Preparation method for monodisperse barium titanate nanopowder

A barium titanate powder and nano-powder technology, applied in nanotechnology, chemical instruments and methods, titanium compounds, etc., can solve the problems of high self-generated pressure, achieve light agglomeration, mild synthesis conditions, and controllable particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

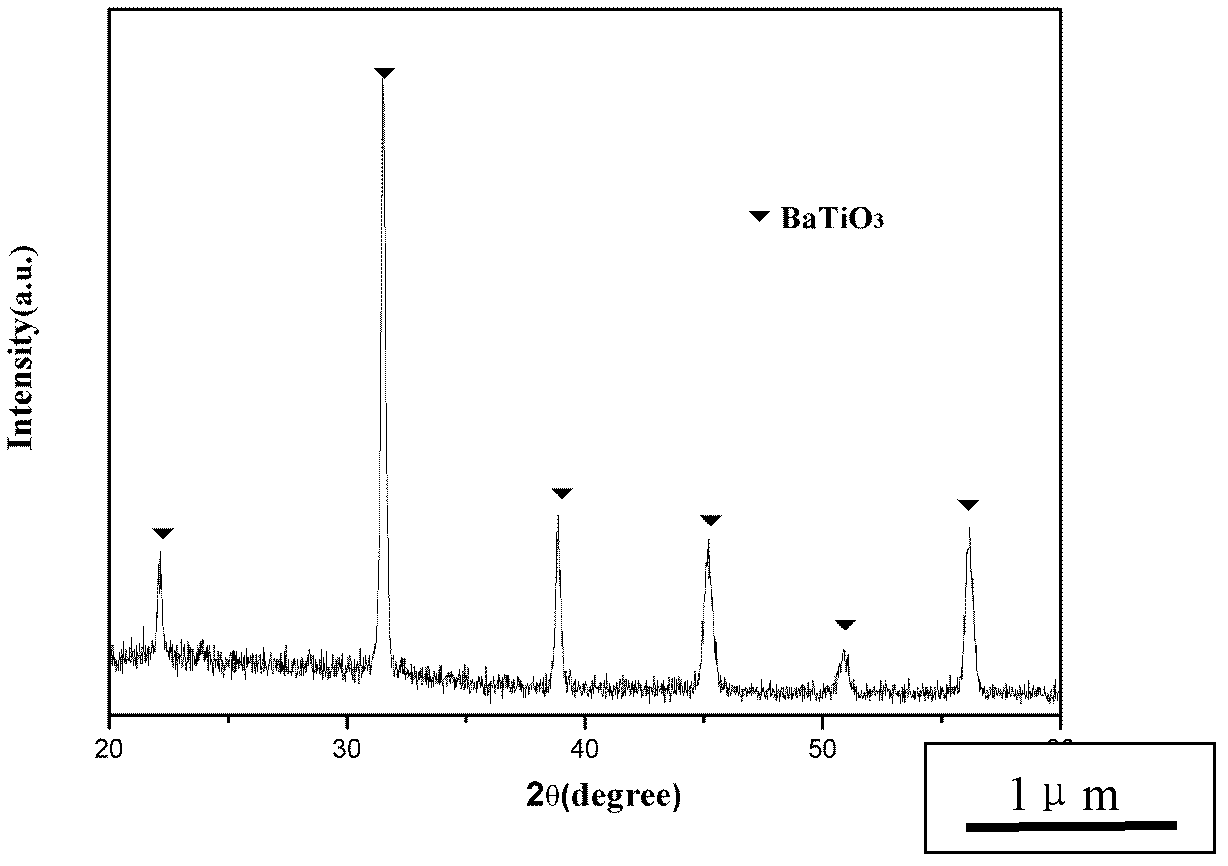

Image

Examples

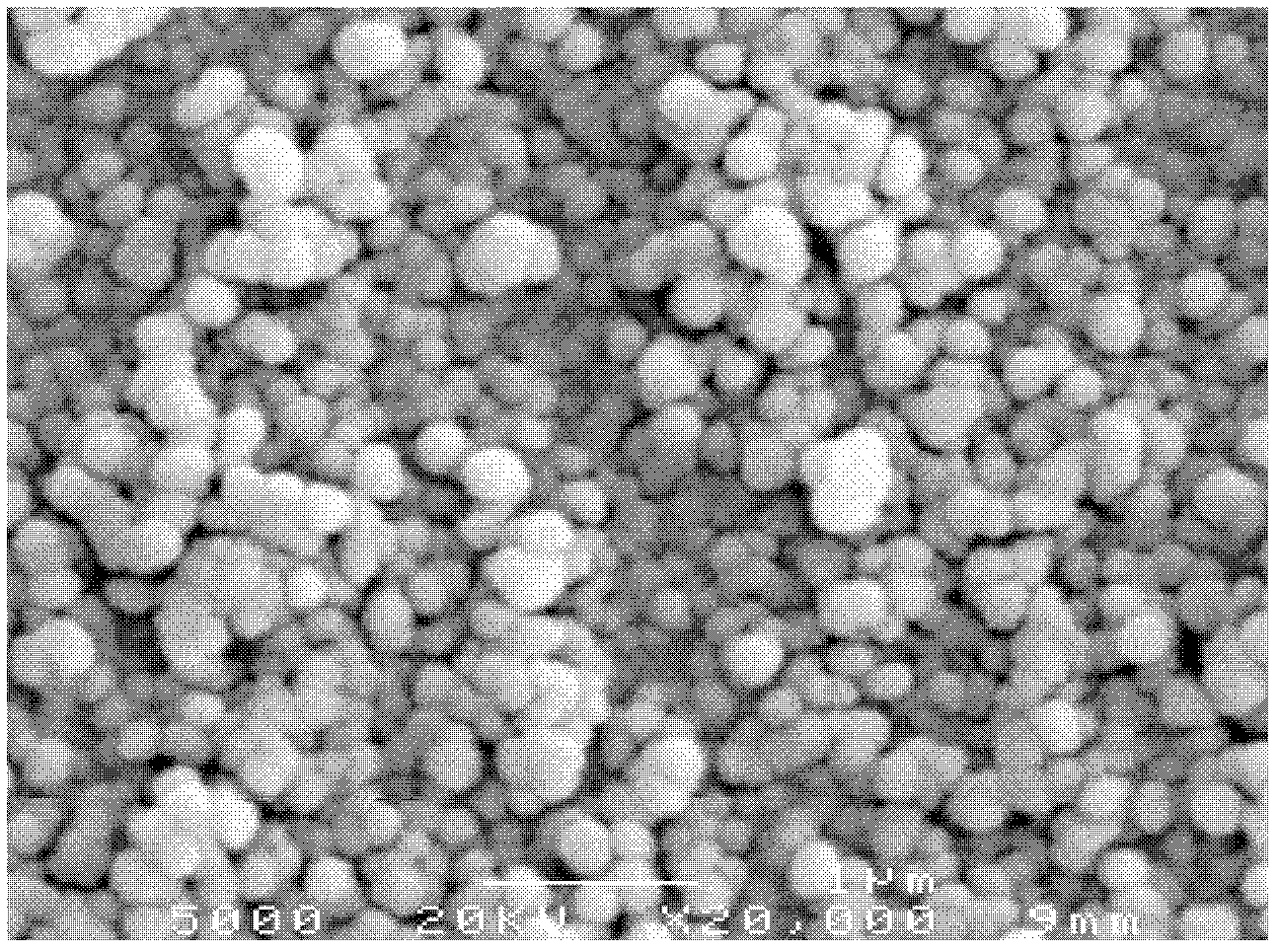

Embodiment 1

[0021] The preparation method of monodisperse barium titanate nano powder of this embodiment includes the following steps:

[0022] Step 1: Add 0.05 mol of tetrabutyl titanate to 0.3 mol of absolute ethanol and stir to form the original solution. Mix 0.6 mol of absolute ethanol with 0.003 mol of nitric acid and 0.15 mol of deionized water to form a dropwise addition Solution

[0023] Step 2: Slowly drop the dropping solution in step 1 into the original solution under strong stirring, the dropping acceleration rate is 15-20 drops / min, and the light yellow transparent TiO can be formed after the dropping is completed 2 Sol

