Magnetically modified hydrotalcite as well as preparation method and application thereof

A technology for modifying water and hydrotalcite, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc. Recycling and other issues, the preparation method is simple and easy to operate, the removal effect is obvious, and the adsorption time is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

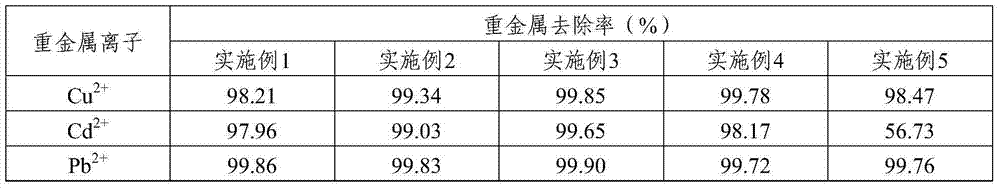

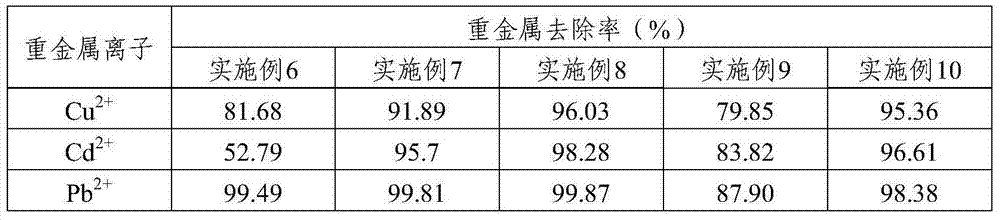

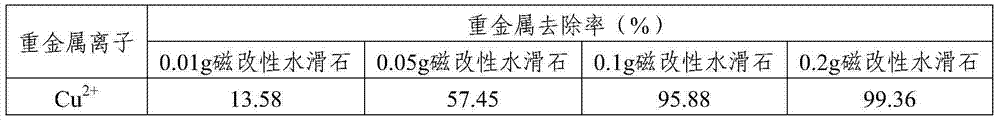

Examples

Embodiment 1

[0039] Embodiment 1: Magnetically modified hydrotalcite

[0040] 1) Calcination of hydrotalcite: place the hydrotalcite in a high-temperature environment of 500° C. for 4 hours and pass through a 100-mesh sieve to obtain the calcined hydrotalcite, which is put into a vacuum desiccator for later use.

[0041] 2) Fe 3 o 4 Preparation and modification of hydrotalcite: FeCl 2 4H 2 O and FeCl 3 ·6H 2 O is the raw material, prepare 0.44mol / L Fe with anaerobic distilled water 3+ , 0.22mol / L of Fe 2+ solution, pipette containing Fe 3+ , Fe 2+ Add 50mL of each solution, mix well, add 15mL of ammonia water dropwise, shake in a water bath at 80°C for 15min, add 1.5g of calcined hydrotalcite, keep at 70°C, and continue to shake for 90min.

[0042] 3) Drying for standby: vacuum sealing, aging at room temperature for 24 hours, placing in a constant temperature blower box at 50°C, drying for several hours, grinding, and passing through a 100-mesh sieve to obtain a magnetically modif...

Embodiment 2

[0043] Embodiment 2: magnetically modified hydrotalcite

[0044] 1) Calcination of hydrotalcite: place the hydrotalcite in a high-temperature environment of 300° C. for 4 hours and pass through a 100-mesh sieve to obtain the calcined hydrotalcite, which is put into a vacuum desiccator for later use.

[0045] 2) Fe 3 o 4 Preparation and modification of hydrotalcite: FeCl 2 4H 2 O and FeCl 3 ·6H 2 O is the raw material, prepare 0.44mol / L Fe with anaerobic distilled water 3+ , 0.22mol / L of Fe 2+ solution, pipette containing Fe 3+ , Fe 2+ Add 50 mL of each solution, mix well, add 15 mL of ammonia water dropwise, shake in a water bath at 80°C for 15 minutes, add 1.5 g of calcined hydrotalcite, keep at 80°C, and continue to shake for 90 minutes.

[0046] 3) Drying for standby: vacuum sealing, aging at room temperature for 24 hours, placing in a constant temperature blower box at 50°C, drying for several hours, grinding, and passing through a 100-mesh sieve to obtain a magne...

Embodiment 3

[0047] Embodiment 3: magnetically modified hydrotalcite

[0048] 1) Calcination of hydrotalcite: place the hydrotalcite in a high-temperature environment of 500° C. for 4 hours and pass through a 100-mesh sieve to obtain the calcined hydrotalcite, which is put into a vacuum desiccator for later use.

[0049] 2) Fe 3 o 4 Preparation and modification of hydrotalcite: FeCl 2 4H 2 O and FeCl 3 ·6H 2 O is the raw material, prepare 0.44mol / L Fe with anaerobic distilled water 3+ , 0.22mol / L of Fe 2+ solution, pipette containing Fe 3+ , Fe 2+ Add 50 mL of each solution, mix well, add 15 mL of ammonia water dropwise, shake in a water bath at 80°C for 15 minutes, add 1.5 g of calcined hydrotalcite, keep at 80°C, and continue to shake for 90 minutes.

[0050] 3) Drying: vacuum sealing, aging at room temperature for 24 hours, placing in a constant temperature blower box at 50°C, drying for several hours, grinding, passing through a 100-mesh sieve to obtain a magnetically modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com