One-dimensional porous carbon coated manganese monoxide composite electrode material and preparation method thereof

A manganese monoxide and composite electrode technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve difficult problems such as rate performance, capacity fading, poor conductivity, etc., and achieve cycle performance And the effects of excellent rate performance, high specific capacity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

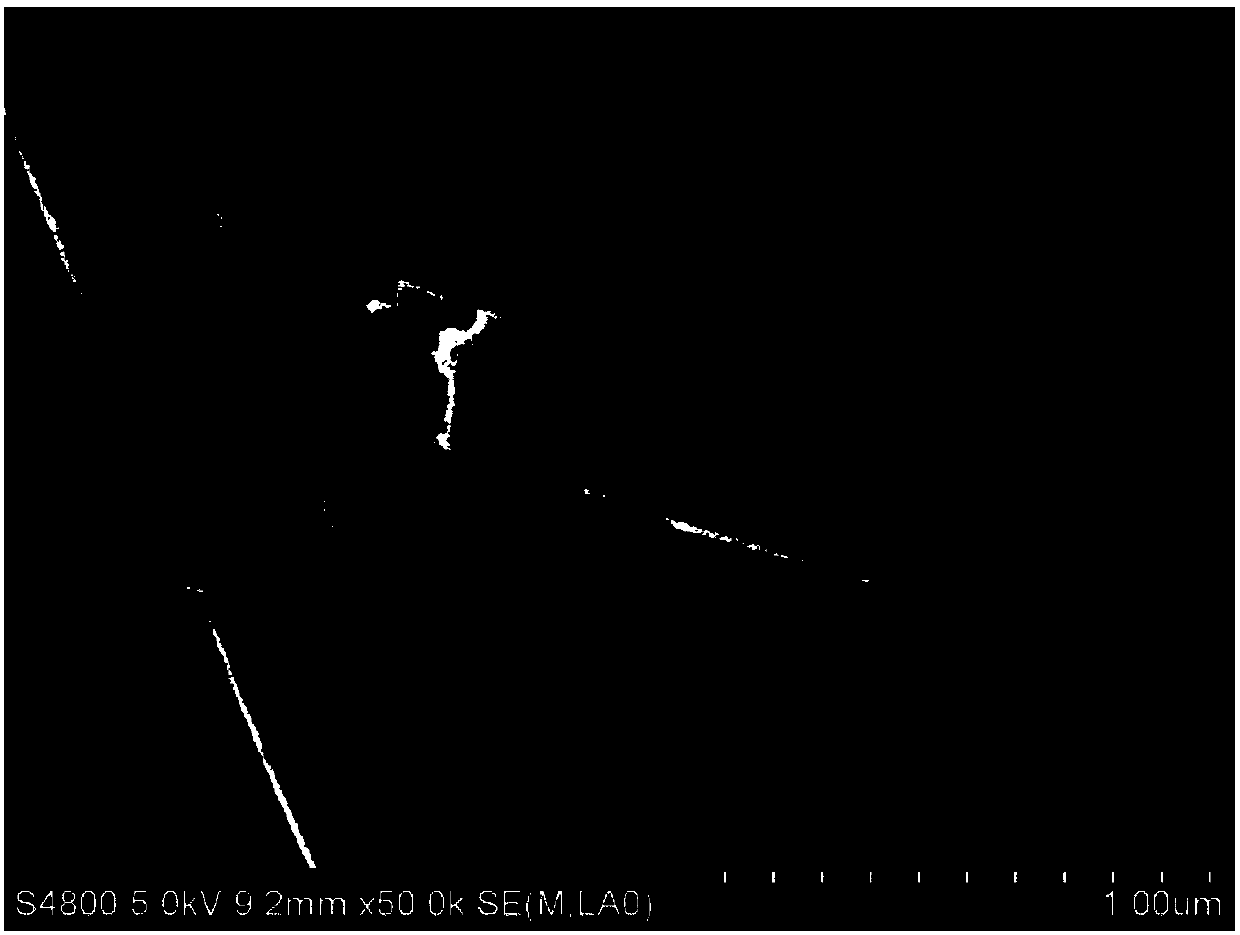

[0017] First, manganese chloride and 1,3,5-benzenetricarboxylic acid were dissolved in solvent deionized water at a molar ratio of 1:1, then the solution was mixed evenly, and left to grow at room temperature for 10 hours, the product was centrifuged, and deionized After washing with water and ethanol three times respectively, a manganese-based metal-organic framework template with a one-dimensional rod structure was obtained. The scanning electron microscope showed figure 1 shown;

