3D printing method and 3D printing system

A technology of 3D printing and printing speed, applied in the field of 3D printing, which can solve the problems of printing failure, difficulty in removing objects, and easy damage to printing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

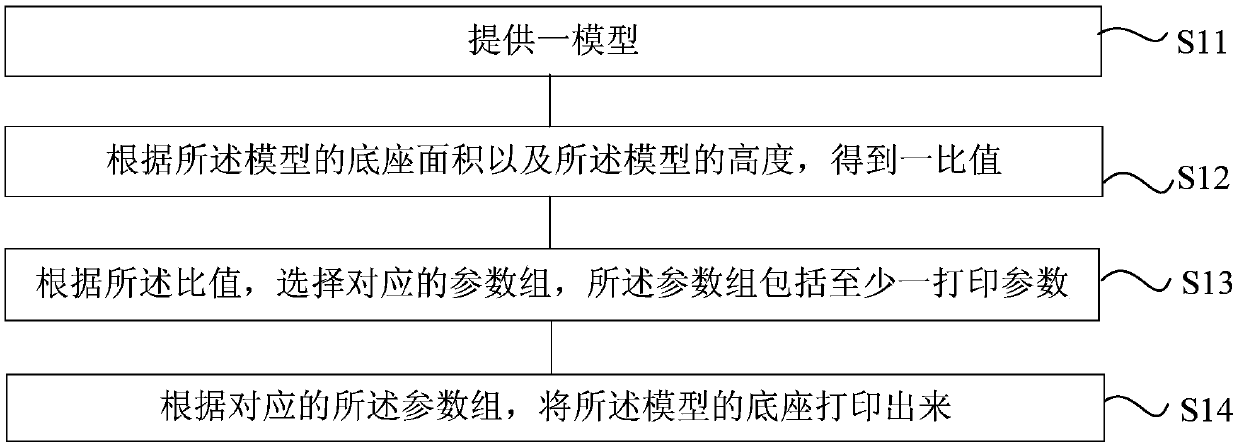

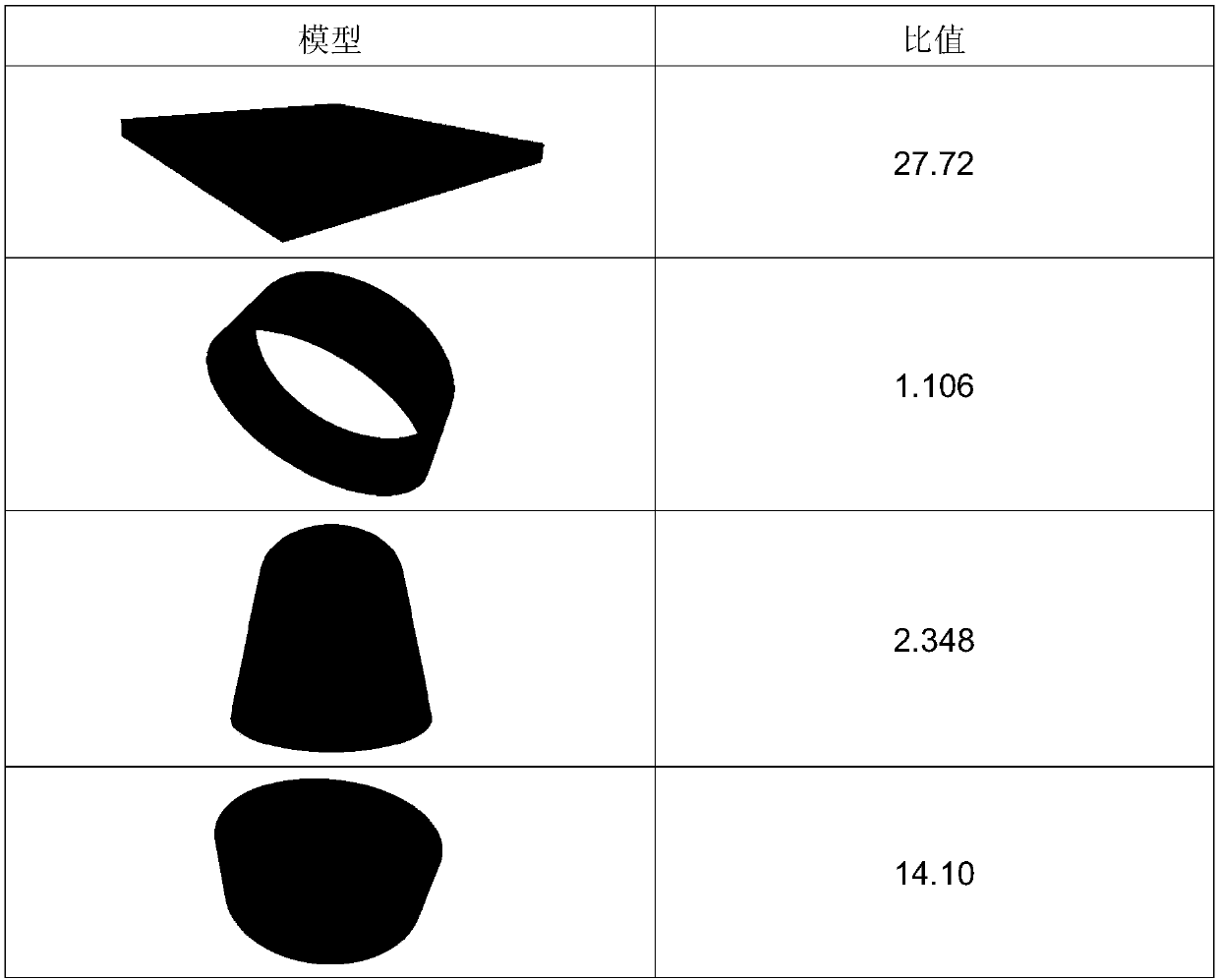

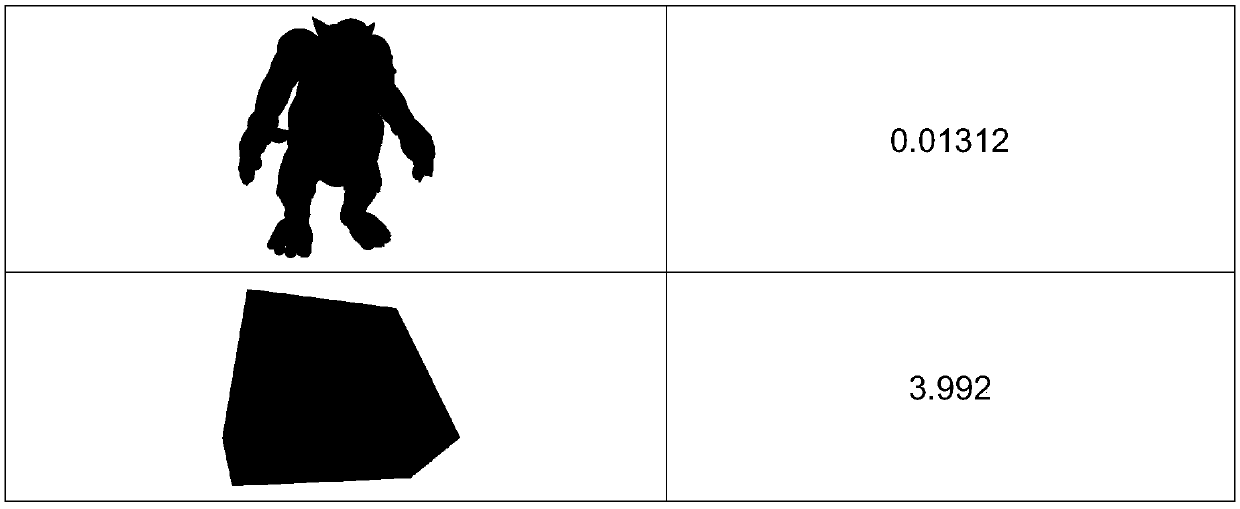

[0032] In the prior art, the adhesion between the objects printed on the workbench and the workbench is often inappropriate. Either the object collapses during the printing process, or the printed object is not easy to remove from the workbench, resulting in the failure of the workbench. damage. The inventor found through research that the printing parameters of the base of the model are very critical. In general, when printing models, the printing parameters of the base are fixed, which cannot adapt to various models: some models have a good base adhesion; some models have insufficient base adhesion to support the entire object (such as a tall tower); Some models are stuck too firmly and cannot be removed (for example, a very thin large round cake).

[0033] The inventors conducted in-depth research and found that, if the ratio of the base area of the model to the height of the model is different, the required printing parameters of the base are different. If the ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com