High and watery coastal area underground continuous wall connector water stop device

A water-stop device and water-rich technology, which is applied to sheet pile walls, water conservancy projects, underwater structures, etc., can solve the problems of the quality of underground diaphragm wall trenches, high construction costs of water-stop methods, and poor engineering geological conditions, etc. Problems, to achieve good wall brushing effect, ideal waterproof effect, and strengthen the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

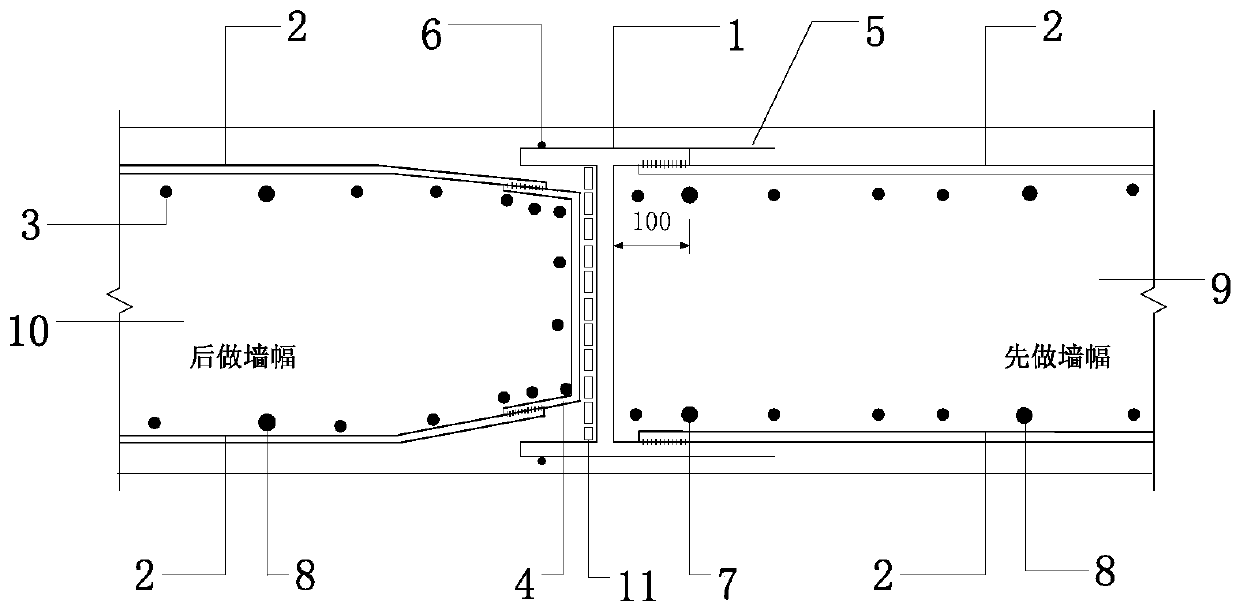

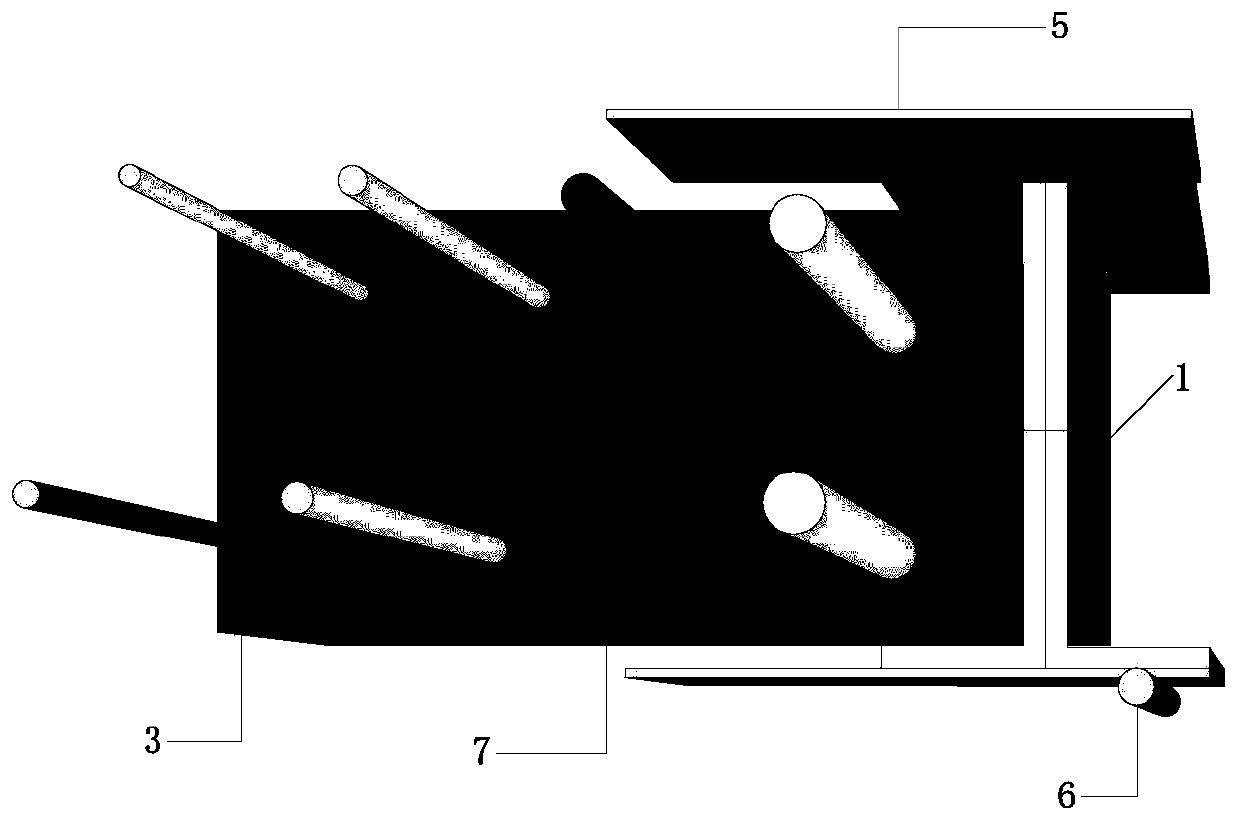

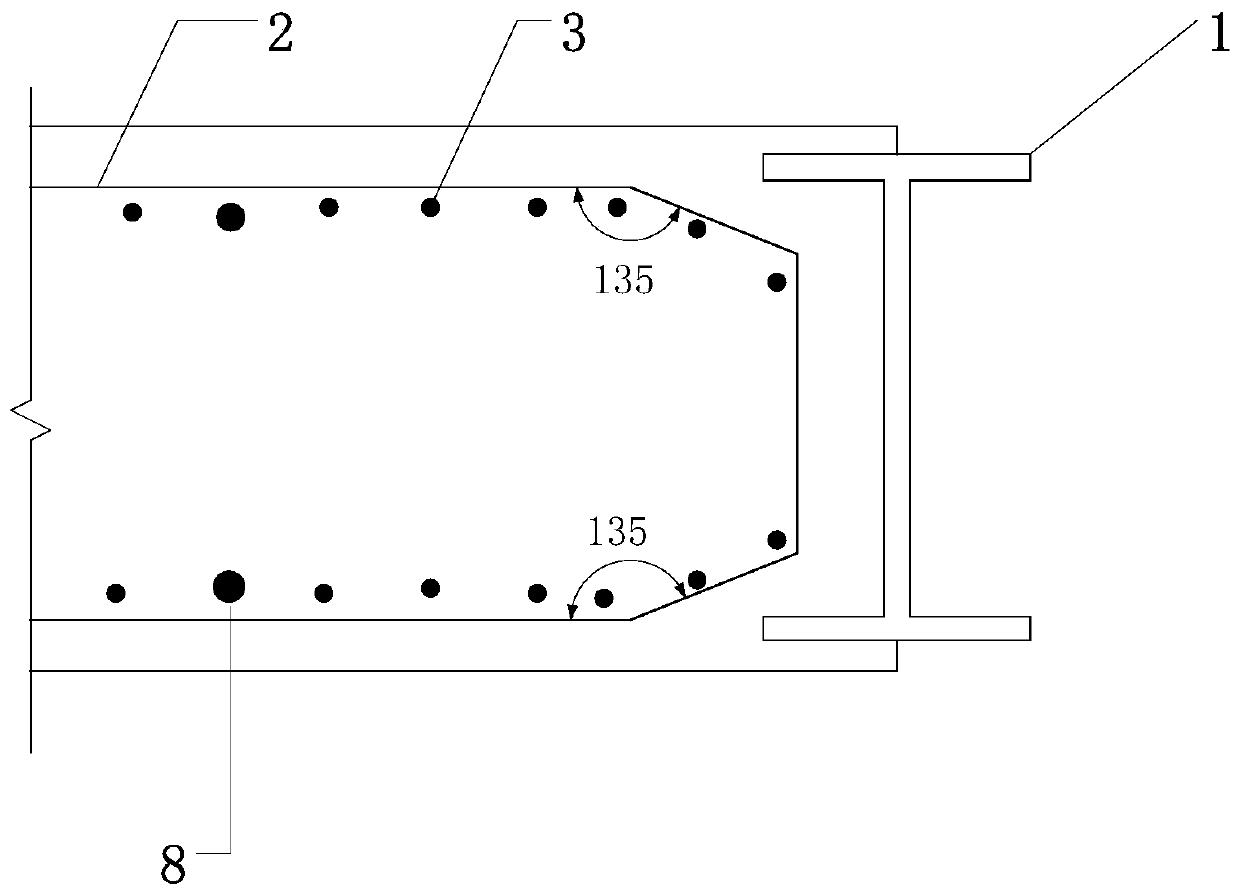

[0029] The main structure of the underground diaphragm wall joint water-stop device in the high-rich water near the sea area of this embodiment includes I-shaped steel plate 1, diaphragm wall horizontal rib 2, diaphragm wall vertical