Patents

Literature

72results about How to "Prevent bypass flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

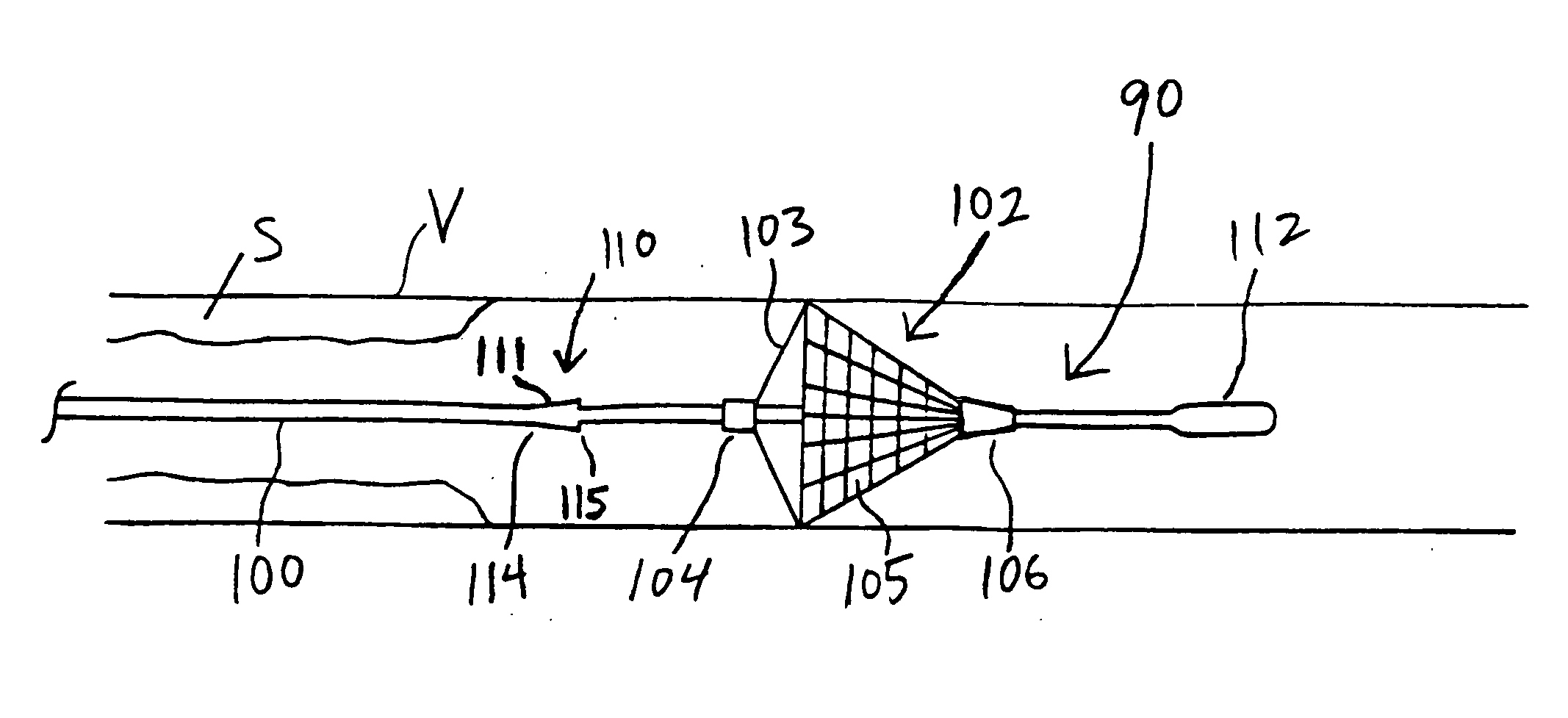

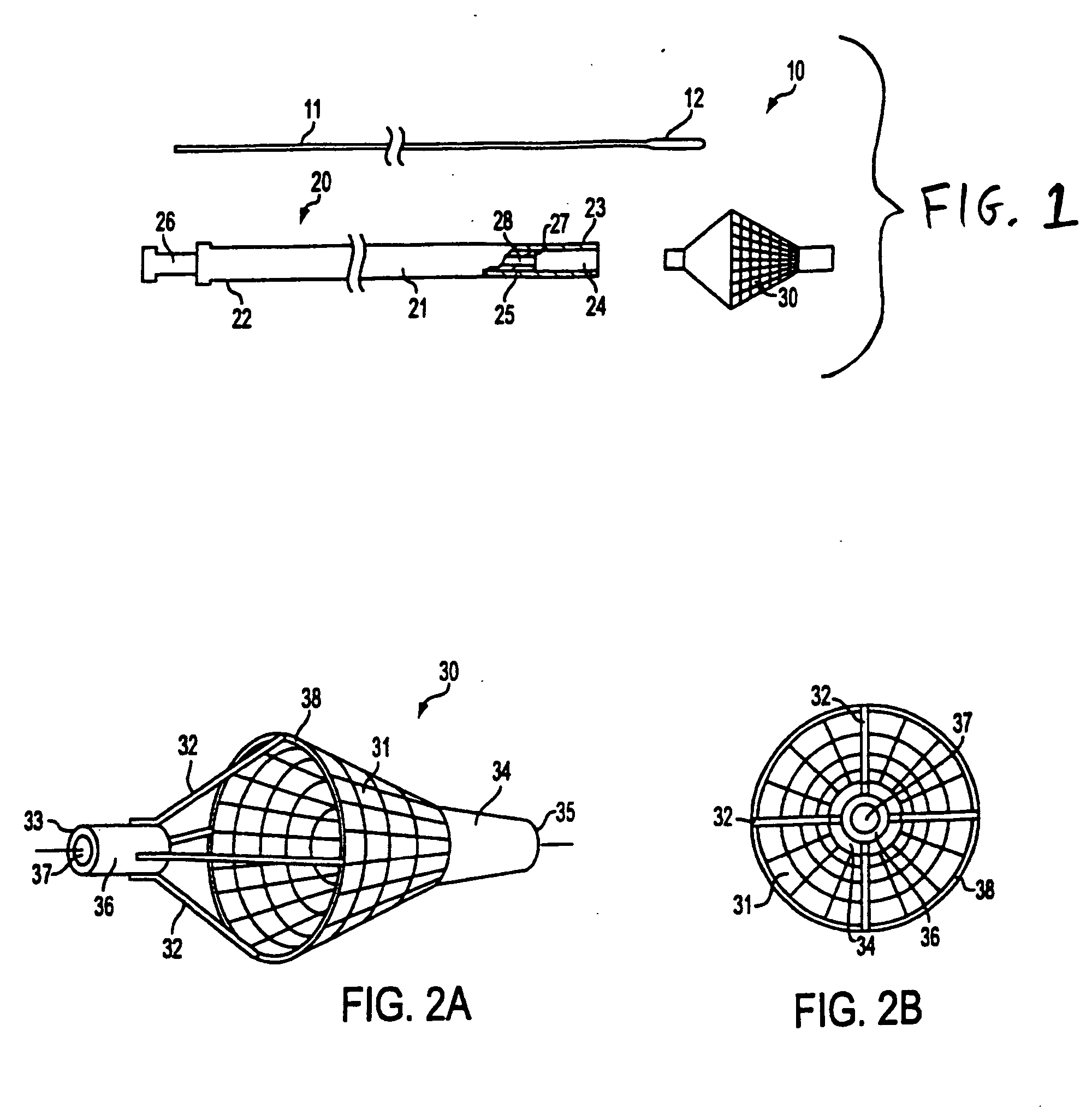

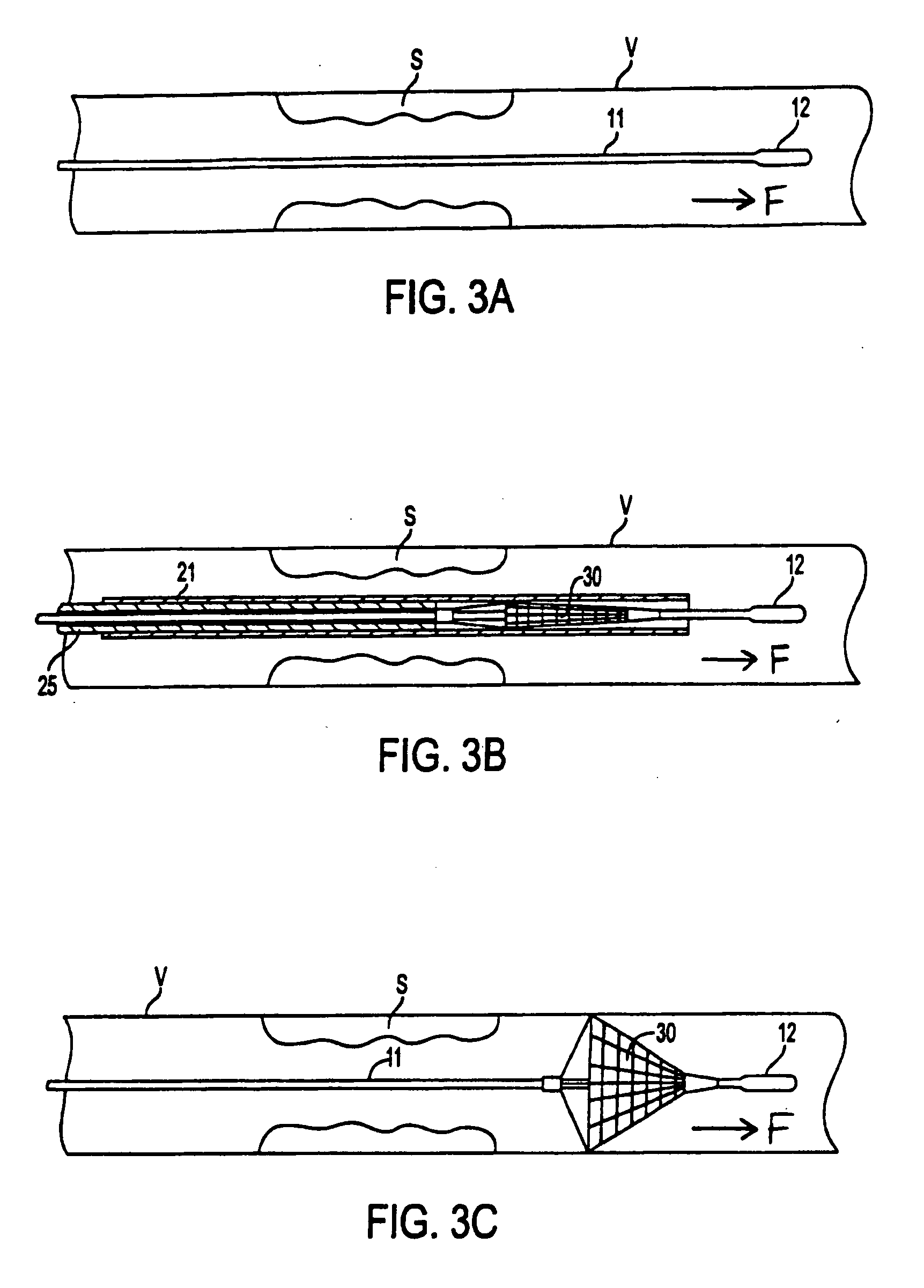

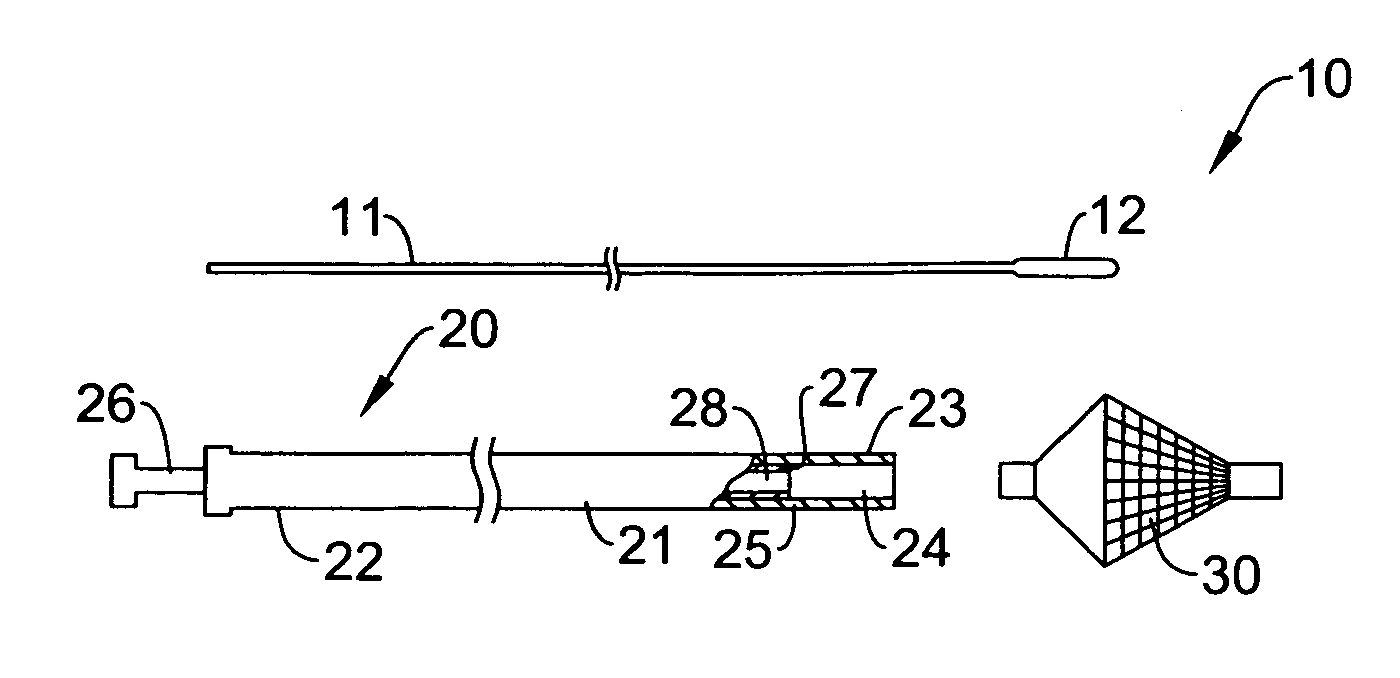

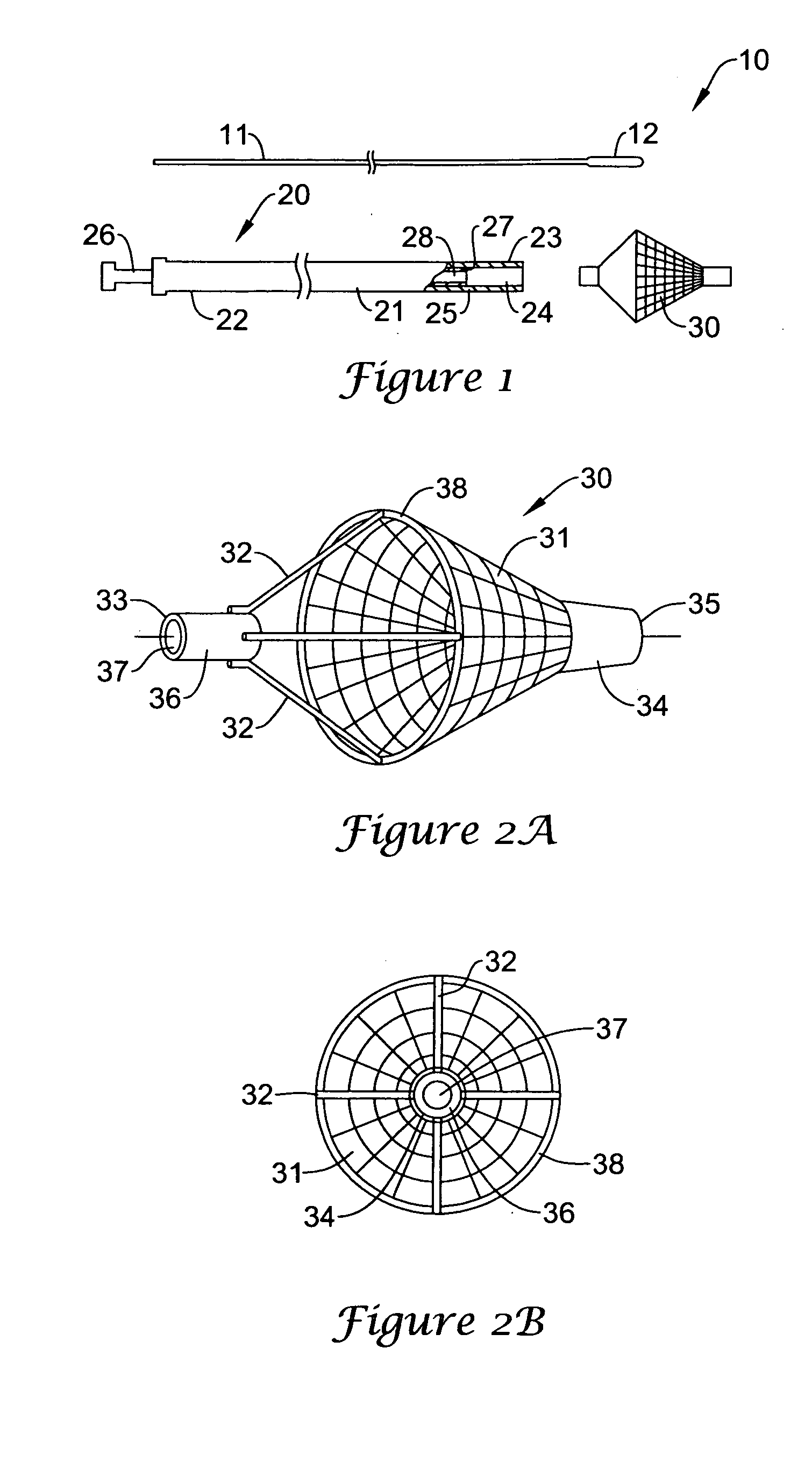

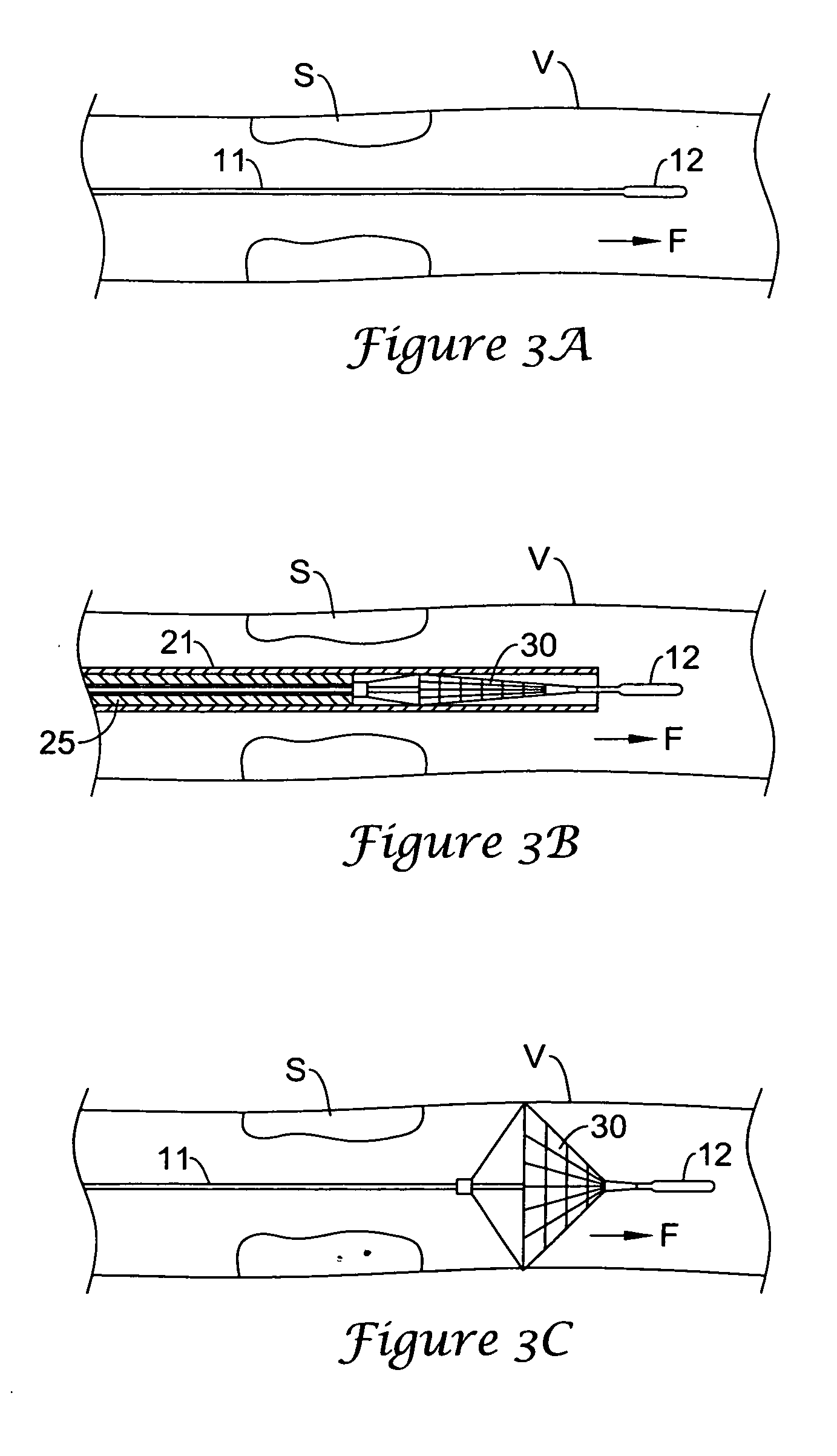

Emboli filtration system and methods of use

InactiveUS20050125023A1Prevent bypass flowReduce riskCannulasGuide wiresBiomedical engineeringMedical procedure

An emboli filtration apparatus is provided comprising a guide wire having a filter element captured thereon, so that the guide wire is free to rotate and translate while the filter element remains stationary. The apparatus allows for movement and rotation of the guide wire as devices are advanced over it to treat occlusive disease, substantially without dislodging the filter element. In a preferred embodiment, the guide wire comprises a proximal stop configured to reposition the filter element during a medical procedure without having to remove or insert additional interventional devices.

Owner:BOSTON SCI SCIMED INC

Emboli filtration system and methods of use

InactiveUS20050182440A1Reduce riskAvoid Insufficient SealingGuide wiresSurgeryFree rotationFiltration

