A plastic prefabricated underground granary

An underground granary and prefabricated assembly technology is applied in the field of underground granaries, which can solve the problems of small storage capacity, troublesome construction and great difficulty, and achieve the effects of resisting earth pressure and grain pressure, being beneficial to waterproofing and moisture-proofing, and improving rigidity and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

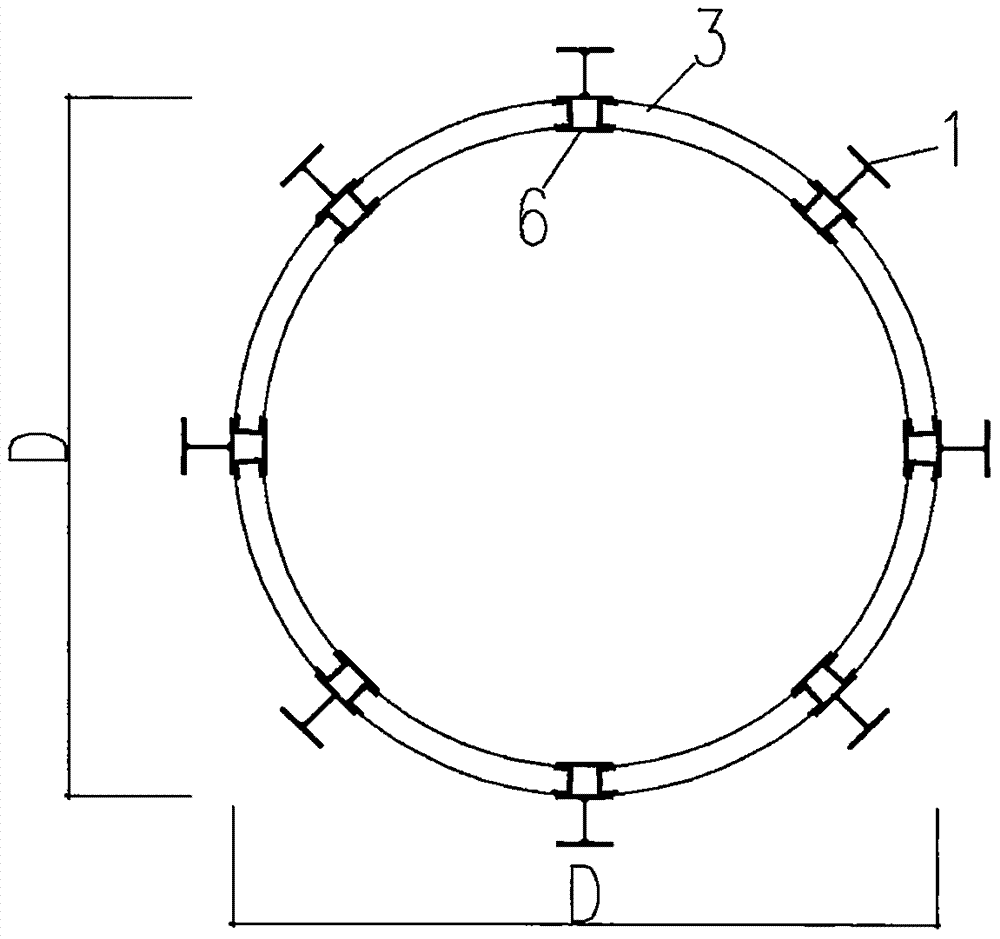

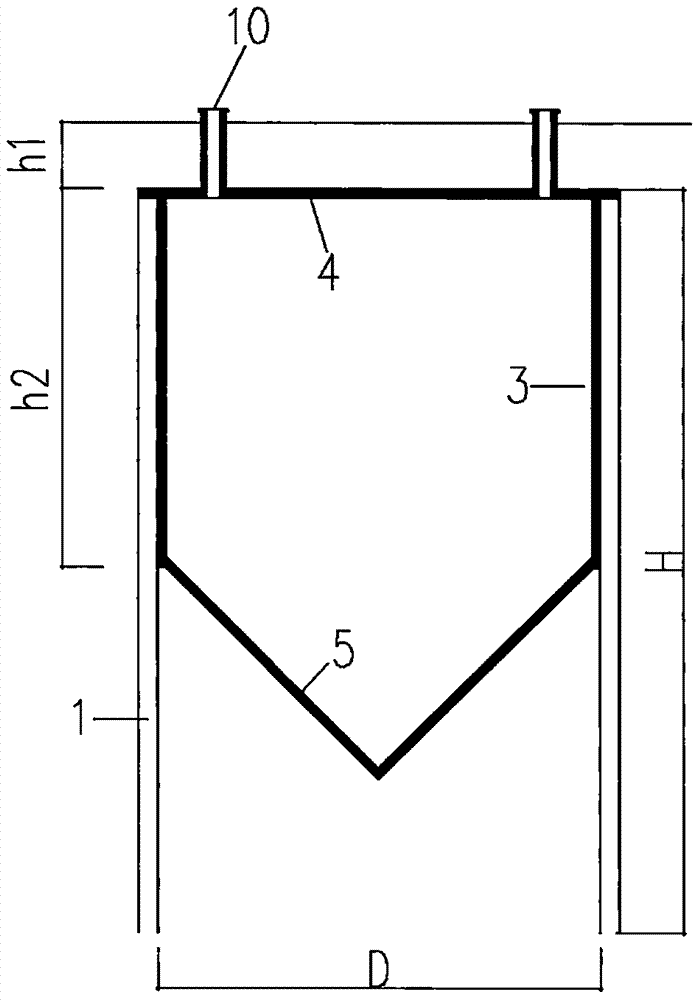

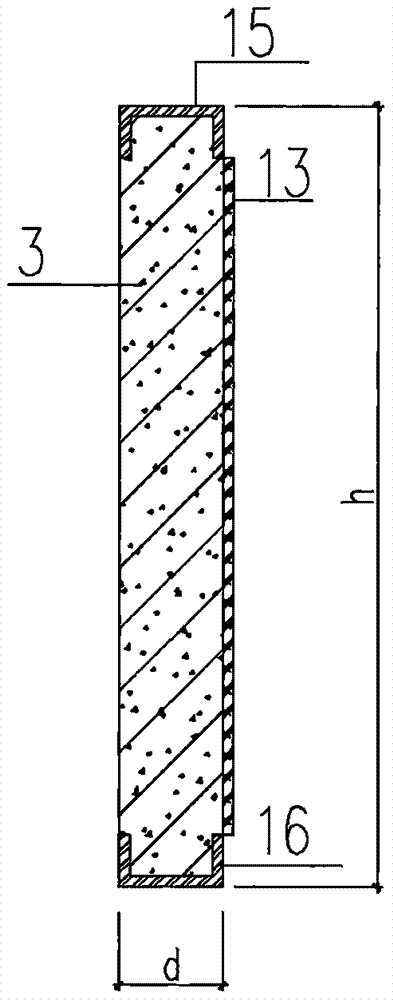

[0034] Such as figure 1 , figure 2 , image 3 , Figure 6 , Figure 7 Shown: this embodiment provides a kind of inner plastic prefabricated assembled underground granary. It includes a warehouse bottom 5, a plurality of prefabricated warehouse wall panels 3, a warehouse roof 4, and a multifunctional column 1. The prefabricated warehouse wall panels 3 are an integral structure composed of an inner plastic board 13 and an outer concrete board, and there are connecting devices on the periphery. The prefabricated warehouse wall panel 3 can be connected with the adjacent prefabricated warehouse wall panel 3 and the multifunctional column 1 through the connecting device; the multifunctional column can position the prefabricated warehouse wall panel 3 . The multifunctional column 1 is divided into several sections from top to bottom, the inner side of the first section of the uppermost layer is provided with a first layer of prefabricated warehouse wall panels 3, and the inner s...

Embodiment 2

