Construction method for preventing diaphragm wall from streaming

A construction method, the technology of ground connection wall, applied in the direction of excavation, sheet pile wall, foundation structure engineering, etc., to achieve the effect of tight combination, no bypass flow, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

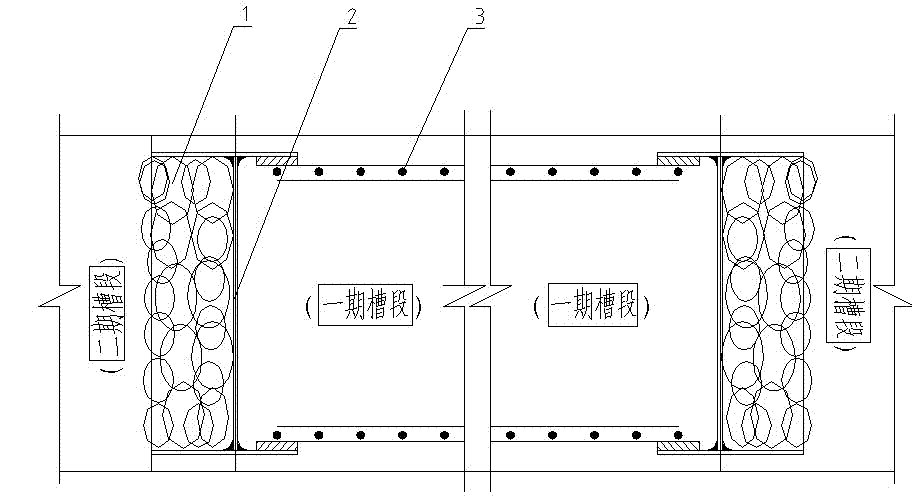

[0018] Throw and fill sand bags behind the I-beam in the first-stage trough section, and then compact it with a cuboid steel box hammer. See( figure 1 ) Schematic diagram of the location of the sand bag.

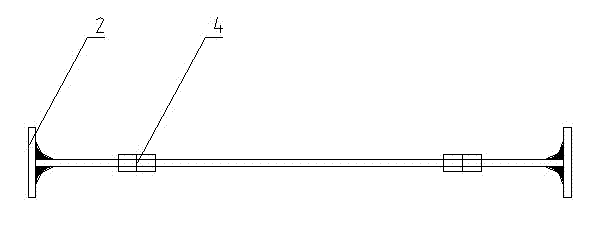

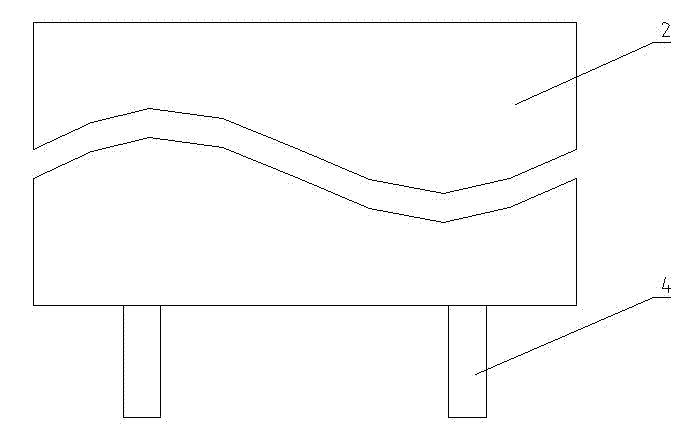

[0019] Since the elevation of the top of the ground connection wall is generally below the ground, it is difficult to control the position when throwing and filling the sand bag. Therefore, it is necessary to process an I-steel member with a slot, which is connected to the I-steel of the reinforcement cage 3 of the ground connection wall. , perforate the upper part of the component, thread the wire rope and the lock; the lower part adopts a card slot, and clamp the component on the steel cage I-beam. After the underwater concrete pouring of the ground connection wall is completed, the I-beam steel member is taken out. See( figure 2 , 3 , 4) I-beam card channel steel components.

[0020] The sand bag is a small-volume ordinary woven bag, filled with 1 / 3 of the volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com