Method for recycling valuable components in waste ternary lithium ion battery through high-temperature in-situ heat treatment

A lithium-ion battery, in-situ technology, applied in battery recycling, secondary battery, recycling technology and other directions, can solve problems such as high cost, low leaching efficiency, inability to separate positive and negative materials, and reduce the interference of impurity elements , Simplify the recycling process and achieve the effect of surface modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

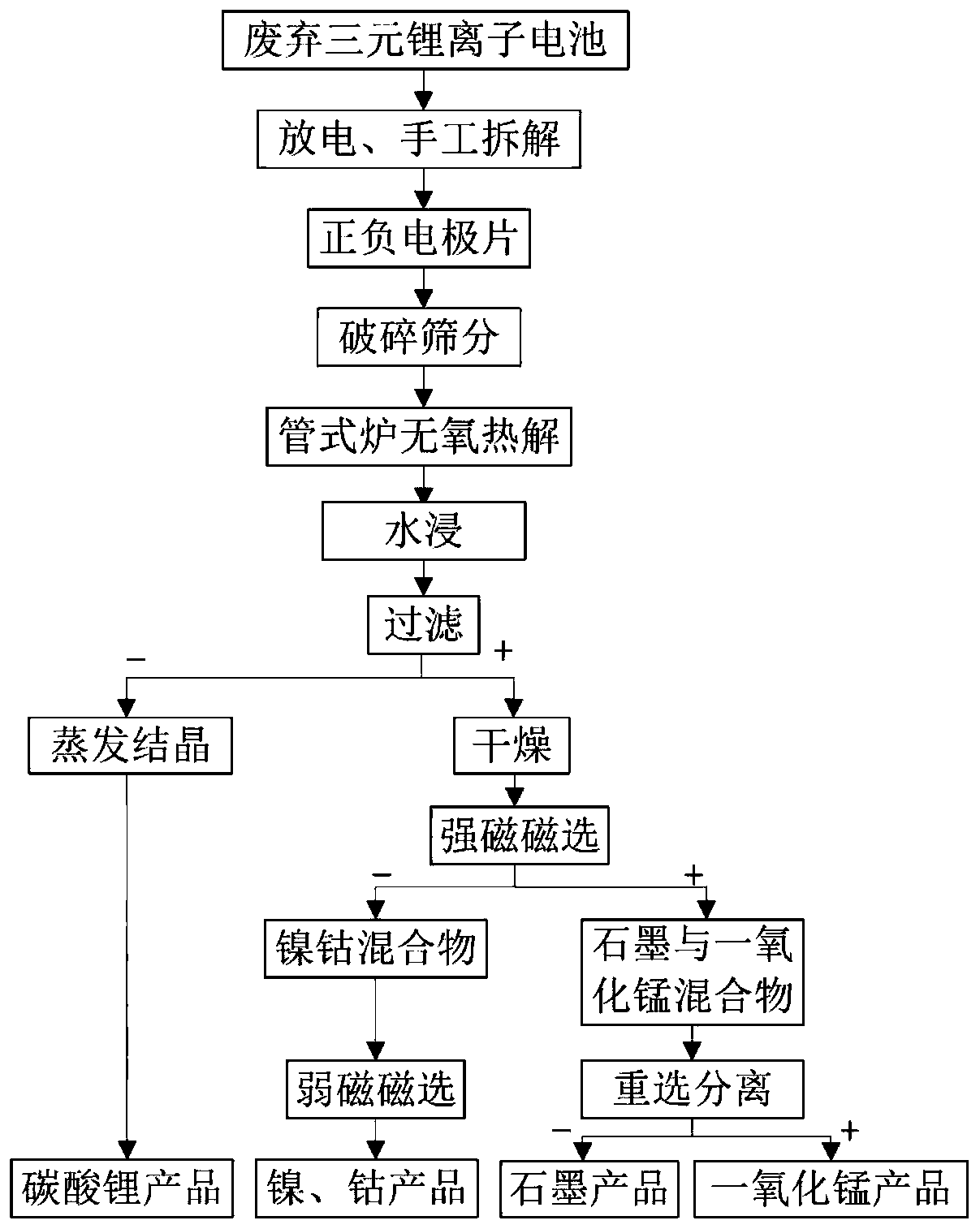

[0024] The method for recovering valuable components in positive and negative electrode materials of waste ternary lithium-ion batteries through high-temperature in-situ pyrolysis treatment technology of the present invention comprises the following steps:

[0025] (1) Pretreatment process: Soak the selected waste ternary lithium-ion battery in 5% NaCl solution for 24 hours, then dry it for discharge, and disassemble it manually to obtain positive and negative electrode sheets;

[0026] (2) Crushing process: cut the positive and negative electrode sheets into square pieces, put them into a universal pulverizer, crush and sieve the positive and negative electrode sheets several times, and obtain the positive and negative electrode material powder mixture; in order to avoid excessive crushing caused by The current collector material is mixed with the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com