Owner:BOSTON SCI SCIMED INC

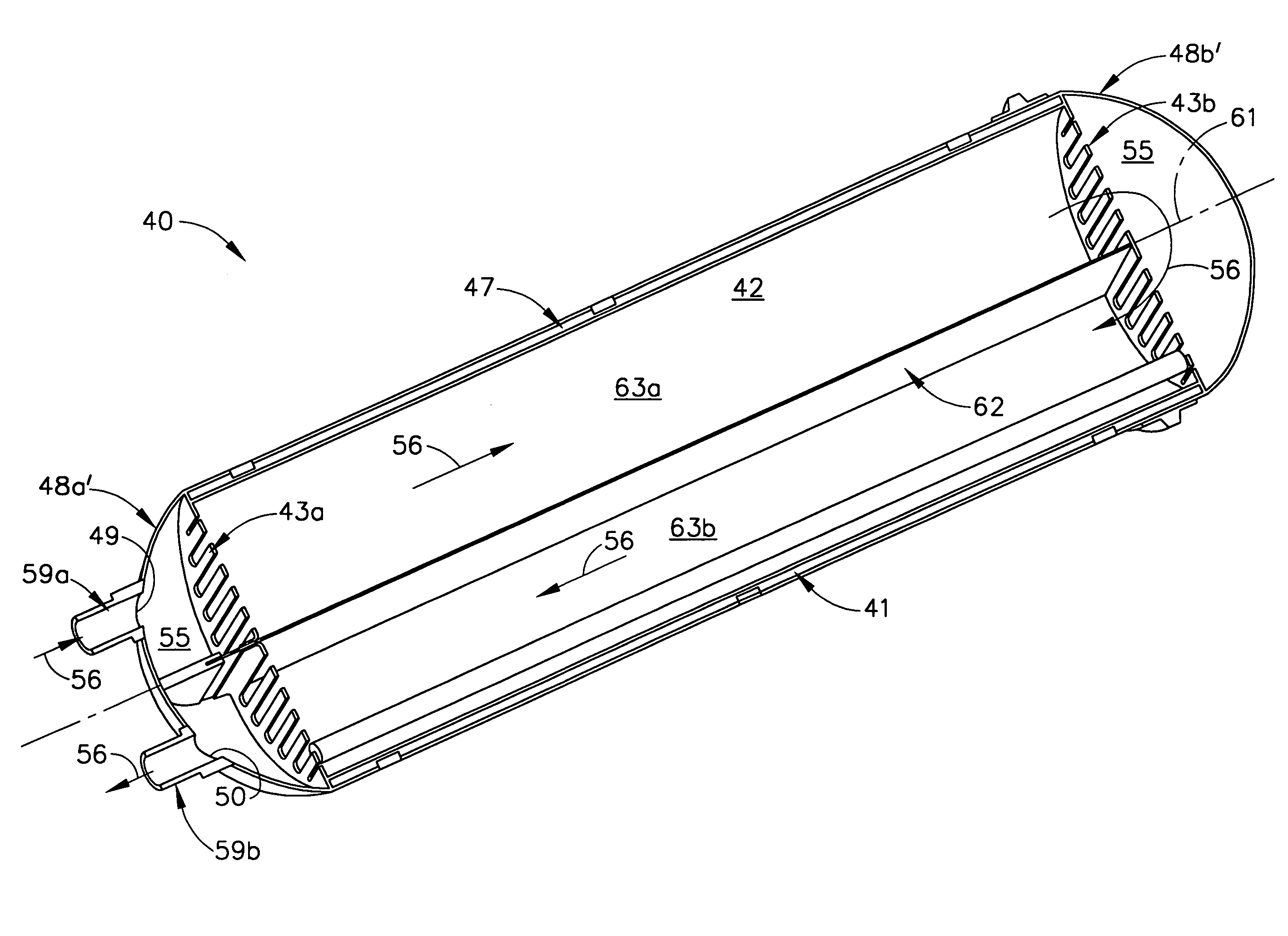

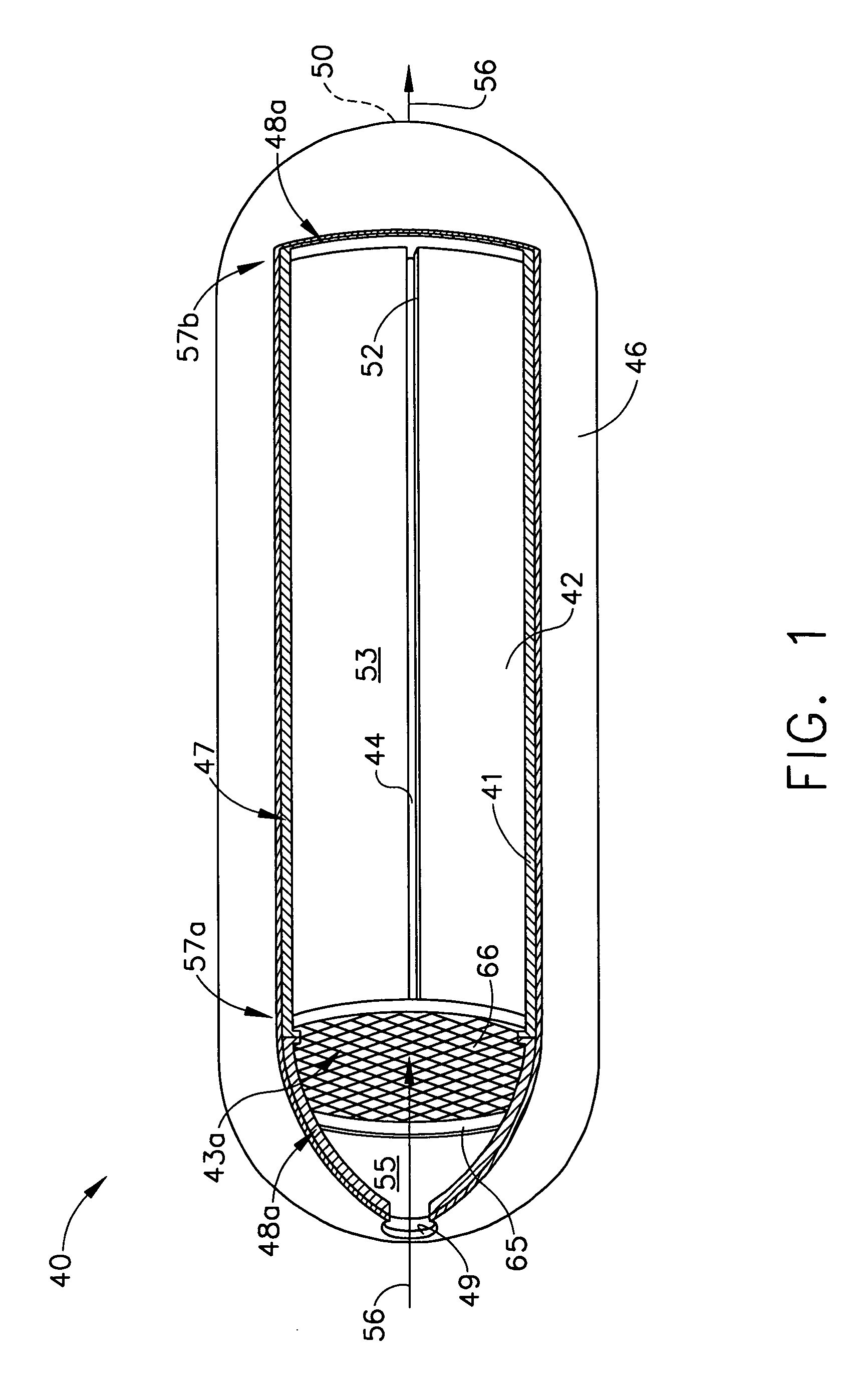

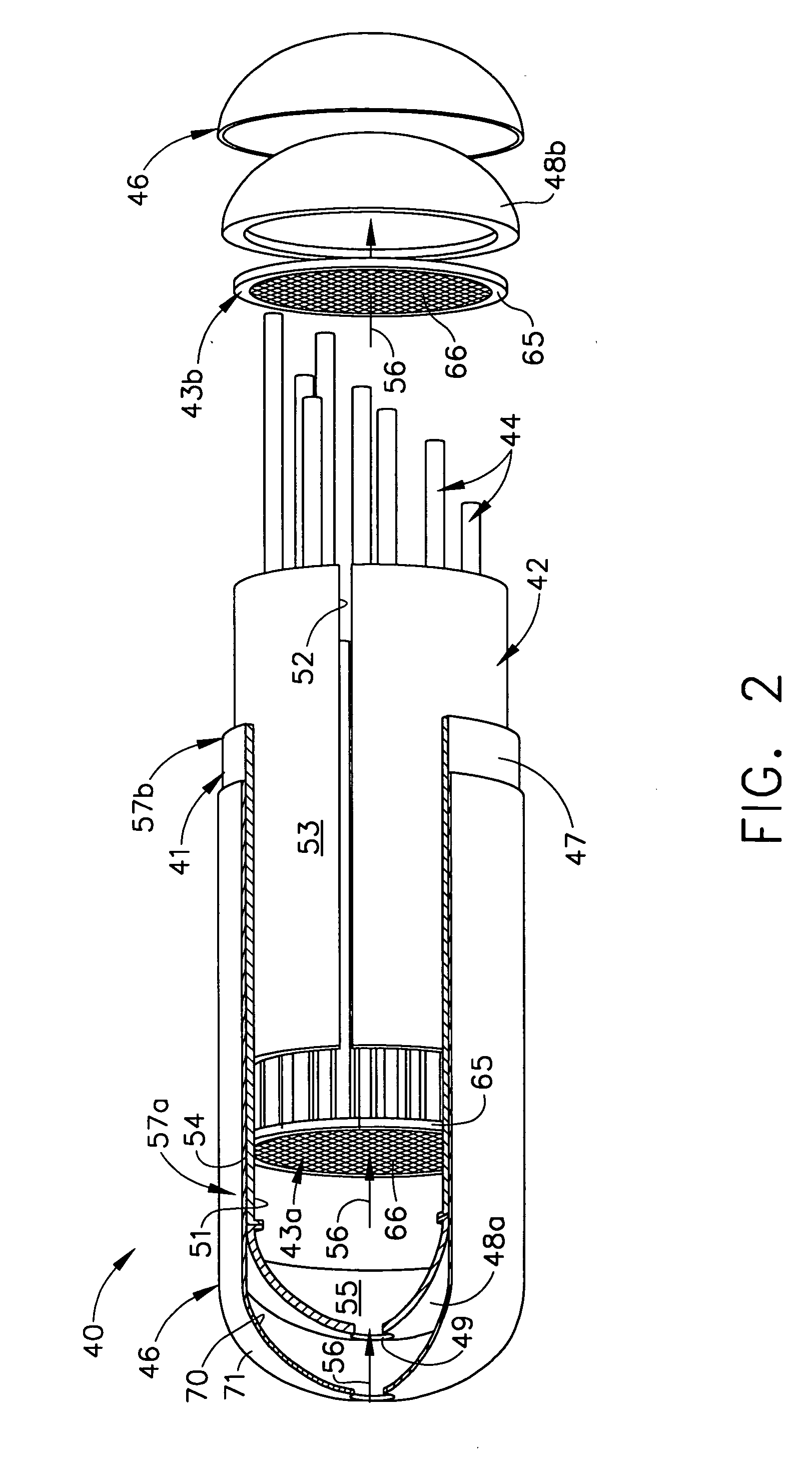

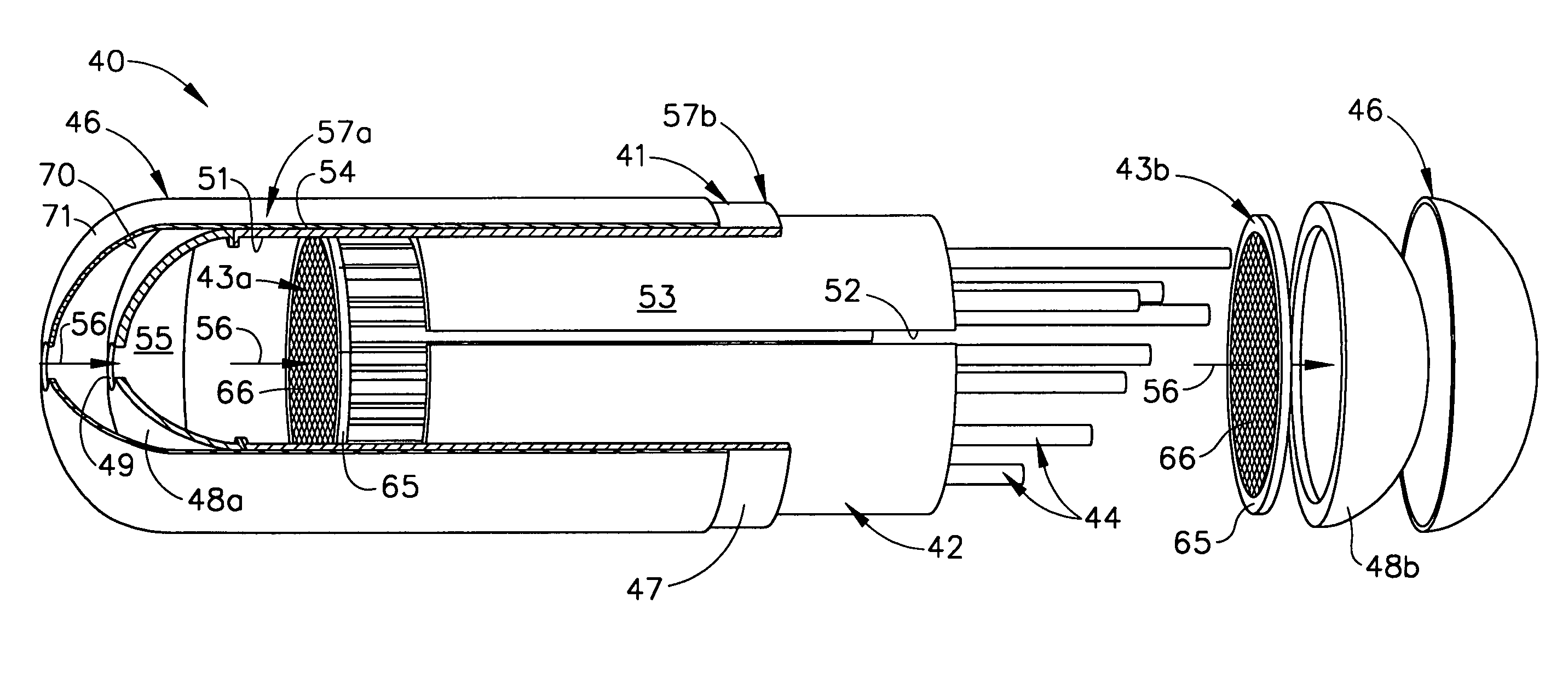

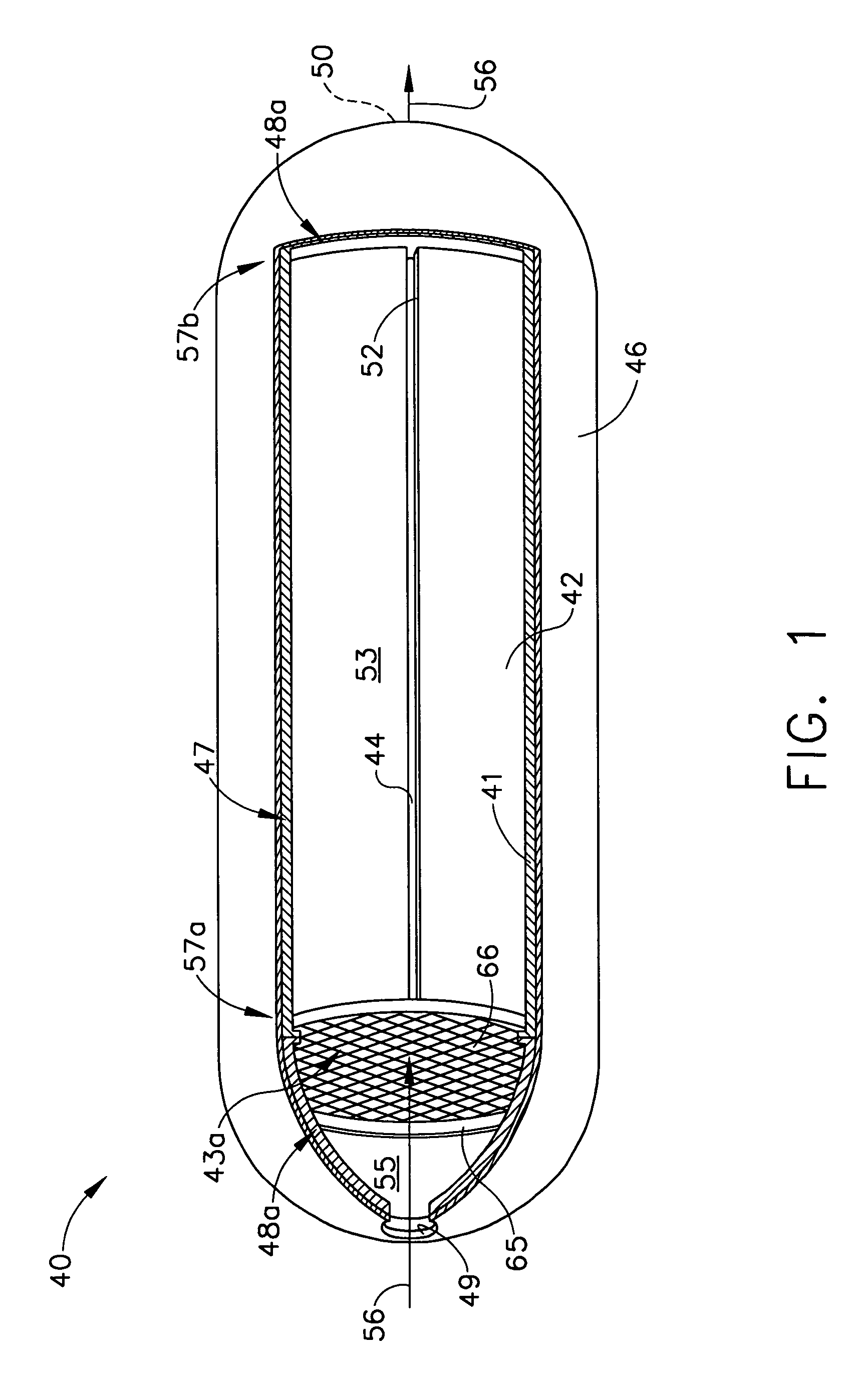

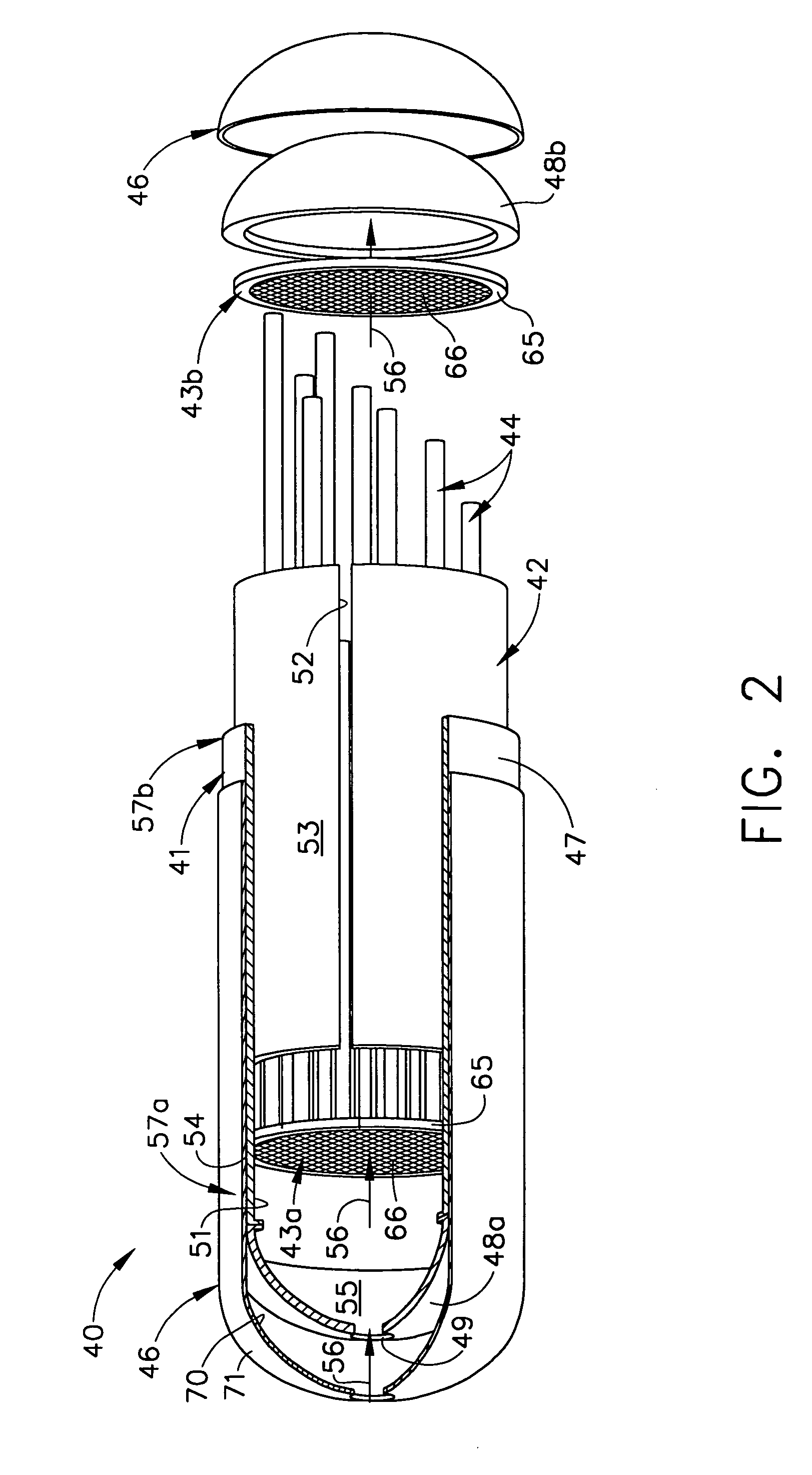

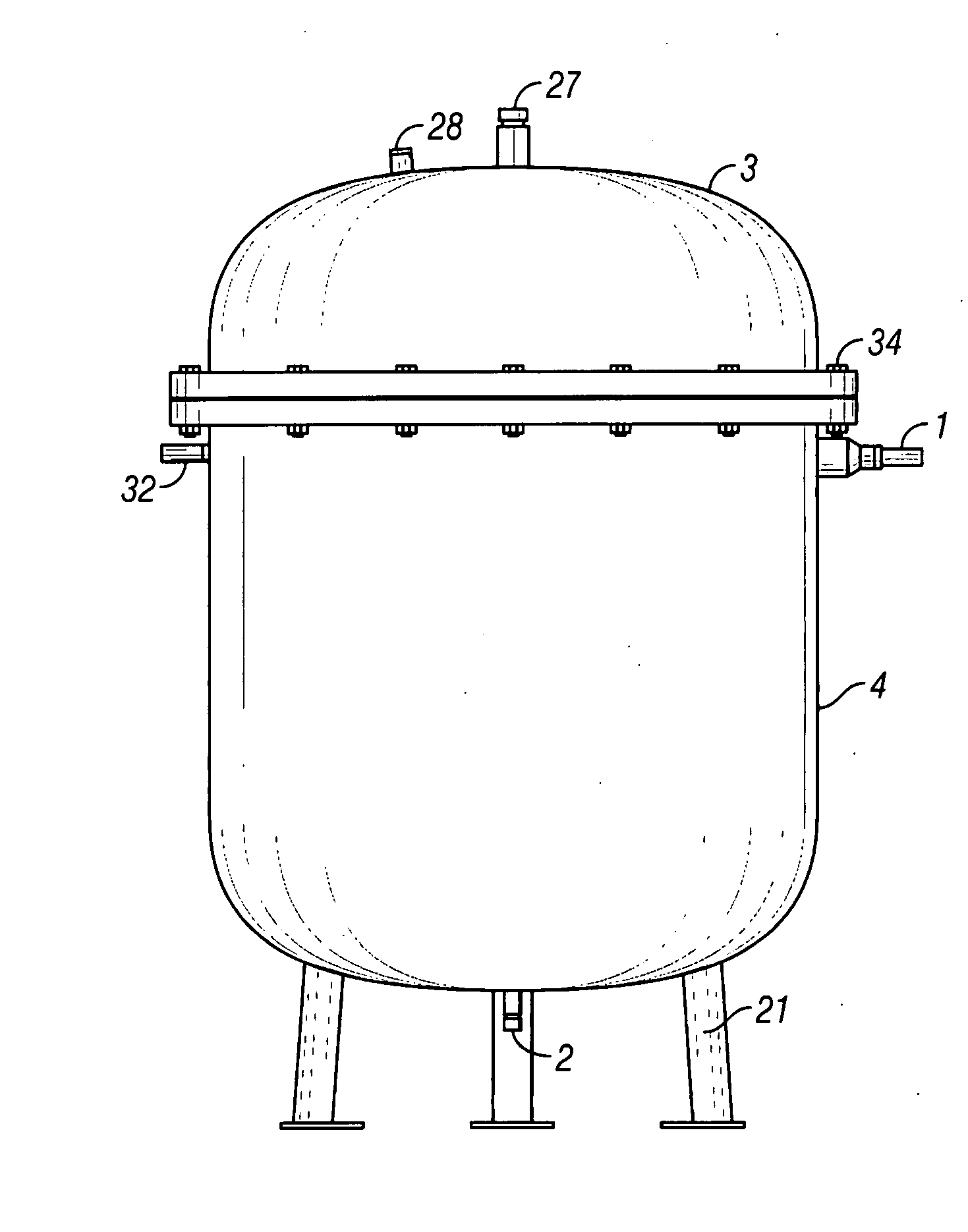

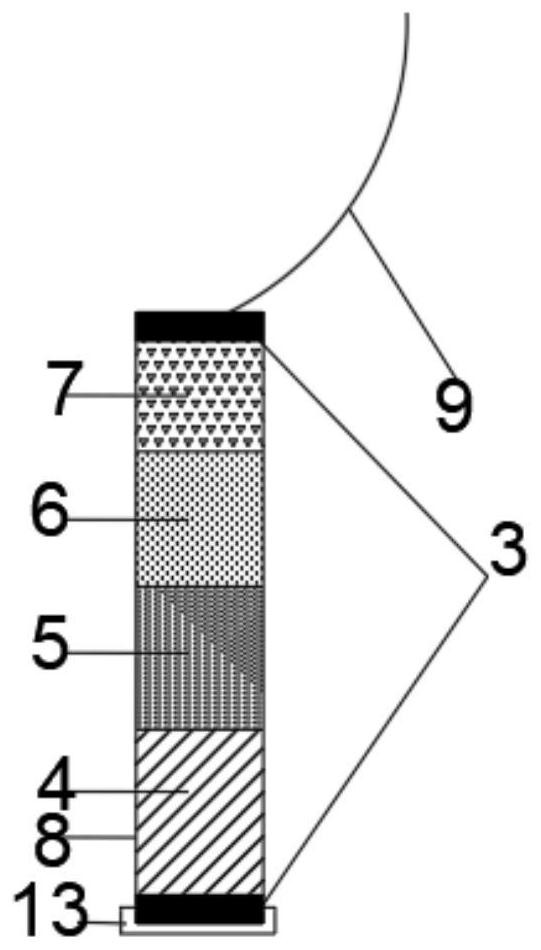

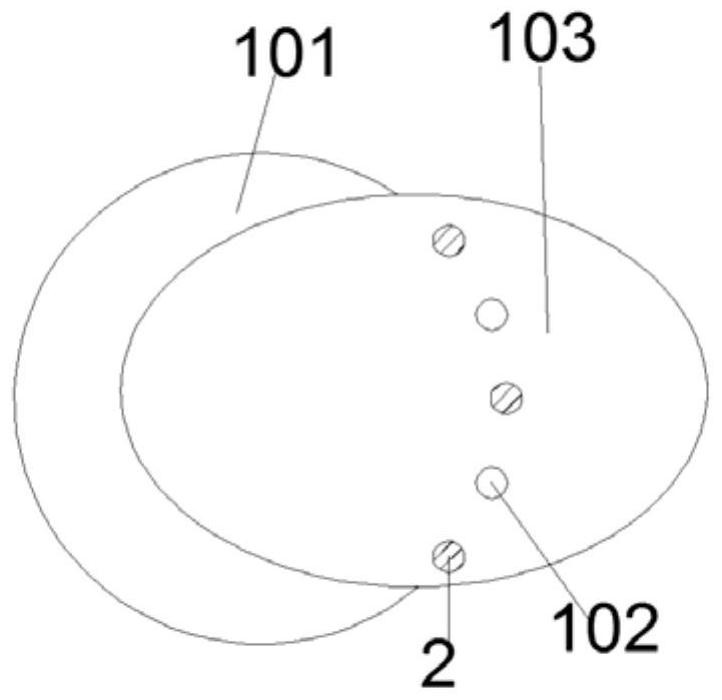

Compact heat battery

ActiveUS20070029064A1Decrease parasitic heat leakageIncreasing usable heat availableHeat storage plantsStorage heatersElectrical batteryEngineering

A compact heat battery (CHB) may comprise a casing, a tube containment sheath, a bundle of hermetically sealed phase change material (PCM) encapsulation tubes, and encapsulation tube inserts. An insulation envelope and insulation shield may be positioned radially outward from the casing. As an alternative the casing, insulation, and insulation shield can be integrated into a double-walled vacuum cylinder. The cylindrical containment sheath can open and close along a split-seam in response to radial expansion of the tubes. The natural packing of the encapsulation tubes within the containment sheath can distribute a heat transfer fluid through the interstitial spaces between the encapsulation tubes. Floating baffle plates provide for axial containment and expansion of the encapsulation tube bundle. The CHB of the present invention can allow for increased tube density, providing increased heat absorption and decreased CHB dimensions. The encapsulation tube inserts can provide slip planes to reduce expansive loading of the encapsulation tube walls during solid phase transition.

Owner:HONEYWELL INT INC

Compact heat battery

ActiveUS7225860B2Decrease parasitic heat leakageIncreasing usable heat availableHeat storage plantsStorage heatersHermetic sealElectrical battery

A compact heat battery (CHB) may comprise a casing, a tube containment sheath, a bundle of hermetically sealed phase change material (PCM) encapsulation tubes, and encapsulation tube inserts. An insulation envelope and insulation shield may be positioned radially outward from the casing. As an alternative the casing, insulation, and insulation shield can be integrated into a double-walled vacuum cylinder. The cylindrical containment sheath can open and close along a split-seam in response to radial expansion of the tubes. The natural packing of the encapsulation tubes within the containment sheath can distribute a heat transfer fluid through the interstitial spaces between the encapsulation tubes. Floating baffle plates provide for axial containment and expansion of the encapsulation tube bundle. The CHB of the present invention can allow for increased tube density, providing increased heat absorption and decreased CHB dimensions. The encapsulation tube inserts can provide slip planes to reduce expansive loading of the encapsulation tube walls during solid phase transition.