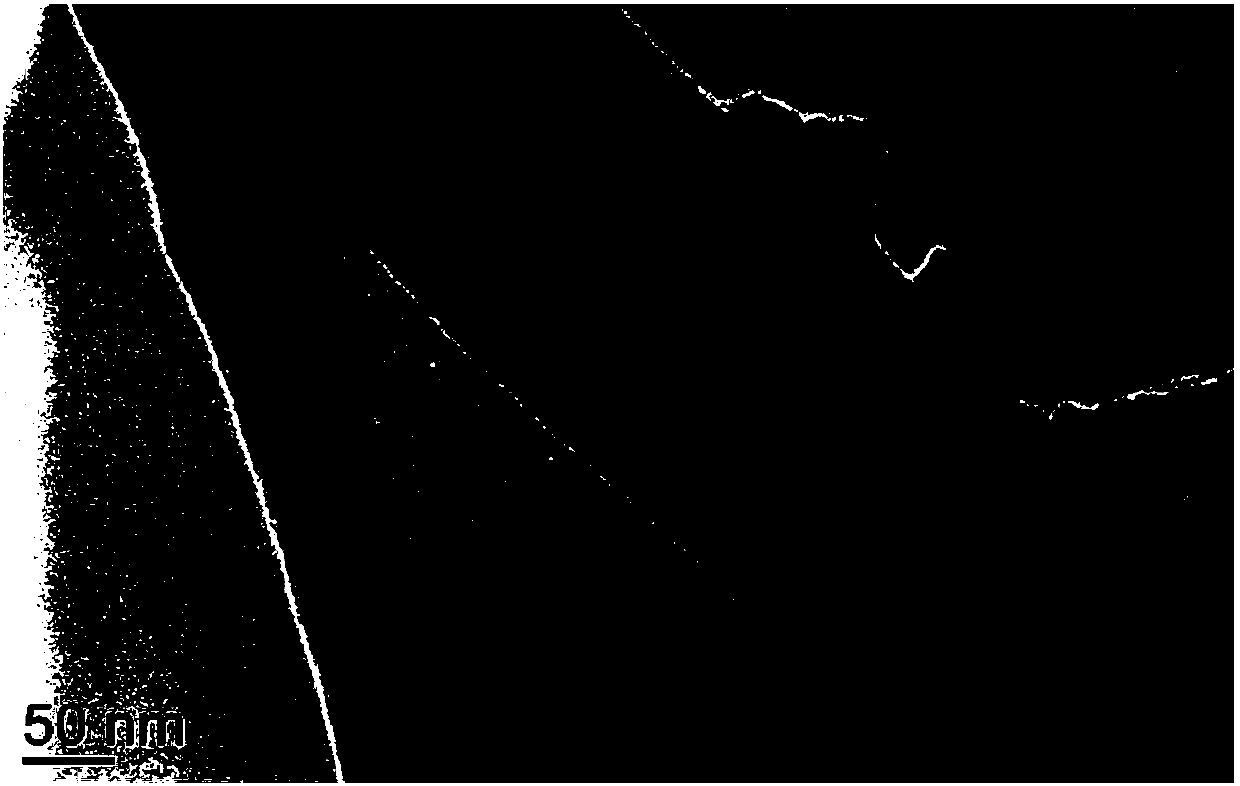

[0018] In the second step, the temperature of the manganese-based metal-organic framework template with one-dimensional rod-like structure obtained in the first step is raised to 400° C. at a rate of 1° C. / min under an inert atmosphere of nitrogen, and kept at this temperature for 3 hours. The temperature is lowered to room temperature to obtain a one-dimensional porous carbon-coated manganese monoxide composite material, and the scanning electron microscope photo is as follows figure 2 shown. ...

Embodiment 2

[0021] First, manganese acetate and 1,3,5-benzenetricarboxylic acid were dissolved in deionized water as a solvent according to the molar ratio of 1:3, then the solution was mixed evenly, and left to grow at room temperature for 30 hours, and the product was centrifuged and washed with deionized water and anhydrous ethanol for 3 times respectively to obtain a manganese-based metal-organic framework template with a one-dimensional rod-like structure;

[0022] In the second step, the temperature of the manganese-based metal-organic framework template with one-dimensional rod-like structure obtained in the first step is raised to 700° C. at a rate of 5° C. / min under an inert atmosphere of nitrogen, and kept at this temperature for 3 hours. The temperature was lowered to room temperature to obtain a one-dimensional porous carbon-coated manganese monoxide composite material.

Embodiment 3

[0024] First, manganese sulfate and 1,3,5-benzenetricarboxylic acid were dissolved in deionized water as a solvent at a molar ratio of 1:5, then the solution was mixed evenly, and left to grow at room temperature for 40 hours, and the product was centrifuged and washed with deionized water and anhydrous ethanol for 3 times respectively to obtain a manganese-based metal-organic framework template with a one-dimensional rod-like structure;

[0025] In the second step, the temperature of the one-dimensional rod-like manganese-based metal organic framework template obtained in the first step is raised to 1000° C. at a rate of 7° C. / min under an inert atmosphere of nitrogen, and kept at this temperature for 4 hours. The temperature was lowered to room temperature to obtain a one-dimensional porous carbon-coated manganese monoxide composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com