[0024] Step 3: Take 10ml of TiO from step 2 2 The sol is poured into the lining of a polytetrafluoroethylene high-pressure reactor with a volume of 80ml, 0.014mol of barium hydroxide octahydrate and 45ml of deionized water are added to form a precursor solution with an alkalinity of 0.5mol / L, which is carried out with a magnetic stirrer Stir for 20min;

[0025] Ste...

Embodiment 2

[0029] The preparation method of monodisperse barium titanate nano powder of this embodiment includes the following steps:

[0030] Step 1: Add 0.05 mol of tetrabutyl titanate to 0.3 mol of absolute ethanol and stir to form the original solution. Mix 0.6 mol of absolute ethanol with 0.003 mol of nitric acid and 0.15 mol of deionized water to form a dropwise addition Solution

[0031] Step 2: Slowly drop the dropping solution in step 1 into the original solution under strong stirring, the dropping acceleration rate is 15-20 drops / min, and the light yellow transparent TiO can be formed after the dropping is completed 2 Sol

[0032] Step 3: Take 10ml of TiO from step 2 2 The sol was poured into the lining of a polytetrafluoroethylene high-pressure reactor with a volume of 80ml, and 0.028mol of barium hydroxide octahydrate and 45ml of deionized water were added to form a precursor solution with an alkalinity of 1.0mol / L, which was carried out with a magnetic stirrer. Stir for 20min;

[0...