Owner:HONEYWELL INT INC

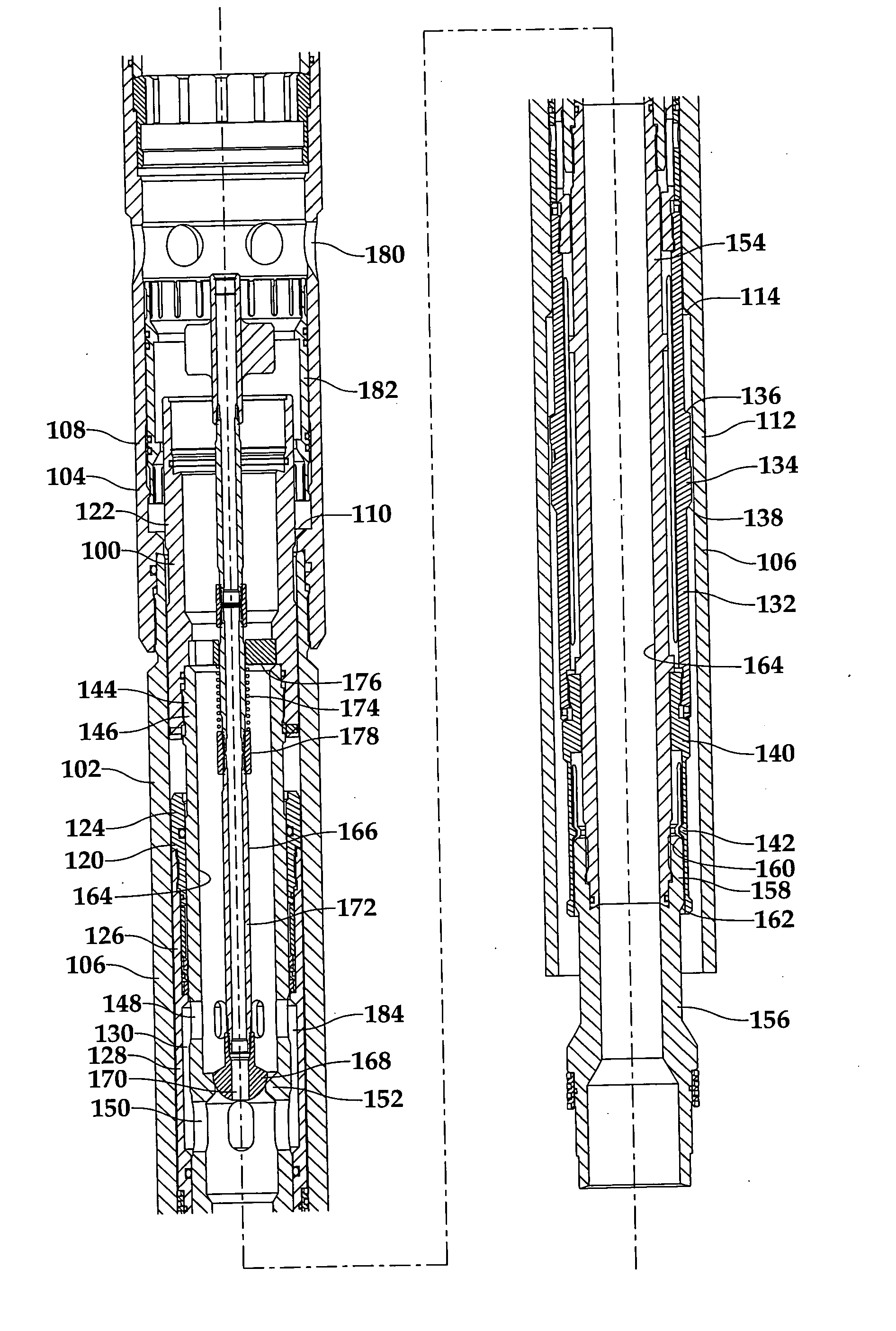

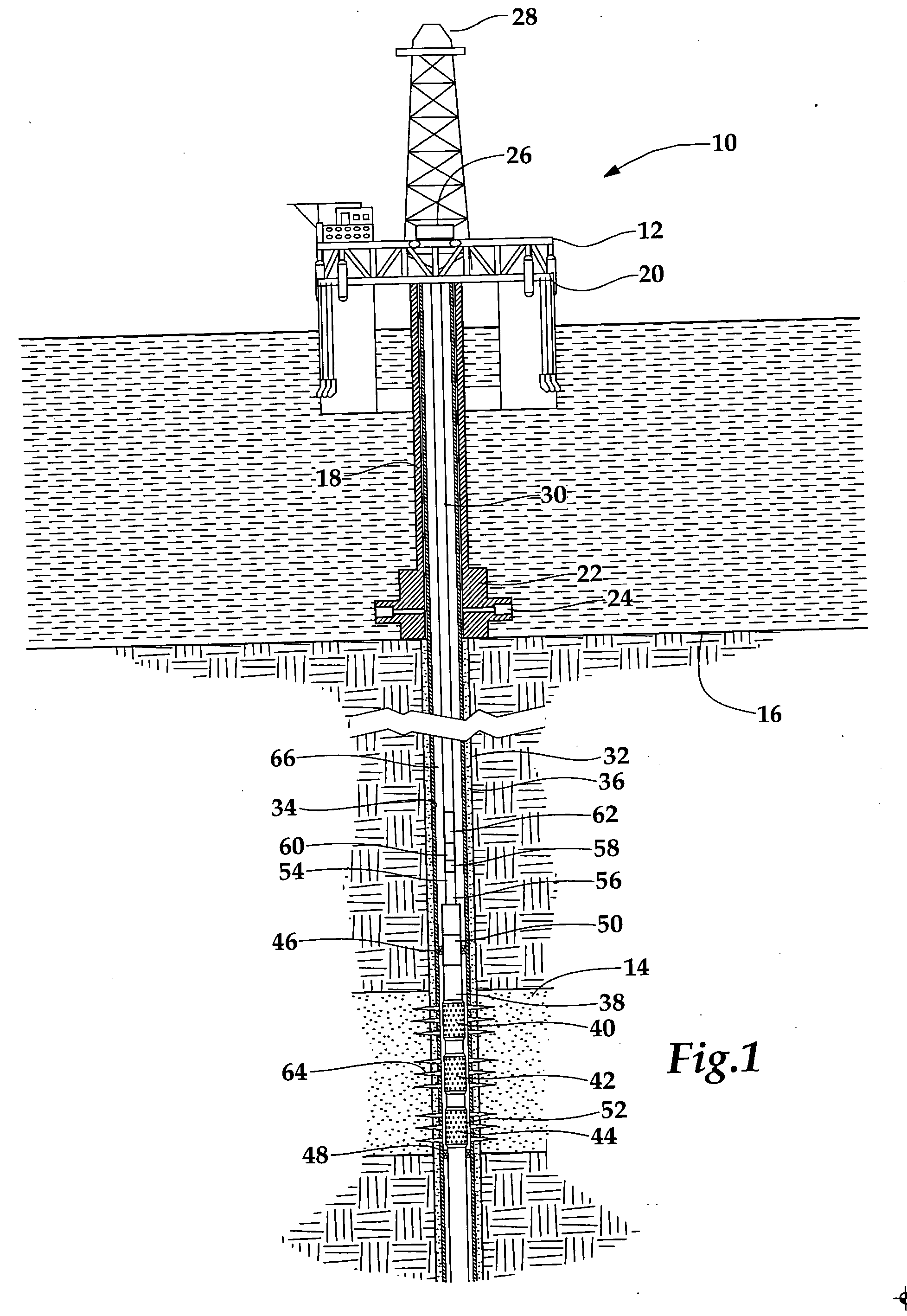

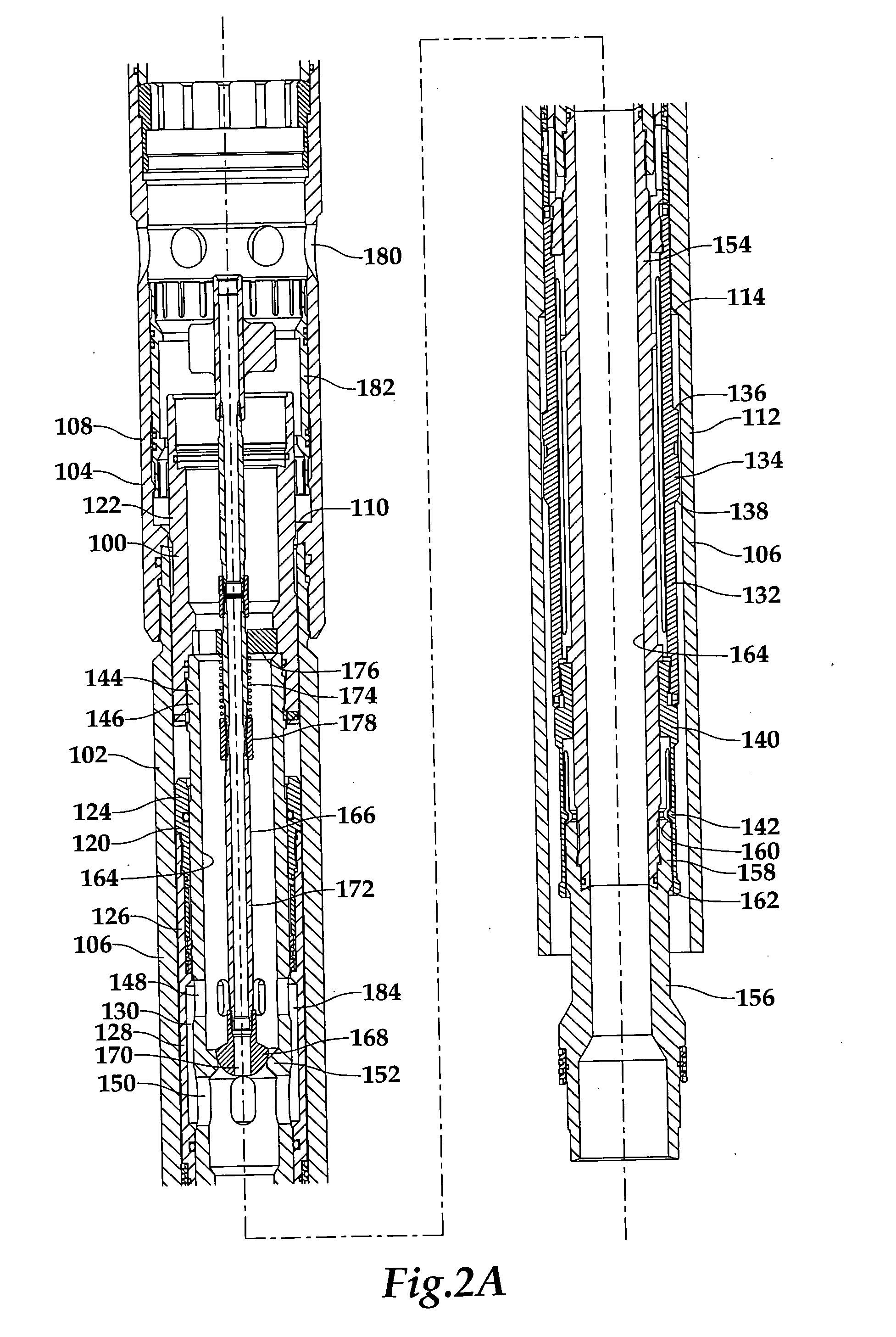

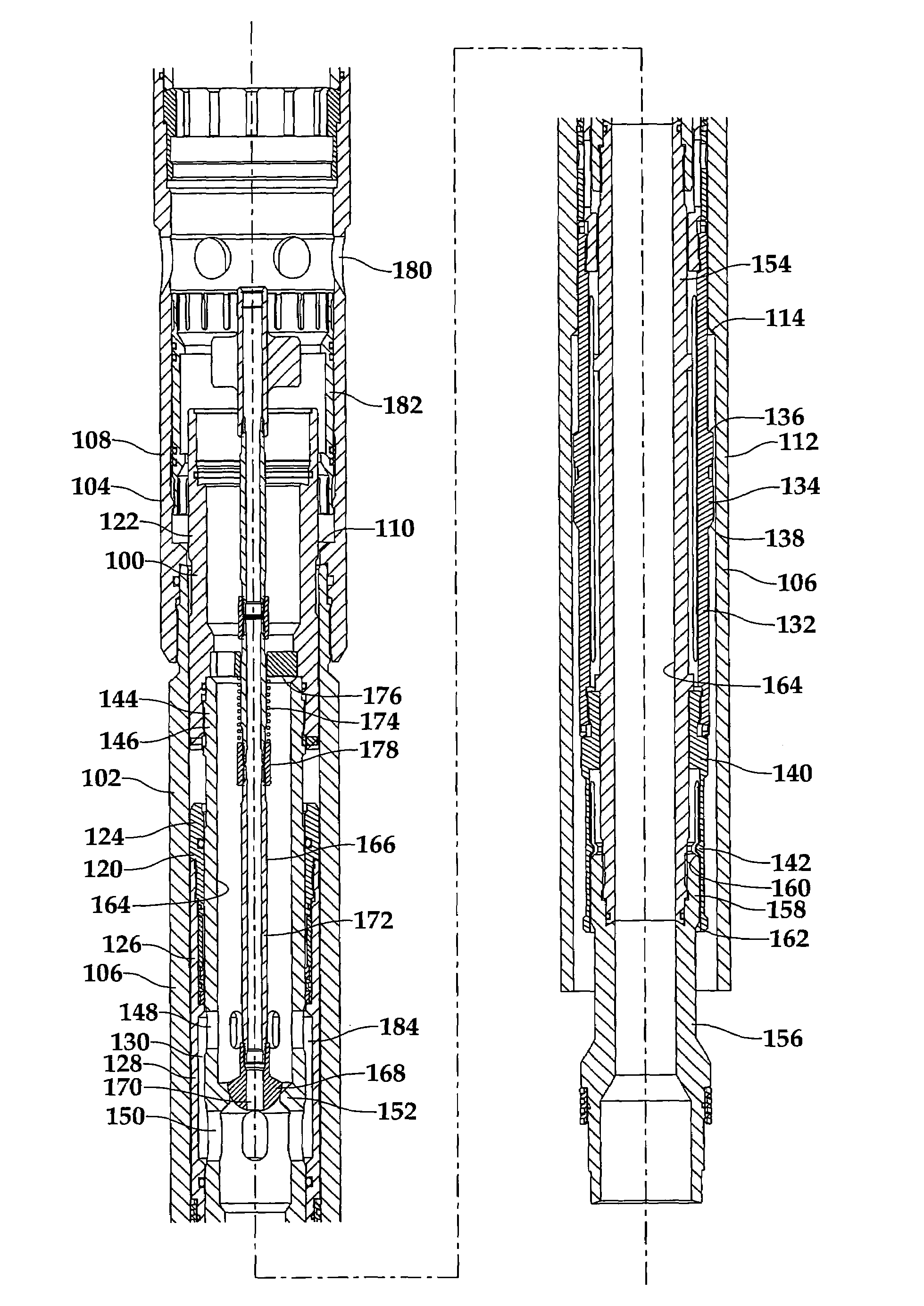

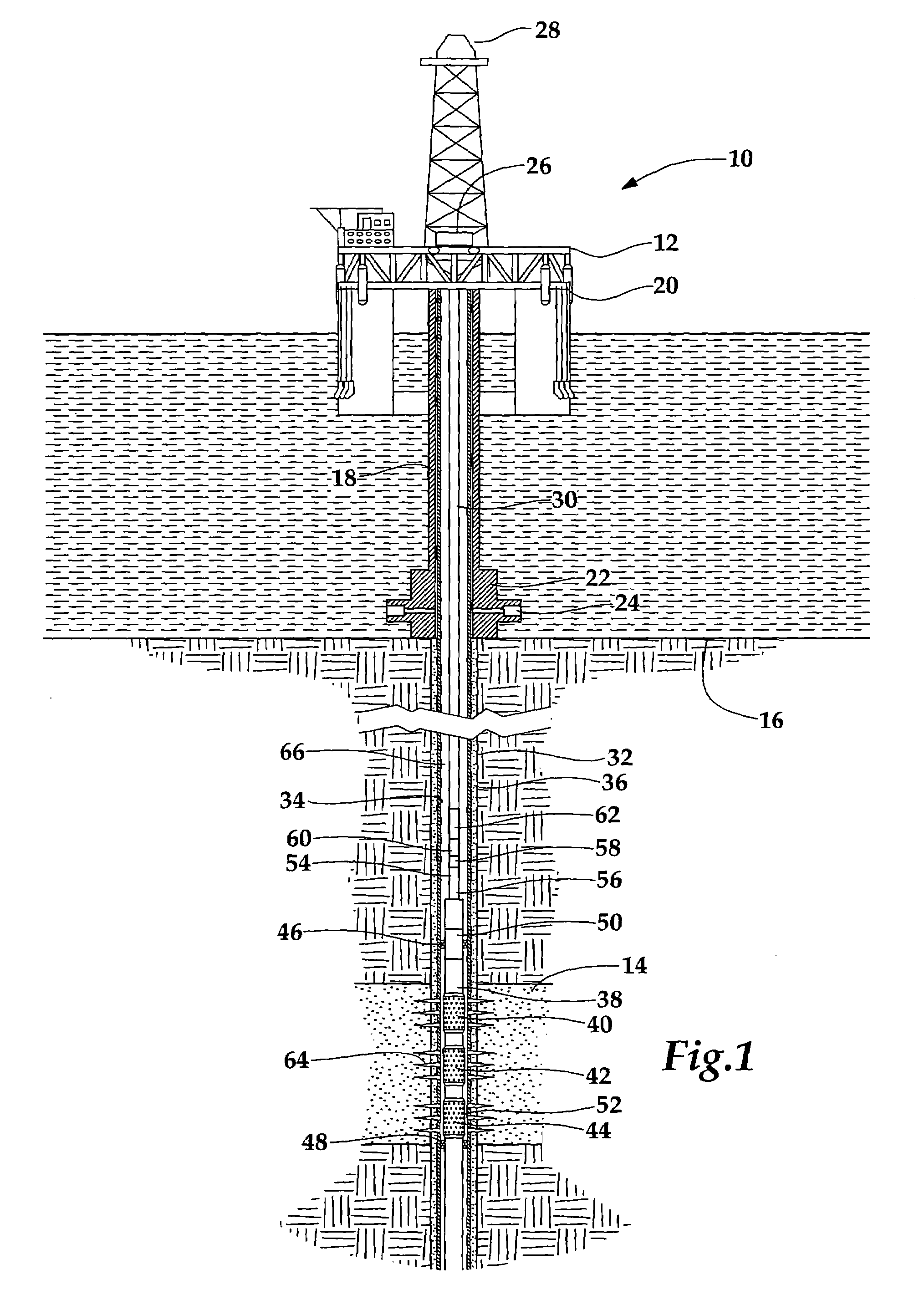

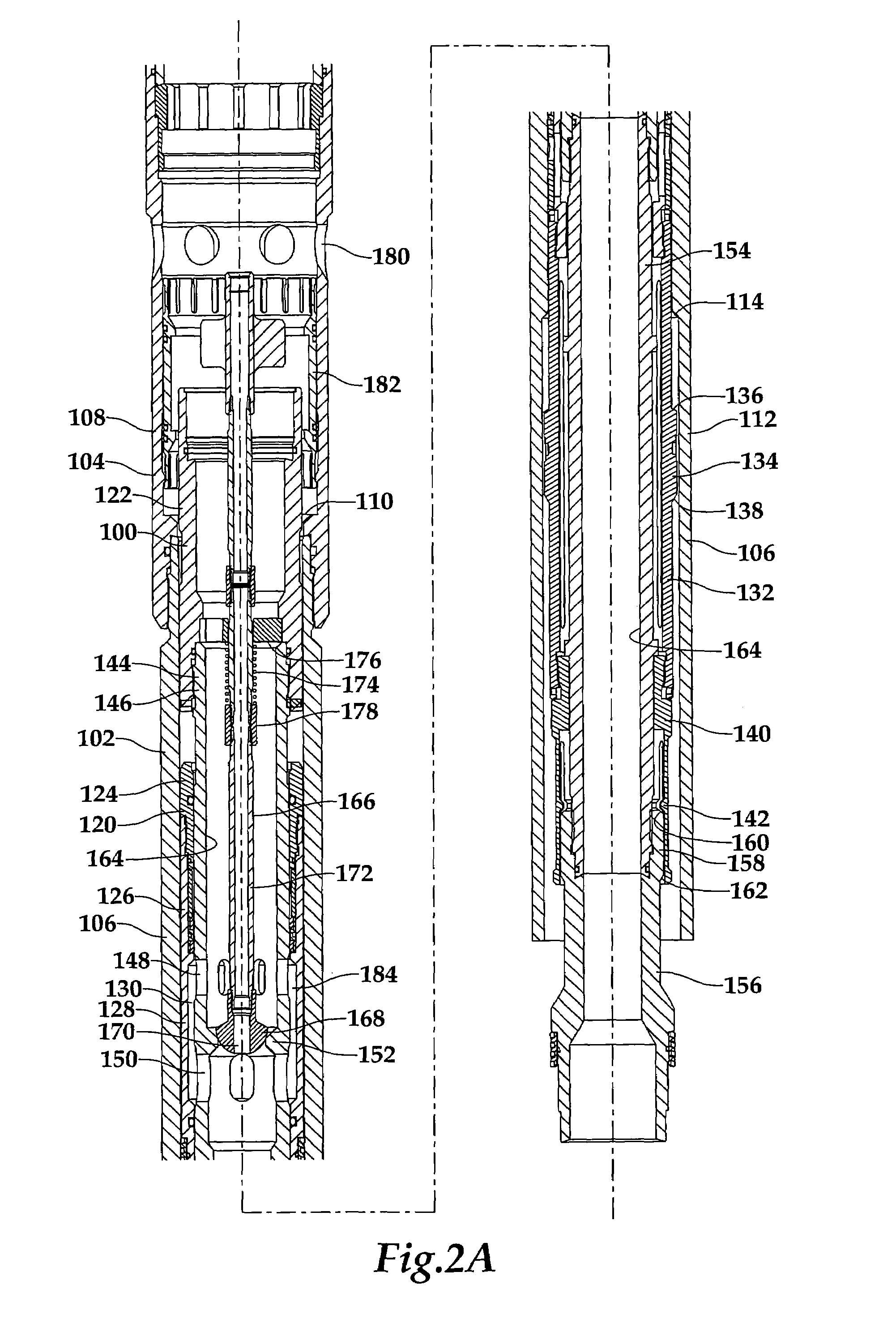

Reverse out valve for well treatment operations

A reverse out valve (100) comprises an outer housing (120) and a mandrel (144) that form a bypass region (130) therebetween. The mandrel (144) includes a central flow path (164) with a valve seat (152) positioned therein and first and second side wall ports (148, 150). A valve element (168) is positioned in the central flow path (164). The valve element (168) and the valve seat (152) having a one way valve configuration that prevents downhole fluid flow and allows uphole fluid flow. The mandrel (144) is axially movable relative to the outer housing (120) between first and second positions. In the first position, a bypass passageway (184) is formed between the first and second side wall ports (148, 150) via the bypass region (130) thereby allowing bypass flow around the valve element (168) and the valve seat (152). In the second position, bypass flow is prevented.

Owner:HALLIBURTON ENERGY SERVICES INC

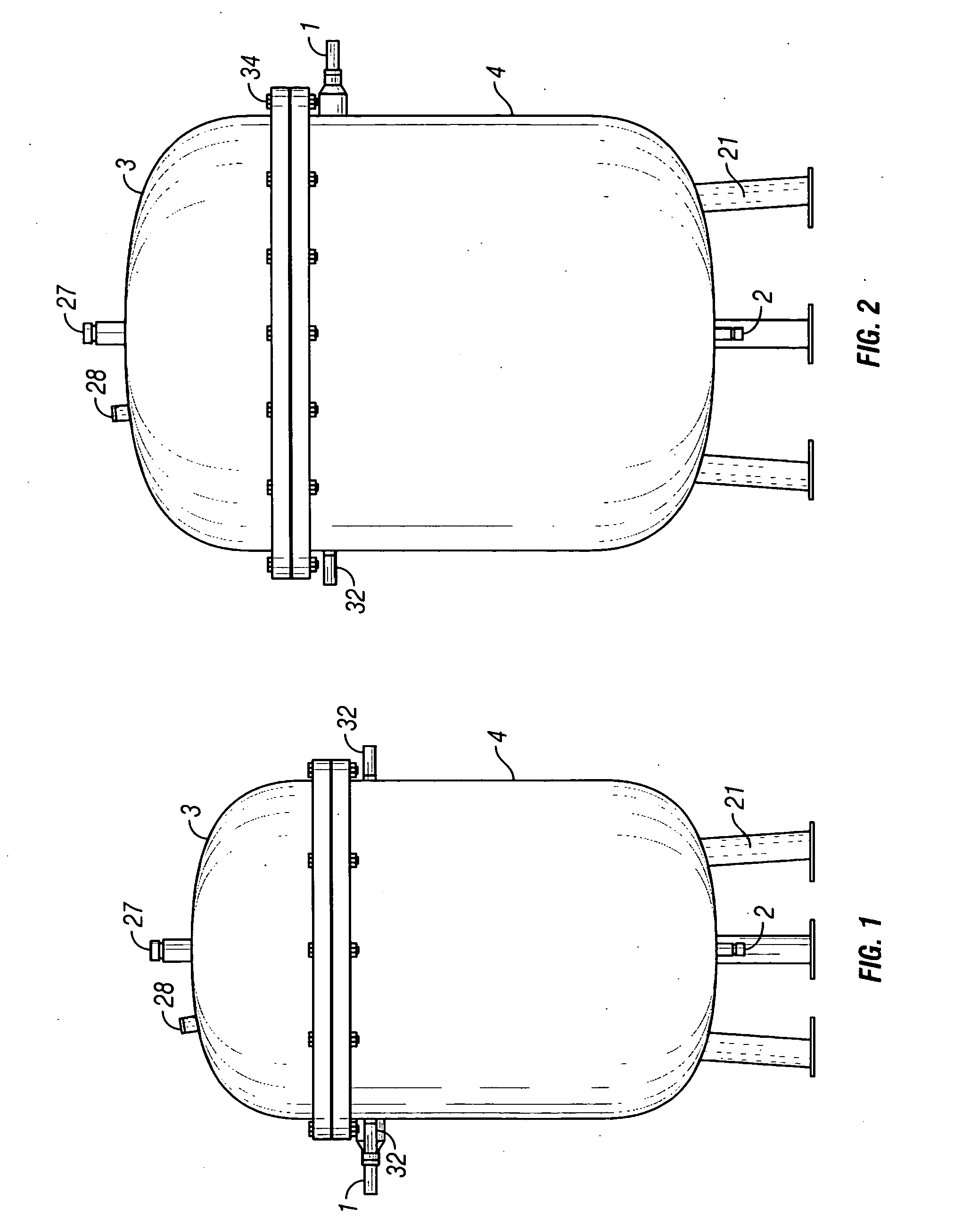

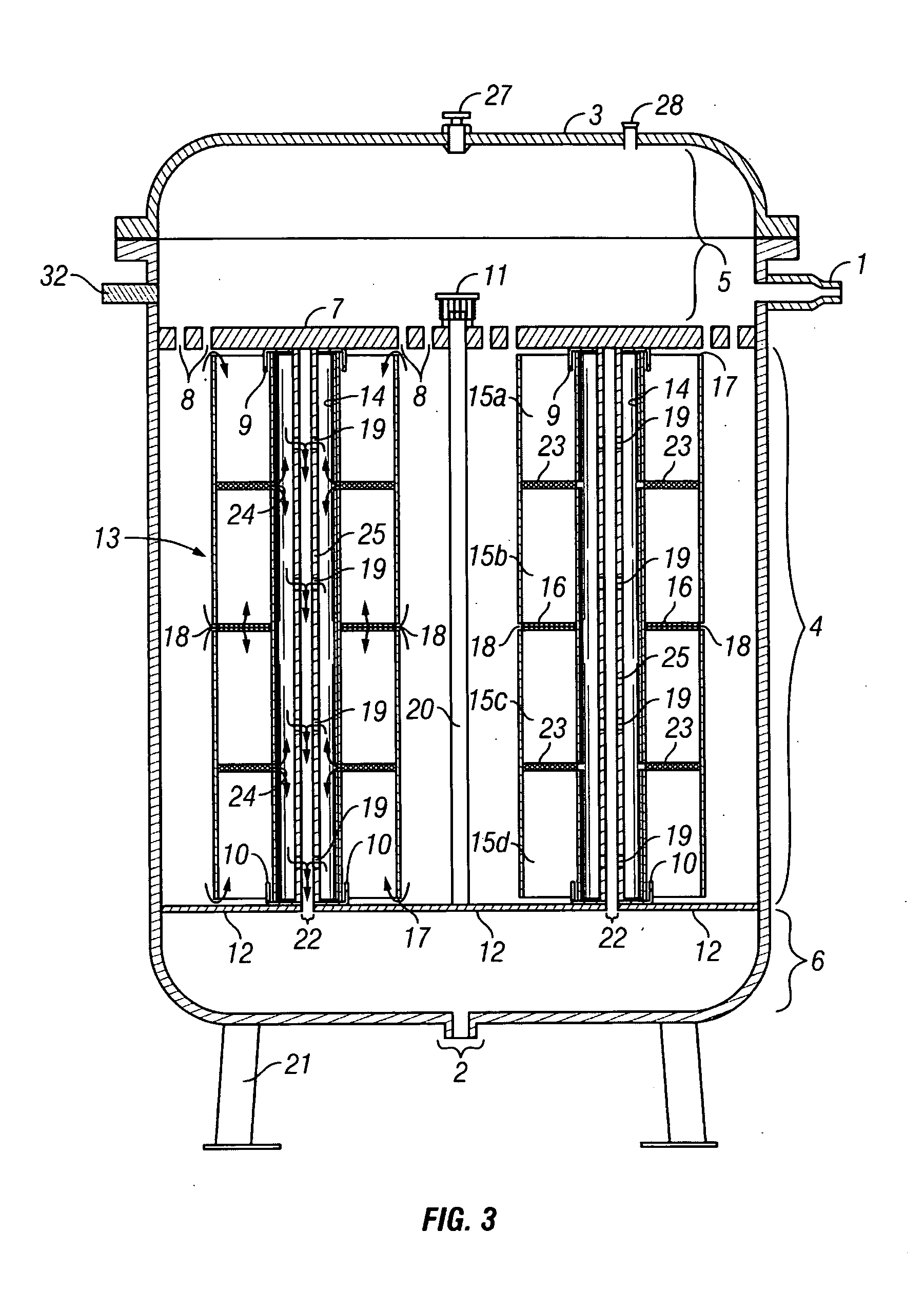

Contaminated liquids filtering apparatus

InactiveUS20060081518A1Effective filteringPrevent bypass flowSettling tanks feed/dischargeMembrane filtersMaterial PerforationFilter element

A filtering apparatus comprising an elongate container body, an inlet, an inlet reservoir, an outlet, an outlet reservoir, and at least two filter elements, wherein each filter units contains two or more space-apart and co-axially stacked filter elements encased in a cylindrical-shaped filter cartridge. Contaminated fluid flows from the inlet, through the perforations located on the inlet reservoir separator, and into the elongate container body. Fluid flows into the filter units through perforations in the filter cartridge and the open ends of the filter cartridge. The filter units use an opposed axial flow method to draw the fluid through the filter elements. The filtered fluid flows through a perforation in the axial conduit, passes through the axial conduit outlet into the outlet reservoir. The filtered fluid then exits through the outlet. The present invention may be used in operation with a motor and pump to filter large flow rates and volumes of contaminated fluid.

Owner:YEE PHILIP W +1

Reverse out valve for well treatment operations

ActiveUS7523787B2Prevent bypass flowMinimize formationFluid removalMultiple way valvesEngineeringValve seat

A reverse out valve (100) comprises an outer housing (120) and a mandrel (144) that form a bypass region (130) therebetween. The mandrel (144) includes a central flow path (164) with a valve seat (152) positioned therein and first and second side wall ports (148, 150). A valve element (168) is positioned in the central flow path (164). The valve element (168) and the valve seat (152) having a one way valve configuration that prevents downhole fluid flow and allows uphole fluid flow. The mandrel (144) is axially movable relative to the outer housing (120) between first and second positions. In the first position, a bypass passageway (184) is formed between the first and second side wall ports (148, 150) via the bypass region (130) thereby allowing bypass flow around the valve element (168) and the valve seat (152). In the second position, bypass flow is prevented.

Owner:HALLIBURTON ENERGY SERVICES INC

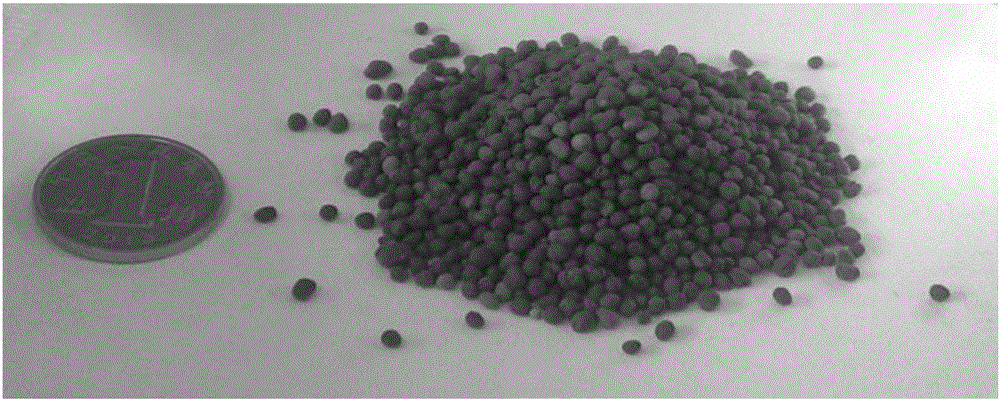

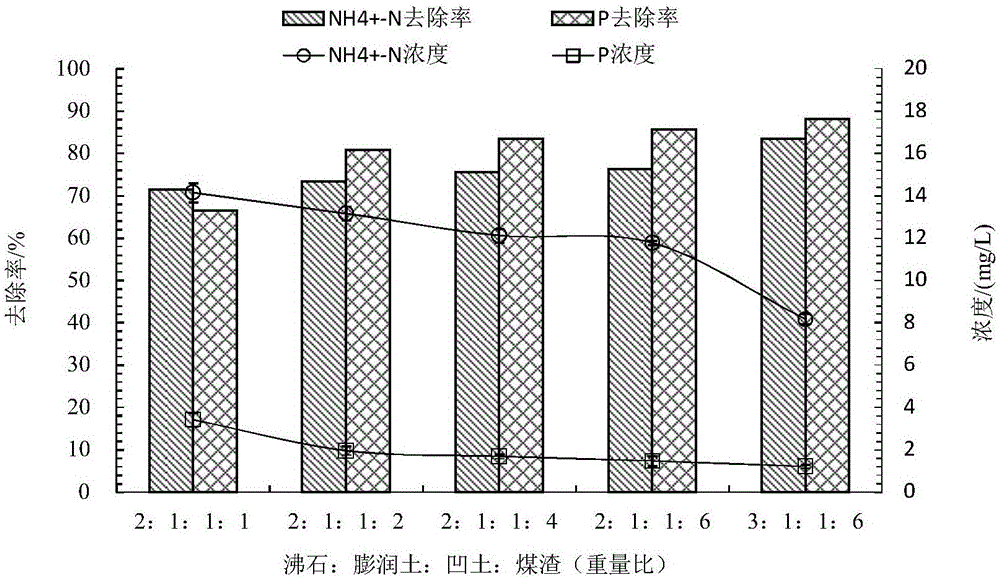

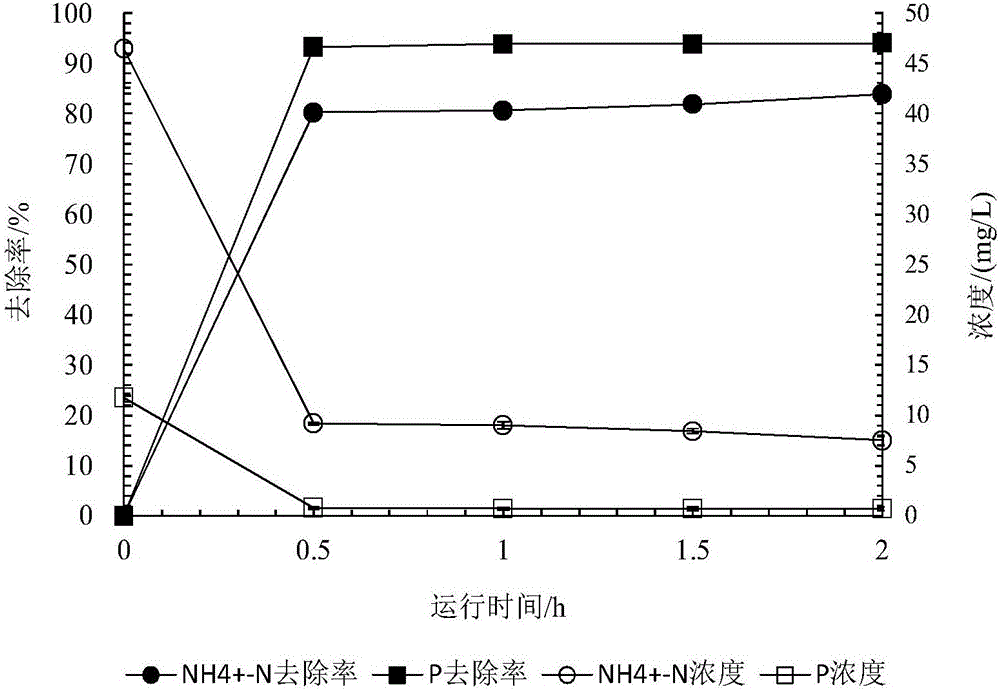

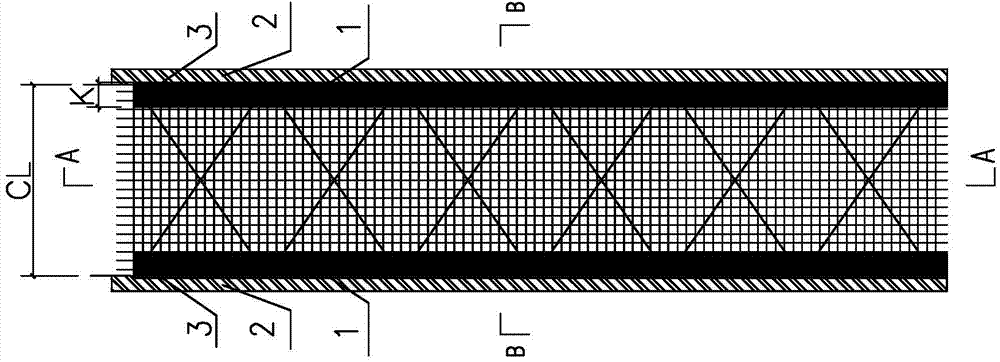

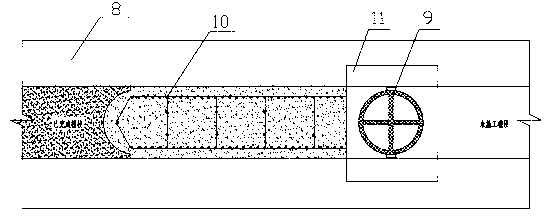

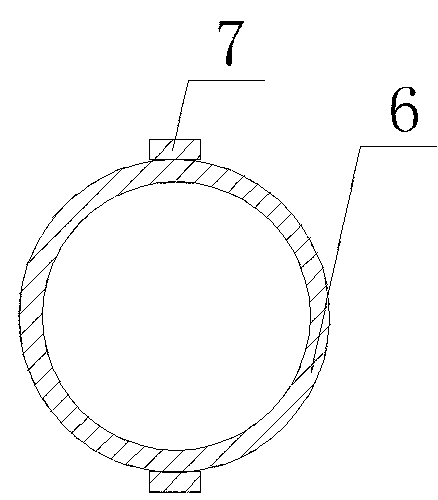

Composite reaction medium for removing nitrogen and phosphorus from underground water permeable reactive barriers and method for preparing composite reaction medium

ActiveCN106396134ASync removalEfficient removalWater contaminantsWater/sewage treatmentSodium BentoniteInstability

The invention discloses a composite reaction medium for removing nitrogen and phosphorus from underground water permeable reactive barriers and a method for preparing the composite reaction medium. The composite reaction medium comprises, by weight, 1.0-3.0 parts of zeolite, 0.7-1.3 parts of bentonite, 0.5-1.5 parts of attapulgite and 1.0-6.0 parts of coal cinder. The zeolite, the bentonite, the attapulgite and the coal cinder are sintered to obtain the composite reaction medium. The composite reaction medium and the method have the advantages that the nitrogen and the phosphorus can be synchronously, efficiently and quickly removed by the composite reaction medium, the composite reaction medium can be used as a biological carrier, accordingly, shortcomings of instability of biological phosphorus removal, large quantity of mud due to chemical phosphorus removal and the like can be overcome, and detour flow of water at the fronts of the barriers and the like can be prevented.

