Connection device of prestress concrete and steel combination wind power generation tower

A connecting device and prestressing technology, applied in wind turbine components, wind energy power generation, wind turbines, etc., can solve the problems of difficult to control crack width, uneven distribution of compressive stress, etc., to avoid stress concentration and uneven distribution, improve Transfer path, effect of controlling crack width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

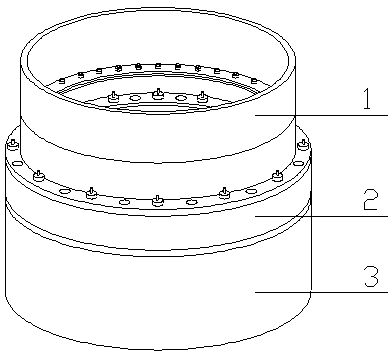

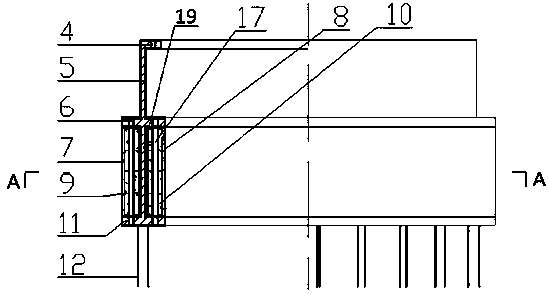

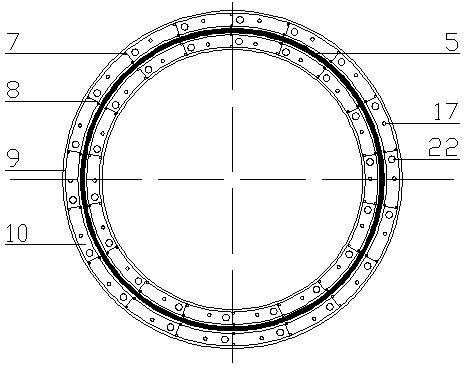

[0024] Such as figure 1 , Figure 4 As shown, a prestressed concrete-steel combined wind power tower connecting device includes a prestressing member 13 and a connecting member for connecting the upper steel tower section 1 and the lower concrete tower section 3 . Such as figure 2 , image 3 As shown, the connecting member includes the upper and lower connecting steel cylinders whose central axes coincide and have the same radius. The top of the upper connecting steel cylinder 5 is connected to the upper steel tower section 1 through a connecting mechanism; the upper connecting steel cylinder 5 is connected to the lower connecting steel cylinder. Between the cylinders 19 is the tension anchor flange 6, the bottom surface of the lower connection steel cylinder 19 is provided with a connection flange 11, the central axis of the tension anchor flange 6, the central axis of the lower connection steel cylinder 19 and the lower connection flange 11 The central axis is on a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com