Preparation method of monodisperse barium titanate cubic nanometer particles

A technology of cubic nanometer and barium titanate, which is applied in the direction of titanate, nanotechnology, alkaline earth metal titanate, etc., can solve the problems of difficult control of grain shape and grain growth, and achieve good crystallization and crystallization Good performance, good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 0.7887g of Ba(OH)·8H 2 O was dissolved in 50 ml of deionized water, 1.21 ml of di(2-hydroxypropionic acid)diammonium titanium dihydroxide (50 wt % aqueous solution) was added thereto, and fully stirred evenly. Add 11.25ml of 5M NaOH solution to the mixed precursor solution to adjust the pH value of the solution, then add 6.35ml oleic acid (OLA) under magnetic stirring, and transfer the above solution to a 100ml autoclave lining after stirring for 10min. At this time, 2.10 ml of tert-butylamine was added to the lining, and the sealed autoclave was placed at 220° C. for 72 hours, and then naturally cooled to room temperature. The precipitate was washed with dilute hydrochloric acid, then washed several times with deionized water and absolute ethanol, filtered, and dried at 60° C. in air to obtain barium titanate nanoparticles.

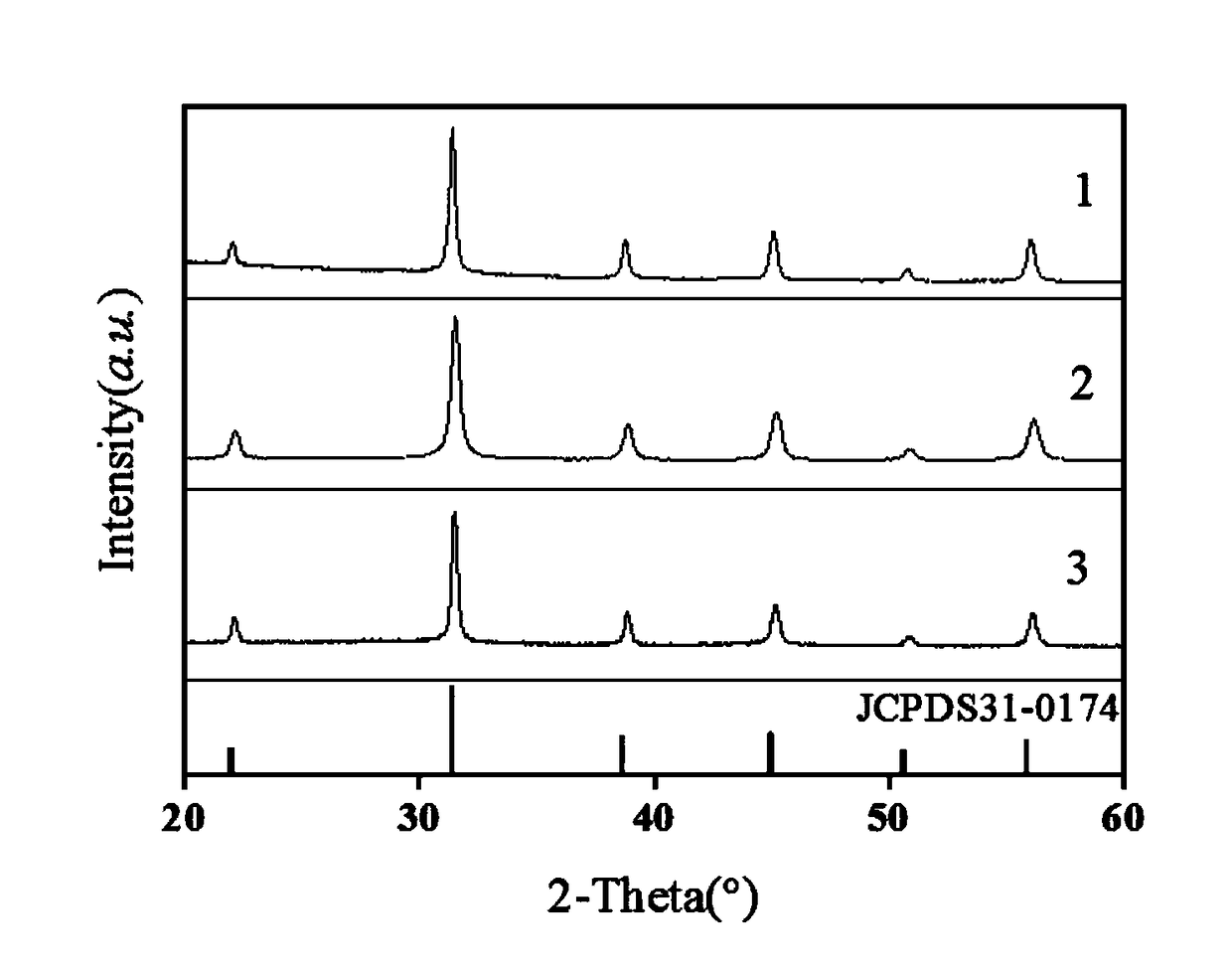

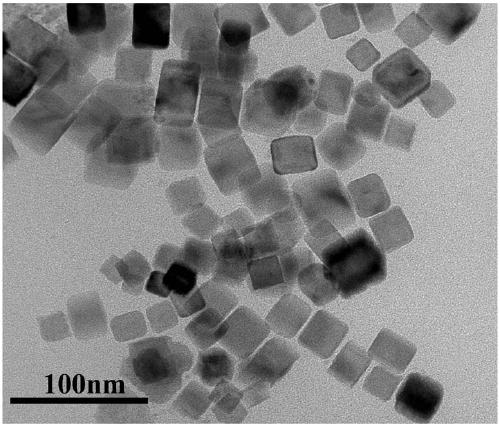

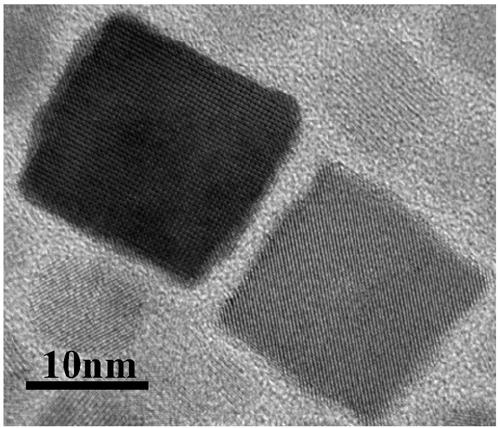

[0024] The XRD pattern of the product is as figure 1 As shown in , all the diffraction peaks of the sample are consistent with the standa...

Embodiment 2