Owner:FOODSTUFF INST BEIJING

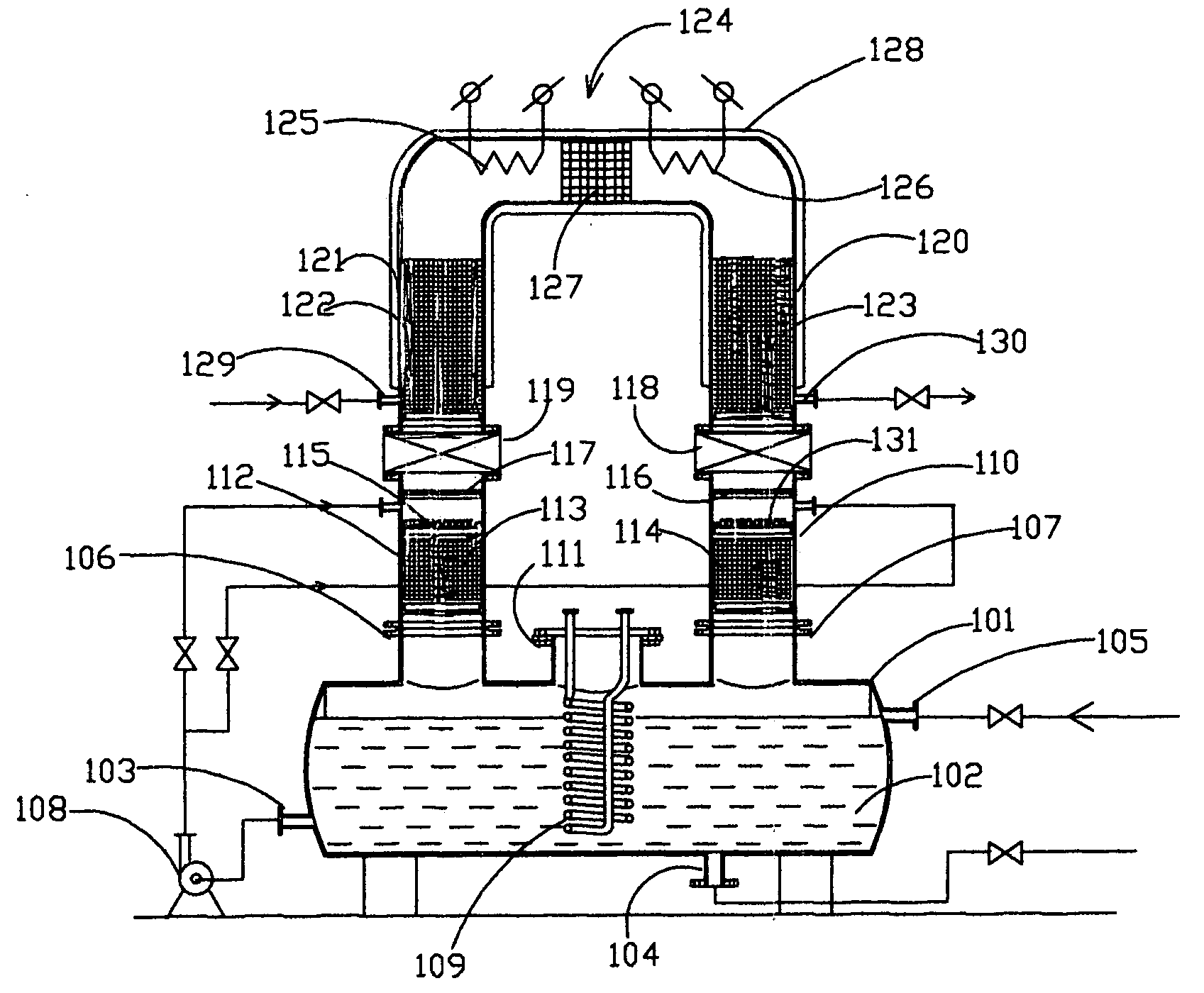

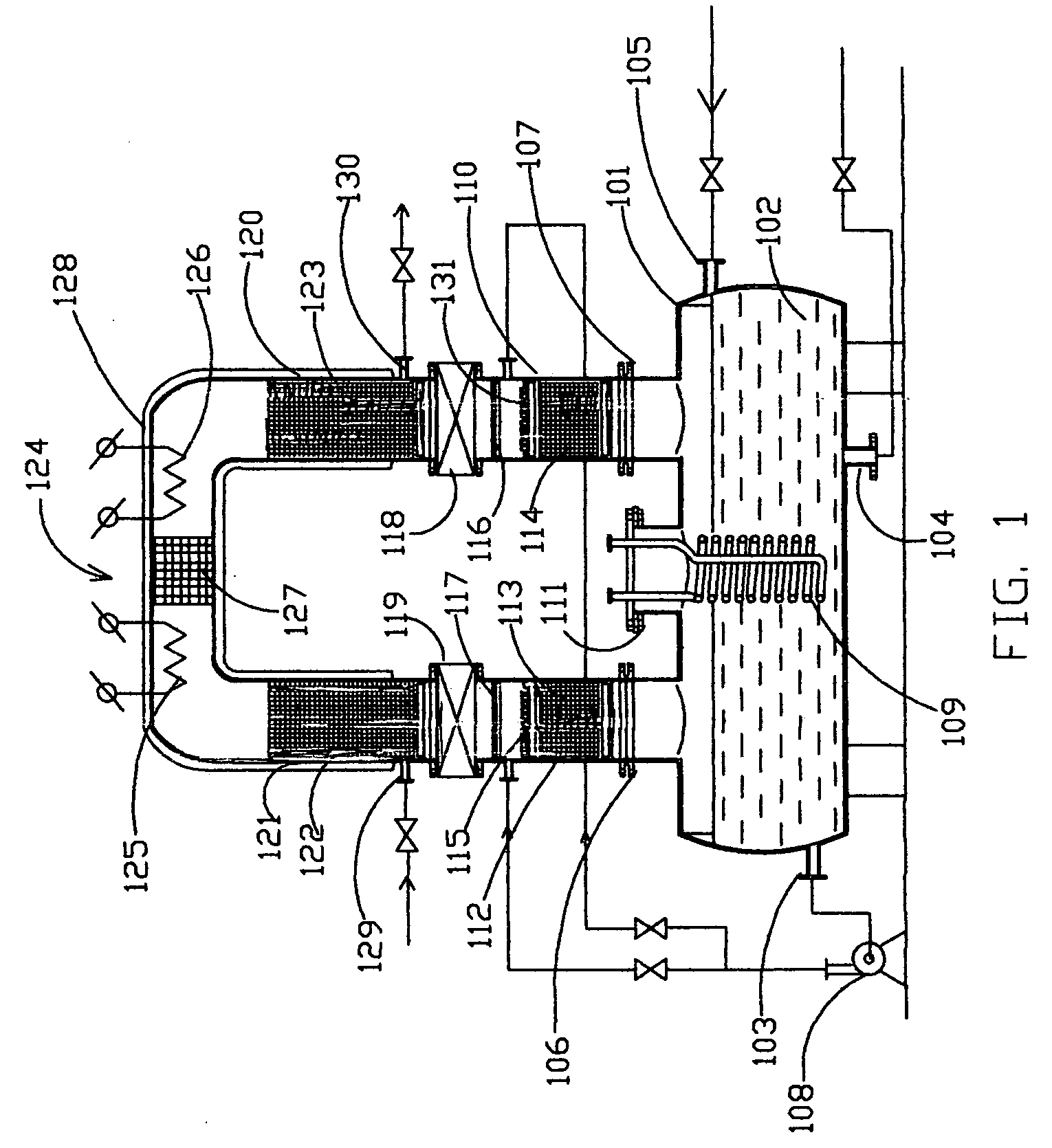

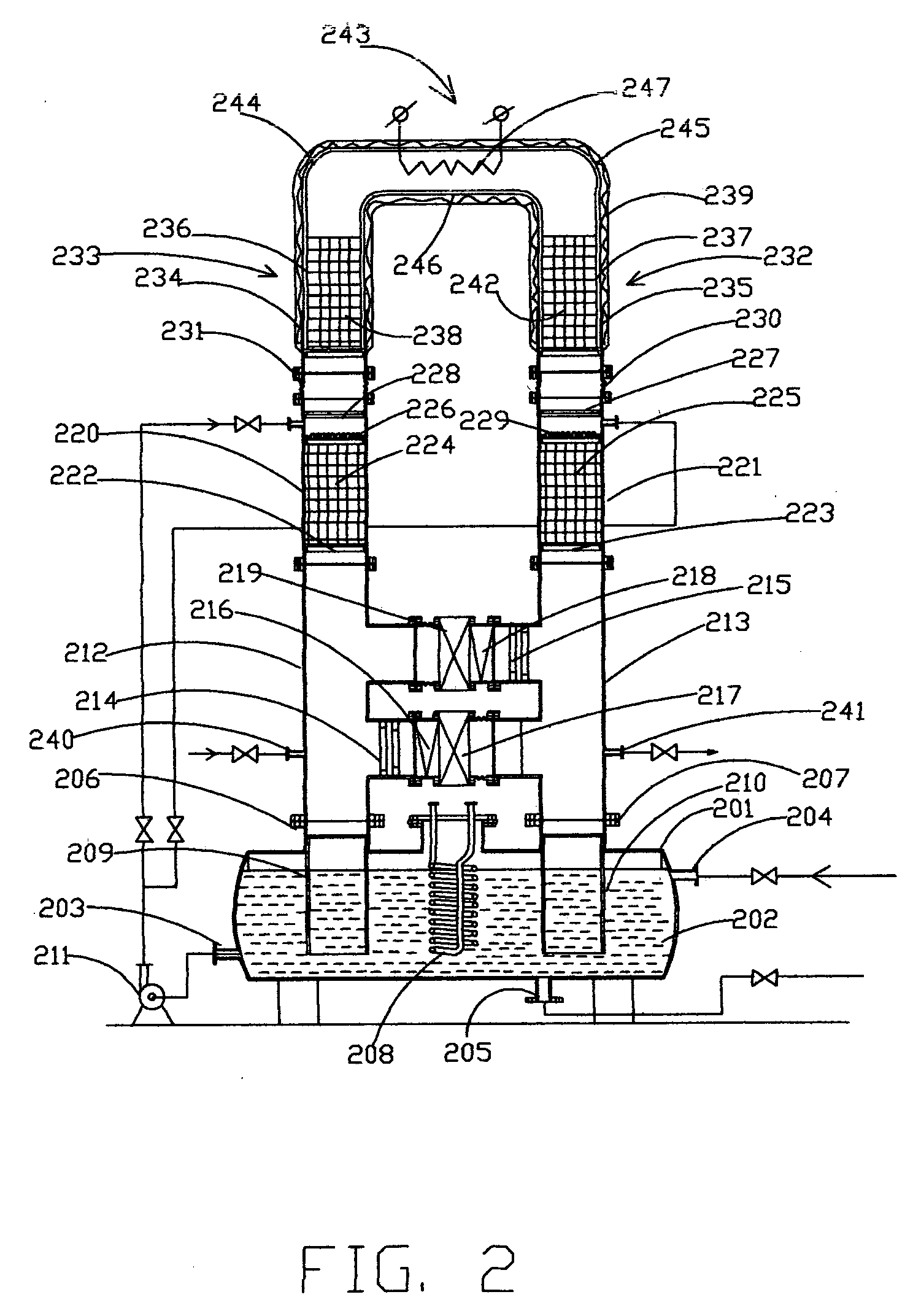

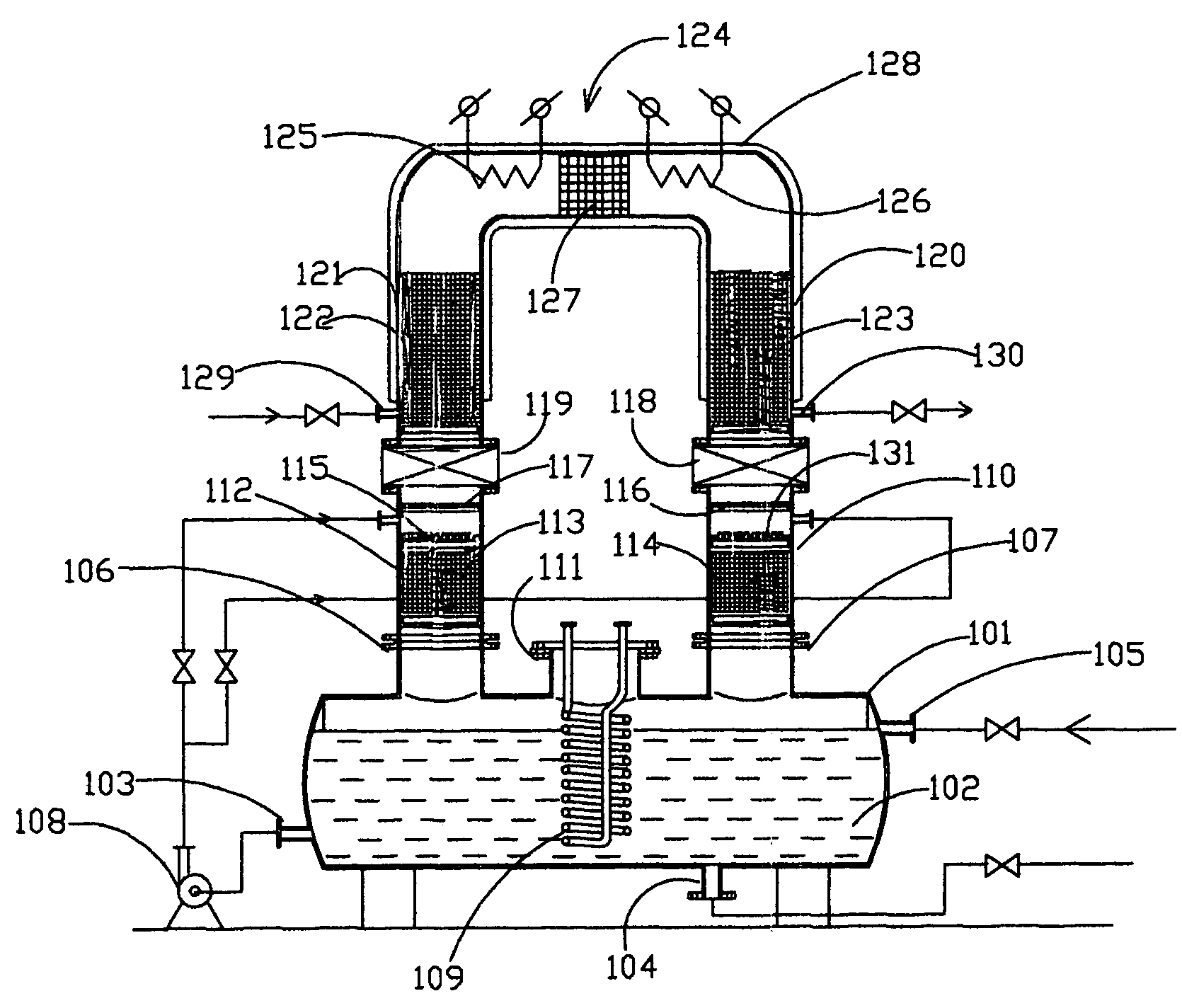

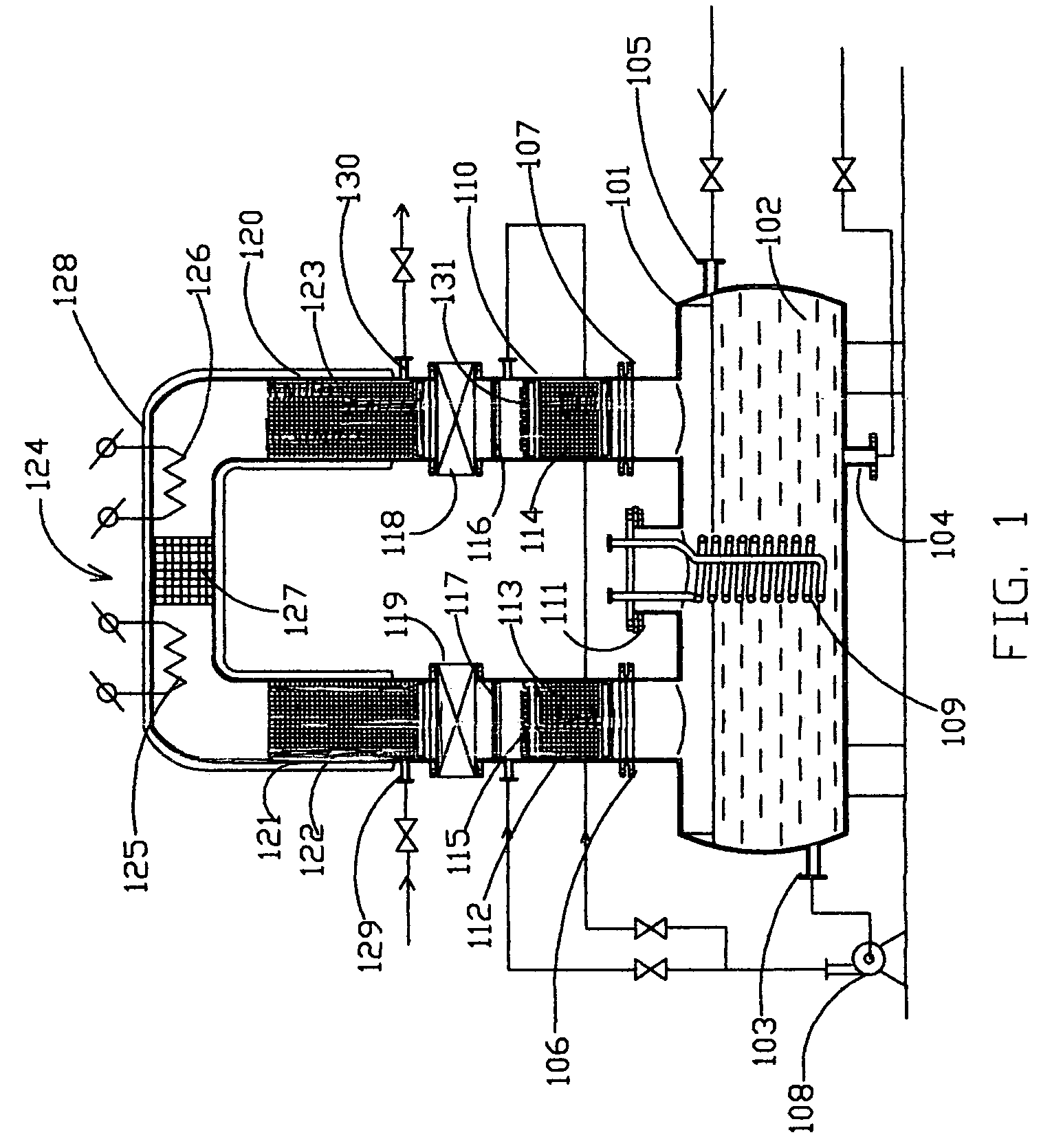

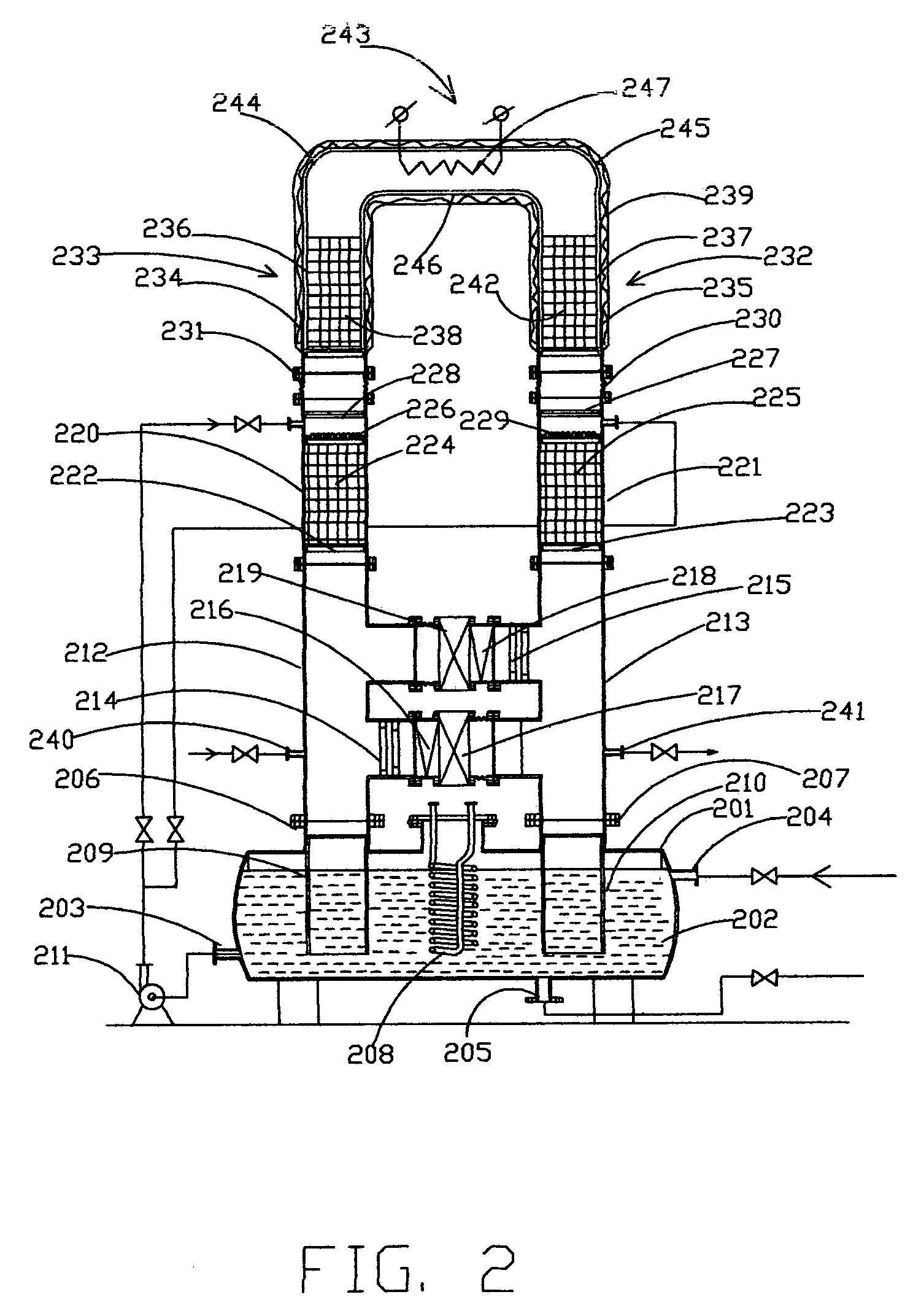

Method and system of destruction of volatile compounds in wastewater

ActiveUS20060196358A1Reduce consumptionReduce energy consumptionLiquid degasificationDistillation separationWastewaterCatalytic oxidation

The invention proposes a method of destruction of volatile organic and inorganic compounds in wastewater, this method includes following stages: stripping the aforementioned volatile compounds in a stripping-chemisorption column; preliminary heating the gaseous medium containing these volatile compounds in a first heat regenerator; thermal, flare or thermo-catalytic oxidation of the volatile compounds in circulating gaseous medium; cooling the gaseous medium in a second heat regenerator; chemisorption of acidic gases from the gaseous medium in the stripping-chemisorption column with stripping at the same time additional amount of the volatile compounds from the wastewater. After specific period, direction of the gaseous medium flow is alternated. The proposed method can be executed at elevated temperature. The invention includes as well systems realizing the proposed method.

Owner:ELCON RECYCLING CENT 2003

Method and system of destruction of volatile compounds in wastewater

ActiveUS7455781B2Prevent bypass flowIncrease evaporation rateLiquid degasificationDistillation separationCatalytic oxidationWastewater

