Method for preparing cell level manganese sulfate by reducing manganese ores at medium and low temperature

A manganese sulfate, battery-grade technology, applied in metallurgy and chemical industry, can solve the problems of high energy consumption, high impurity content, etc., and achieve the effect of low energy consumption, low temperature and easy price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

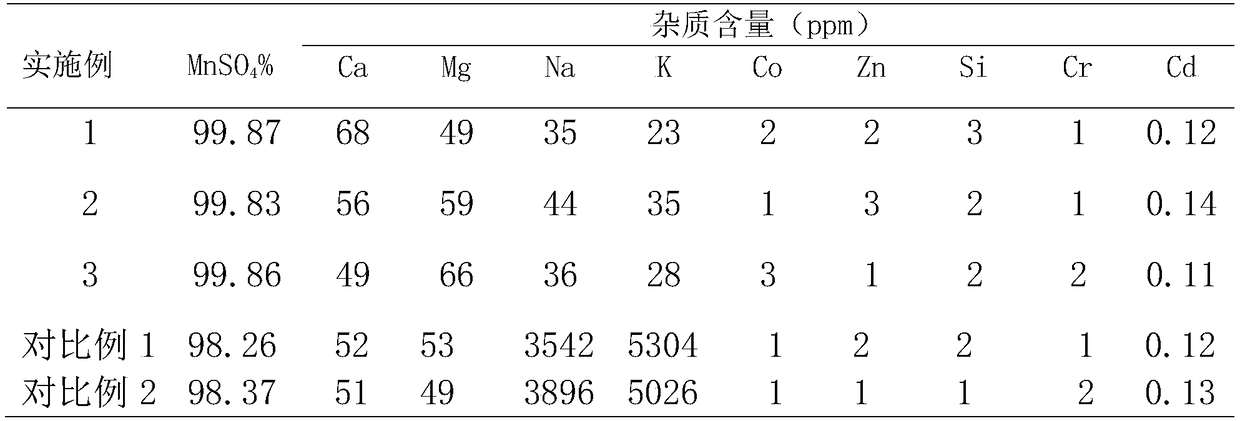

Examples

Embodiment 1

[0023] 1kg of Australian seed ore and 200g of biomass fuel taken from a manganese ore grinding plant in Guangxi were passed through 120 mesh, mixed evenly, put into a muffle furnace for roasting, roasted at 550°C for 80min, taken out, and naturally cooled to below 50°C;

[0024] Take out the manganese monoxide product, add 1L of water and 10g of composite rinse agent, stir for 30 minutes, and separate the solid and liquid; the composite rinse agent is composed of turpentine, polyacrylic acid, ethanol, and water in a weight ratio of 2:3:3:1;

[0025] Add 370ml of sulfuric acid and 3L of water to the wet product of manganese monoxide for leaching, adjust the pH to 5, and heat to 60°C;

[0026] Then add 15ml of ammonium sulfide and 2g of manganese fluoride and stir for 20 minutes, separate the solid and liquid to obtain a high-purity manganese sulfate liquid, then concentrate and dry to obtain a battery-grade manganese sulfate product.

Embodiment 2

[0028] 1kg of Gabon manganese ore and 150g of biomass fuel from a manganese ore grinding plant in Guangxi were passed through 150 meshes, mixed evenly, put into a muffle furnace for roasting, roasted at 600°C for 50min, taken out, and naturally cooled to below 50°C;

[0029] Take out the manganese monoxide product, add 1L of water and 15g of composite rinse agent, stir for 40 minutes, and separate the solid and liquid; the composite rinse agent is composed of turpentine, polyacrylic acid, ethanol, and water in a weight ratio of 2:3:3:1;

[0030] Add 360ml of sulfuric acid and 2.5L of water to the wet product of manganese monoxide for leaching, adjust the pH to 5, and heat to 60°C;

[0031] Then add 5ml of barium sulfide and 3g of manganese fluoride and stir for 20 minutes, separate the solid and liquid to obtain a high-purity manganese sulfate liquid, then concentrate and dry to obtain a battery-grade manganese sulfate product.

Embodiment 3

[0033] 1kg of local manganese ore and 100g of biomass fuel from a manganese ore grinding plant in Guangxi were passed through 100 meshes, mixed evenly, put into a muffle furnace for roasting, roasted at 600°C for 90 minutes, taken out, and naturally cooled to below 50°C;

[0034] Take out the manganese monoxide product, add 1.5L of water and 10g of composite rinse agent, stir for 20 minutes, and separate the solid and liquid; the composite rinse agent is composed of turpentine, polyacrylic acid, ethanol, and water in a weight ratio of 2:3:3:1 ;

[0035] Add 375ml of sulfuric acid and 3L of water to the wet product of manganese monoxide for leaching, adjust the pH to 6, and heat to 50°C;

[0036] Then add 5ml of ammonium sulfide and 5g of ammonium fluoride, stir for 30 minutes, and separate the solid and liquid to obtain a high-purity manganese sulfate liquid, which is then concentrated and dried to obtain a battery-grade manganese sulfate product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com