Phase-change energy-storage material

A phase-change energy storage material and energy storage technology, applied in the field of energy storage materials, can solve the problems of reducing the cycle life of materials, easy overcooling of inorganic salt hydrates, and restrictions on practical applications, and achieve improved cycle stability and cycle stability Excellent performance and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0027] Weigh 40g of lithium nitrate trihydrate, 3g of carbon fiber, 4g of starch, and 6g of barium sulfate in a reaction vessel, stir for 10 minutes to mix evenly, place in a water bath at 40°C, and heat the water bath until lithium nitrate trihydrate is completely melted. After melting, use The stirrer stirred for 20 minutes until the components were evenly mixed, and the phase change energy storage material was obtained. Conduct cycle stability experiments on phase change energy storage materials, and conduct DSC tests and thermal conductivity tests. The sample was cycled 1000 times, the enthalpy value was 240J / g, and the thermal conductivity was 2.2 times that of the unreinforced material.

experiment example 2

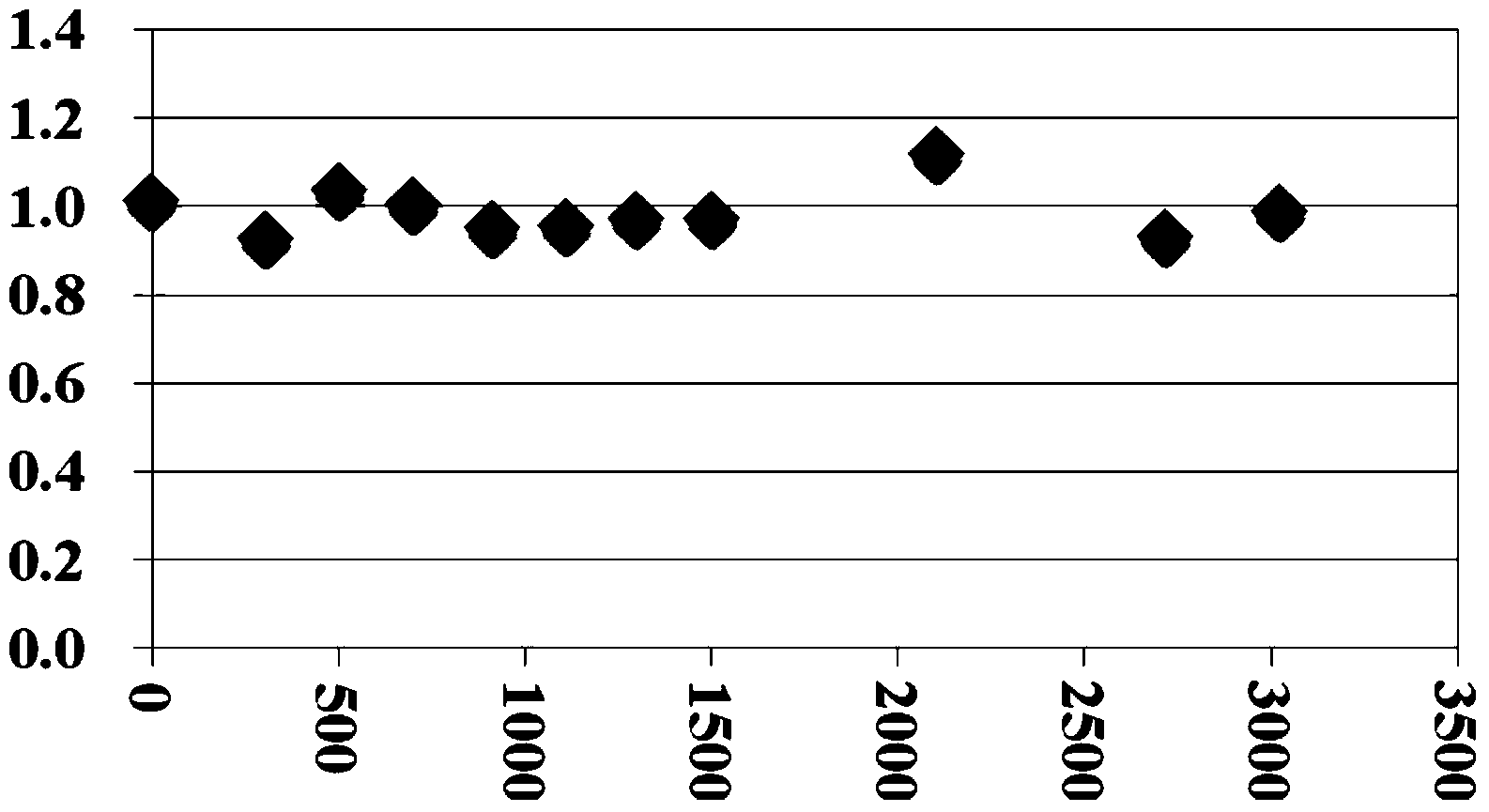

[0029] Weigh 46g of sodium acetate trihydrate, 1g of expanded graphite, 2g of starch, and 1g of disodium hydrogen phosphate dodecahydrate in a reaction vessel, stir for 10 minutes to mix evenly, heat in a water bath at 80°C until sodium acetate trihydrate is completely melted, After the sample is melted, mix the components with a stirrer for 20 minutes until the sample is evenly mixed, and then the phase change energy storage material is obtained. Conduct cycle stability experiments, DSC tests, and thermal conductivity tests on phase change energy storage materials. For its cycle stability diagram, see figure 1 , 3000 cycles, still no attenuation; thermal conductivity is twice that of phase-change energy storage materials without reinforcement materials.

experiment example 3

[0031] Weigh 49g of sodium acetate trihydrate, 0.25g of nano-copper powder, 0.5g of gelatin, and 0.25g of sodium pyrophosphate in a reaction vessel, stir for 10 minutes to mix evenly, and heat in a water bath at 80°C until the sample is completely melted. , fully stirred for 20 minutes until the samples were evenly mixed, and the phase change energy storage material was obtained. Conduct cycle stability experiments on phase change energy storage materials, and conduct DSC tests and thermal conductivity tests. After 2500 cycles, the enthalpy value is 230J / g; the thermal conductivity is 2.5 times that of the unreinforced material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com