Flexible juncture net cage frame

A flexible connection and cage technology, applied in fish farming, application, climate change adaptation, etc., can solve problems such as poor wind and wave resistance of cages, avoid economic losses, high overall strength, and ensure fixed installation and positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

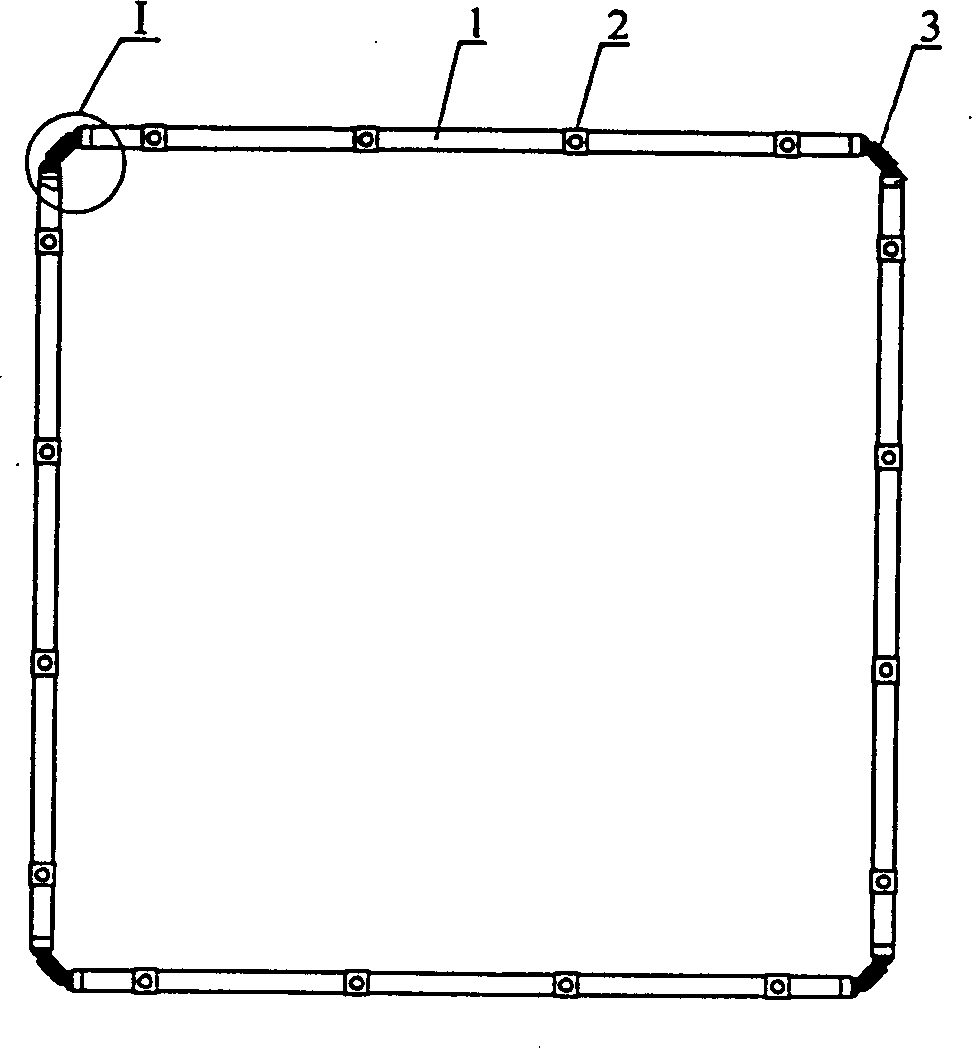

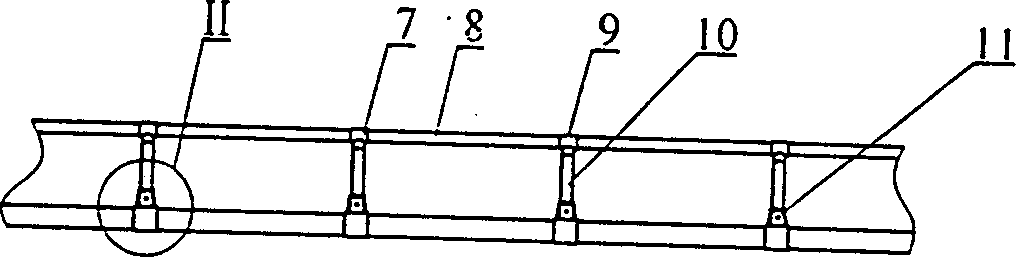

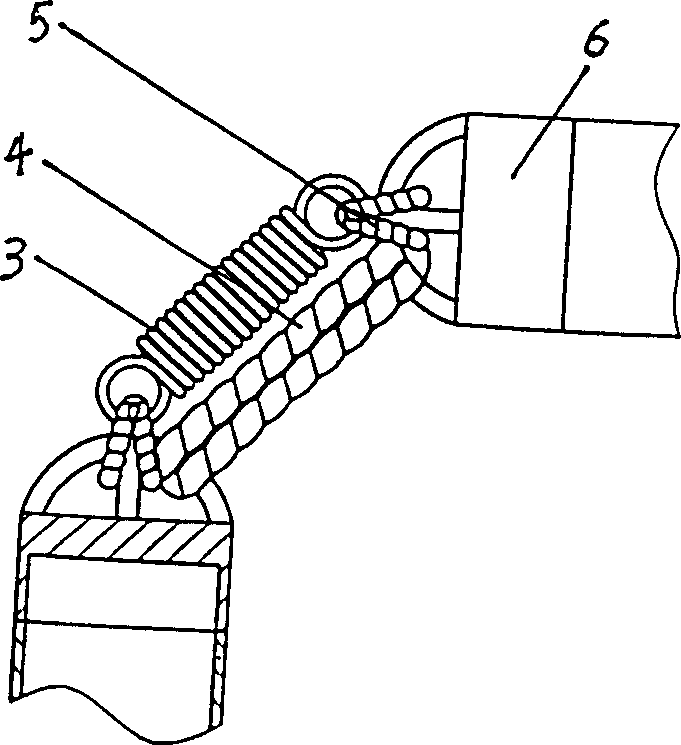

[0022] In the figure, 1, main floating pipe; 2, main floating pipe tee 3, spring 4, safety rope 5, connecting rope 6, connecting joint 7, guardrail pipe tee 8, guardrail pipe 9, net hook 10, guardrail post Tube; 11, column pin 12, positioning block.

[0023] see Figure 1-Figure 7 , a flexible connection square net cage frame, the main floating pipe 1 has 4 sections of independent HDPE straight main floating pipes, each of the two ends of the straight main floating pipe 1 is equipped with a connecting joint 6, and is integrated with it by hot-melt welding. The outer end of the connector 6 is provided with a criss-cross semicircular ring. The head and tail of each straight main floating pipe 1 are movably connected as a whole through the connecting piece, and each section of the straight main floating pipe can be moved relative to each other to form a quadrilateral net cage frame. The specific connection method is: the two adjacent connecting joints 6 of the two sections of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com