Scanning method used for metal laser selective melting forming process

A laser selective melting and forming process technology, applied in the field of additive forming manufacturing, can solve problems such as cracking and warping deformation, and achieve the effect of avoiding warping deformation, reducing residual stress, and reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0054] A scanning method for metal laser selective melting, the main steps include:

[0055] 1. Contour offset

[0056] Obtain the first-layer cross-sectional shape of the part entity, and offset the outer contour line of the part entity toward the center of the part entity by 0.5-2 mm to form an inner contour line, thereby dividing the first-layer cross-sectional shape into an inner contour area and A narrow-edge outer contour area; the part entity is composed of N sections; such as figure 1 As shown in , the specific offset distance can be determined according to the wall thickness of the part at the current position and the quality requirements of the side of the part;

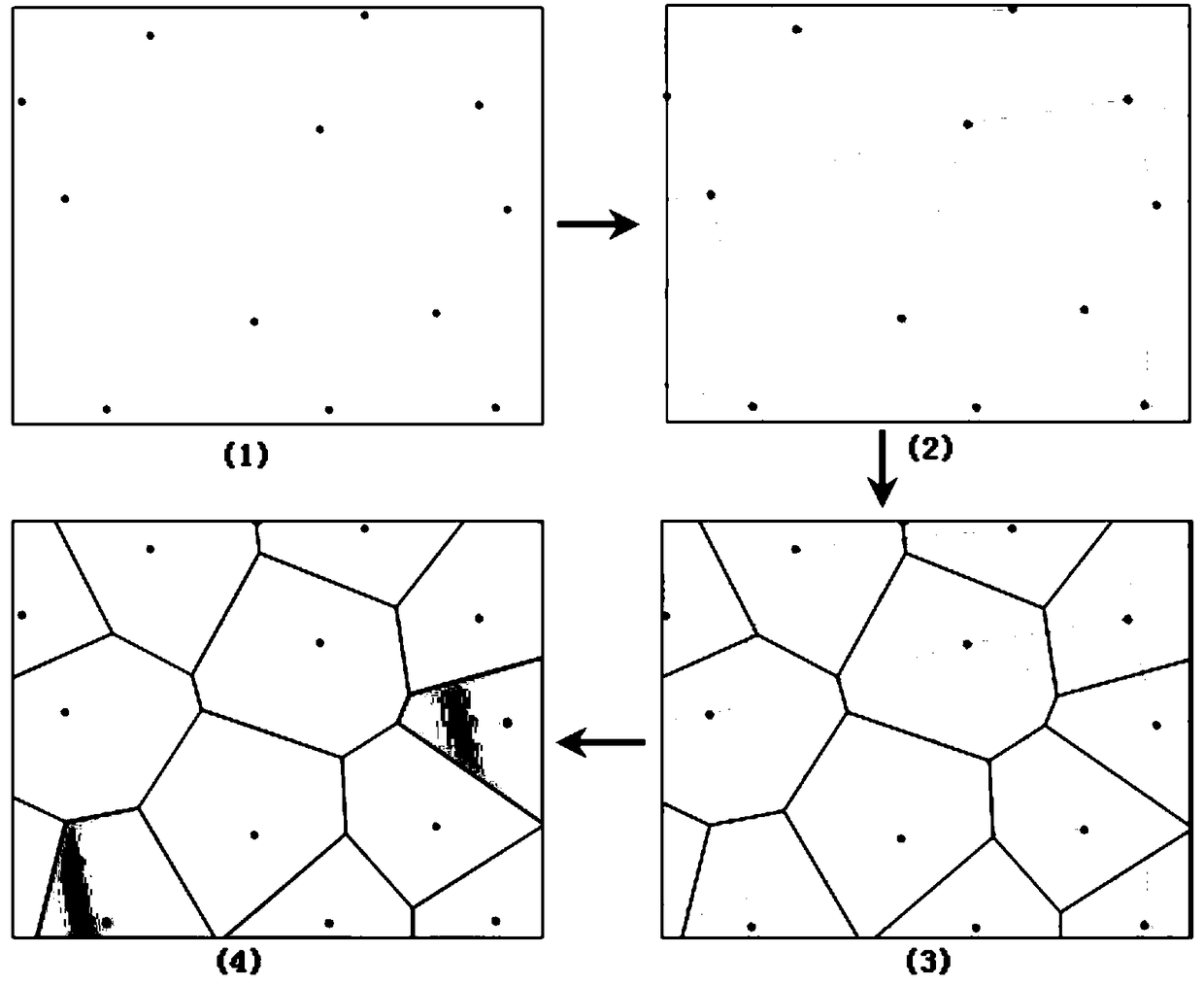

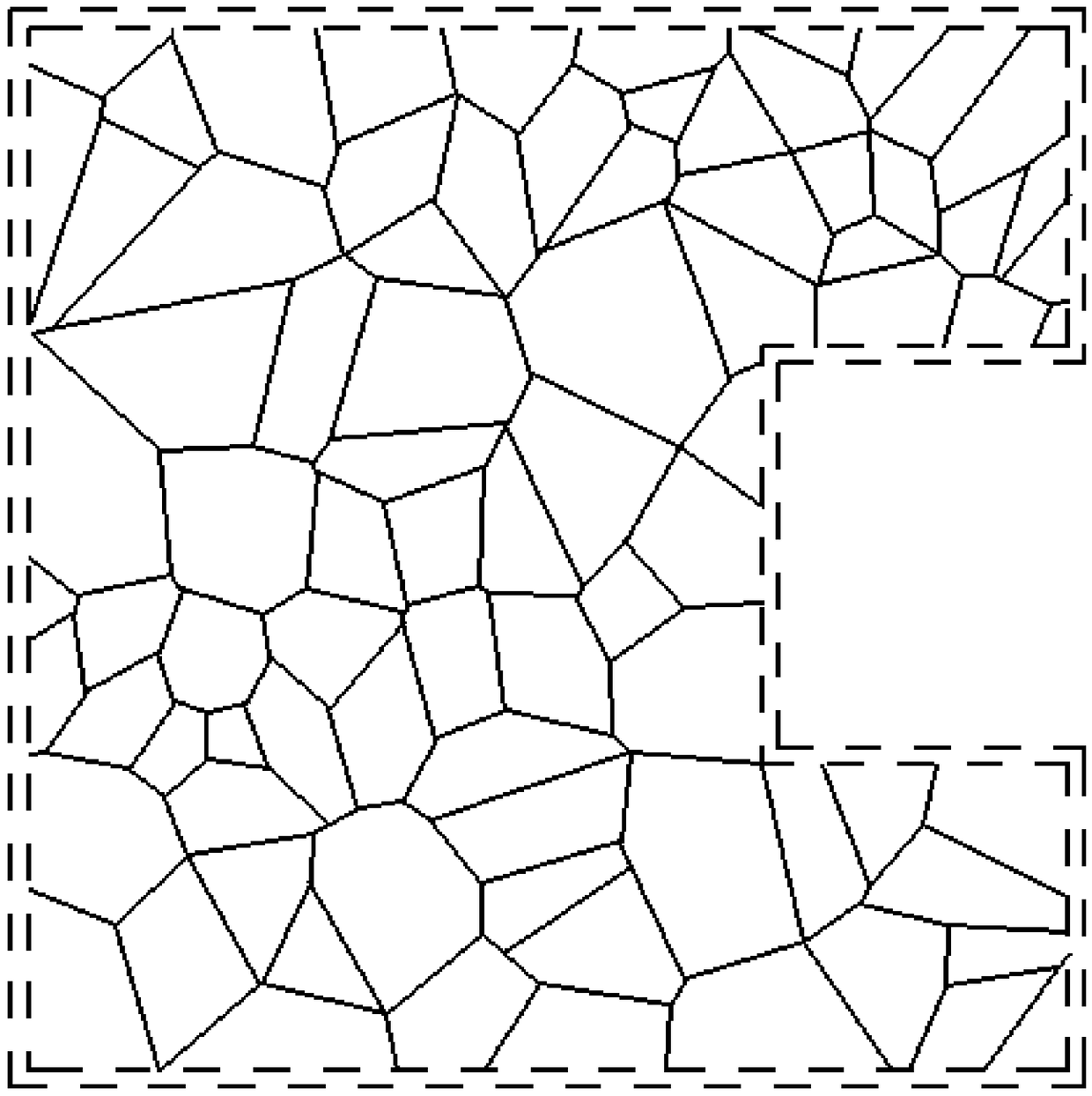

[0057] 2. If figure 2 As shown, the partition graph is divided, and the Thiessen polygon is constructed;

[0058] 2.1) Construct a triangle network;

[0059] 2.1.1) Randomly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com