Underground diaphragm wall construction method

A technology of underground diaphragm wall and construction method, applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve problems such as inability to completely solve the problem of water leakage, and achieve the effect of solving the problem of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] The present invention is illustrated by setting an underground continuous wall around the foundation pit as an example. A method for constructing an underground diaphragm wall, comprising the steps of:

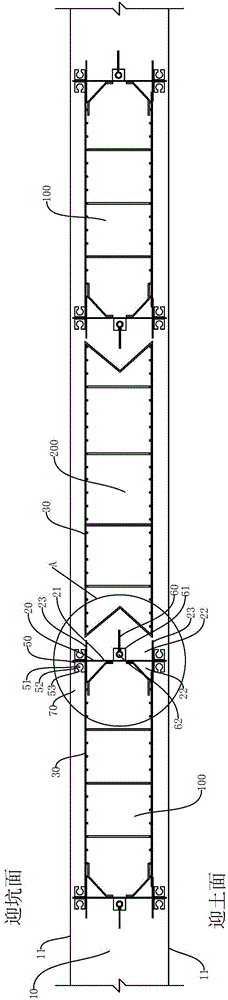

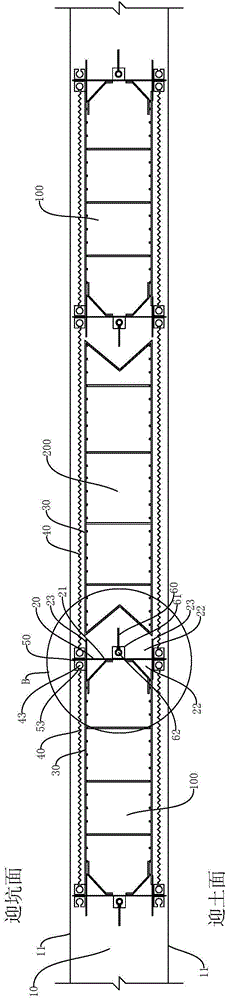

[0032] 1), such as figure 1 As shown, a groove 10 is formed; a groove 10 is formed at a position where an underground continuous wall needs to be installed, and the groove 10 has groove walls 11 on both sides. In this step, a special trenching machine is used for construction, and it is equipped with wall protection mud.

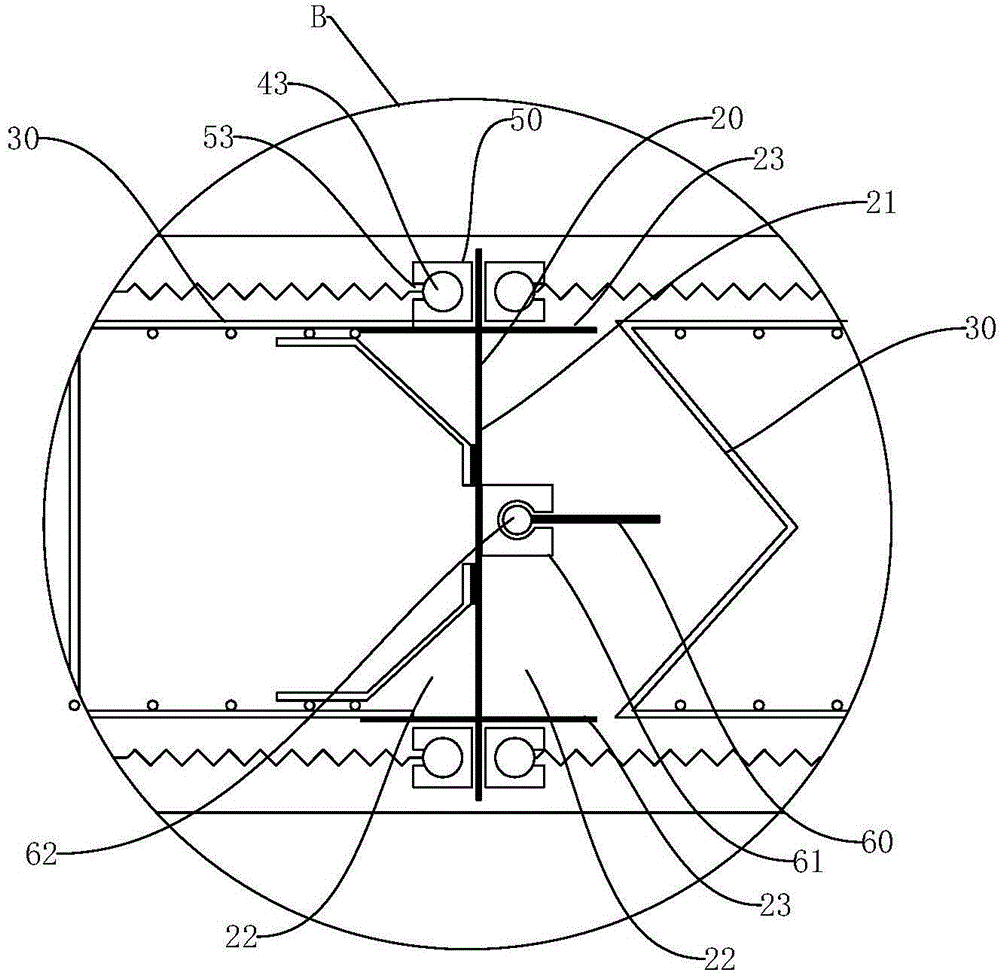

[0033] 2), such as figure 1 , figure 2 As shown, the joint 20 and the steel bar 30 are hung and placed in the groove 10 . Joints 20 are arranged at one or both ends of the reinforcement cage 30 , depending on the shape of the underground continuous wall and the position of the reinforcement cage 30 . If the underground continuous wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com