Manganese-zinc ferrite with high BS, High ZN and excellent ultra-wide-band characteristic and preparation method thereof

A manganese-zinc ferrite, excellent technology, applied in the field of magnetic materials and its preparation, can solve the problems of insufficient Curie temperature and saturation magnetic induction intensity characteristics, inability to maximize the comprehensive performance of materials, and low saturation magnetic induction intensity, etc., to achieve expanded use field, the advantage of enhancing the material, and the effect of excellent widescreen characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

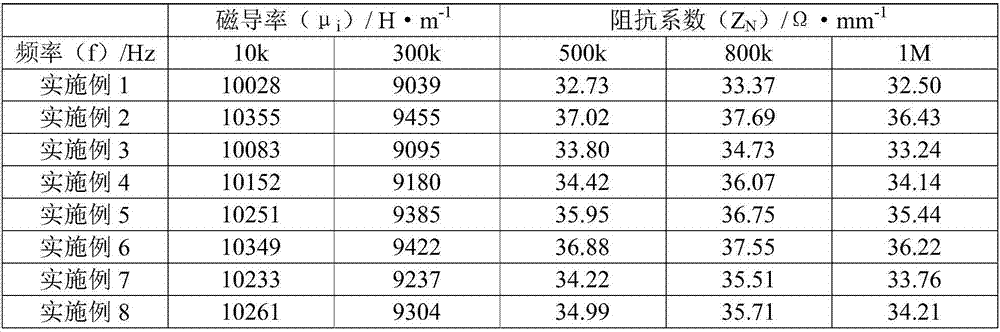

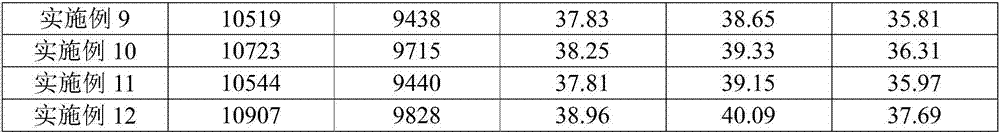

Examples

Embodiment 1

[0033] A combination of high T C High B S High Z N Manganese-zinc ferrite with excellent broadband characteristics, which includes main materials and auxiliary materials, the main materials are composed of the following components in molar percentages: 62.8 mol% of ferric oxide, 10.5 mol% of zinc oxide, and 26.7 mol% of manganese monoxide; Based on the total mass of the main material, the addition amount of each component in the auxiliary material is 100 ppm of calcium oxide, 100 ppm of bismuth oxide and 600 ppm of dicobalt trioxide.

[0034] A combination of high T C High B S High Z N And the preparation method of the manganese zinc ferrite of excellent broadband characteristic, comprises the following steps:

[0035] a) material preparation: prepare the main material and auxiliary materials respectively according to the above formula;

[0036] b) main ingredient mixing: ball mill wet mixing after mixing each raw material in the main ingredient, and make powder after dr...

Embodiment 2

[0048] A combination of high T C High B S High Z N Manganese-zinc ferrite with excellent broadband characteristics, which includes main materials and auxiliary materials, the main materials are composed of the following components in molar percentages: 66.3 mol% of ferric oxide, 14.5 mol% of zinc oxide, and 19.2 mol% of manganese monoxide; Based on the total mass of the main material, the addition amount of each component in the auxiliary material is 600ppm of calcium oxide, 600ppm of bismuth oxide, 300ppm of molybdenum oxide, 300ppm of niobium pentoxide, and 600ppm of dicobalt trioxide.

[0049] A combination of high T C High B S High Z N And the preparation method of the manganese zinc ferrite of excellent broadband characteristic, comprises the following steps:

[0050] a) material preparation: prepare the main material and auxiliary materials respectively according to the above formula;

[0051] b) main ingredient mixing: ball mill wet mixing after mixing each raw ma...

Embodiment 3

[0063] A combination of high T C High B S High Z N Manganese-zinc ferrite with excellent broadband characteristics, which includes main materials and auxiliary materials, the main materials are composed of the following components in molar percentages: 52.37 mol% of ferric oxide, 20.59 mol% of zinc oxide, and 27.04 mol% of manganese monoxide; Based on the total mass of the main material, the addition amount of each component in the auxiliary material is 200ppm of calcium oxide, 300ppm of bismuth oxide, 100ppm of molybdenum oxide, 100ppm of niobium pentoxide, and 400ppm of dicobalt trioxide.

[0064] A combination of high T C High B S High Z N And the preparation method of the manganese zinc ferrite of excellent broadband characteristic, comprises the following steps:

[0065] a) material preparation: prepare the main material and auxiliary materials respectively according to the above formula;

[0066] b) main ingredient mixing: ball mill wet mixing after mixing each raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com