Semi-rigid connection-flection restriction support steel skeleton construction

A technology of buckling restraint and frame structure, which is applied in the direction of building components, building structure, earthquake resistance, etc., can solve the problems of limiting the energy dissipation capacity of supporting and anti-lateral force components, the difficulty of guaranteeing welding quality, and the difficulty of structural repair, etc., to achieve energy dissipation performance Excellent, good energy consumption performance, superior performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

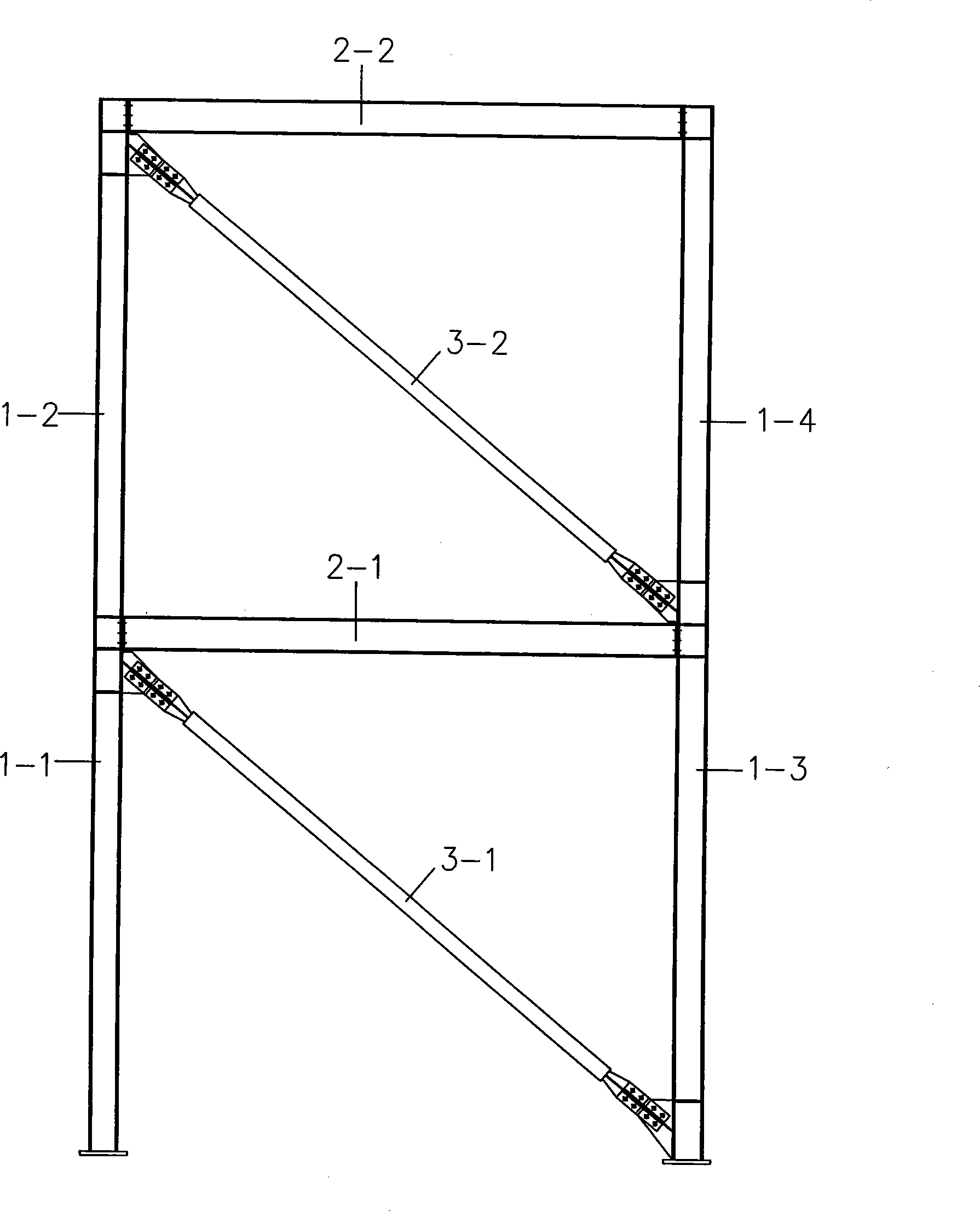

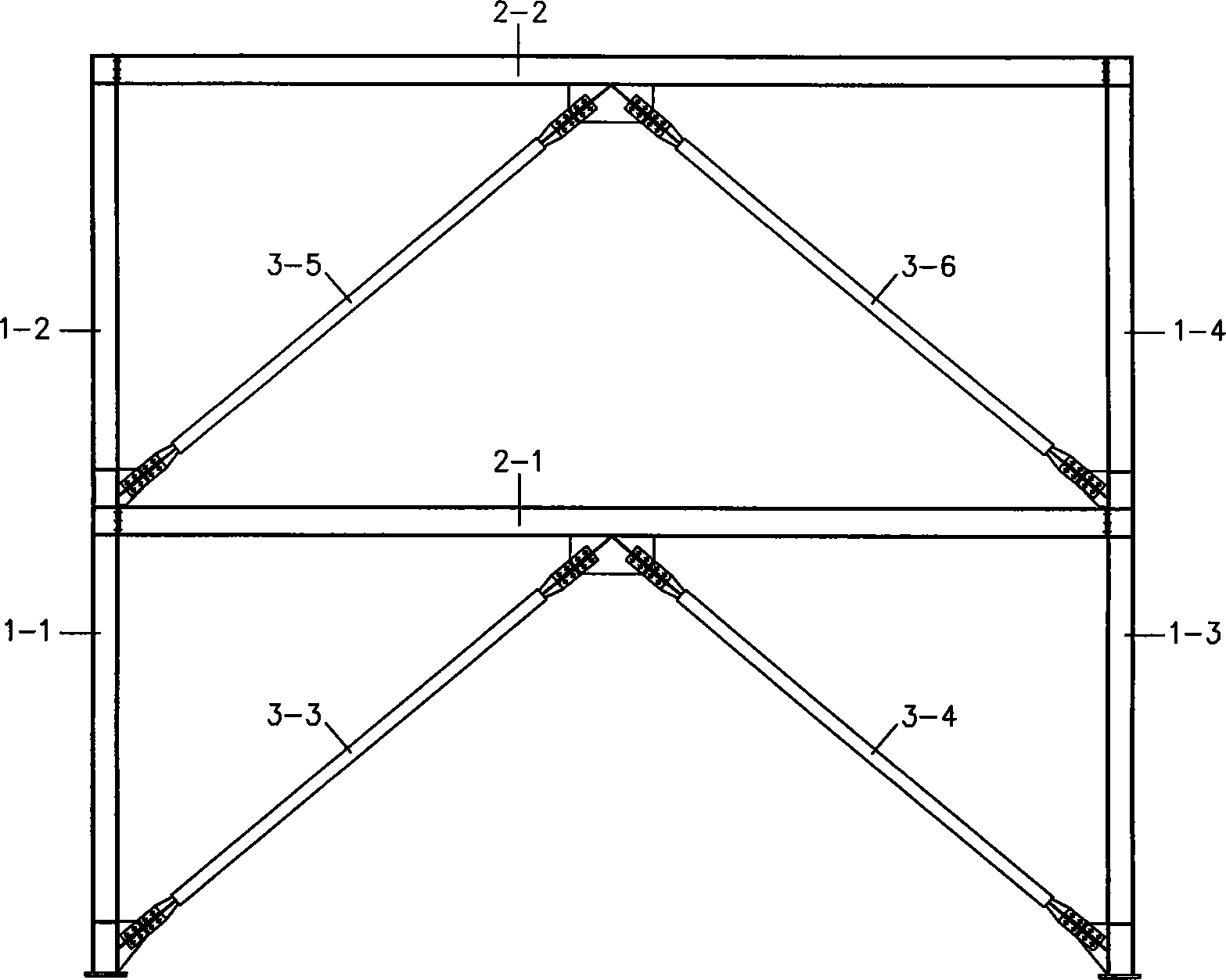

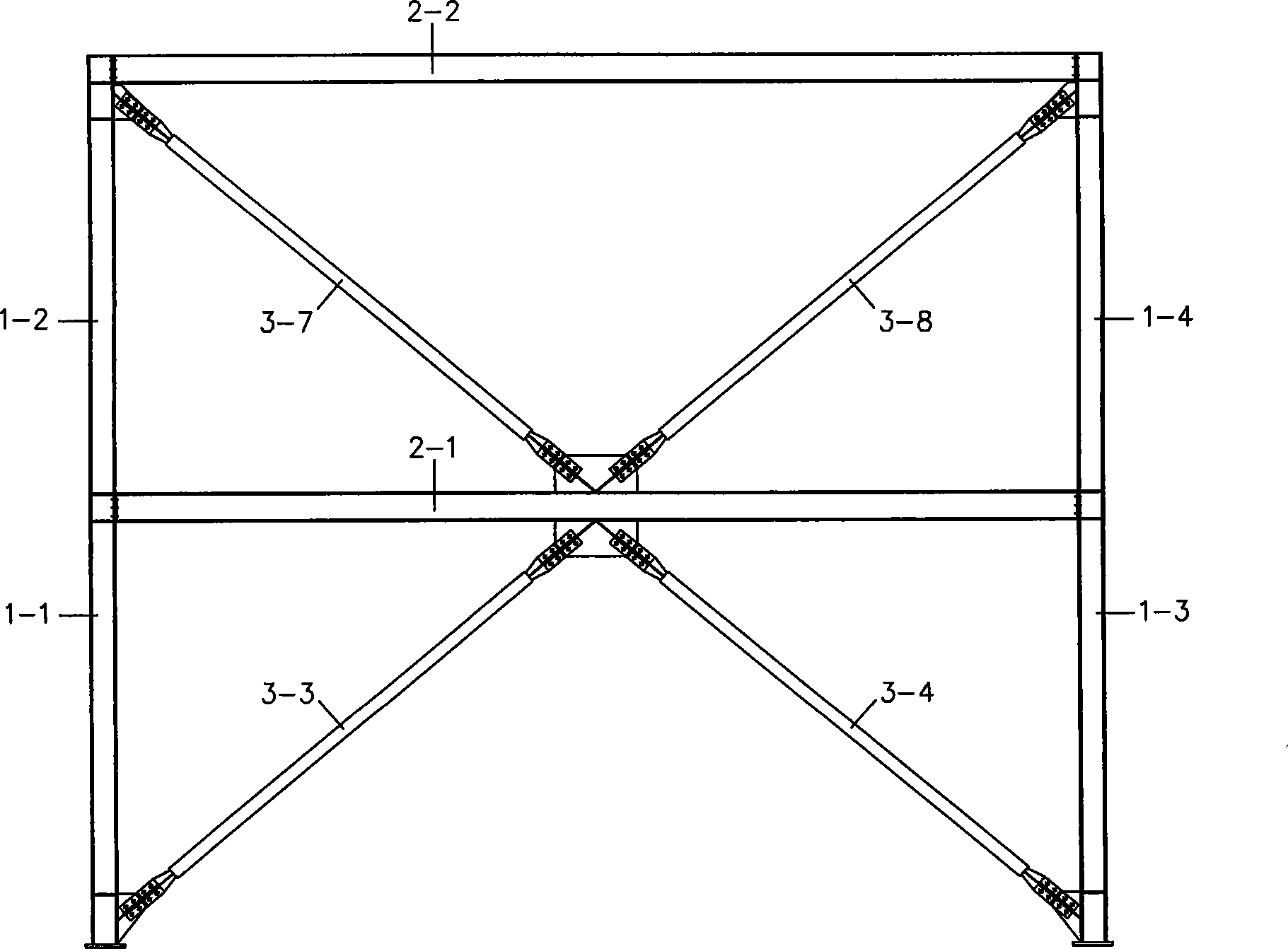

[0019] The invention provides a structural system suitable for multi-storey and high-rise buildings. In the preliminary design stage, the sections of frame beams and frame columns are determined by vertical loads, and the buckling restrained support sections are determined by horizontal loads. In the construction drawing design stage, the optimal design is carried out through finite element analysis. The semi-rigid connection form of end plate connection is adopted for the connection of frame beam and frame column during construction. The connection nodes between the frame columns and frame beams and supports are processed in the steel structure processing plant. After the beams and columns are installed on the construction site, the buckling restraint supports are connected to the frame beams and frame columns through bolt connections.

[0020] Taking a 6-story teaching building as an example to illustrate its use process. The building has a total width of 16m and a total le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com