Retainer for roller bearing

A roller bearing and cage technology, applied in the field of cages, can solve the problems of low wear resistance, low bending stress and mechanical strength, and achieve the effects of preventing abnormal wear, improving mechanical strength, and inhibiting wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Embodiments of the present invention will now be described with reference to the drawings.

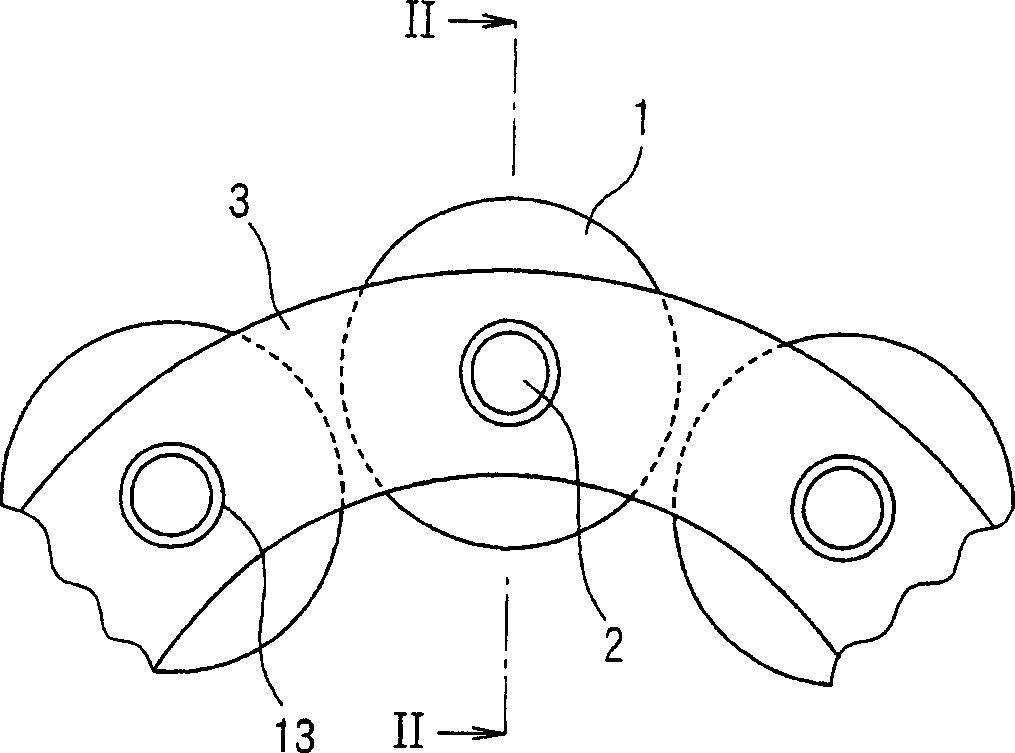

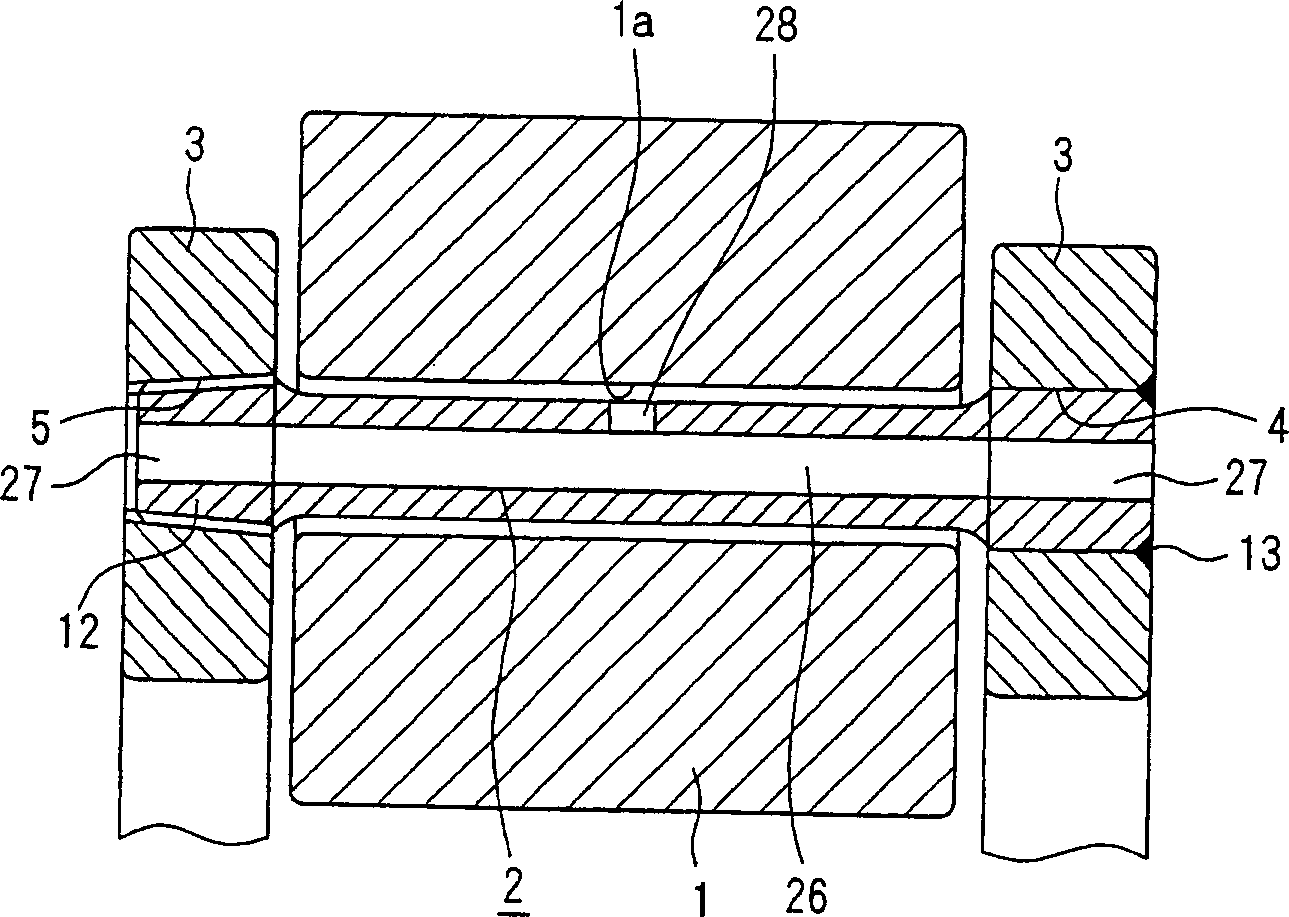

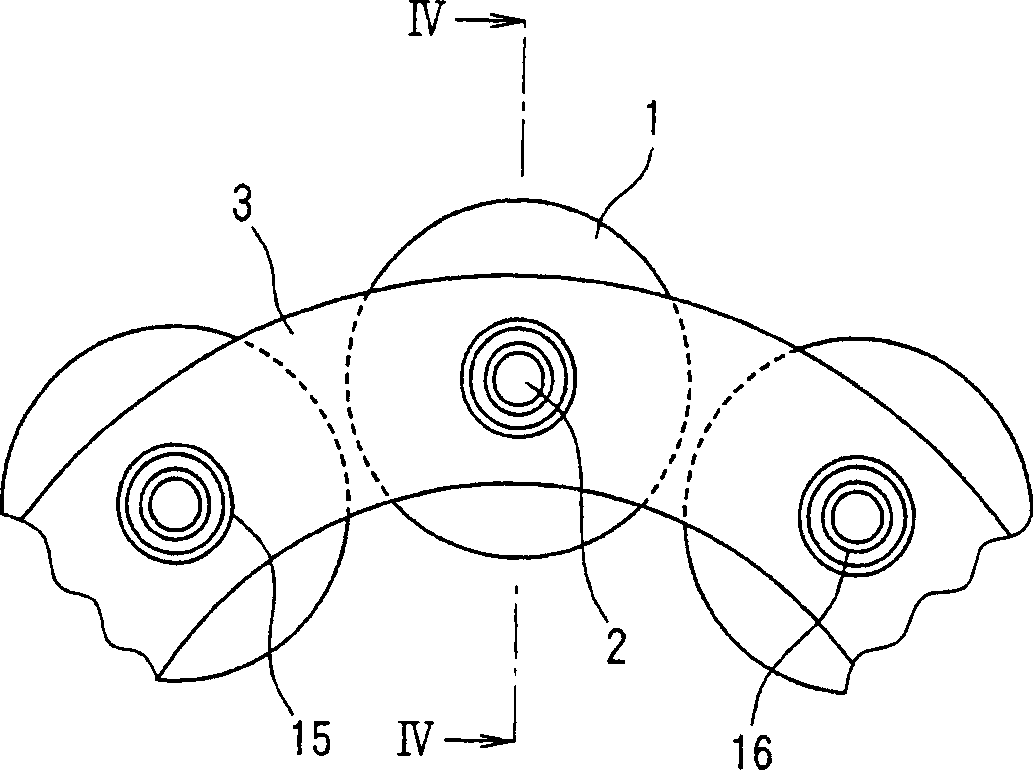

[0075] According to a first embodiment of the invention, a cage for a roller bearing comprises a plurality of pins 2 and a pair of annular side plates 3, 3, as figure 1 and 2 As shown, wherein the plurality of pins 2 are used to rotatably support a plurality of rolling elements 1 of the cylindrical roller bearing, and the annular side plate is used to hold the rolling elements by means of the pins, each rolling element 1 along The circumferential direction equidistant setting of the not shown bearing retaining ring.

[0076] The annular side plates 3, 3 are arranged oppositely, and the rolling body 1 formed in the shape of a cylindrical roller is placed between the pair of annular side plates, and in the pair of annular side plates 3, the figure 2 An annular side plate 3 on the left side is formed with a plurality of threaded holes 5, wherein the plurality of threaded holes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com