[0026] Weigh 0.9465g of Ba(OH)·8H 2 O is dissolved in 50ml of deionized water, to which two (2-hydroxypropionic acid) diammonium dihydroxide titanium (50wt% aqueous solution) of 1.21ml is added, after fully stirring, Ba in the solution 2+ and Ti 4+ The molar ratio is 1.2:1. Add 11.25ml of 5M NaOH solution to the mixed precursor solution to adjust the pH value of the solution, then add 6.35ml oleic acid (OLA) under magnetic stirring, and transfer the above solution to a 100ml autoclave lining after stirring for 10min. At this time, 2.10 ml of tert-butylamine was added to the lining, and the sealed autoclave was placed at 220° C. for 24 hours, and then cooled to room temperature naturally. The precipitate was washed with dilute hydrochloric acid, then washed several times with deionized water and absolute ethanol, filtered, and dried at 60°C in air to obtain barium titanate nanoparticles.

[0027] The XRD pattern of the product is as figure 1 As shown in , all the diffractio...

Embodiment 3

[0029] Weigh 0.7887g of Ba(OH)·8H 2 O was dissolved in 50 ml of deionized water, 1.21 ml of di(2-hydroxypropionic acid)diammonium titanium dihydroxide (50 wt % aqueous solution) was added thereto, and fully stirred evenly. Add 11.25ml of 5M NaOH solution to the mixed precursor solution to adjust the pH value of the solution, then add 6.35ml oleic acid (OLA) under magnetic stirring, and transfer the above solution to a 100ml autoclave lining after stirring for 10min. After adding 2.10ml of tert-butylamine into the lining, place the sealed autoclave at 220°C for 24 hours of reaction, and then cool it down to room temperature naturally. The precipitate was washed with dilute hydrochloric acid, then washed several times with deionized water and absolute ethanol, filtered, and dried in air at 60° C. to obtain barium titanate nanoparticles.

[0030] The XRD pattern of the product is as figure 1 As shown in , all the diffraction peaks of the sample correspond well to the diffractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com