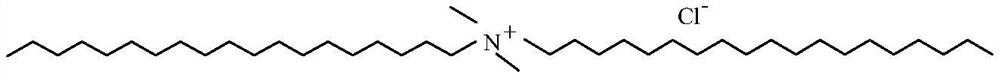

Application of quaternary ammonium salt derivative in preparation of red pigment, red pigment and preparation method of red pigment

A technology of derivatives and quaternary ammonium salts, which is applied in the field of pigment production for water-based UV inks, can solve problems such as poor storage stability, ink crystallization, poor dispersion, etc., to prevent re-aggregation, improve wettability, and significantly The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The following preparation examples and experimental examples can illustrate the present invention in more detail, but do not limit the present invention in any form.

[0036] Unless otherwise specified, the content of each component used in the following is the weight percentage content.

[0037] The following are the raw materials used in each example:

[0038]Hydrochloric acid solution: the mass percentage of HCl is 30%;

[0039] Caustic soda solution: the mass percentage of NaOH is 20%;

[0040] Sodium nitrite solution: NaNO 2 The mass percentage content is 35%;

[0041] Acetic acid solution: the mass percentage of HAc is 80%;

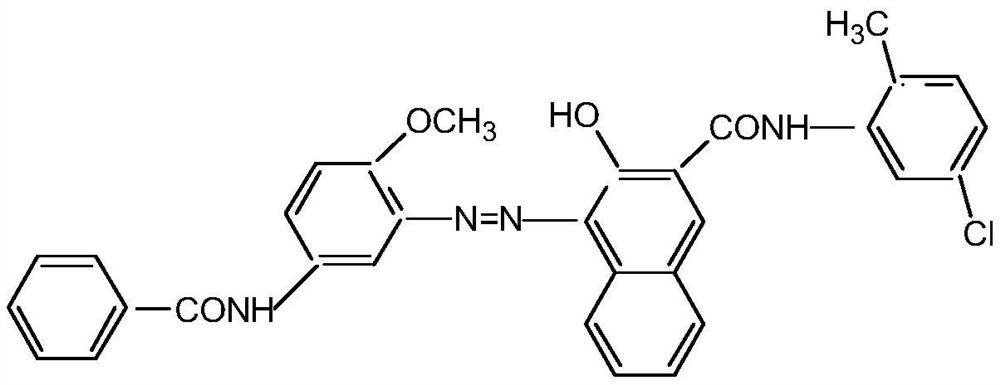

[0042] The mass percentage of 3-amino-4-methoxybenzanilide (KD-bass) is 100%;