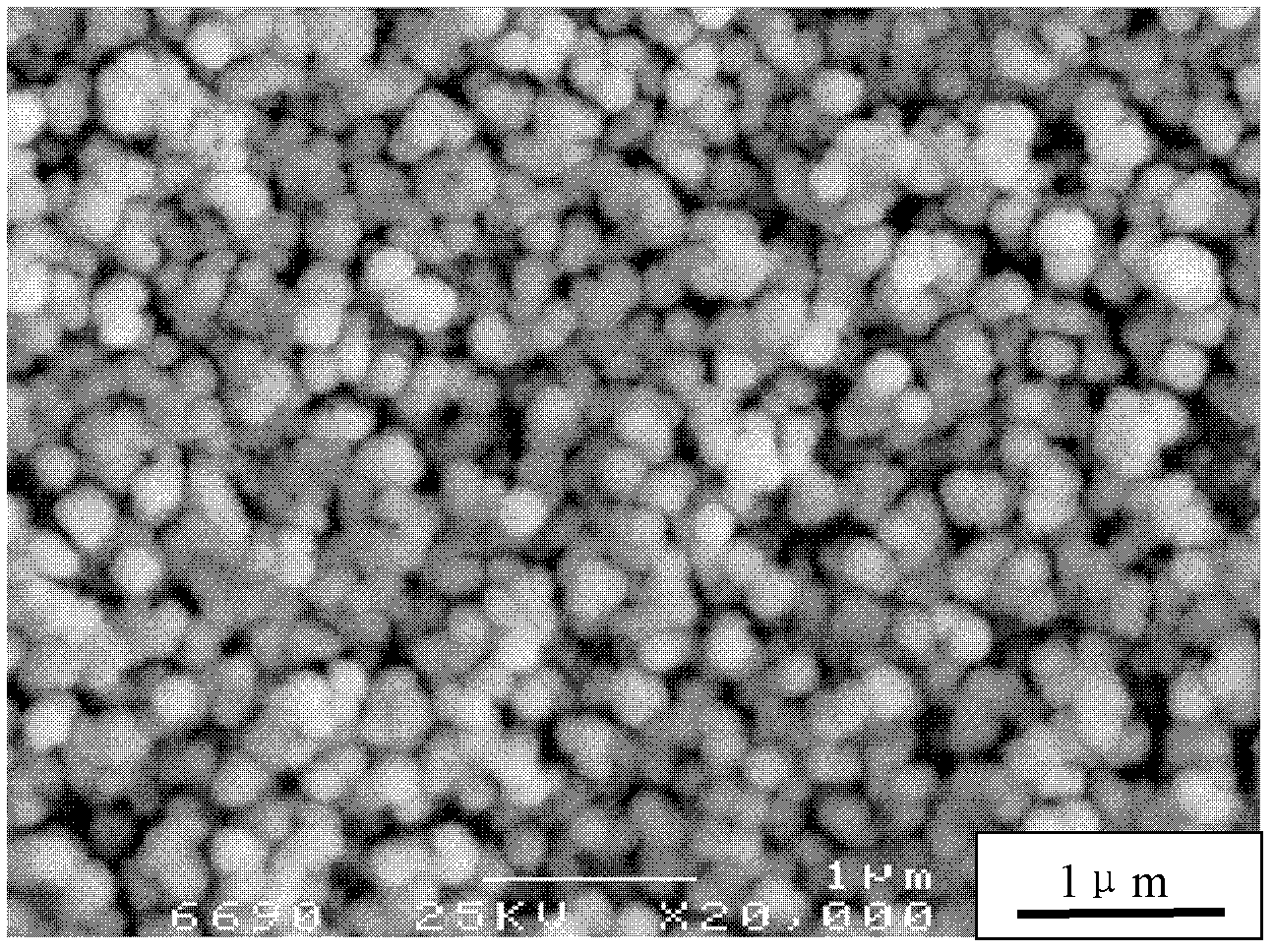

Embodiment 3

[0037] The preparation method of monodisperse barium titanate nano powder of this embodiment includes the following steps:

[0038] Step 1: Add 0.05 mol of tetrabutyl titanate to 0.3 mol of absolute ethanol and stir to form the original solution. Mix 0.6 mol of absolute ethanol with 0.003 mol of nitric acid and 0.15 mol of deionized water to form a dropwise addition Solution

[0039] Step 2: Slowly drop the dropping solution in step 1 into the original solution under strong stirring, the dropping acceleration rate is 15-20 drops / min, and the light yellow transparent TiO can be formed after the dropping is completed 2 Sol

[0040] Step 3: Take 10ml of the TiO2 sol from Step 2 and pour it into the lining of a polytetrafluoroethylene high-pressure reactor with a volume of 80ml, add 0.014mol of barium hydroxide octahydrate and 45ml of deionized water to form an alkalinity of 1.0mol / L Use a magnetic stirrer to stir for 20 min;

[0041] Step 4: Put the lining containing the precursor solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com