Owner:ELCON RECYCLING CENT 2003

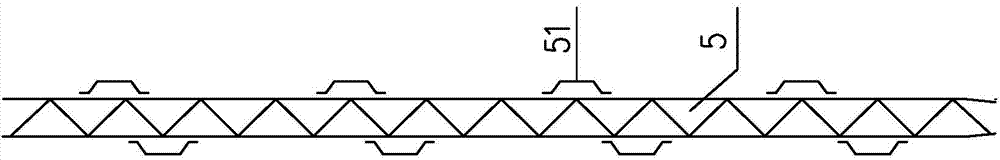

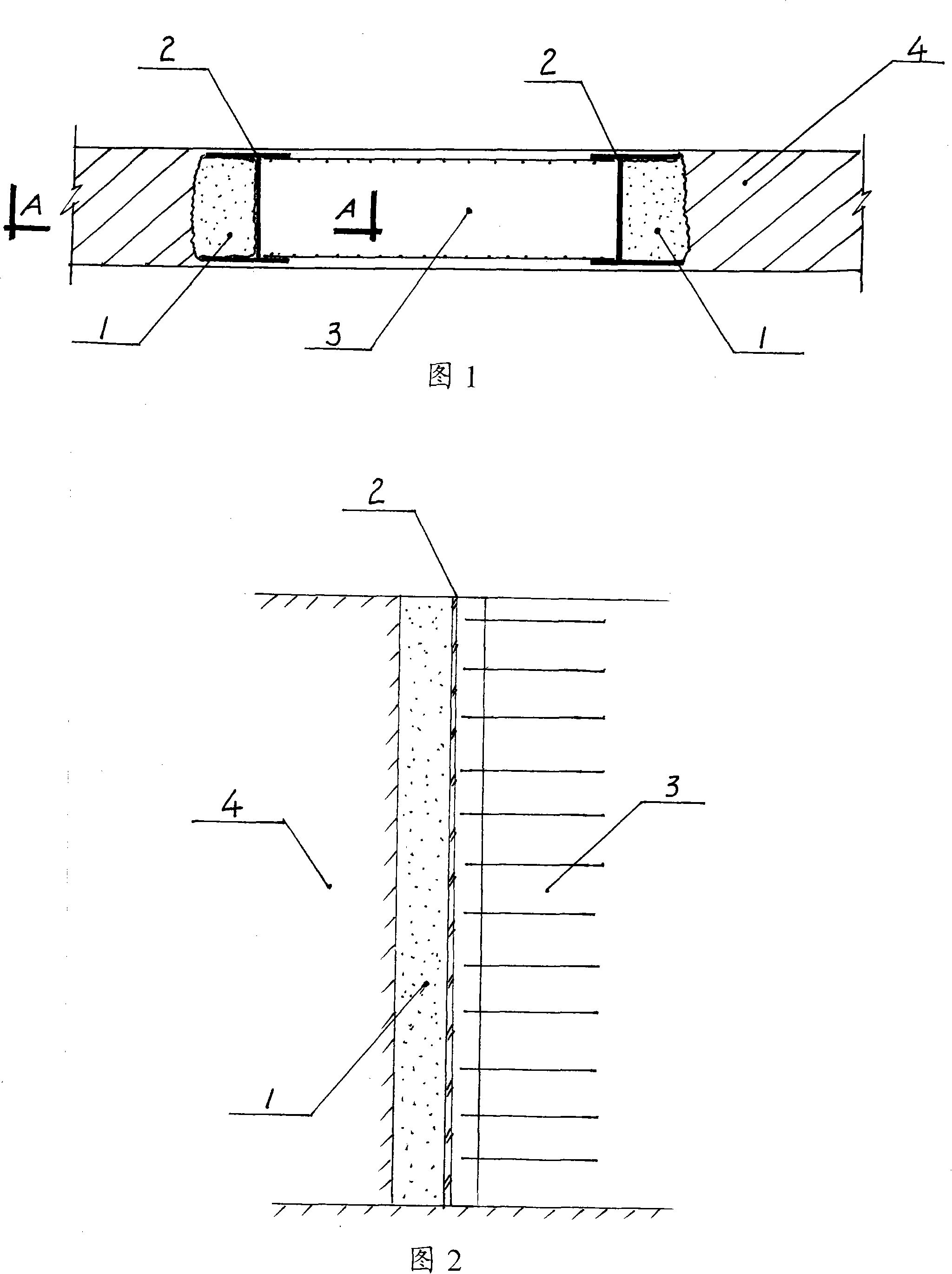

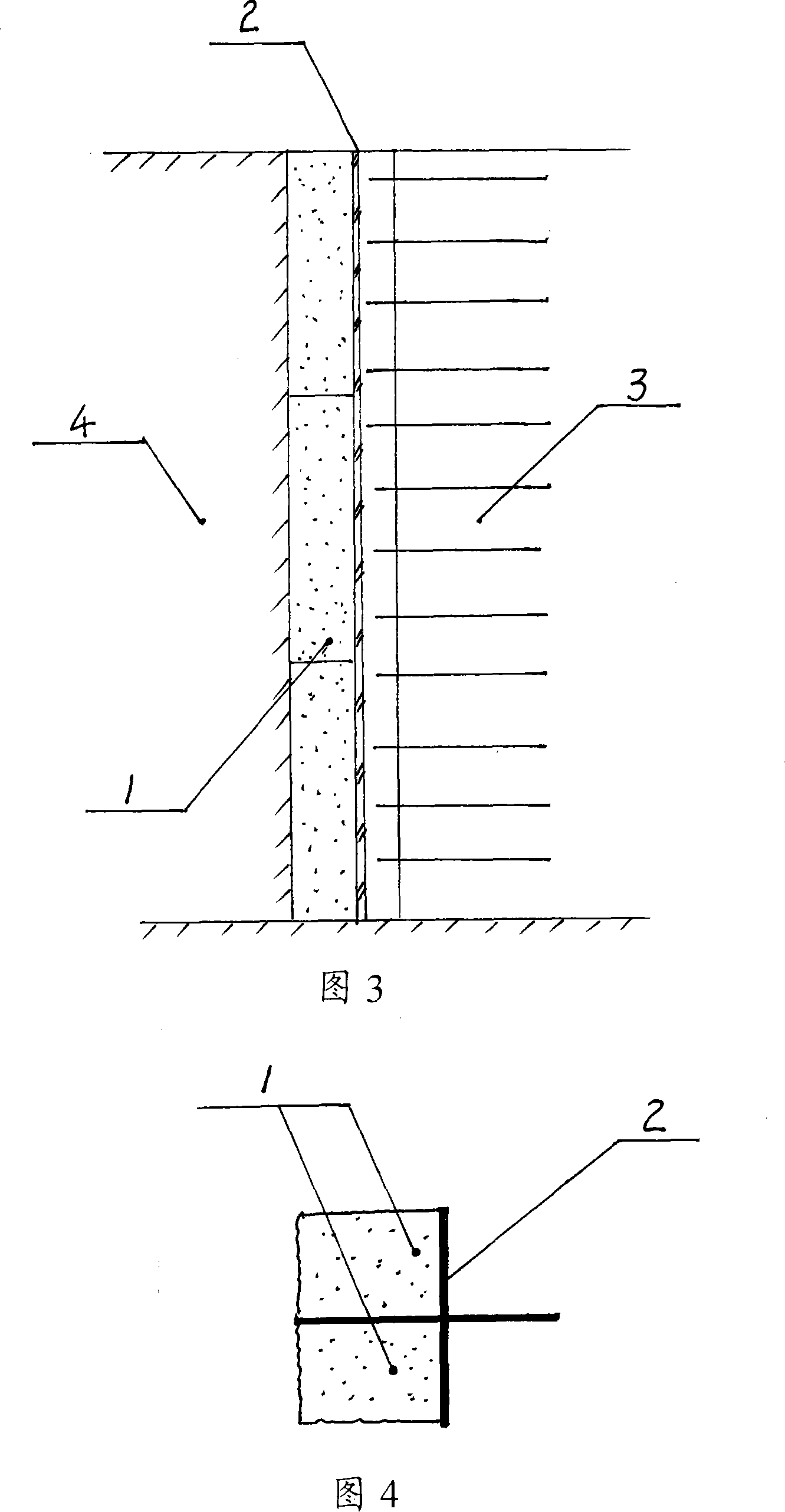

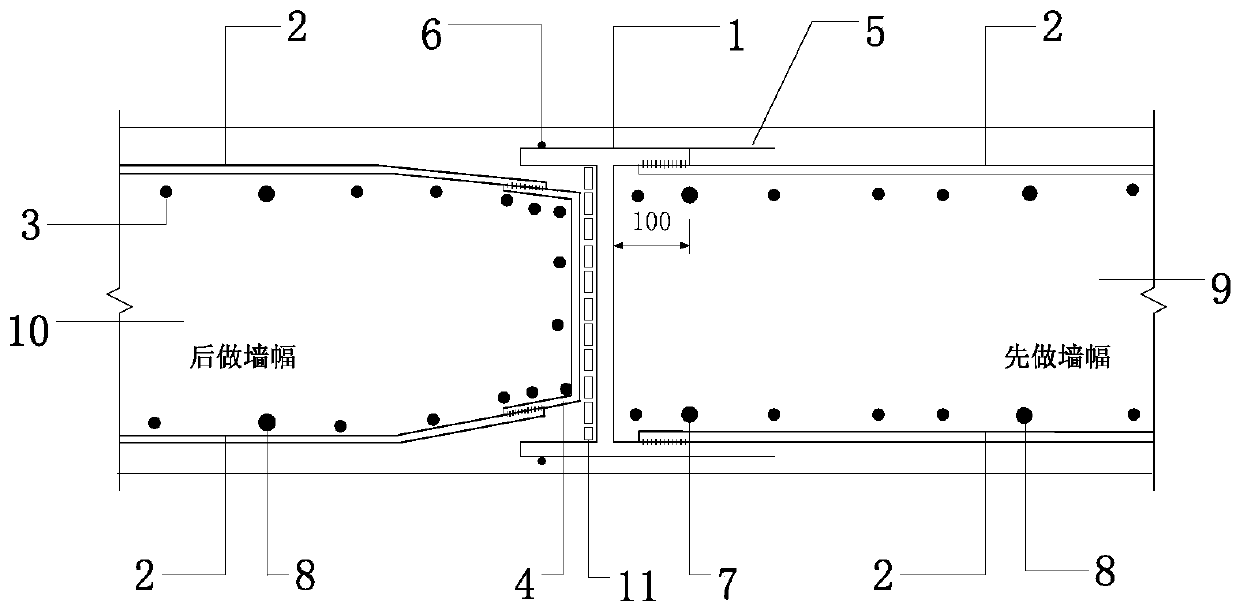

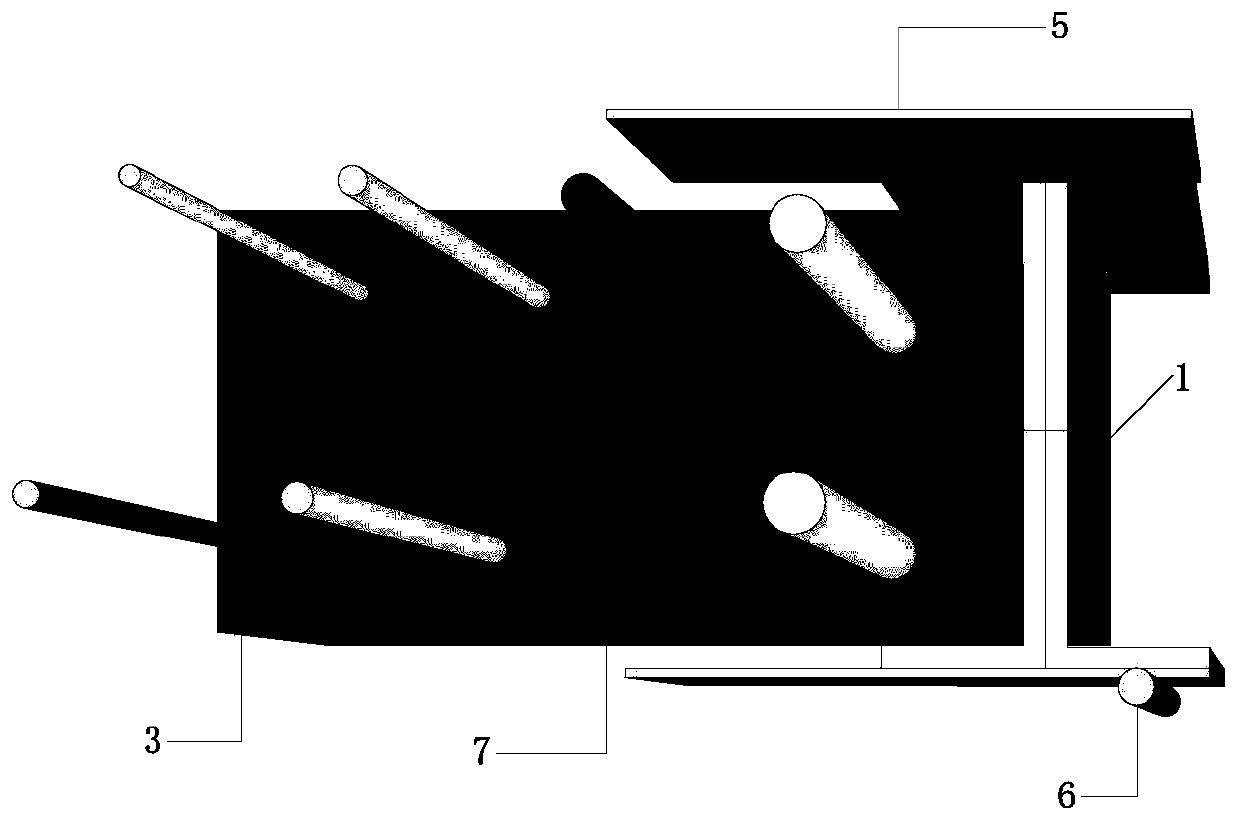

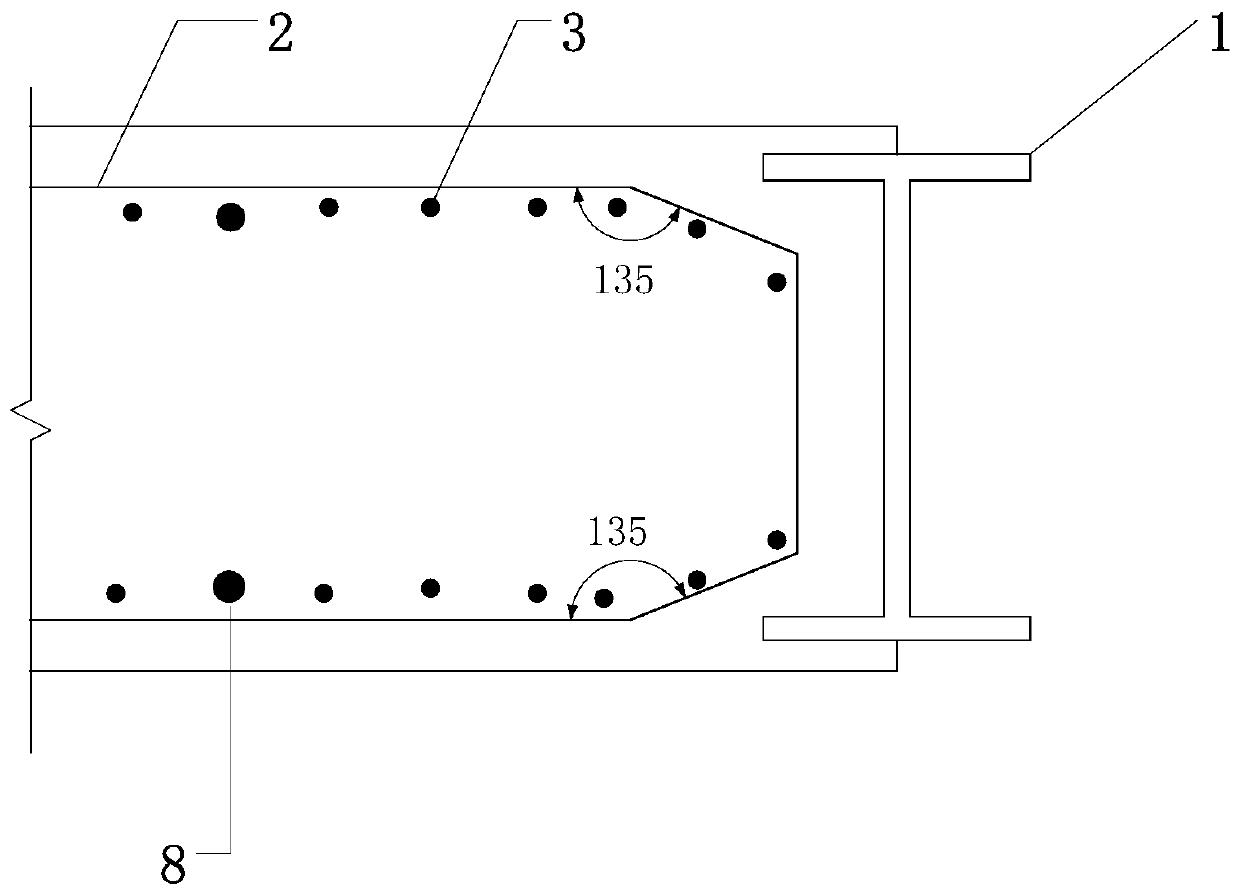

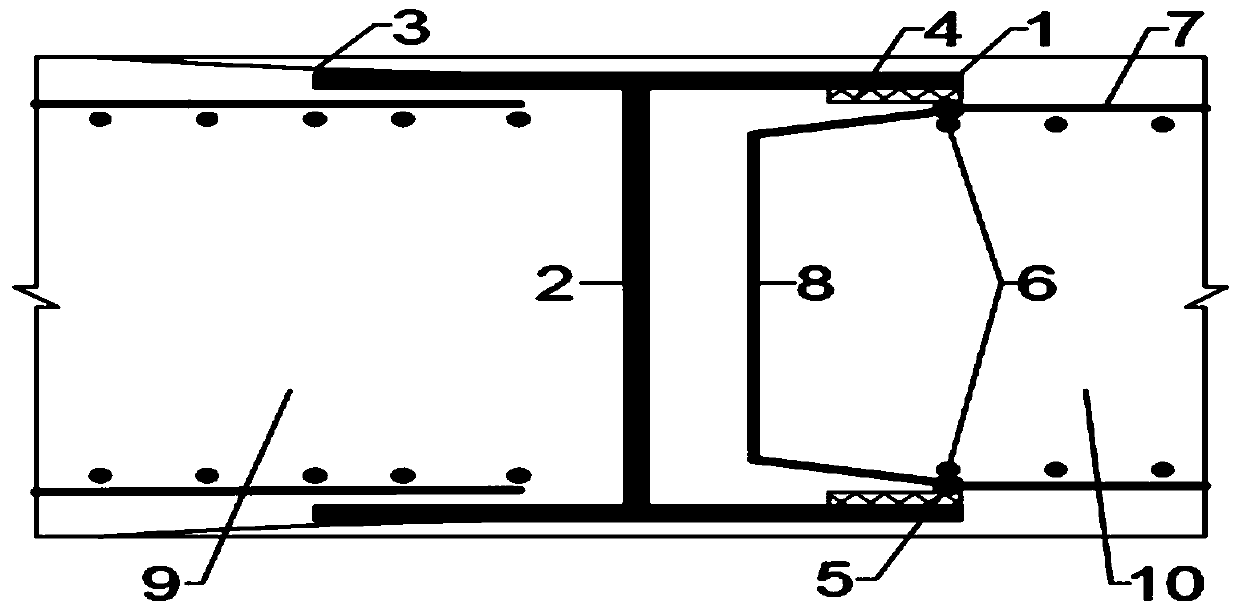

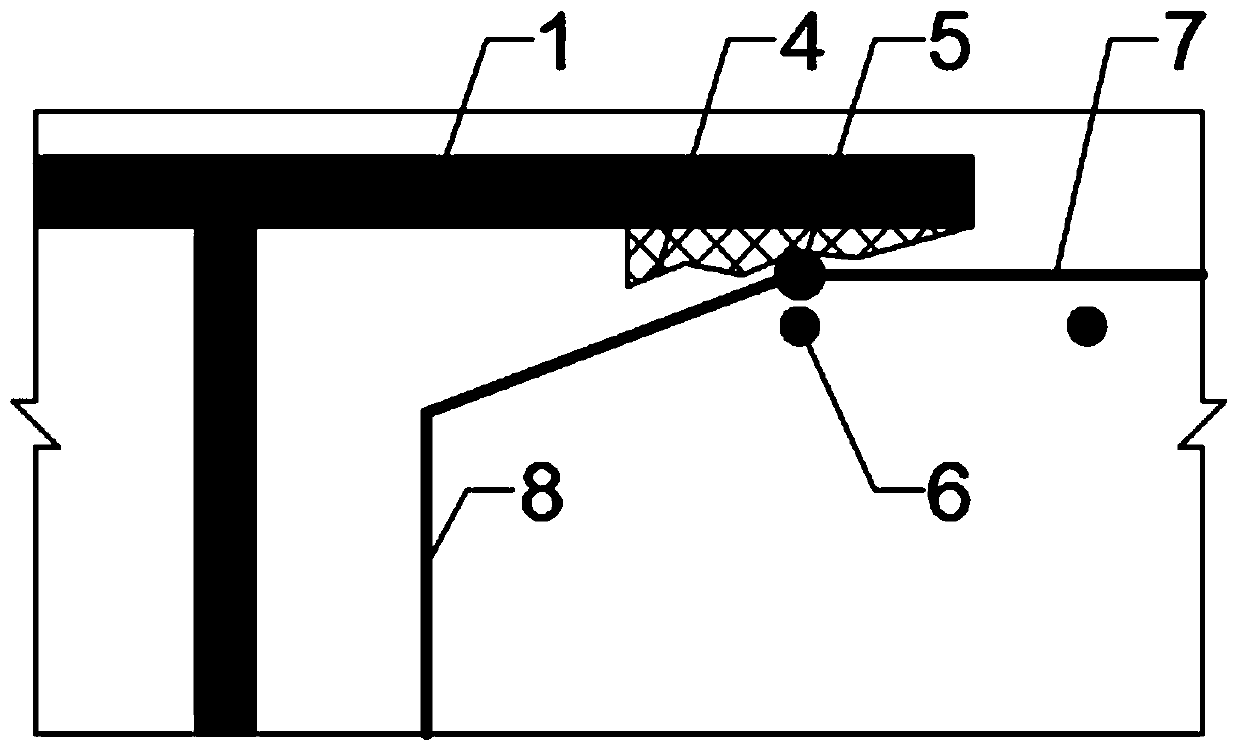

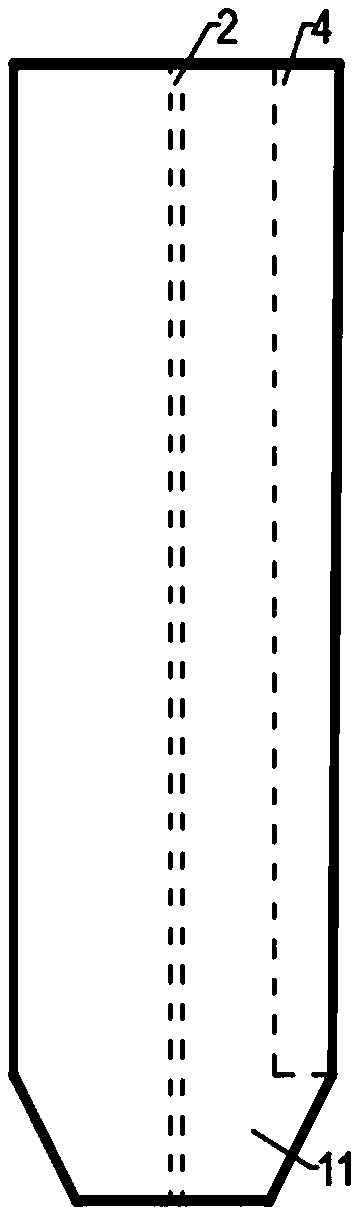

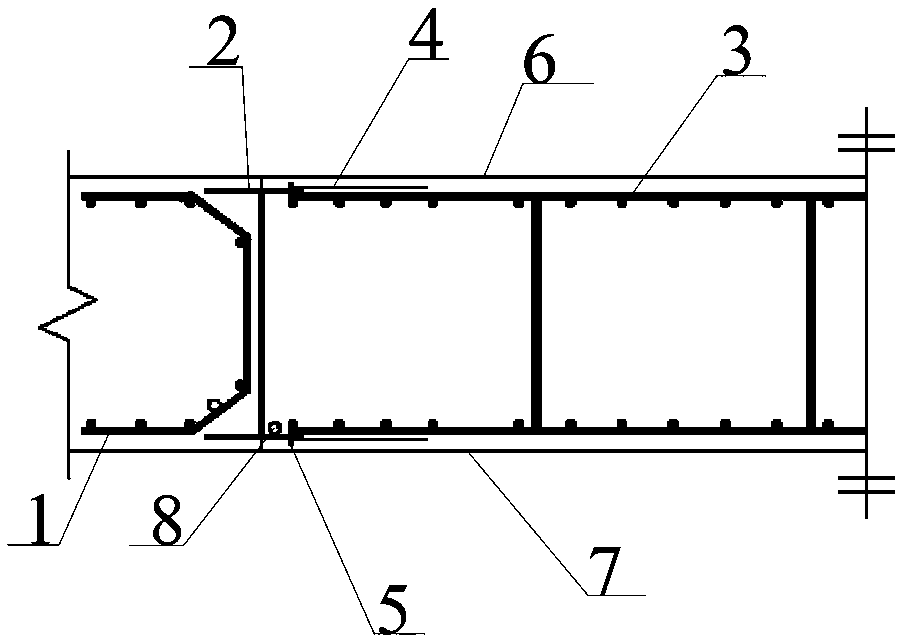

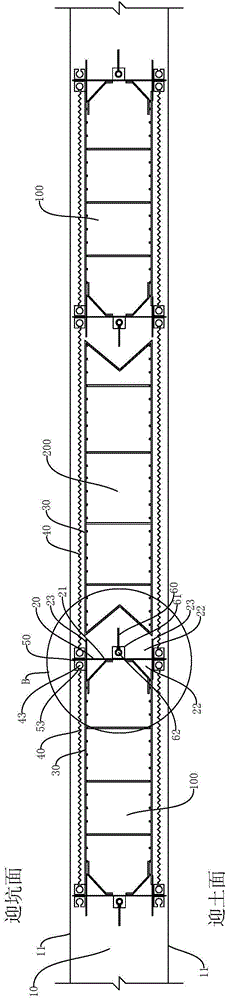

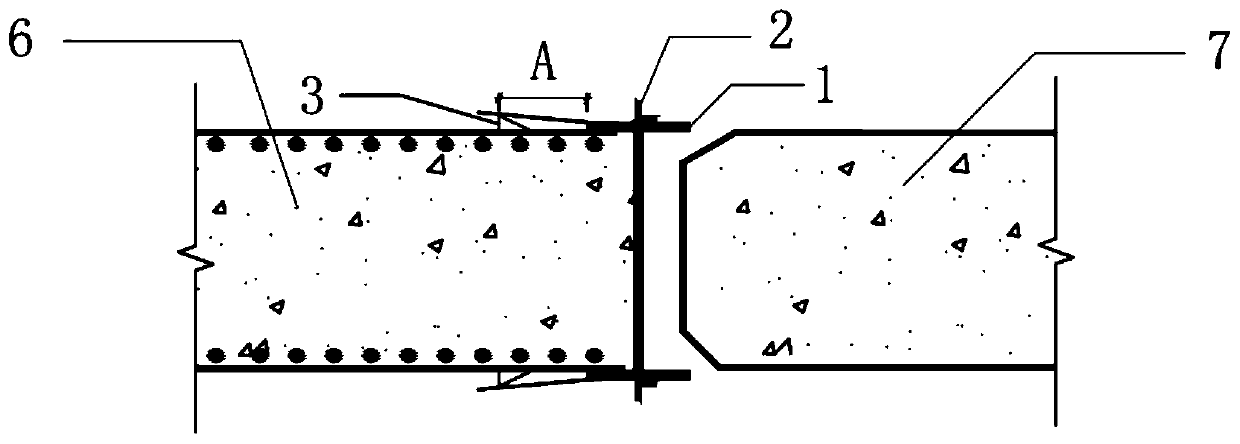

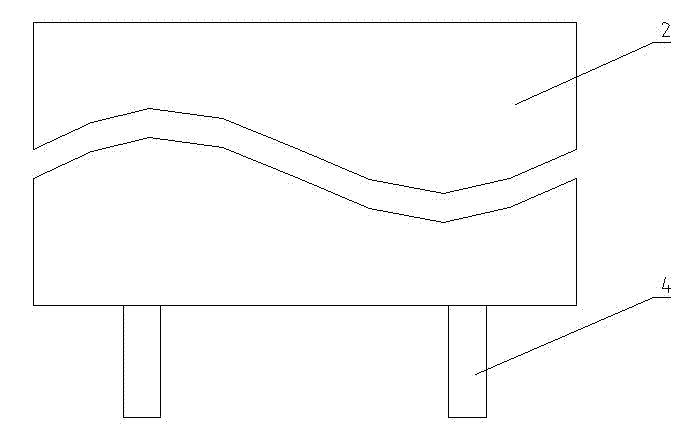

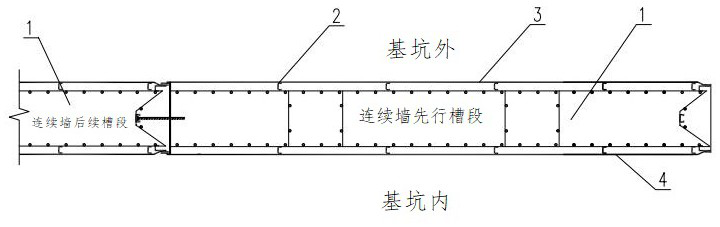

Concrete bypassing preventing device with pulp stopping plates and concrete bypassing preventing construction method for H-shaped steel joint of wall chase of underground continuous wall

InactiveCN103924621AReduce weightLow costArtificial islandsUnderwater structuresSlurry wallPulp and paper industry

A concrete bypassing preventing device provided with pulp stopping plates and used for an H-shaped steel joint of a wall chase of an underground continuous wall comprises two pulp stopping plates, wherein the two pulp stopping plates are respectively arranged on flange plates of an H-shaped water stopping steel plate of the underground continuous wall; one ends of the pulp stopping plates are fixedly connected with the flange plates of the H-shaped water stopping steel plate; the other ends of the pulp stopping plates are free ends; one of the pulp stopping plates is fixedly connected with the inside of one of the flange plates of the H-shaped water stopping steel plate; the other pulp stopping plate is fixedly connected with the outside of the flange plate on the other side of the H-shaped water stopping steel plate; the pulp stopping plates are galvanized iron sheets; the thicknesses of the galvanized iron sheets are 0.5mm; and the lengths of the galvanized iron sheets are longer than a reinforcement cage by about 500mm. During construction, the pulp stopping plate on the inner side of the flange plate on the lower side of the H-shaped water stopping steel plate is arranged at first, then the pulp stopping plate on the outer side of the flange plate on the upper side of the H-shaped water stopping steel plate is arranged, the free ends of the pulp stopping plates are not required to be connected with reinforcing steel bars, so that the free ends of the pulp stopping plates can be opened without limitation during pouring of concrete, and can be totally opened according to designed requirements, the poured concrete is effectively prevented from bypassing and entering an H-shaped steel web plate, and the problem of bypassing of the concrete at the joint can be well solved.

Owner:广西建工第五建筑工程集团有限公司

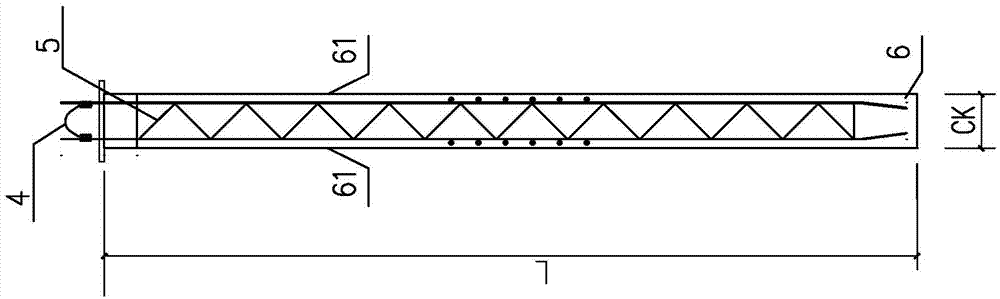

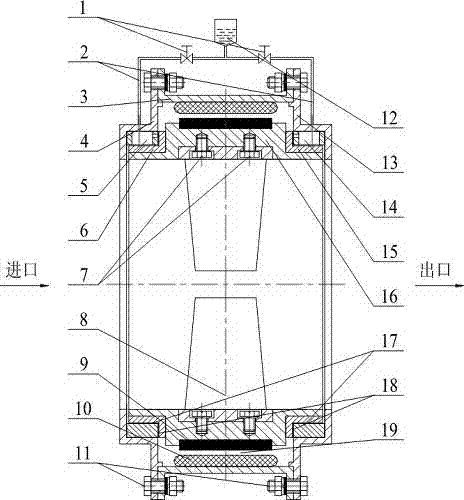

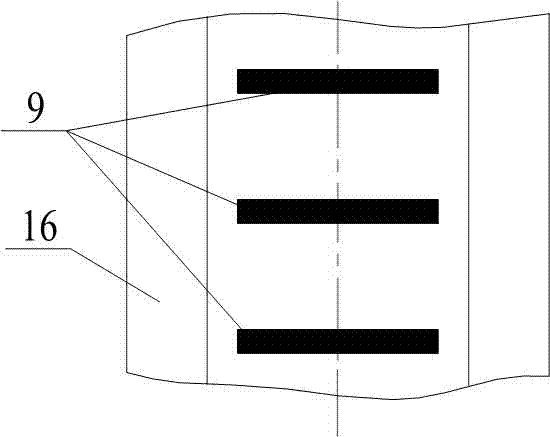

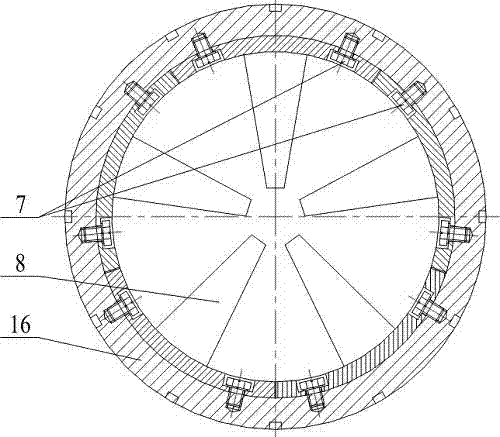

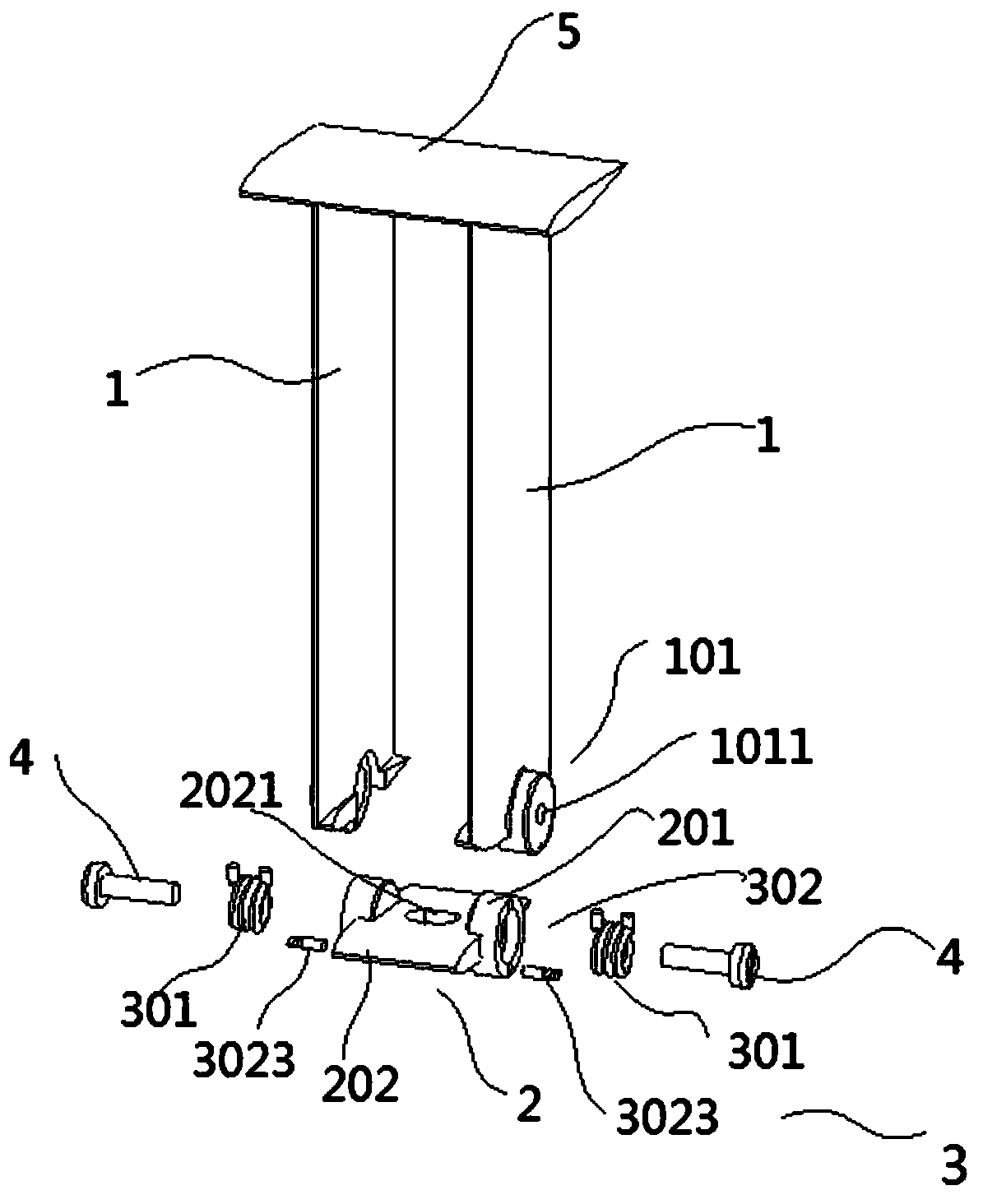

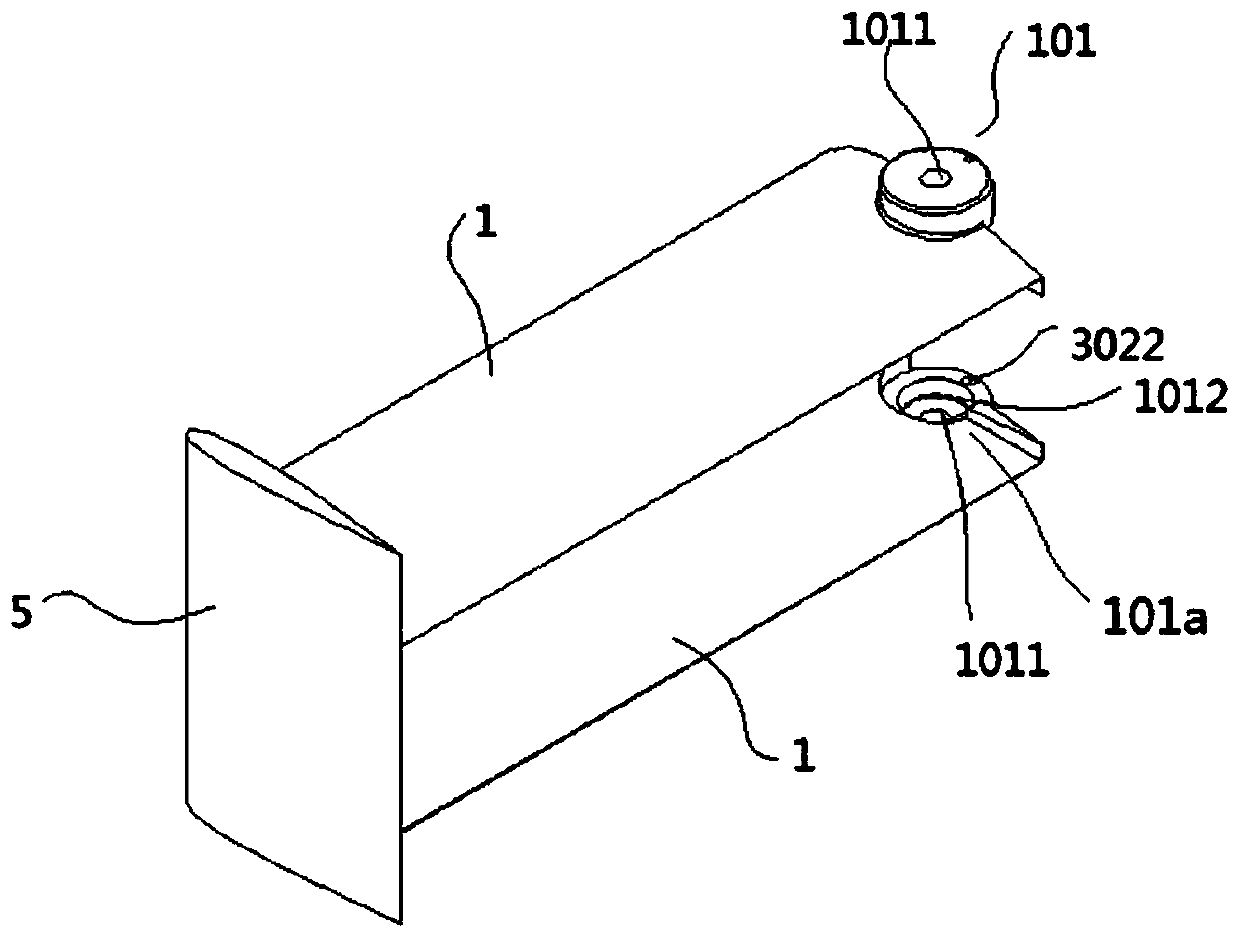

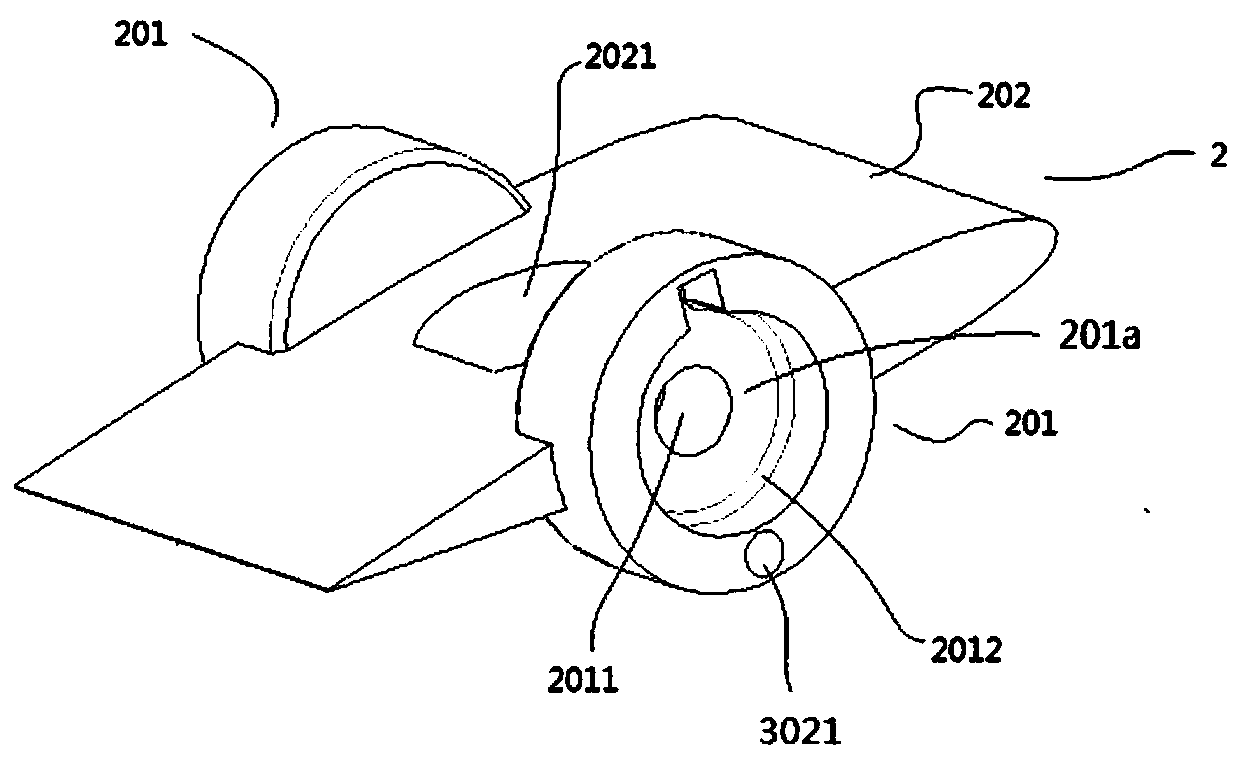

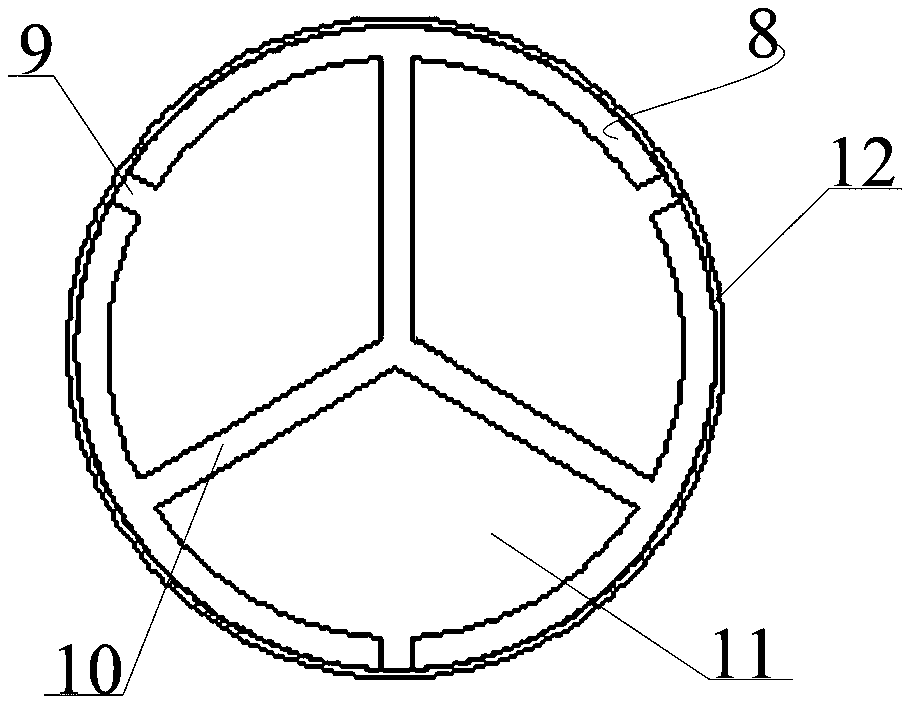

Wheel rim-driven shaftless fan

InactiveCN107461354ASave flow spaceSave materialPump componentsPump installationsInterference fitEngineering

The invention specifically relates to a wheel rim-driven shaftless fan. The wheel rim-driven shaftless fan comprises a stator component, a rotor component and a lubrication device, wherein the stator component comprises a front end cover 4, an inlet-side slide bearing 5, an air barrel 3, an armature 10, an outlet-side slide bearing 14 and a rear end cover 13, wherein the rotor component comprises an inlet-side shaft neck 6, a wheel hub 16, permanent magnets 9, blades 8 and an outlet-side shaft neck 15, the inlet-side shaft neck 6 and the outlet-side shaft neck 15 are both L-shaped and both installed on the wheel hub 16 in a manner of interference fit, a plurality of grooves are uniformly formed in the excircle surface of the wheel hub 16, and the permanent magnets 9 are inlaid in the grooves in the excircle surface of the wheel hub 16; a blade handle is arranged at the blade tip of each blade 8, each blade handle is an incurved tile, and all the tiles are spliced to just form the inner diameter of the wheel hub; and the lubrication device comprises an oil cup 12, a guide pipe 2 and an adjustment valve 1, one end of the guide pipe 2 is connected to the oil cup 12, and two outlets are formed in the other end of the guide pipe 2. According to the wheel rim-driven shaftless fan disclosed by the invention, a wheel hub needed for driving the central shaft of a traditional fan is avoided, the separation of secondary flow and a boundary layer at each blade root is reduced, and the flowing condition at each blade root is improved, so that the efficiency of the fan is increased; and moreover, a blade tip gap at each blade tip is avoided, so that detouring flow at each blade tip is avoided, a flow field structure is improved, energy conversion efficiency is increased, and a pneumatic noise is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Cross section-variable underground continuous wall and construction method thereof

InactiveCN102425156APrevent bypass flowAdapt to the characteristics of large height differenceExcavationsBulkheads/pilesSlurry wallBuilding construction

The invention discloses a cross section-variable underground continuous wall, which is formed by connecting multiple underground continuous walls. The wall bottom of the single underground continuous wall is in a double-step shape along the width direction of a wall body. The invention also discloses a construction method for the cross section-variable underground continuous wall, which comprises the following steps: (a1) measuring the rock depth condition at a construction position to determine the embedded rock depth of the steps at the wall bottom of the single cross section-variable underground continuous wall; (a2) performing construction operation to manufacture an underground continuous wall slot with two steps, wherein the depth of the two steps meets the requirement of the embedded rock depth determined in the step (a1); and (a3) lowering a steel net, and casting underwater concrete to form the cross section-variable underground continuous wall. The wall bottom of the cross section-variable underground continuous wall is provided with two steps, and the two steps are embedded into a rock face, thus, a good water interception effect is achieved. The construction method disclosed by the invention is capable of rapidly, accurately and conveniently processing the cross section-variable underground continuous wall disclosed by the invention. The cross section-variable underground continuous wall disclosed by the invention can be widely applied to the construction operation of the underground continuous wall.