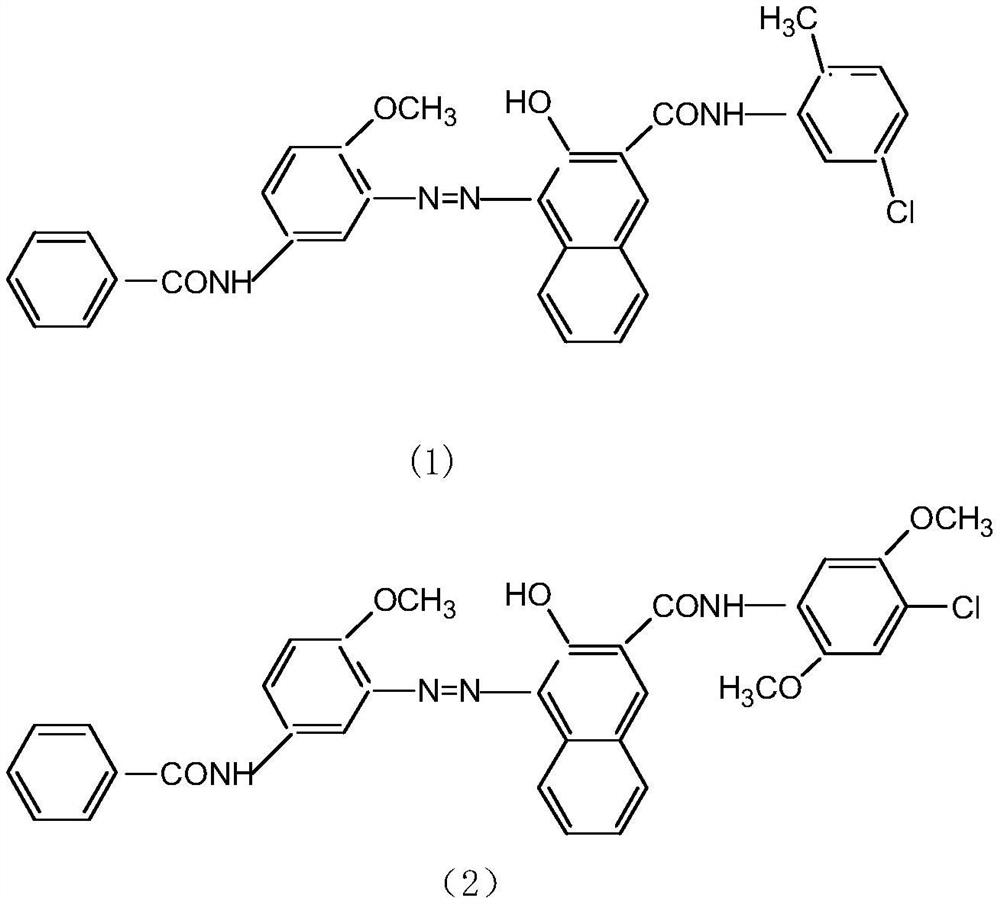

[0043] 3-hydroxy-N-(4 chloro-2.5-dimethoxyphenyl)-2-naphthylcarboxamide (AS-LC) mass percentage content is 98%;

[0044] The mass percentage content of 3-hydroxy-N-(2-methyl 5-dichlorophenyl)-2-naphthylcarboxamide (AS-KB) is 98%;

[0045] The mass percentag...

example 1

[0052] The addition of quaternary ammonium salt derivatives is 24% (3g) of the weight of the AS component, and the addition of the compound solution of the surfactant is 0.8% (0.1g) of the weight of the AS component.

[0053] S1. Diazotization reaction

[0054] Add 110ml of water into the diazotization reaction container, stir 13.2g of 3-amino-4-methoxybenzanilide (KD-bass), mix and stir for 0.5 hours, add 19.4g of hydrochloric acid solution and stir to dissolve, Add ice and cool down to below -5°C, add 11.9 g of sodium nitrite solution, stir for 1 hour, use sulfamic acid to destroy excess sodium nitrite, until the KI starch test paper is slightly blue at the end point, and obtain diazonium salt solution I;

[0055] S2. Coupling solution

[0056] S2.1 Add 120ml of water to the coupling component dissolution container, add 27g of sodium hydroxide solution, raise the temperature to 85°C, and then add N-(4chloro-2.5-dimethoxyphenyl)-3-hydroxyl-2- Naphthalene carboxamide (AS-LC)...

example 2

[0067] The difference from Example 1 is that step S2.1 of this example does not add quaternary ammonium salt derivatives.

[0068] Specifically, S2.1 Add 120ml of water to the coupling component dissolution container, add 27g of sodium hydroxide solution, raise the temperature to 85°C, and then add N-(4chloro-2.5-dimethoxyphenyl)-3-hydroxy -2-naphthylcarboxamide (AS-LC) 8.2g, 3-hydroxy-N-(2-methyl 5-dichlorophenyl)--2-naphthylcarboxamide (AS-KB) 4.1g, stirred and dissolved Transparent, add ice and cool down to 45°C to obtain coupling component solution II. The rest of the steps are the same.

[0069] Result: Compared with Example 1, the hue is bluer, the tinting strength is 90%, and the viscosity is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tinctorial strength | aaaaa | aaaaa |

| tinctorial strength | aaaaa | aaaaa |

| tinctorial strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com