Oval single-tube two-way vacuum pipeline traffic system

A vacuum pipeline and transportation system technology, applied in tunnel systems, roads, rails, etc., can solve the problems of increased construction costs, increased vacuum formation and vacuum maintenance costs, and high consumption of pipeline materials, so as to save engineering costs and facilitate construction and installation. Check the effect of maintenance and simplification of construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

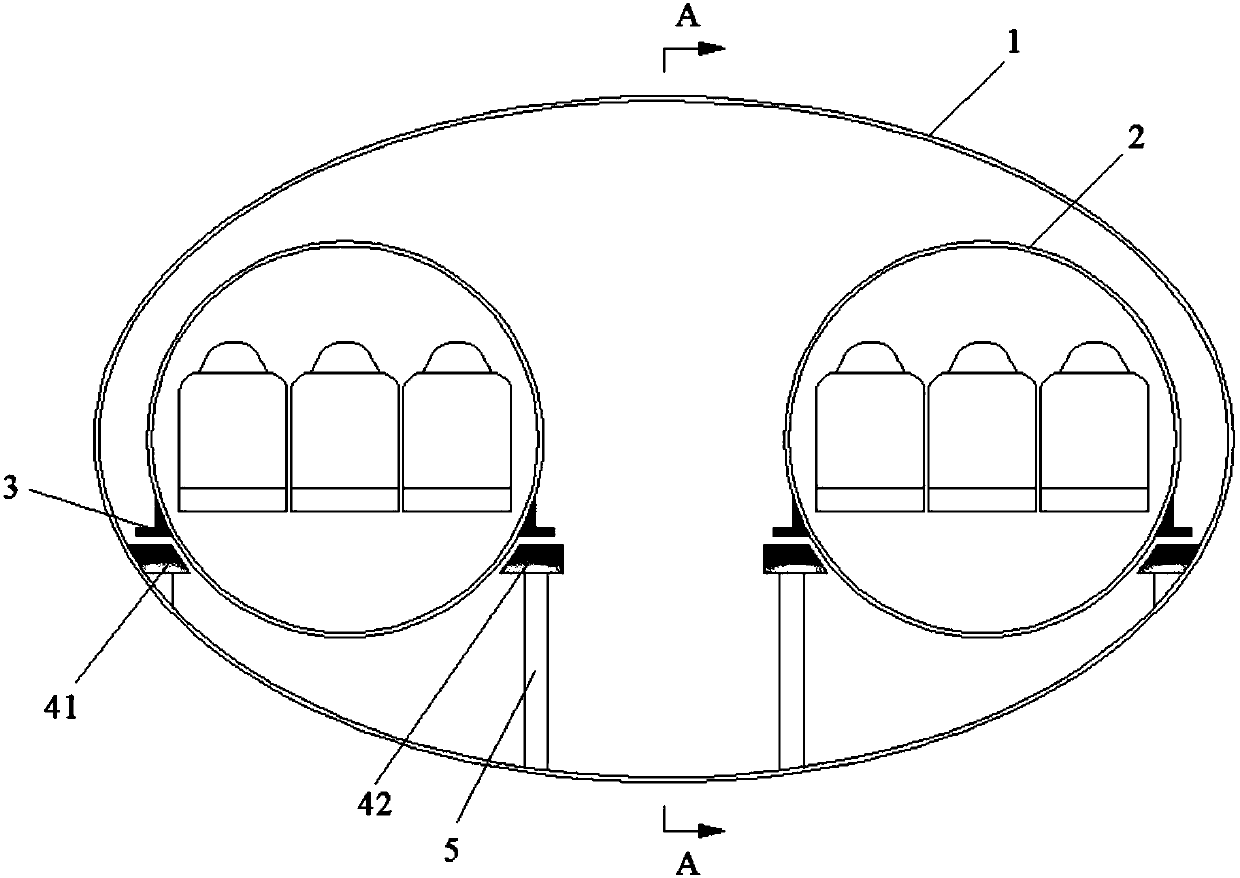

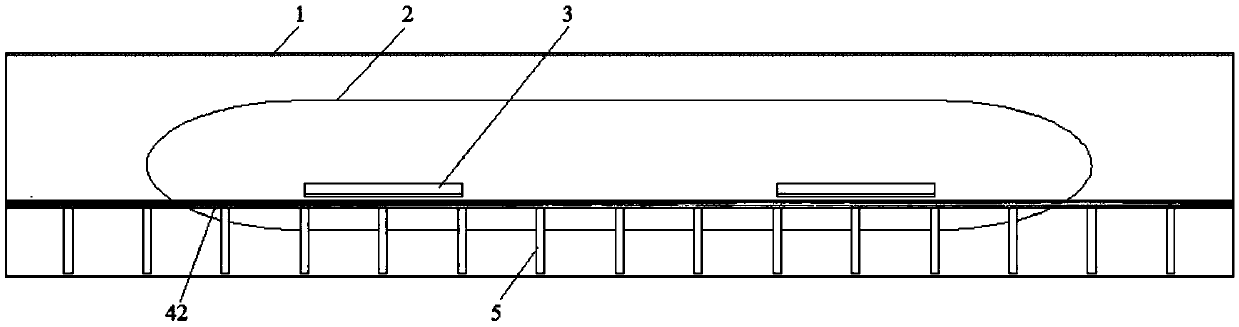

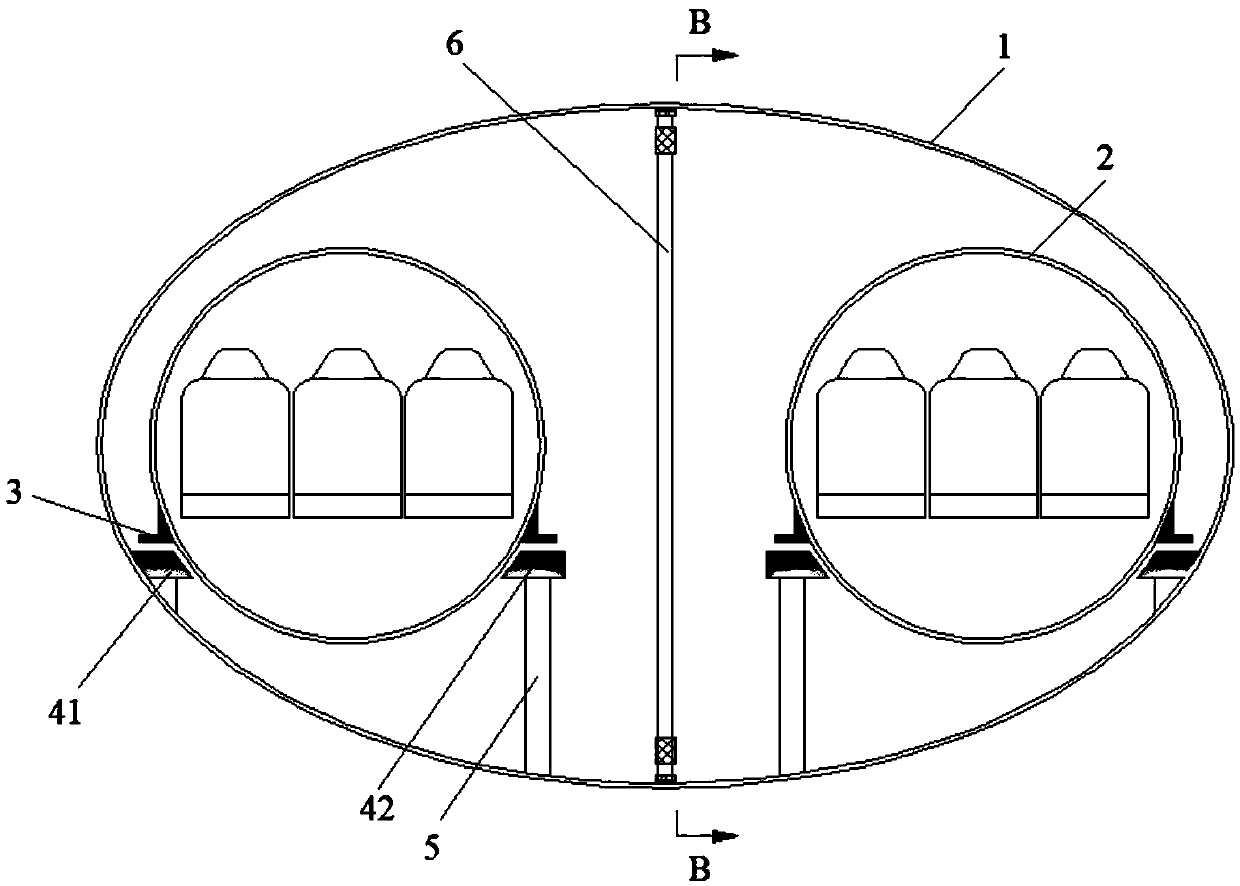

[0029] Such as figure 1 , figure 2 As shown, an elliptical single-tube two-way vacuum pipeline traffic system includes an elliptical pipeline 1, and a bidirectional running vehicle 2 is arranged in the elliptical pipeline 1, and suspension magnetic poles 3 on the vehicle are arranged on both sides of the running vehicle 2, and The suspension magnetic pole 3 cooperates with the outer suspension track 41 and the inner suspension track 42 respectively, the outer suspension track 41 is connected on the inner wall of the elliptical pipeline 1, and the inner suspension track 42 is supported on the inner wall of the elliptical pipeline 1 by the first support 5 of the track.

[0030] The ratio of the length of the major axis to the minor axis of the section of the elliptical pipeline 1 is 1.5-1.9, wherein the minor axis, that is, the inner height of the pipeline, is 2.2-3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com