Even wall construction method capable of preventing concrete from streaming around

A construction method and a technology for connecting walls to ground, which are applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problem of not taking into account the flow of concrete to adjacent grooves, etc., so as to achieve a solid wall joint connection quality and a stress-bearing effect. Uniform and improve the effect of project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

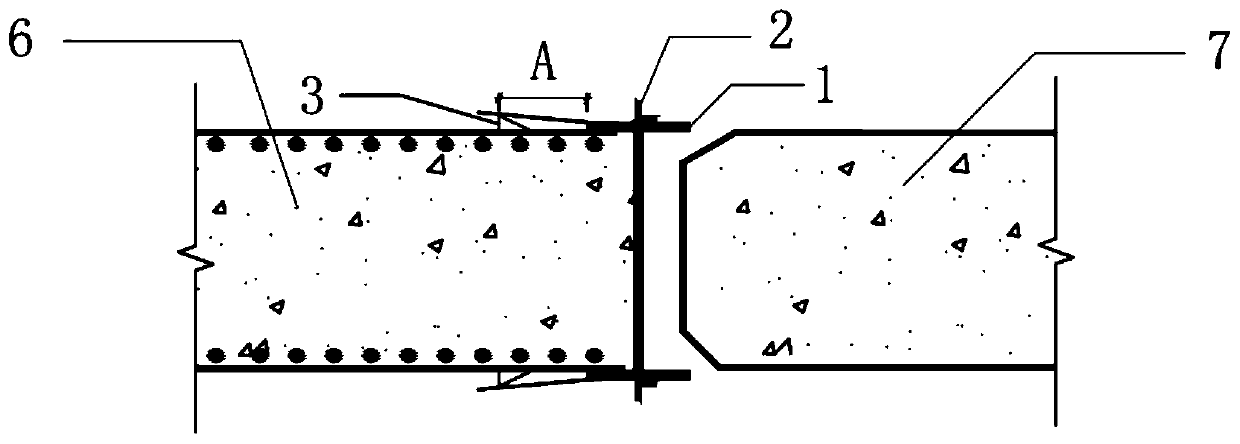

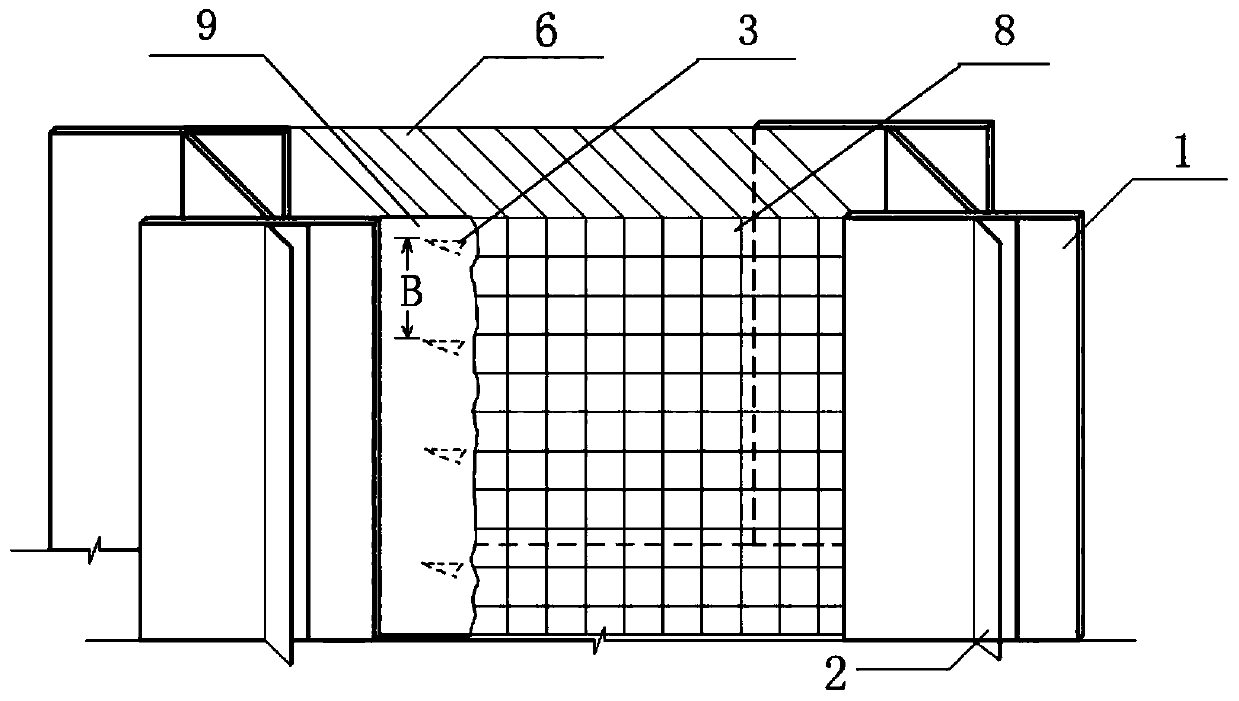

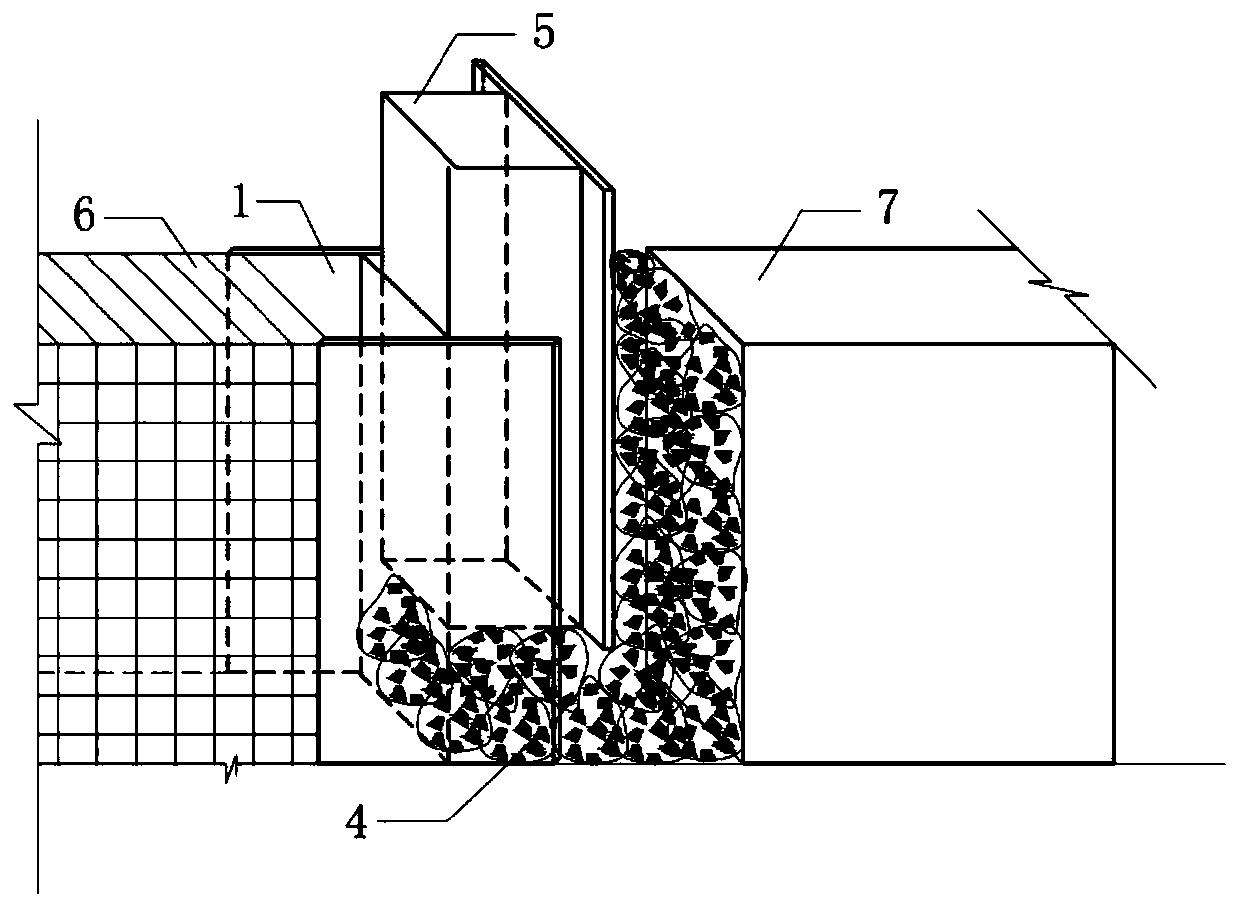

[0039] Such as figure 1 , figure 2 and image 3 As shown, a ground connection wall construction method to prevent concrete flow, including the following steps:

[0040] S1: Prefabrication of the reinforcement cage for the current trough section 8:

[0041] S1.1: Weld the steel cage I-steel flange plate 1 on both sides of the I-steel joint with the horizontal reinforcement of the reinforcement cage 8 in the current trough section to form a whole;

[0042] S1.2: The outside of the I-beam flange plate 1 of the reinforcement cage is respectively welded with the anti-slip iron sheet 9;

[0043] S1.3: Install the anti-grouting iron sheet 9 in order from bottom to top; after the lower part of the anti-grouting iron sheet 9 is laid, weld the triangular support steel bar 3 on the horizontal steel bar of the reinforcement cage 8, so that the laid anti-grouting iron sheet The ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com