main rib 3, U-shaped stirrup 4, galvanized iron sheet 5, layering strip Steel bar 6, steel flower pipe 7, grouting pipe 8, first wall reinforcement cage 9, second wall reinforcement cage 10 and sandbag 11; diaphragm wall horizontal reinforcement 2 and diaphragm wall vertical main reinforcement 3 are mechanically connected, and steel flower pipe 7 is bound Lap on the first wall reinforcement cage 9; the galvanized iron sheet 5 is installed on the outside of the I-shaped steel plate 1, the galvanized iron sheet 5 and the bead reinforcement 6 are spot welded, and the I-shaped steel 1 is welded to the first wall reinforcement cage 9 , the weld length is 100mm; the U-shaped stirrup 4 and the horizontal bar 2 of the continuous wall are welded on one si...

Embodiment 2

[0037] In this embodiment, the joint water-stop device described in Embodiment 1 is applied to the construction of an underground diaphragm wall of a certain subway station. The specific construction process is as follows:

[0038] (1) Pouring guide wall: After the measurement and setting-out is completed, the construction of the guide wall begins. The construction quality of the guide wall is directly related to the construction quality of the underground diaphragm wall. The cross-section of the guide wall is made of inverted "L" cast-in-place reinforced concrete, with HRB400C12@200 steel skeleton evenly distributed, and the guide wall is made of C30 concrete. Before excavation of the guide wall, the excavation trench must be manually excavated. When the excavator is operating, a special person must stand by Supervise the construction, then bind the guide wall reinforcement and vertical formwork, pour C30 concrete, remove the formwork and add lateral support, and finally backf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com