Owner:GUANGDONG FOUND ENG GRP CO LTD

Construction method of complex inclined rock and boulder geological bored pile

ActiveCN111720051AAvoid severe reamingImprove crushing effectDrilling using explosivesGeotextilesRebarGeotextile

The invention relates to a construction method of a complex inclined rock and boulder geological bored pile. The construction method comprises the following steps of: S1, drilling first drill holes ina foundation and boulders on the pile side by using a coring machine; S2, manufacturing an explosive tube; S3, burying wall protecting tubes in the first drill holes every other first drill hole; S4,mounting a lifting rope at the top of a limiting rod; S5, sleeving the outer side of the limiting rod with a steel casing to the highest point of the rock surface; S6, pre-cracking and loosening rocks by using a static crushing agent; S7, lifting the lifting rope to recover the limiting rod and a PVC tube for secondary utilization; S8, arranging a geotextile bag at the position, corresponding toa boulder hole, of a reinforcement cage; S9, arranging water-swellable rubber between a first iron sheet and a second iron sheet; and S10, sinking the assembled reinforcement cage to a designated position, and pouring concrete. The construction method has the advantages that the limiting rod is arranged on the inclined rock and boulders, so that the casing can be prevented from deflecting; and when a drill bit is ejected and deflects to affect the casing, the drill bit can be limited by the limiting rod, so that the perpendicularity of a pile hole is improved.

Owner:ZHEJIANG UNIV CITY COLLEGE

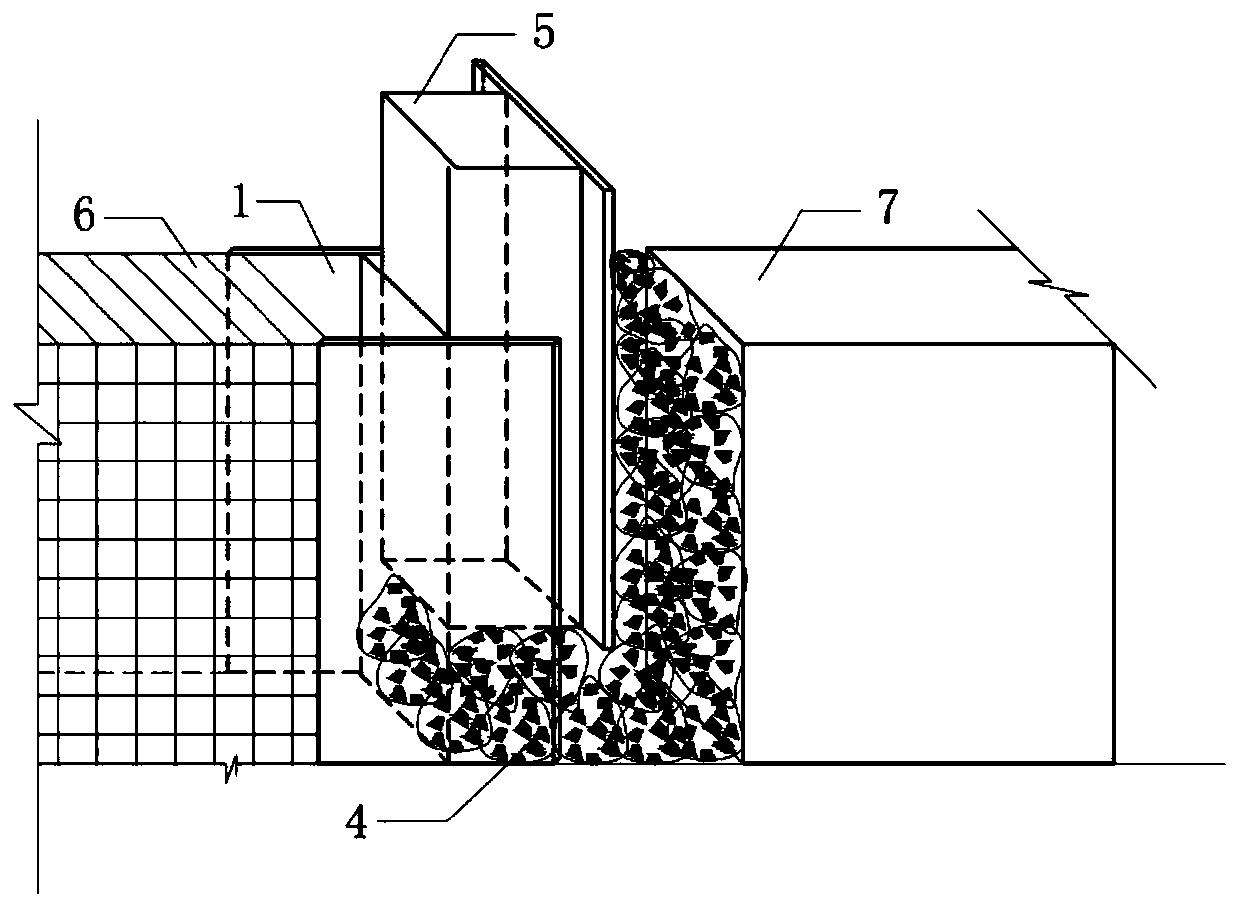

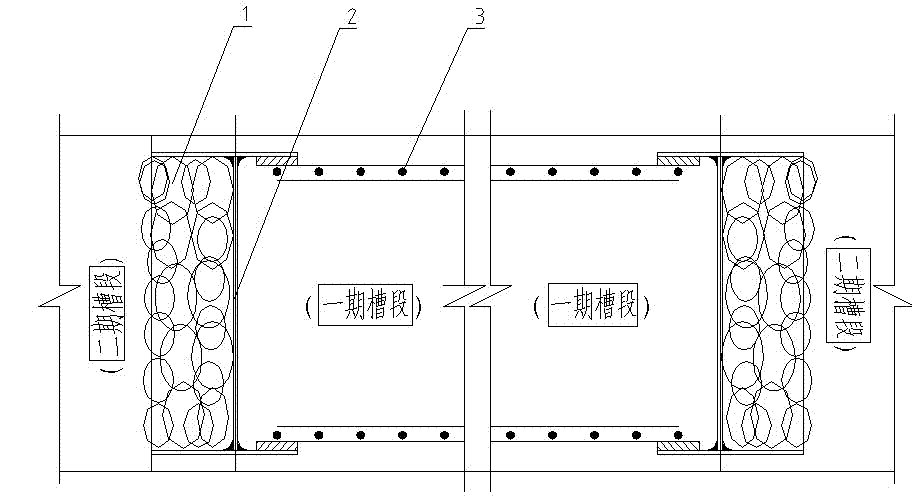

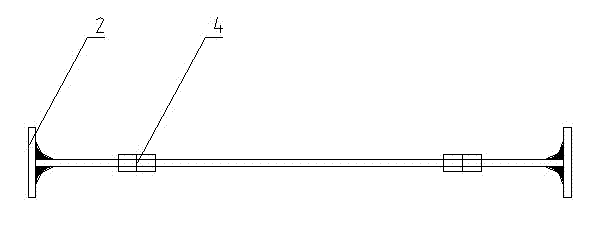

Flexible device of underground continuous wall for preventing concrete circuitous flowing

InactiveCN101235637AClose contactPrevent bypass flowArtificial islandsUnderwater structuresSlurry wallBuilding construction

The invention relates to a flexible device of continuous concrete wall for preventing concrete flow around, which is characterized in that the flexible device comprises a capsule and filling in the capsule, wherein the capsule is located between the connector of the first-period groove and the second-period groove and the earth of the second-period groove, and the periphery of the capsule can contact with the inner walls of the connector of the first-period groove and the second-period groove after the capsule is filled with filling. The flexible device has the characteristics of excellent compactness, convenient construction and high efficiency, solves the problem that a rigid device can not be pulled out expressing in the background technology, and can effectively prevent the concrete flow around to the second-period groove section to affect the construction of the second-period groove section when used on the first-period groove section construction of the continuous concrete wall.

Owner:王萍

High and watery coastal area underground continuous wall connector water stop device

PendingCN110528501APrevent bypass flowImprove integrityArtificial islandsUnderwater structuresSlurry wallLap joint

The invention belongs to the technical field of foundation pit supporting and relates to a high and watery coastal area underground continuous wall connector water stop device. Continuous wall horizontal ribs are mechanically connected with continuous wall vertical main beams. Steel flower pipes are bond to a first wall reinforcement cage in a lap joint manner. Galvanized sheet iron is installed on the outer side of an I-shaped steel plate. The galvanized sheet iron is welded to pressing bar steel bars in a spot welding manner. The I-shaped steel is connected with the first wall reinforcementcage in a welded manner. A U-shaped stirrup is connected with the single faces of the continuous wall horizontal ribs in a welded manner. Grouting pipes are bond to a second wall reinforcement cage ina lap joint manner. The second wall reinforcement cage is embedded and fixed in an I-shaped steel plate wing plate in a lifting manner. Sand bags are stacked on the outer side of an I-shaped steel plate connector web, and the lower filling height of the sand bags is the height of an underground continuous wall. The high and watery coastal area underground continuous wall connector water stop device is ideal in waterproof effect, concrete can be effectively prevented from streaming around, and due to the arrangement of the steel flower pipes, the water stop effect at the seam position is ensured.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

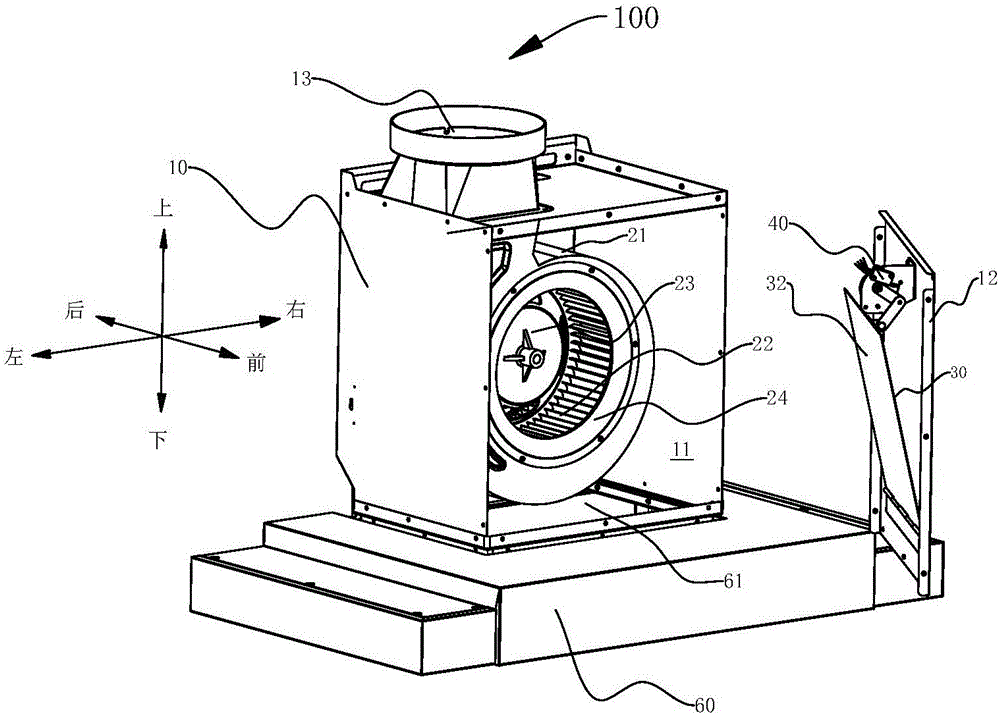

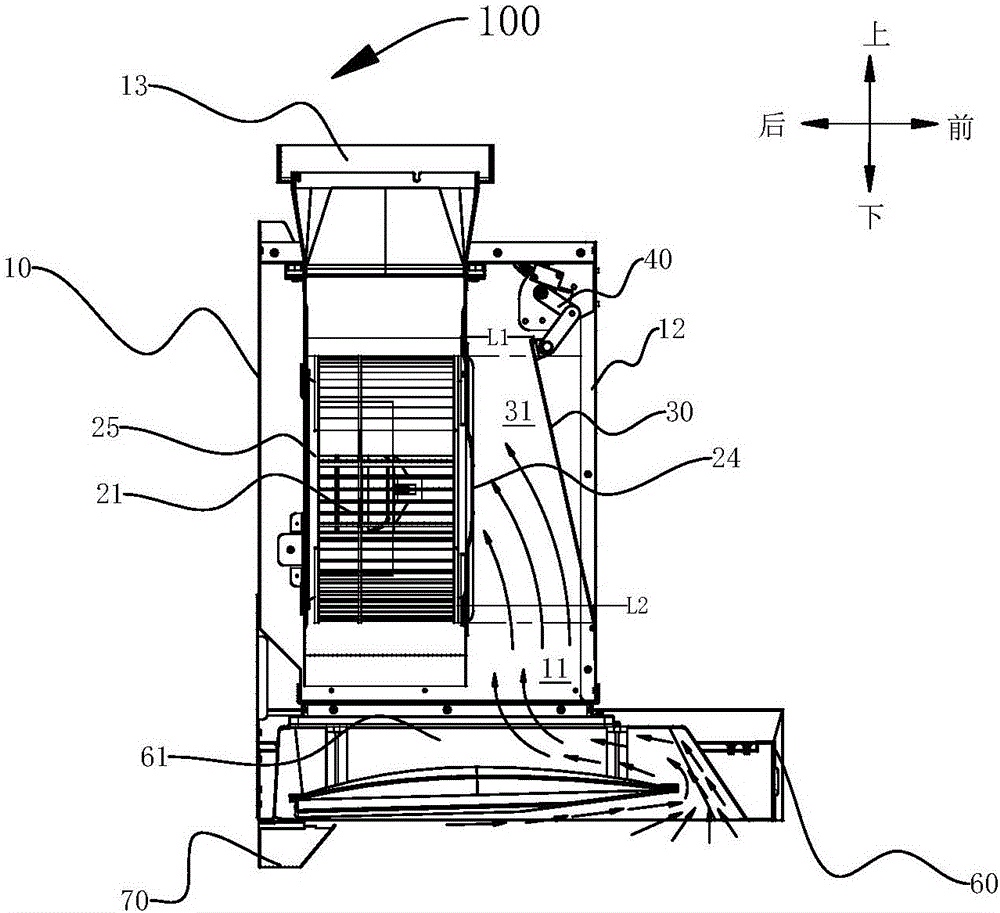

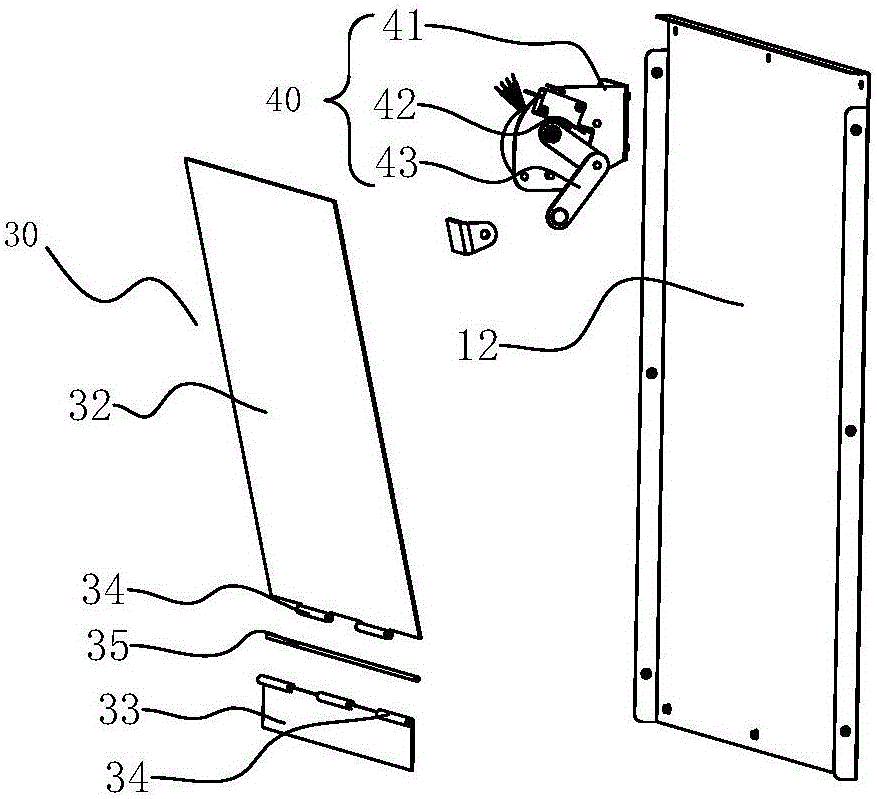

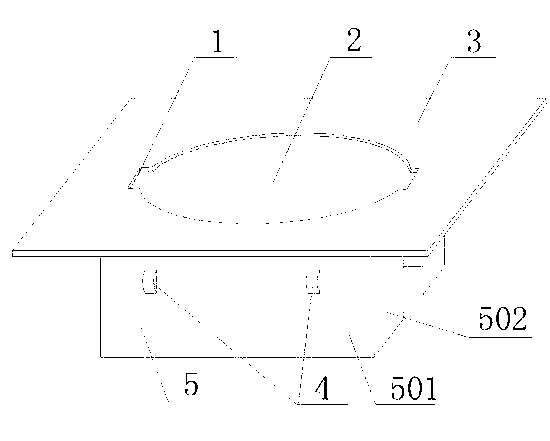

Extractor hood

ActiveCN105674365AReduce working noiseReduce air lossDomestic stoves or rangesLighting and heating apparatusAir volumeFlue gas

The invention discloses an extractor hood. The extractor hood comprises a machine shell, a volute fan and a rectifying device; the volute fan is arranged in the machine shell, and the machine shell is internally provided with a flue gas channel communicated with a volute gas inlet; the rectifying device is arranged in the flue gas channel and is opposite to the volute gas inlet; a rectifying flue is limited between the rectifying device and the volute gas inlet, and the rectifying device is arranged to be adjustable relative to the position of the volute gas inlet so as to increase or decrease the flue gas flow inside the rectifying flue in the unit time; and according to the extractor hood, the rectifying device is arranged to be adjustable relative to the position of the volute gas inlet so as to increase or decrease the flue gas flow inside the rectifying flue in the unit time, and therefore cyclone, steaming around and the noise generated before lampblack is guided into a volute are avoided; and accordingly, the working noise and the air amount losses of the extractor hood are effectively reduced.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Construction method for nonstandard diaphragm wall

ActiveCN102852158AEasy constructionImprove construction efficiencyArtificial islandsUnderwater structuresConductor pipeBuilding construction

The invention discloses a construction method for a nonstandard diaphragm wall and belongs to the technical field of the construction technology. Construction tools are improved, and the method includes excavating a guide wall groove, producing a guide wall, grooving through a hydraulic grab, placing an special-shaped locked port pipe, a reinforcement cage and the like, arranging a conduit to pour concrete, and repeating the operation to obtain the nonstandard diaphragm wall which is used for retaining soil and water and the like during building pit construction. The construction method is simple in process and convenient to operate, high in working efficiency and low in cost; the obtained nonstandard diaphragm wall is smooth in surface and good in water retaining effect; the used equipment is low in cost and little in improvement time; compared with the existing method in which the locked port pipe is reprocessed, the cost is reduced from one million to below 30 thousands, the time is reduced from one month to three days, and therefore the nonstandard diaphragm wall is low in construction cost, convenient to construct, attractive in appearance and easy to popularize and apply.

Owner:浙江省地矿建设有限公司

Folding double-face rudder and underwater vehicle with double-face rudder

The invention relates to a folding double-face rudder and an underwater vehicle with the double-face rudder. The double-face rudder comprises two rudder faces arranged oppositely and a base connectedbetween the two rudder faces. The folding double-face rudder has the beneficial effects that the double-face rudder has the high rudder effect relative to a single rudder face, and under the conditionof the same aspect ratio, the double-face rudder has larger control force and control torque; the double-face rudder can be folded to the tail of the vehicle, the mounting size is reduced, and when acarrying platform suffers from size limiting, the vehicle with the folding rudder faces has high adaptability; according to the vehicle controlled by the double-face rudder, the posture of the vehicle can be effectively adjusted under the conditions of a low speed and a high speed; and relative to other underwater vehicles, the underwater vehicle has the advantages of being simple in structure and flexible in control form and has the characteristics of energy saving, high efficiency and stability especially for the underwater high-speed navigational status.

Owner:NAVAL UNIV OF ENG PLA

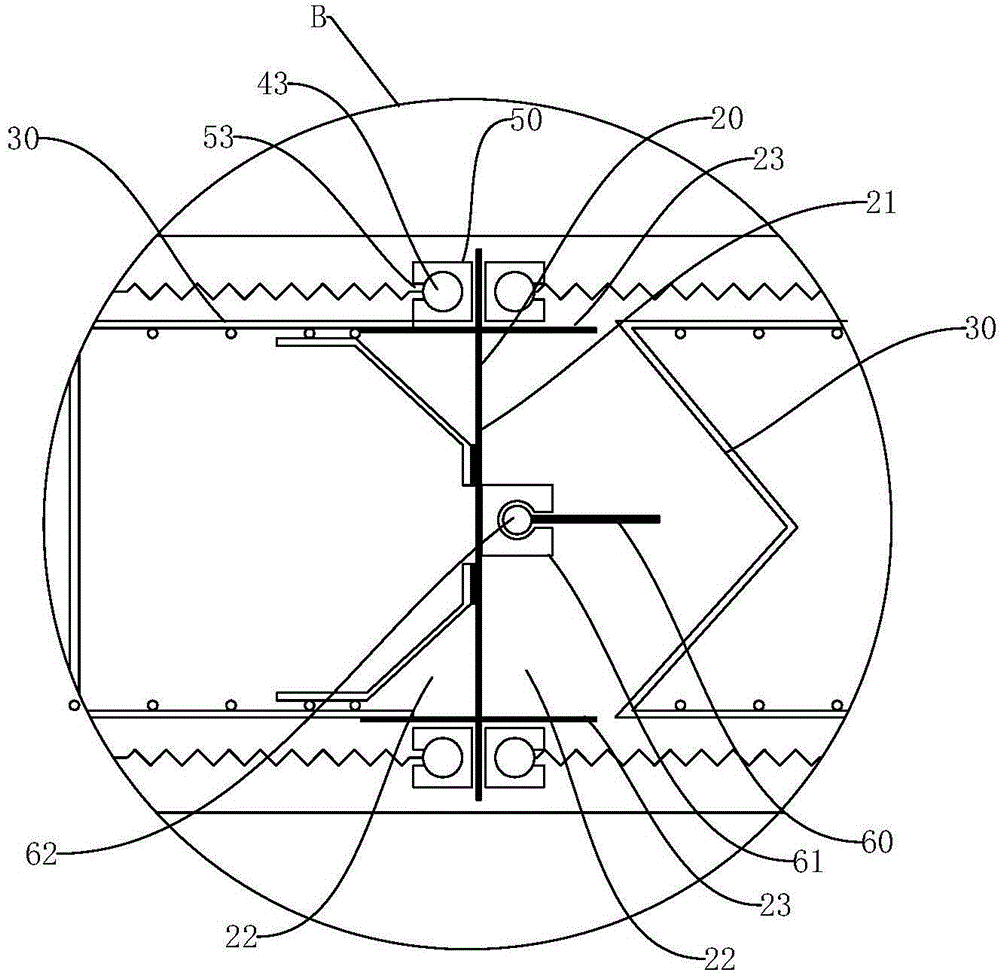

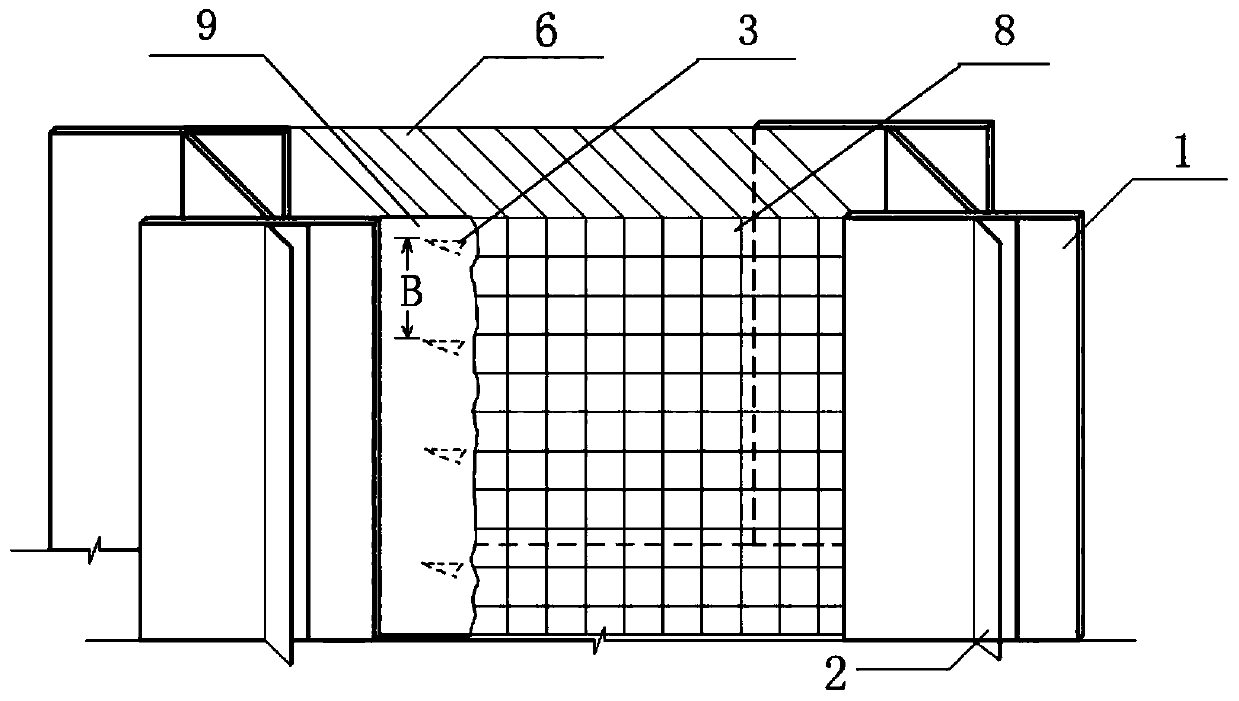

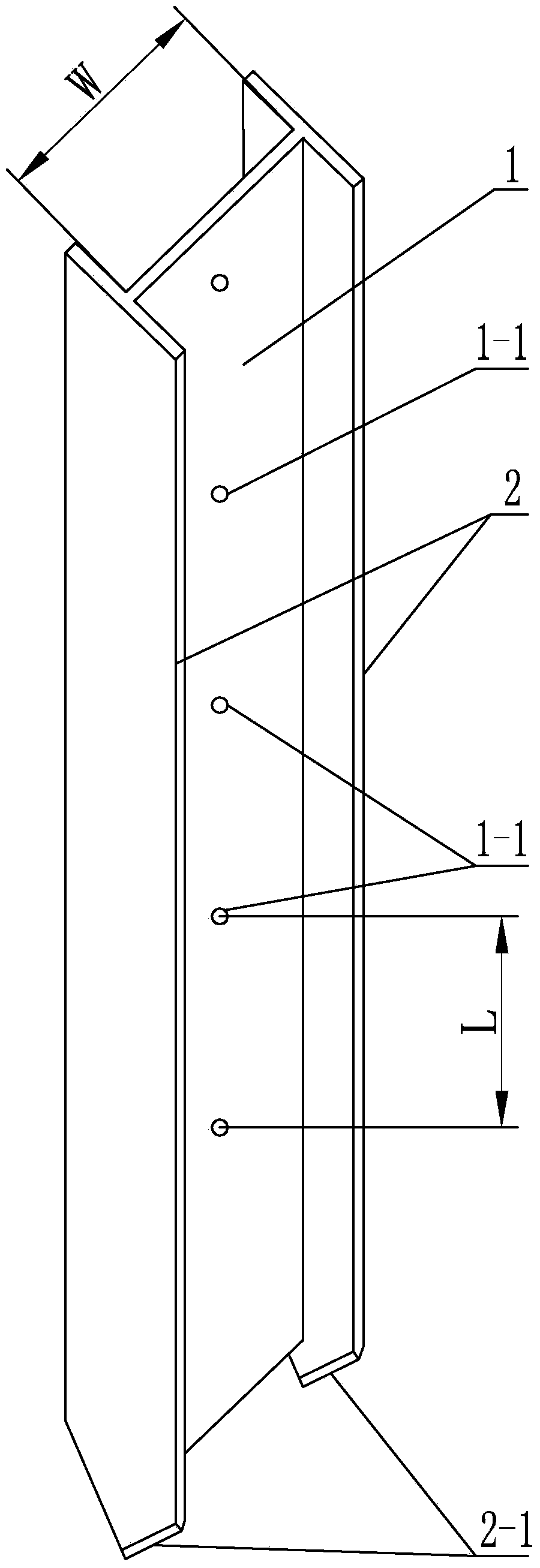

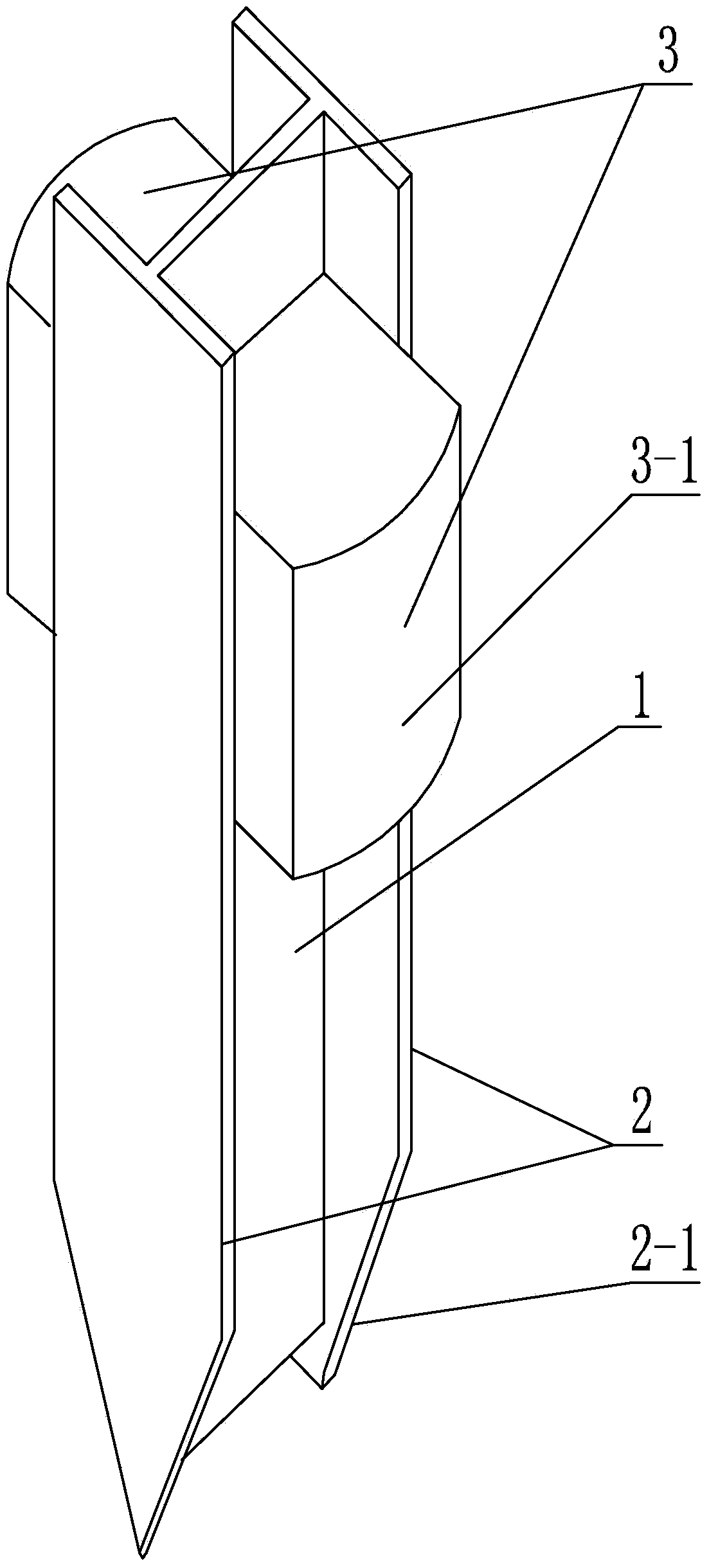

I-beam joint structure preventing flowing around body and water seeping of underground diaphragm wall and construction method thereof

The invention discloses an I-beam joint structure preventing flowing around a body and water seeping of an underground diaphragm wall and a construction method thereof. The joint structure is composedof an I-beam formed by welding two pieces of wing plate section steel to one piece of web section steel, grout stopping iron sheets, rubber water stopping belts, vertical sealing ribs at the cornersof the ends of a subsequent slot section, blade feet on the bottom of the I-beam joint and the like; the inner sides of the wing plate section steel of the I-beam joint are welded to horizontally distributed ribs of an early slot section, and the grout stopping iron sheets are welded to the outer sides of the wing plate section steel; the rubber water stopping belts stick to the inner sides of thewing plates of the I-beam of the subsequent slot section by means of binder; the vertical sealing ribs are welded at the corners of the ends of a subsequent slot section steel reinforcement cage. According to the joint structure, the integrity is good, construction is easy, the problem that concrete flows around a body is effectively prevented, the anti-seepage effect in a joint is good, and thestructure is applicable to joint connection of an ultra deep underground diaphragm wall.