[0041] Such as figure 1 , figure 2 , Figure 4 , Figure 6 , Figure 8 Shown: this embodiment provides a kind of inner plastic prefabricated assembled underground granary. It includes a warehouse bottom 5, a plurality of prefabricated warehouse wall panels 3, a warehouse roof 4, and a multifunctional column 1. The prefabricated warehouse wall panels 3 are an integral structure composed of an inner plastic board 13 and an outer concrete board, and there are connecting devices on the periphery. The prefabricated warehouse wall panel 3 can be connected with the adjacent prefabricated warehouse wall panel 3 and the multifunctional column 1 through the connecting device; the multifunctional column can position the prefabricated warehouse wall panel 3 . The multifunctional column 1 is divided into several sections from top to bottom, the inner side of the first section of the uppermost layer is provided with a first layer of prefabricated warehouse wall panels 3, and the inner ...

Embodiment 3

[0048] Such as figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 9 Shown: this embodiment provides a kind of inner plastic prefabricated assembled underground granary. It includes a warehouse bottom 5, a plurality of prefabricated warehouse wall panels 3, a warehouse roof 4, and a multifunctional column 1. The prefabricated warehouse wall panels 3 are an integral structure composed of an inner plastic board 13 and an outer concrete board, and there are connecting devices on the periphery. The prefabricated warehouse wall panel 3 can be connected with the adjacent prefabricated warehouse wall panel 3 and the multifunctional column 1 through the connecting device; the multifunctional column can position the prefabricated warehouse wall panel 3 . The multifunctional column 1 is divided into several sections from top to bottom, the inner side of the first section of the uppermost layer is provided with a first layer of prefabricated warehouse wall panels 3, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com