Underground diaphragm wall joint, clamping device matched with underground diaphragm wall joint and underground diaphragm wall construction method

A technology of a clamping device and a construction method, which is applied to artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of difficulty in fixing the locking pipe, difficult to grasp the lifting and pulling, and the installation of the locking pipe is skewed, etc. The effect of reliable compactness, reduction of production cost and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

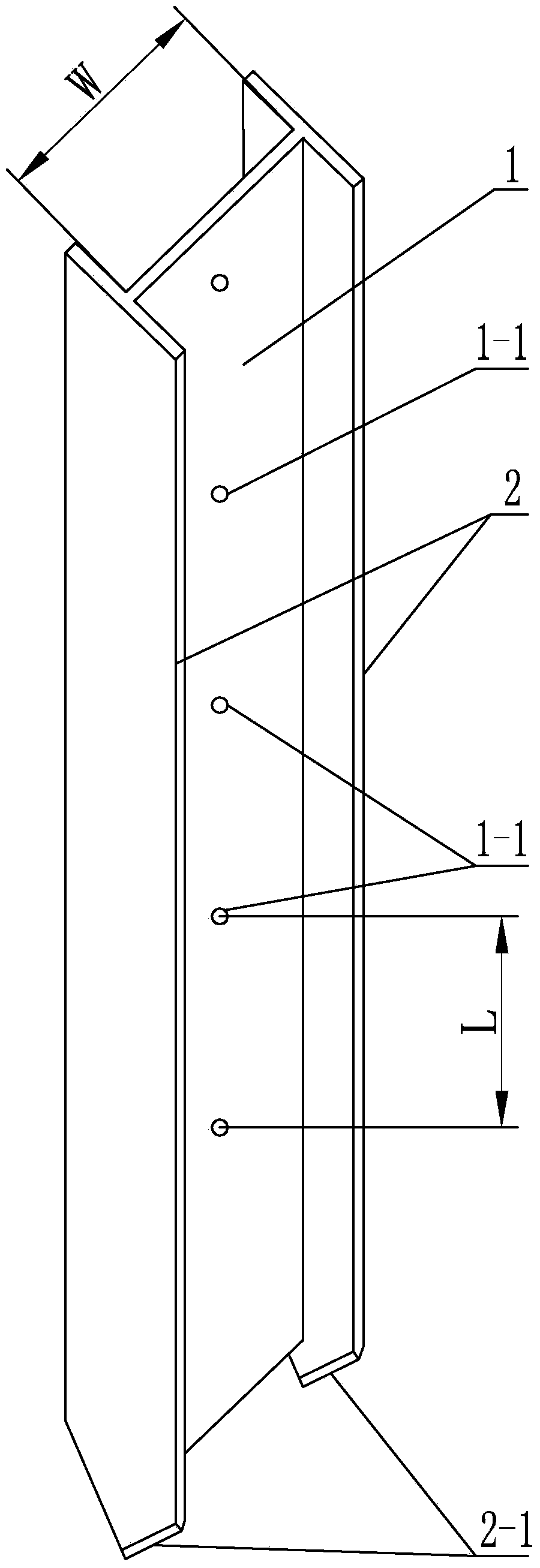

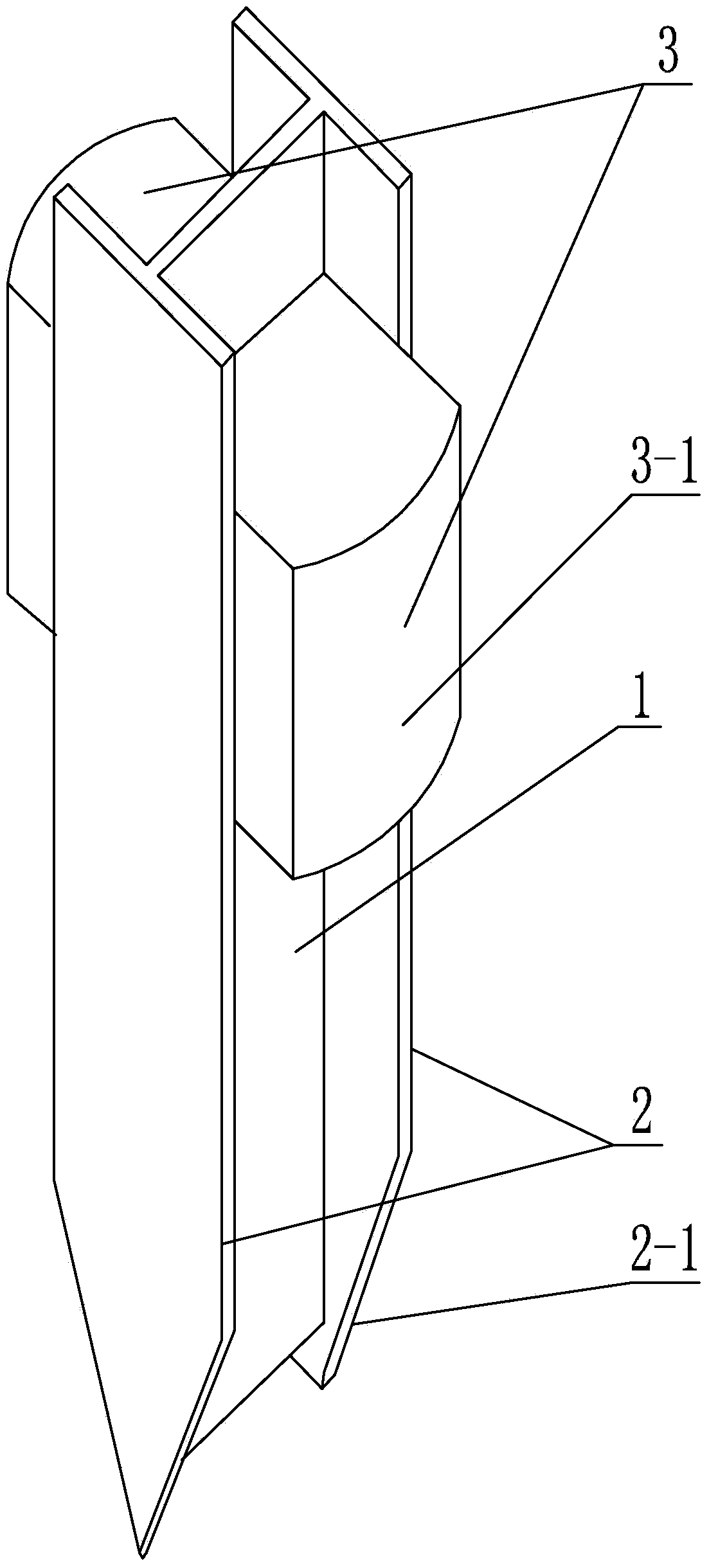

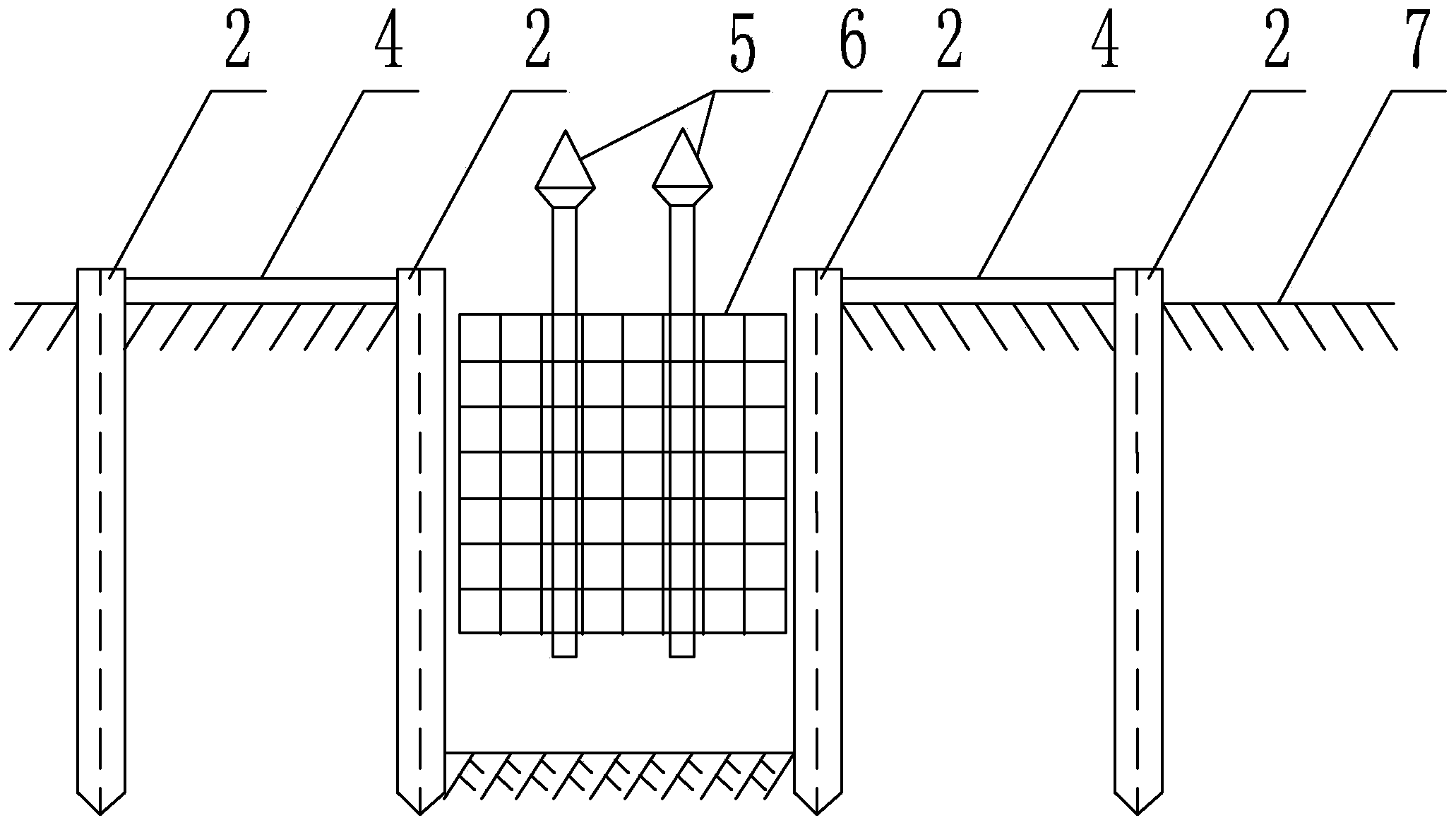

[0031] Specific implementation mode one: as Figure 1~2 As shown, the ground connection wall joint of this embodiment includes a web 1 and two side plates 2, the two side plates 2 are arranged in parallel and facing each other, and the two side plates 2 are fixed in one body through the web 1 along the length direction, and the two side plates 2 The two side plates 2 are arranged vertically to the web 1, the cross-section of the ground connection wall joint is "H" shaped, the lower ends of the two side plates 2 are processed with a bevel 2-1, and the width W of the web 1 is 550~ 650mm, the web 1 is uniformly processed with a plurality of circular through-holes 1-1 along its length direction, the diameter of the circular through-holes 1-1 is 100-110mm, and the diameter of two adjacent circular through-holes 1-1 The center distance L is 1750-1850mm.

[0032] The length of the ground connection wall joint of the present invention is made on site according to the designed wall de...

specific Embodiment approach 2

[0033] Specific implementation mode two: as figure 1 As shown, the width W of the web 1 in this embodiment is 600 mm.

[0034] Such design is to consider that the conventional design thickness of the connecting wall is used in the case of 1000mm, and the width W can be adjusted according to the designed connecting wall thickness. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0035] Specific implementation mode three: as figure 1 As shown, the diameter of the circular through hole 1-1 in this embodiment is 105mm. This design is to ensure that the 100mm diameter stud bolts pass through and fix the two side plates smoothly. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com