Owner:TAIYUAN UNIV OF TECH

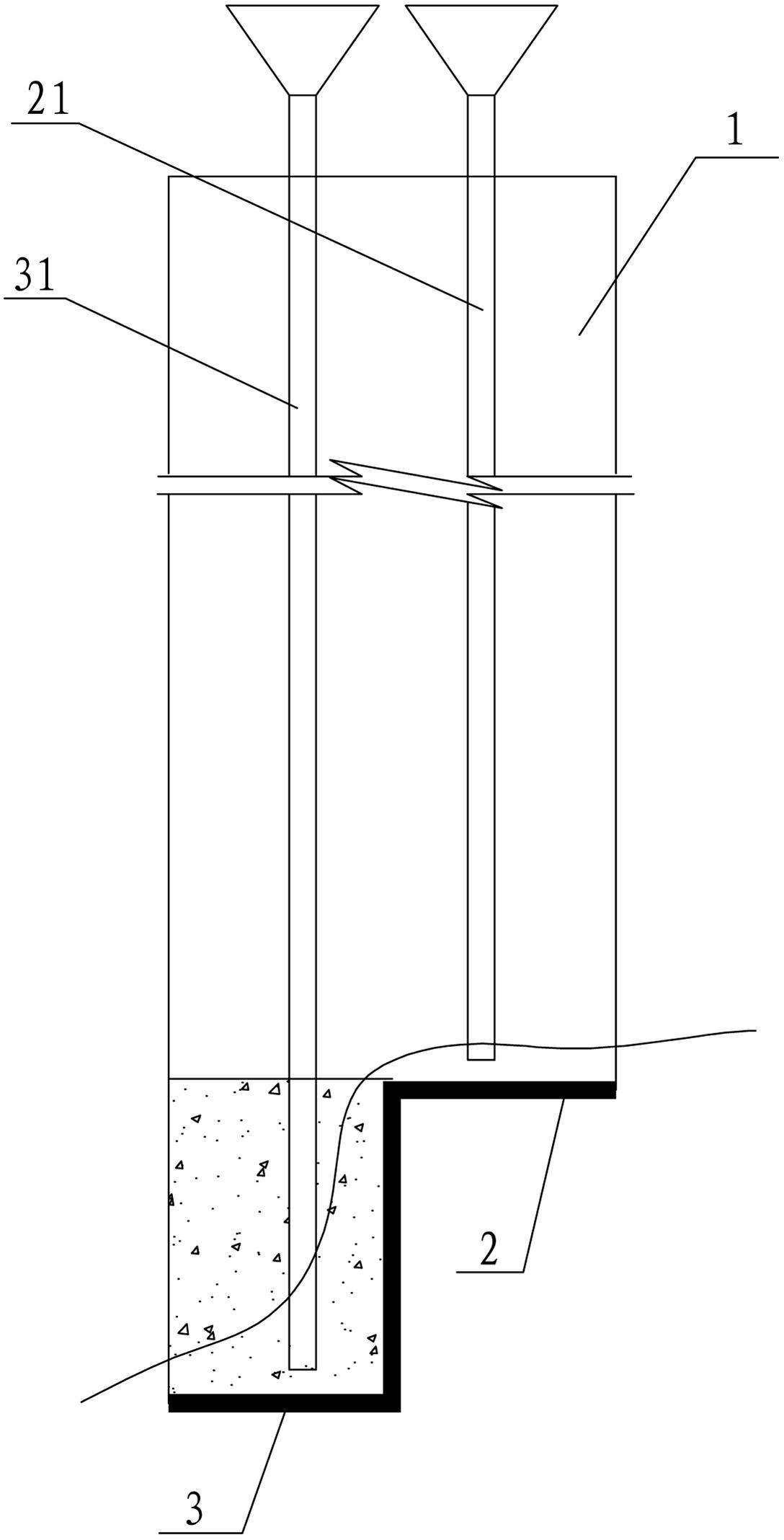

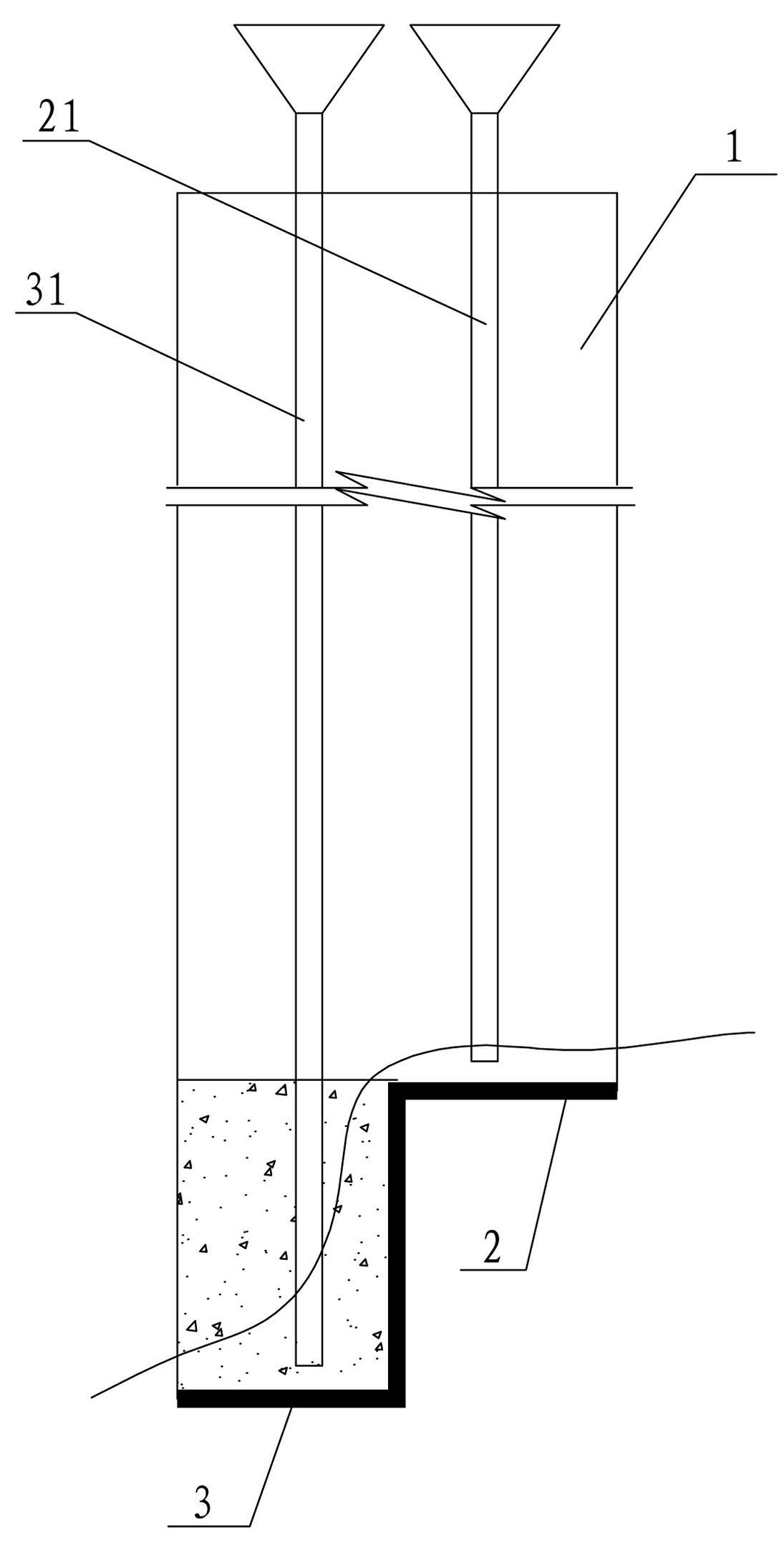

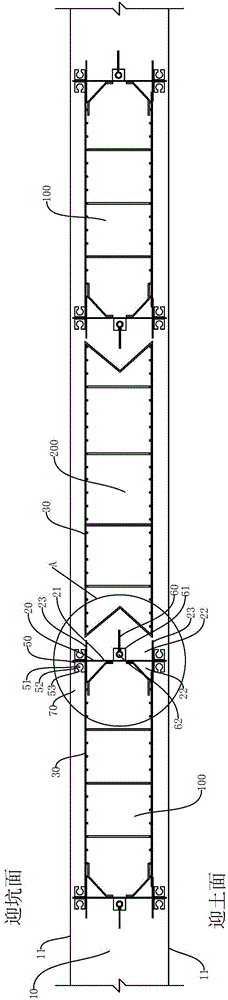

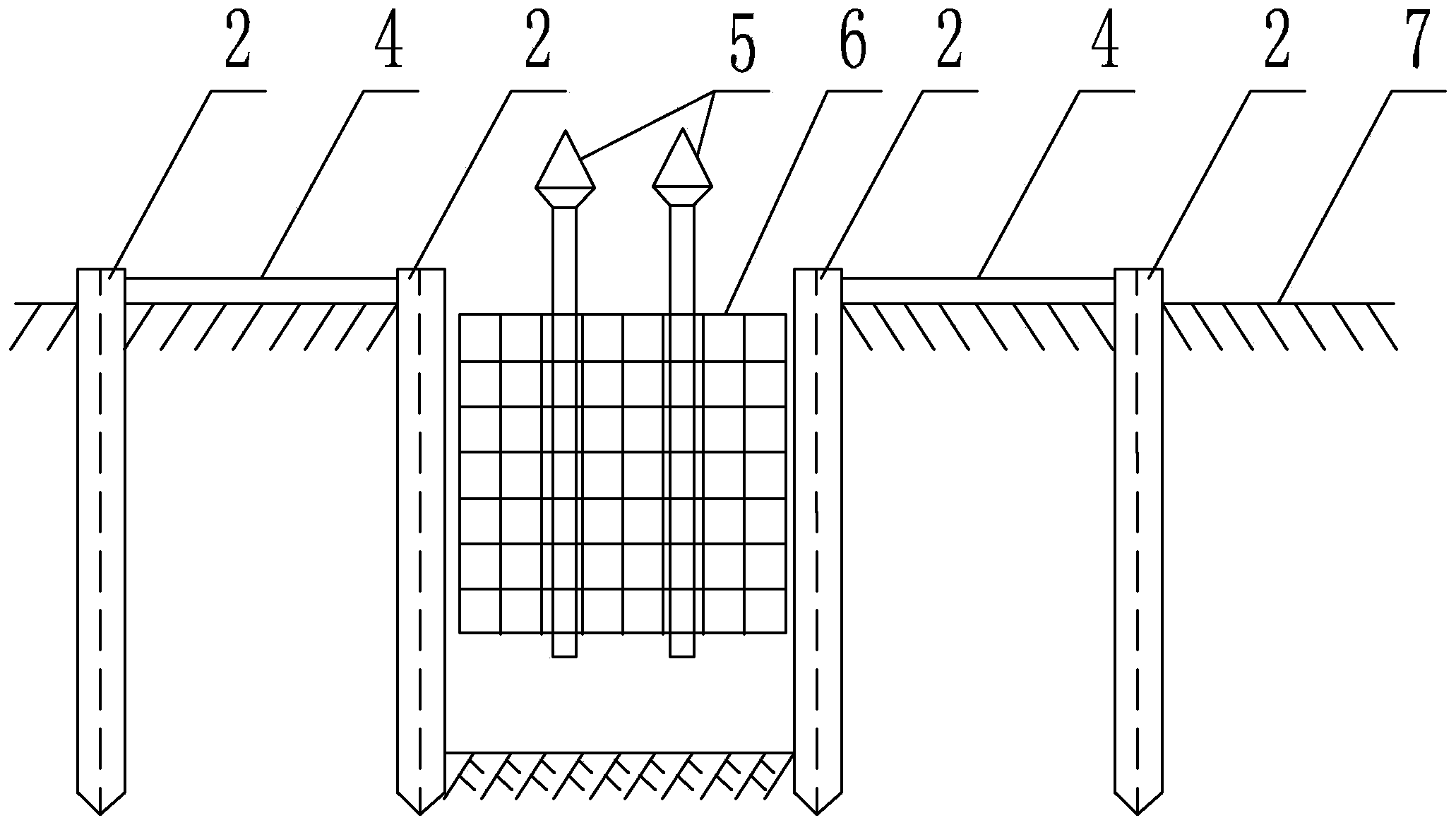

Super-deep diaphragm wall rigid connector comprehensive water stop system and construction method thereof

PendingCN107653872APrevent bypass flowAvoid it happening againBulkheads/pilesWater stopAdhesive belt

The invention discloses a super-deep diaphragm wall rigid connector comprehensive water stop system and a construction method thereof. The super-deep diaphragm wall rigid connector comprehensive waterstop system is arranged between a pit facing face and a soil facing face and comprises a first-stage groove section reinforcement cage, an I steel connector and a second-stage groove section reinforcement cage, wherein the first-stage groove section reinforcement cage, the I steel connector and the second-stage groove section reinforcement cage are sequentially arranged from left to right. The connector end of the first-stage groove section reinforcement cage is provided with a head sealing rib. The second-stage groove section reinforcement cage is fixedly connected with the inner side of anI steel connector flange slab, and grout stop iron sheets and pressure welding ribs are arranged on the outer sides of connecting joints of the second-stage groove section reinforcement cage and the Isteel connector flange slab. A multi-time grouting pipe is arranged at the position, close to the corner portion of the soil facing face, of the connecting end of the first-stage groove section reinforcement cage and the second-stage groove section reinforcement cage, the bottom of the multi-time grouting pipe is sealed, and the outer wall of the multi-time grouting pipe is wrapped by grouting adhesive tape. Partition blades are arranged in the multi-time grouting pipe and separate the multi-time grouting pipe into three one-time grouting channels, and the outer wall of each one-time groutingchannel is provided with a row of grout jetting holes which are evenly arranged along the multi-time grouting pipe at intervals. The super-deep diaphragm wall rigid connector comprehensive water stopsystem and the construction method thereof have the beneficial effects of being safe, applicable and the like, very good popularization and practical value is achieved, and good economic benefits canbe generated after wide application and popularization.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

