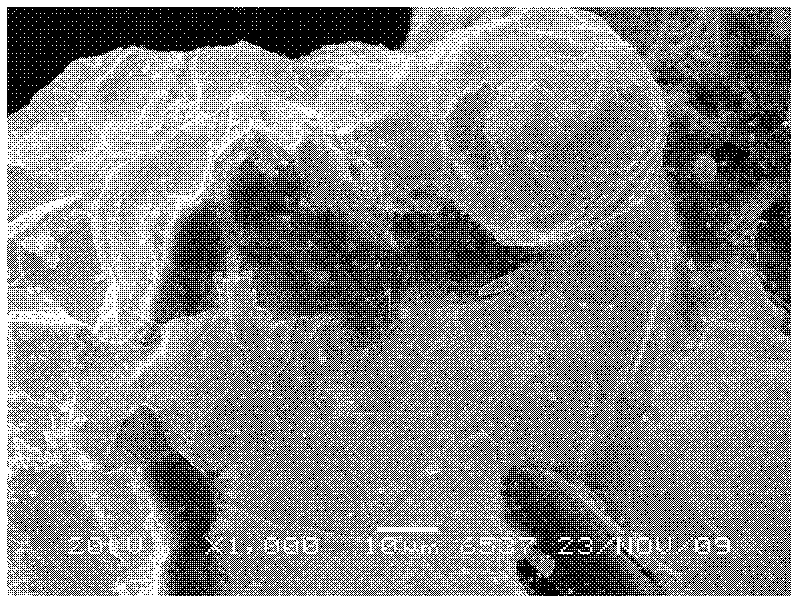

[0101] Preparation of WC-7Co cemented carbide

[0102] Take the ultra-coarse tungsten carbide powder with a particle size of (30-31) μm and the subfine tungsten carbide powder with a particle size of (0.9-1) μm, mix them, and perform a ball mill for 8 hours to obtain a pre-milled tungsten carbide powder; The mass ratio of extra-coarse tungsten carbide powder to sub-fine tungsten carbide powder is 12:1; the technical parameters of one ball mill are: ball-material ratio: 2:1, speed: 36 rpm, ball mill medium: gasoline;

[0103] The second step: preparation of tungsten carbide-cobalt mixed powder

[0104] Mix the tungsten carbide pre-mill powder obtained in the first step with cobalt powder and forming agent, and perform secondary ball milling for 6 hours to obtain tungsten carbide-cobalt-forming agent mixed powder. 7.5% and 0.7% of the mass of pre-ball milling powder, the particle size of the cobalt powder is 2 μm; the molding agent is selected from resin-improved cis-1,4-polybu...

Embodiment 3

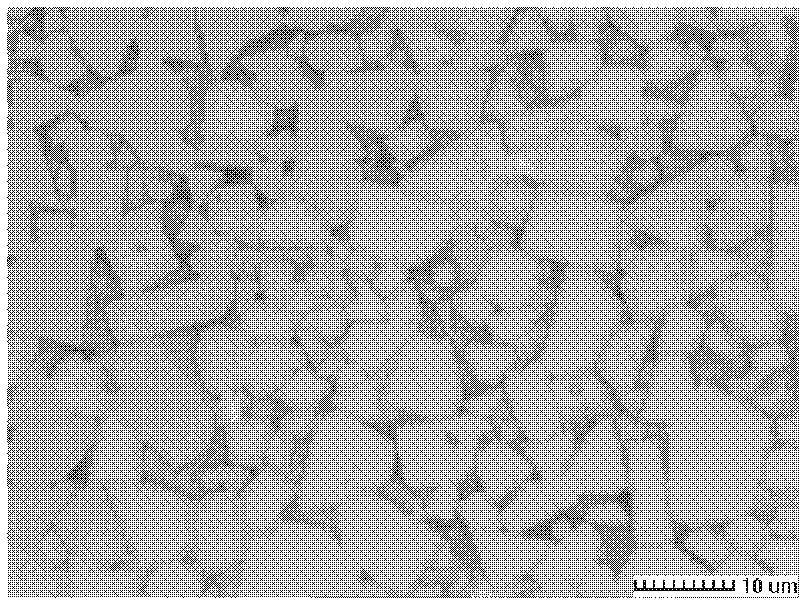

[0121] Preparation of WC-15Co cemented carbide

[0122] Take ultra-coarse tungsten carbide powder with a particle size of (30-31) μm and sub-fine tungsten carbide powder with a particle size of (0.7-0.8) μm, mix them, and perform a ball mill for 10 hours to obtain tungsten carbide pre-milled powder; The mass ratio of extra-coarse tungsten carbide powder to sub-fine tungsten carbide powder is 10:1; the technical parameters of one ball mill are: ball-material ratio: 2:1, speed: 40 rpm, ball mill medium: gasoline;

[0123] The second step: preparation of tungsten carbide-cobalt mixed powder

[0124] Mix the tungsten carbide pre-mill powder obtained in the first step with cobalt powder and forming agent, and perform secondary ball milling for 7 hours to obtain tungsten carbide-cobalt-forming agent mixed powder. 15% and 1% of the mass of the pre-ball milling powder, the particle size of the cobalt powder is 3 μm; the molding agent is selected from resin-improved cis-1,4-polybutadi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com