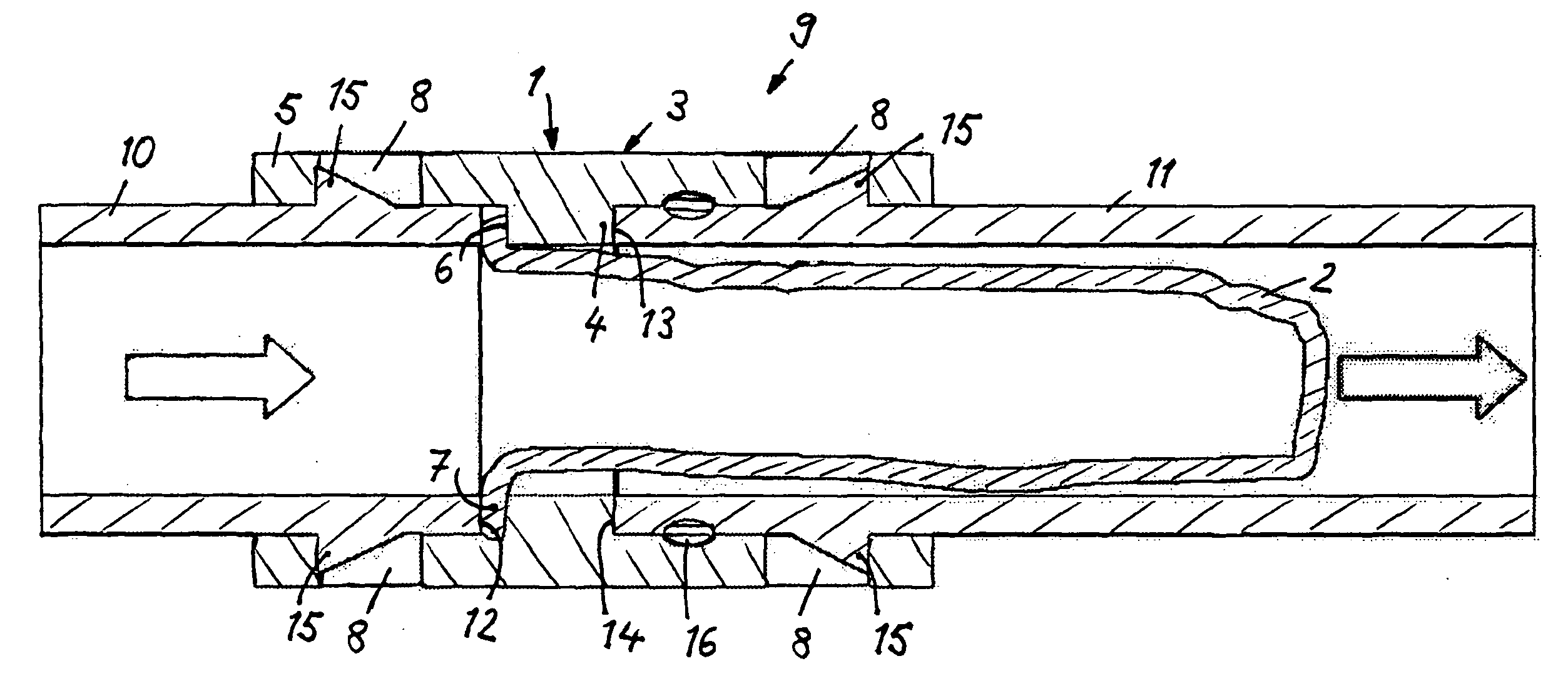

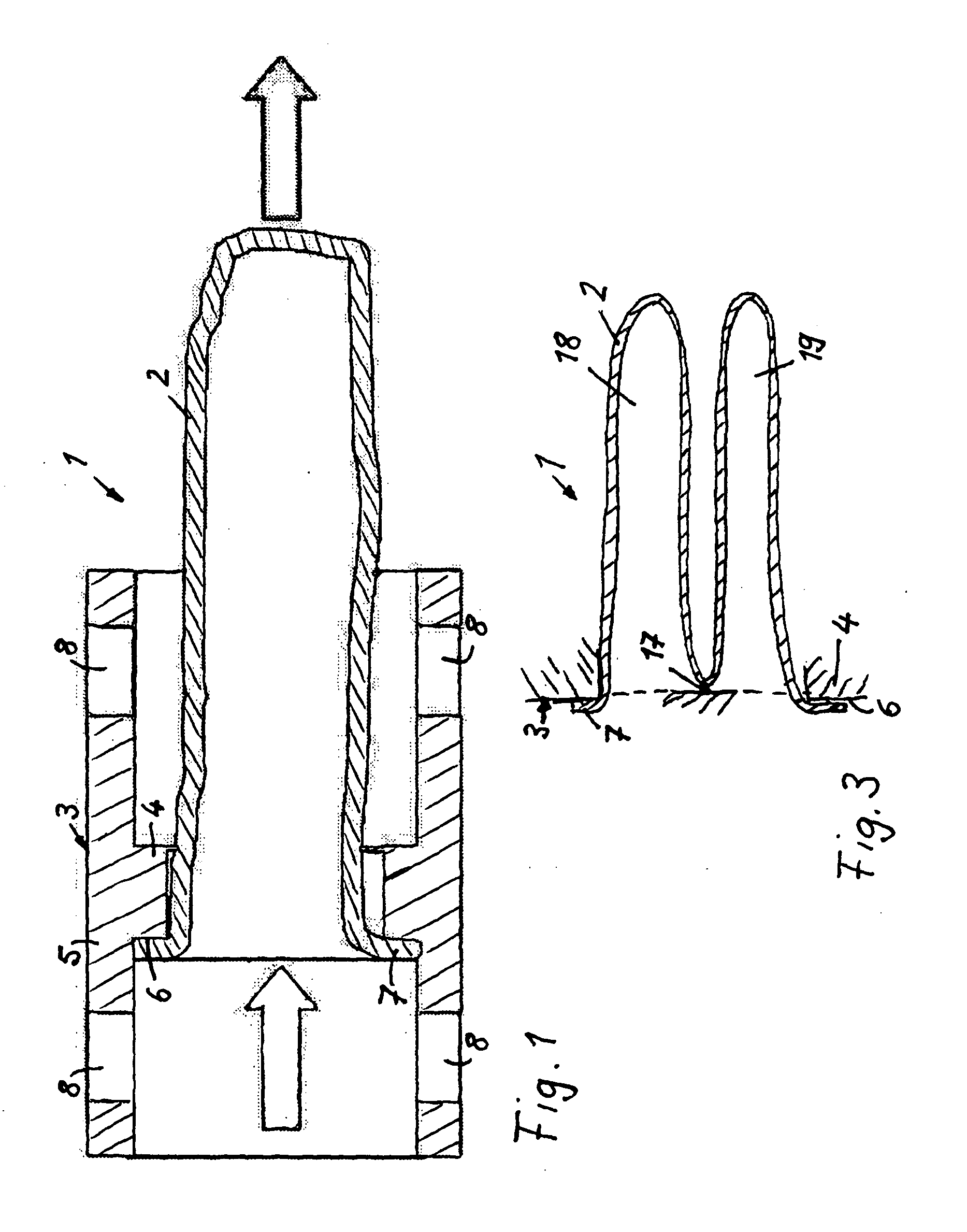

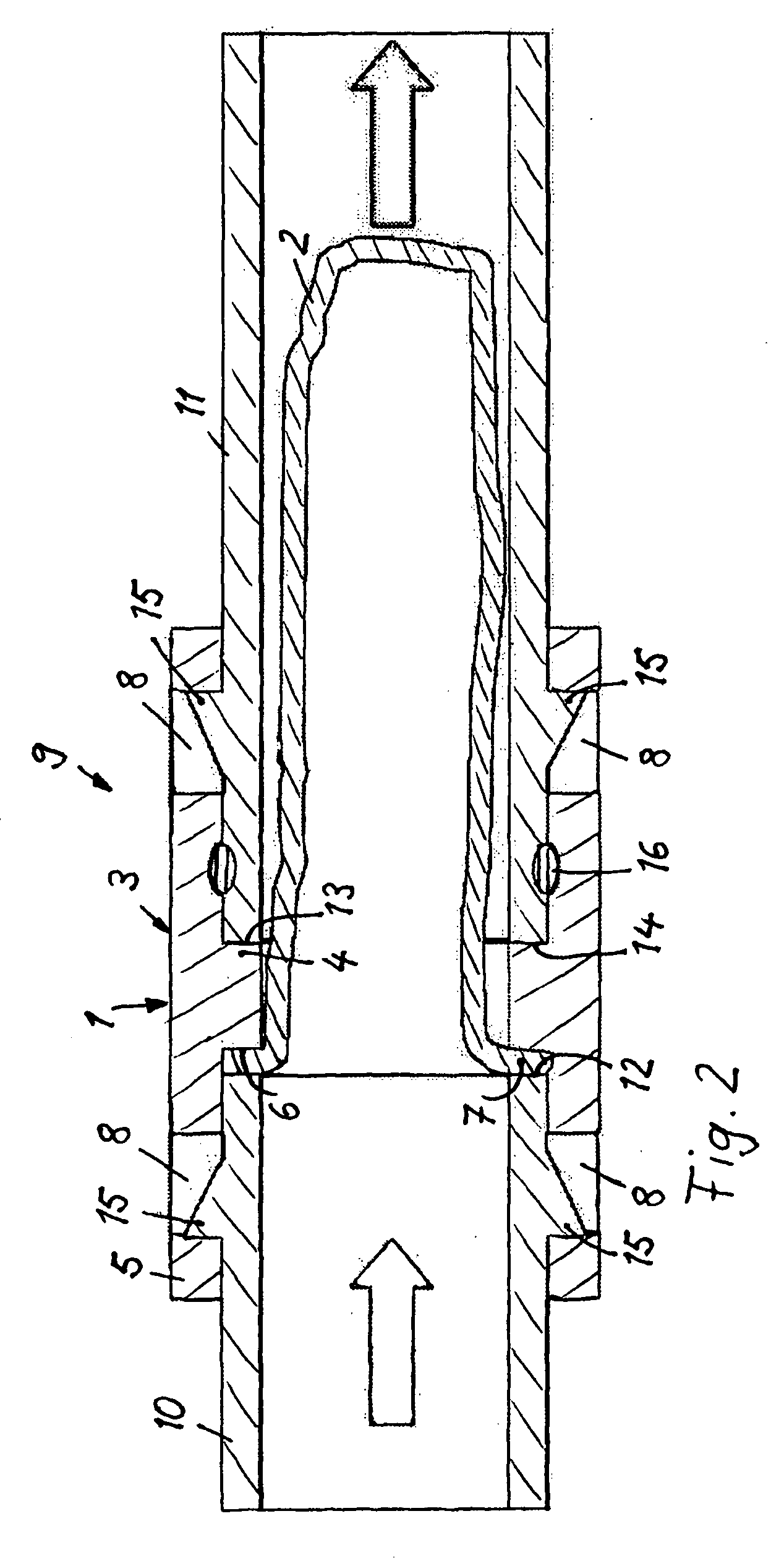

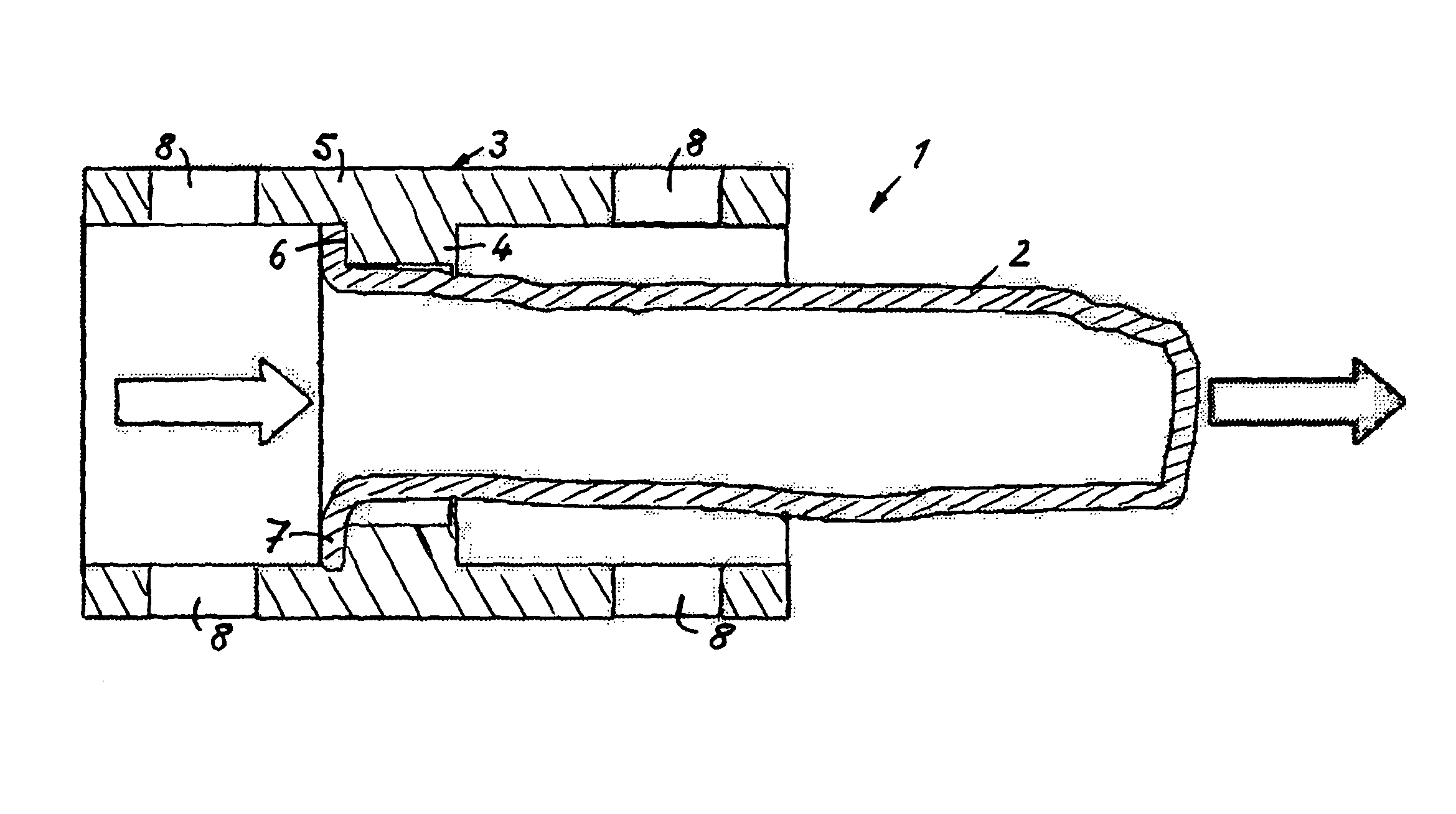

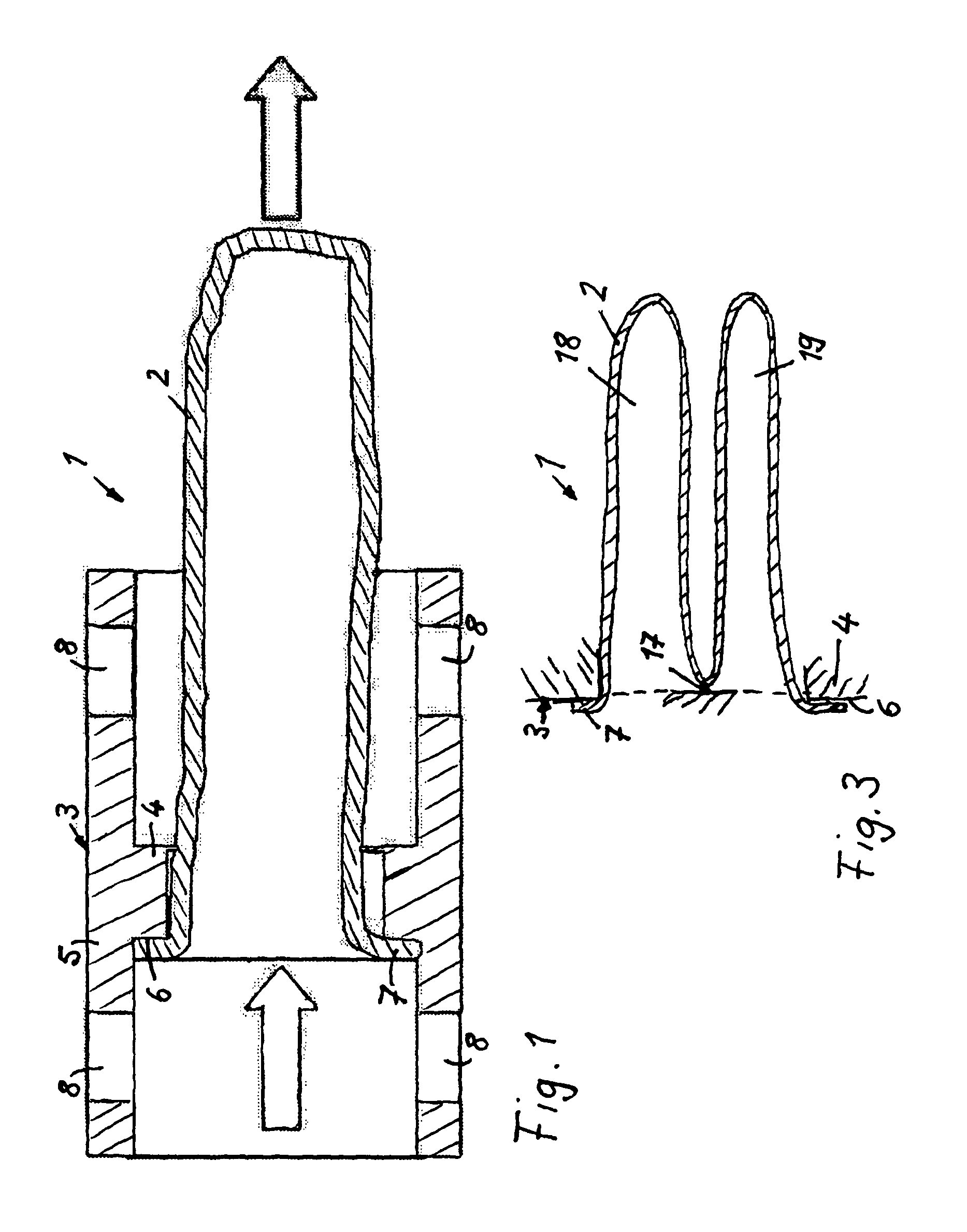

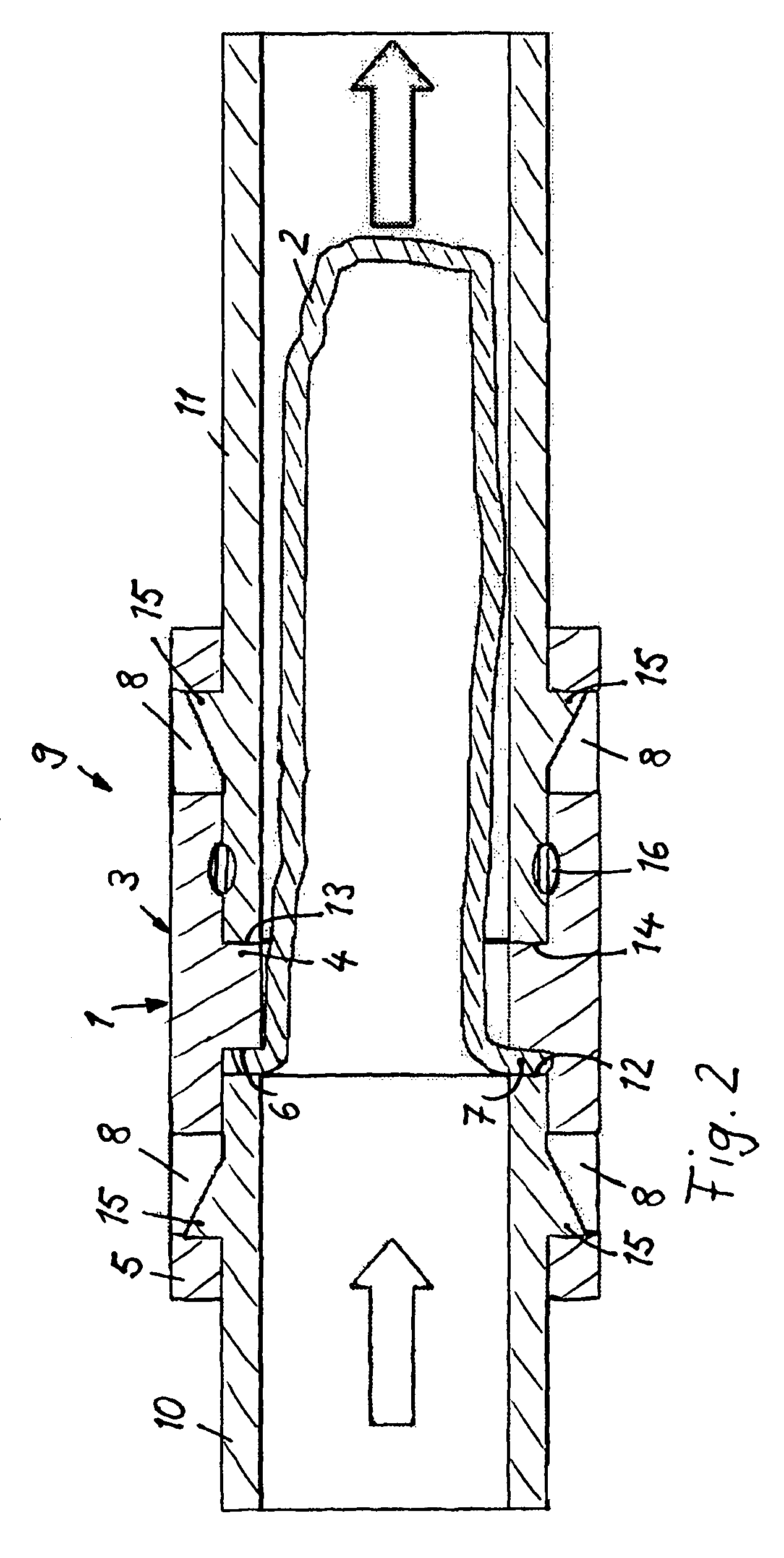

Filtering device

InactiveUS20100005766A1Shorten the axial lengthPromote circulationCombination devicesGas treatmentEngineeringContinuous flow

The invention relates to a filtering device, comprising a tubular filter element and a carrier part, with the filter element fastened thereon. The carrier part can be inserted between an unfiltered fluid pipe and a filtered fluid pipe. The pipes can be assembled into a continuous flow pipe, wherein the filter element protrudes into the pipe interior.

Owner:MANN HUMMEL GMBH

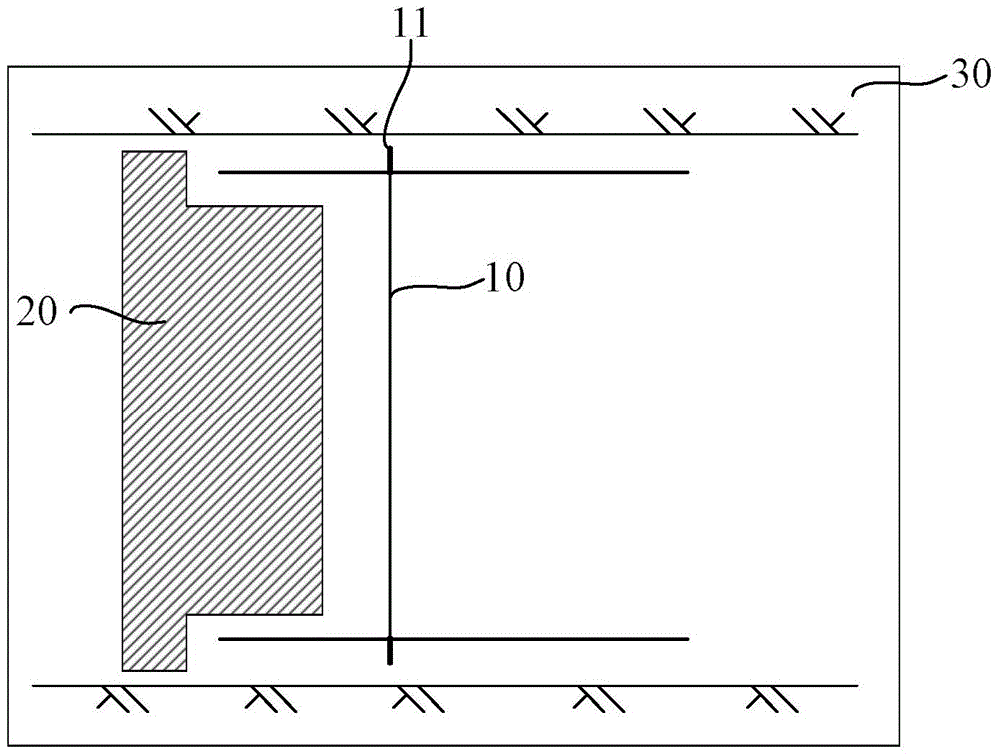

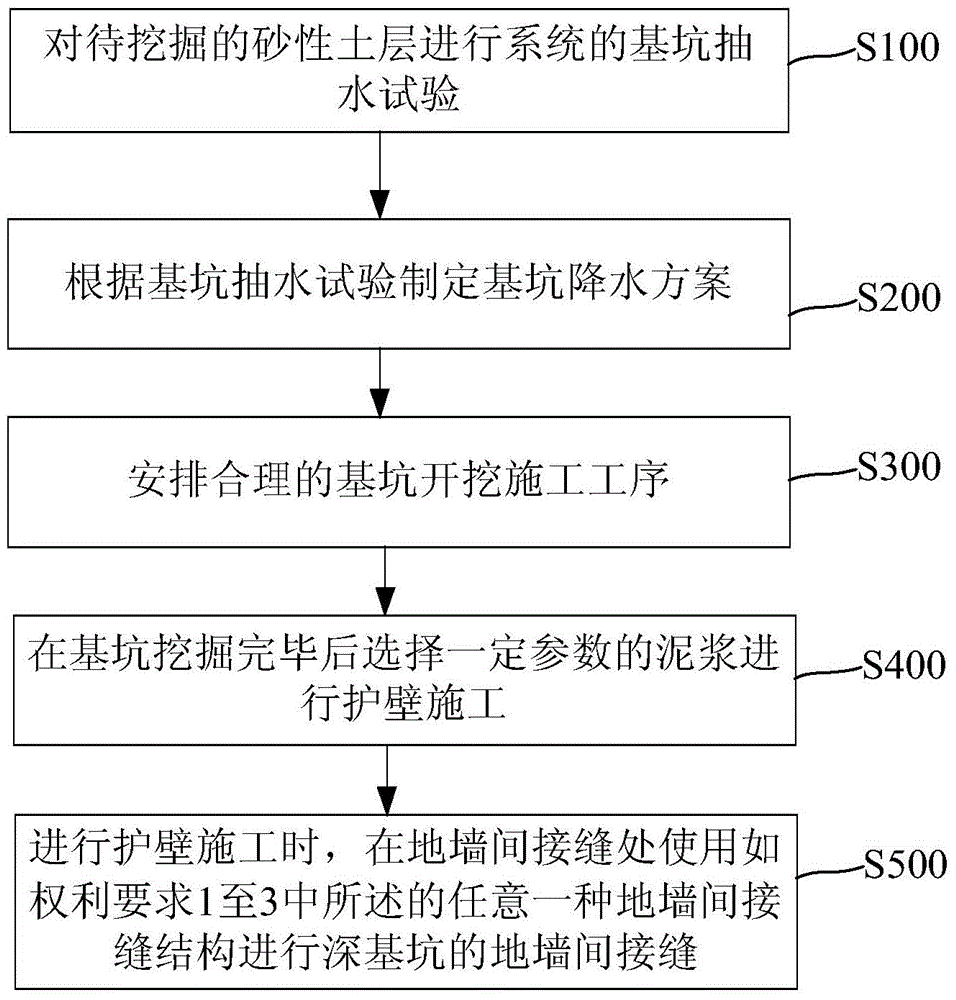

Joint structure between ground and wall and sandy soil layer foundation pit construction method

InactiveCN103981904APrevent bypass flowAvoid churnArtificial islandsExcavationsSoil horizonPrecipitation

The invention provides a joint structure between ground and a wall and a sandy soil layer foundation pit construction method. A lock catch pipe is installed at the position of an H-steel connector and can effectively ensure bonding of the H-steel connector and have the effect of preventing concrete flowing around. In addition, wing plates are arranged on two sides of H-steel and can prevent a gap between the H-steel and a foundation pit groove wall from being overlarge and accordingly prevent concrete from easily flowing out of a groove section, and accordingly the water seepage and leakage problem at the joint position between the ground and the wall is solved. Furthermore, by adopting the sandy soil layer foundation pit construction method, good precipitation treatment can be performed on a foundation pit, the water seepage and leakage risk is avoided during construction, and the risk of deep foundation pit construction in a sandy soil layer can be further reduced.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Underground diaphragm wall construction method

ActiveCN104790430APrevent bypass flowSolve the leakArtificial islandsUnderwater structuresSlurry wallWater leakage

The invention discloses an underground diaphragm wall construction method. The underground diaphragm wall construction method is characterized by comprising the steps that 1, grooving is performed, wherein a groove is provided with groove walls; 2, connectors and steel reinforcement cages are placed in the groove, and the connectors are arranged at one end or the two ends of each steel reinforcement cage; 3, concrete is filled, the concrete is wrapped around steel reinforcement cages, and an underground diaphragm wall is formed after the concrete is solidified; isolating devices are arranged between all or parts of the steel reinforcement cages and the groove walls of the groove, and the two ends of each isolating device are connected to the ends of the steel reinforcement cages or the connectors respectively; the isolating devices seal at least one side of each steel reinforcement cage and is used for stopping the concrete filled in one steel reinforcement cage to perform detour flow from the side to the other steel reinforcement cages or the concrete poured in the adjacent steel reinforcement cage to perform the detour flow to the section of steel reinforcement cage. According to the underground diaphragm wall construction method, the wall is arranged outside the steel reinforcement cages in an isolated mode, the detour flow when the concrete is poured in the section of steel reinforcement cage can be effectively prevented, the concrete poured in the section is prevented from performing the detour flow to another adjacent section of steel reinforcement cage, the concrete respectively poured in the adjacent steel reinforcement cages can not make contact, a seam can not be generated, and therefore the water leakage problem is solved.

Owner:SHANGHAI YUANFANG GROUNDWORK ENG

Even wall construction method capable of preventing concrete from streaming around

InactiveCN110700237AEven by forceReduce side pressureArtificial islandsUnderwater structuresArchitectural engineeringRebar

The invention provides an even wall construction method capable of preventing concrete from streaming around. The method comprises the steps that S1, a reinforcement cage of a current groove segment is prefabricated, pulp stop iron sheets are welded to the outer sides of flange structural steel on the two sides of I steel, after the pulp stop iron sheet on the lower layer is laid, triangular supporting steel reinforcing ribs are welded to horizontal steel reinforcing ribs of the reinforcement cage and, after the pulp stop iron sheet on the upper layer is laid, according to the manner of arranging triangular supporting steel reinforcing ribs on the lower layer, the triangular supporting steel reinforcing ribs are laid on the pulp stop iron sheet on the lower layer; S2, the groove segment isgrooved, along with step-by-step lowering of the reinforcement cage, equal leg angles are added on flange plates on the two sides of the I steel in a welded manner, the specification of the equal legangles is L5cm*5cm*5mm, and the equal leg angles are arranged in a length passing manner from the bottom to the top of the I steel; and S3, a guide pipe method is used for pouring concrete to the groove segment. In the even wall pouring process, the concrete can be prevented from streaming around, construction work efficiency of adjacent groove segments can be improved, and the wall seam connection quality of two groove segments is firmer.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

Filtering device

InactiveUS8409311B2Easy to measureSimple exchangeabilityCombination devicesGas treatmentContinuous flowBiomedical engineering

Owner:MANN HUMMEL GMBH

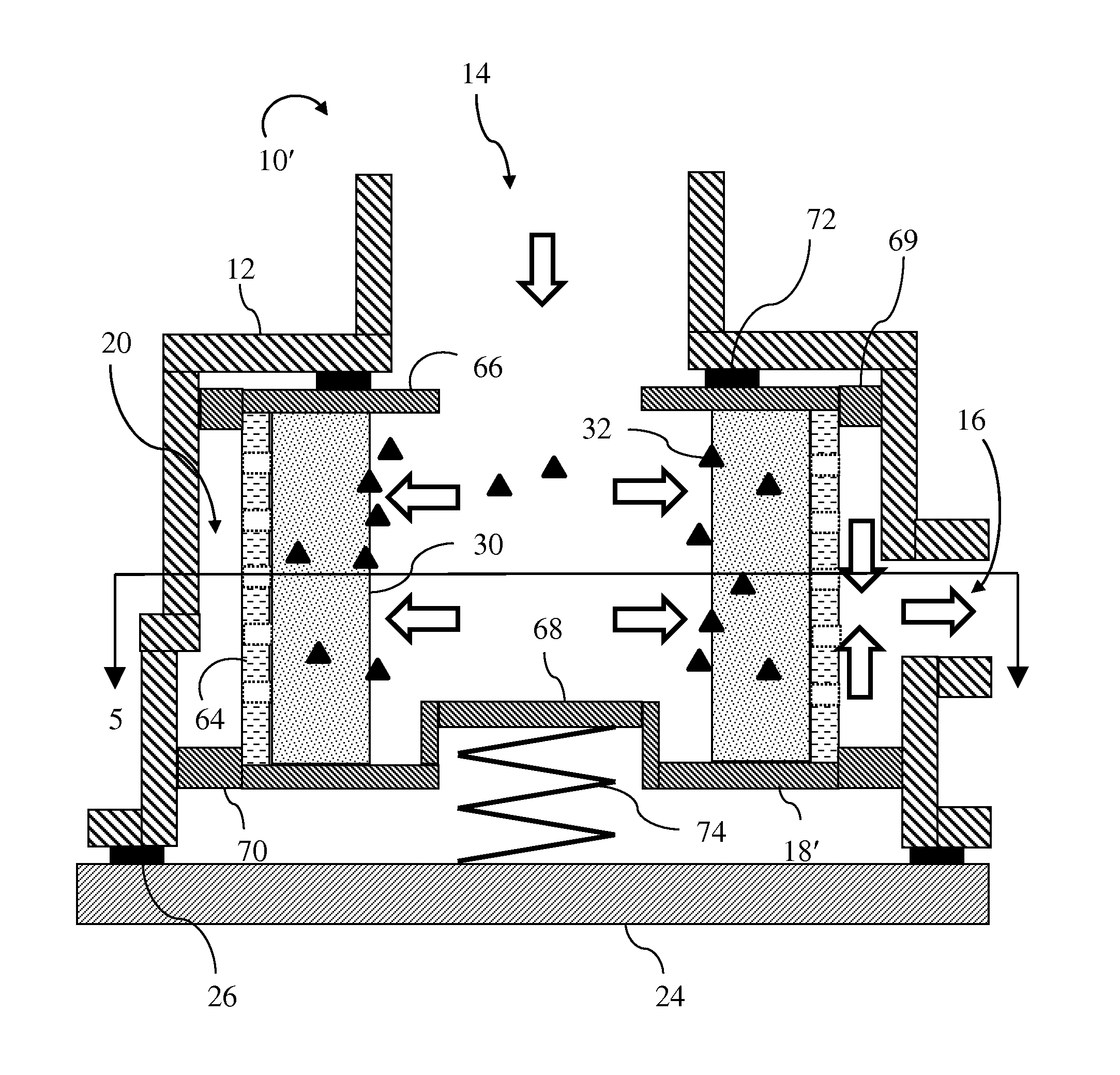

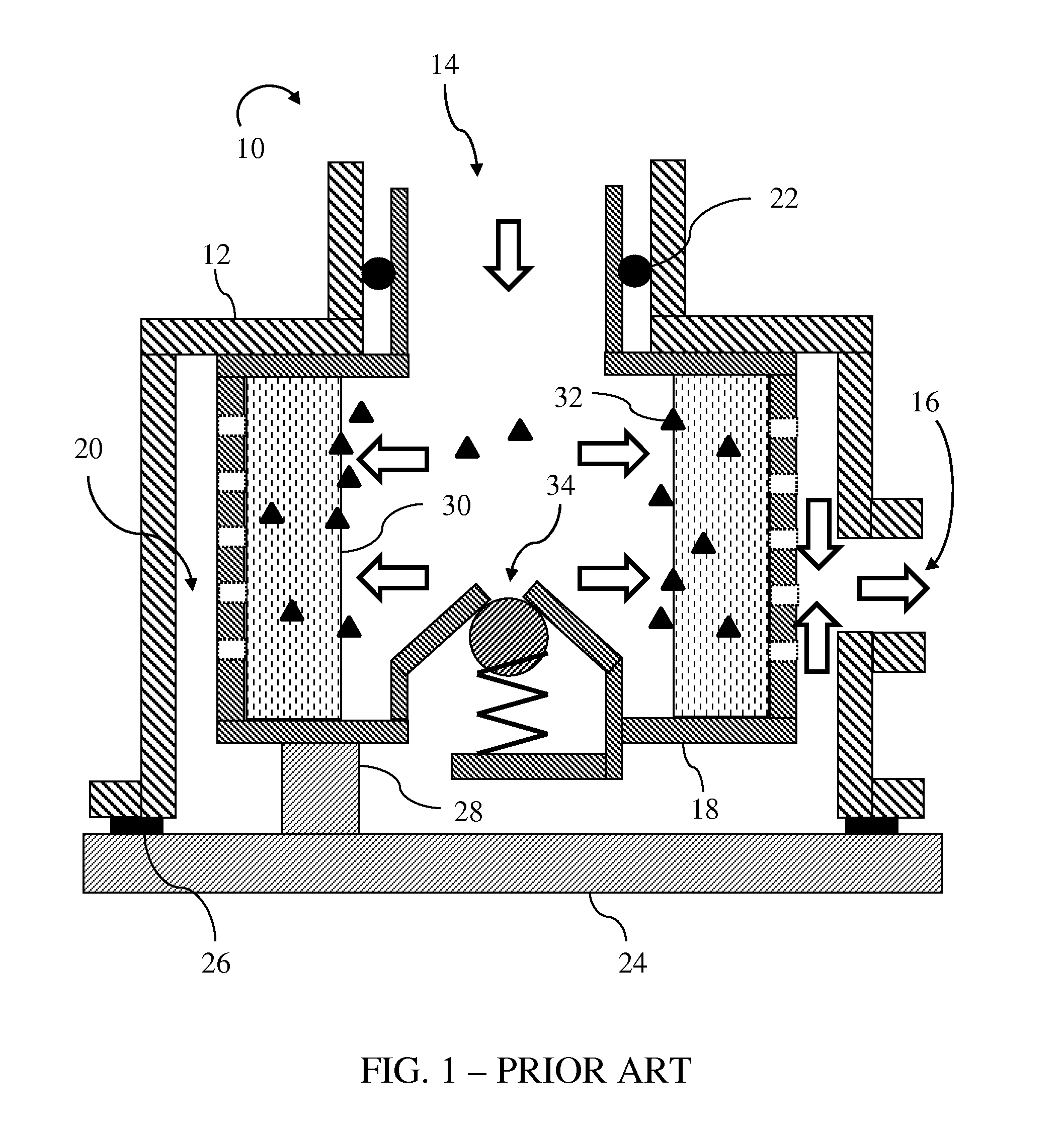

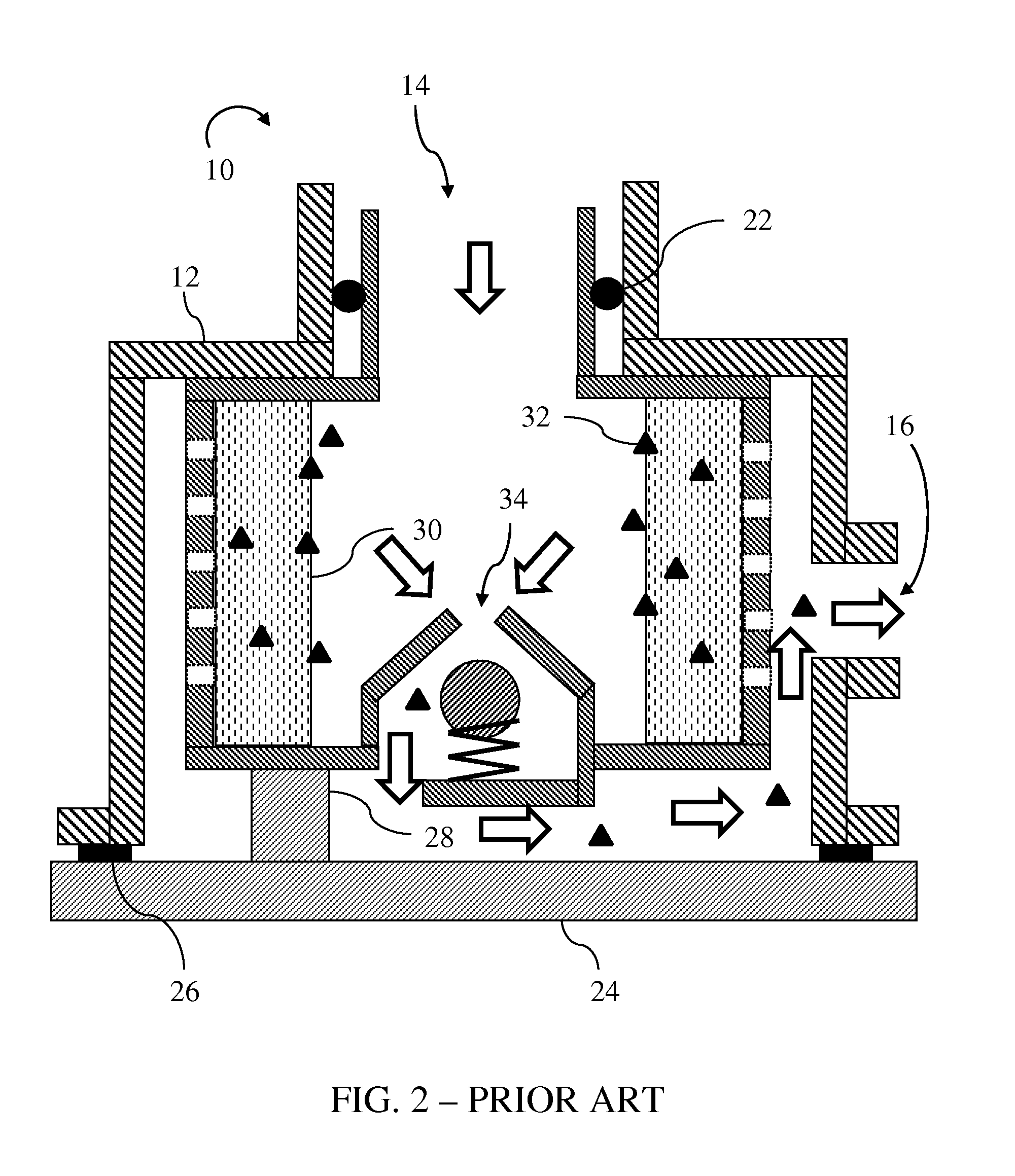

Transmission Oil Filter Assembly

InactiveUS20160341298A1Prevent bypass flowGear lubrication/coolingMembrane filtersFilter mediaMechanical engineering

A transmission filter assembly utilizes a filter cartridge that slides axially with respect to the filter chamber. In normal operation, a spring pushes the filter cartridge into a position such that fluid flows into the interior of the cartridge, through filter media, and then radially out of the cartridge. If the pressure drop across the filter is excessive, the pressure forces the filter cartridge to slide to a position in which fluid bypasses the filter media. In this bypass mode, fluid does not flow into the interior of the cartridge and therefore has a very low tendency to dislodge previously captured contaminants. Two sets of tabs position the cartridge radially within the chamber. The two sets are separated axially to prevent tilting of the cartridge.

Owner:FORD GLOBAL TECH LLC

Construction method for preventing diaphragm wall from streaming

InactiveCN102776878ASolve tightly coupled problemsTightly boundExcavationsBulkheads/pilesWater leakageBuilding construction

A construction method for preventing diaphragm wall from streaming comprises the following steps of: filling a plurality of sand bags behind an I-beam of a primary slot section, wherein the sand bags are small-volume normal woven bags filled with 1 / 3 volume of sand, bag mouths are tied firmly and the bags are paved, the sand in the bags are loose, and the bags are arranged behind the I-beam, and beaten and compacted by a steel box hammer so that the sand bags are filled behind the I-beam completely; repeating the operation till the whole process is finished; and taking out the filled sand bags when drilling during a secondary slot section. With the adoption of the method, the purpose of tight connection between the concrete of the secondary slot section and the I-beam joint in the diaphragm wall construction is achieved. The construction method has the characteristics of being convenient in construction and easy in operation, the streaming of concrete is avoided, the concrete of the secondary slot section is tightly combined with the I-beam joint, and the water leakage rate of the underground diaphragm wall is reduced.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP

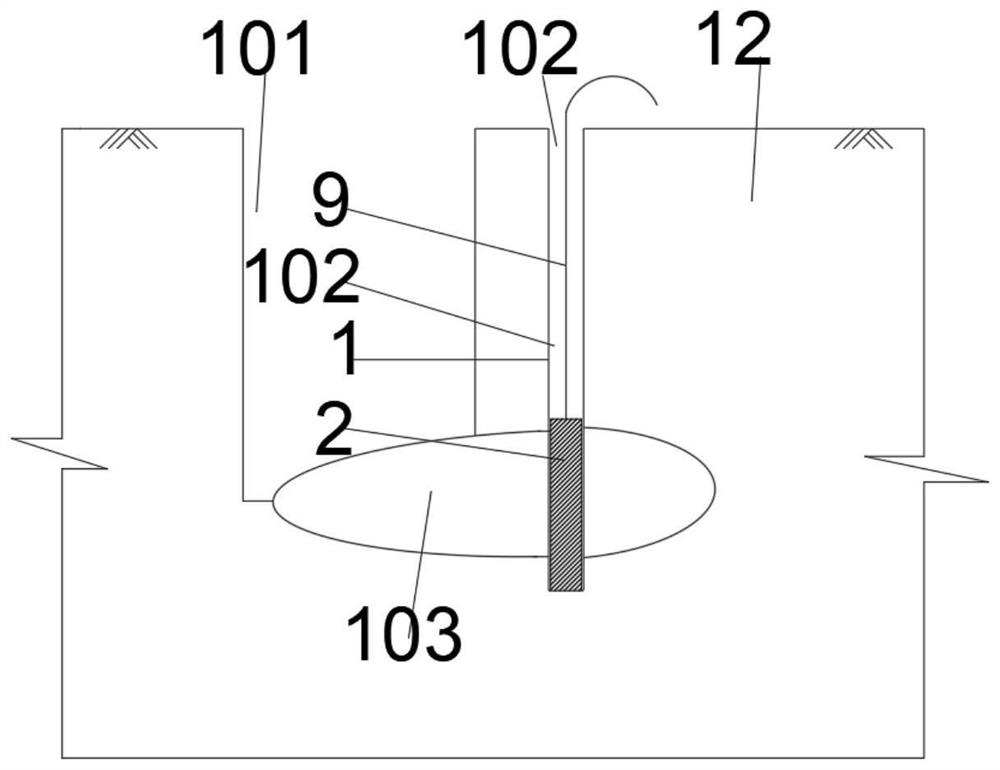

Underground diaphragm wall joint, clamping device matched with underground diaphragm wall joint and underground diaphragm wall construction method

ActiveCN103898927ASoil compactness is reliablePrevent bypass flowArtificial islandsUnderwater structuresSlurry wallH shaped

The invention provides an underground diaphragm wall joint, a clamping device matched with the underground diaphragm wall joint and an underground diaphragm wall construction method and relates to the underground diaphragm wall joint and the underground diaphragm wall construction method in order to solve the problems that slurry walls are out of plumb, lock catch tubes are installed obliquely or not in place and are hard to fix, and the pulling time of the lock catch tubes is hard to grasp in the construction process of the existing lock catch tubes. The underground diaphragm wall joint is characterized in that two side plates are fixedly connected into a whole through a web plate in the length direction, the cross section of the underground diaphragm wall joint is in an H shape, the lower end of each side plate is provided with an edge angle, a plurality of round through holes are evenly formed in the web plate in the length direction, and two cast steel balancing weights are fixed to the positions above the round through holes in the web plate through bolts and nuts. The underground diaphragm wall construction method includes the steps of carrying out guide wall construction, determining a position, assembling the clamping device, pressing the underground diaphragm wall joint into a soil body, dismantling clamping units, cleaning a groove, hoisting and placing a steel reinforcement cage into the groove, pouring concrete and directly carrying out excavation construction beside the groove after the concrete strength meets requirements. The underground diaphragm wall joint, the clamping device matched with the underground diaphragm wall joint and the underground diaphragm wall construction method are applied to construction of underground diaphragm walls.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP NO 4 ENG

Underground diaphragm wall reinforcement cage structure with formworks and construction method of underground diaphragm wall reinforcement cage structure

The invention belongs to the technical field of municipal engineering underground diaphragm wall construction, and particularly relates to an underground diaphragm wall reinforcement cage structure with formworks and a construction method of the underground diaphragm wall reinforcement cage structure. The underground diaphragm wall reinforcement cage structure comprises an underground diaphragm wall reinforcement cage, and steel plates are arranged at the bottom end and on the two side surfaces of the underground diaphragm wall reinforcement cage. Multiple pieces of channel steel are welded to the two side surfaces of the underground diaphragm wall reinforcement cage, and the underground diaphragm wall reinforcement cage is provided with the steel plates through the channel steel. The channel steel is welded with the steel plates or is in adhesive connection with the steel plates through an adhesive. The steel plate on the outer side surface of the underground diaphragm wall reinforcement cage is a stainless steel plate, and the underground diaphragm wall reinforcement cage is welded with the stainless steel plate through the channel steel; and the steel plate on the inner side surface of the underground diaphragm wall reinforcement cage is a common steel plate, and the underground diaphragm wall reinforcement cage is in adhesive connection with the common steel plate through the channel steel by using the adhesive. According to the invention, the steel plate formworks are between the inner and outer surfaces of a preset underground diaphragm wall and a soil body, the surface quality and the internal compactness of concrete are improved, a continuous waterproof layer is formed on the outer surface of the diaphragm wall, and the leakage and seepage resistance of the underground diaphragm wall is greatly improved.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com