Flexible device of underground continuous wall for preventing concrete circuitous flowing

An underground diaphragm wall and flexible device technology, applied in sheet pile walls, underwater structures, water conservancy projects, etc., can solve the problems of inconvenient construction, bypass flow, time-consuming and laborious, etc., and achieve good compactness, high efficiency, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

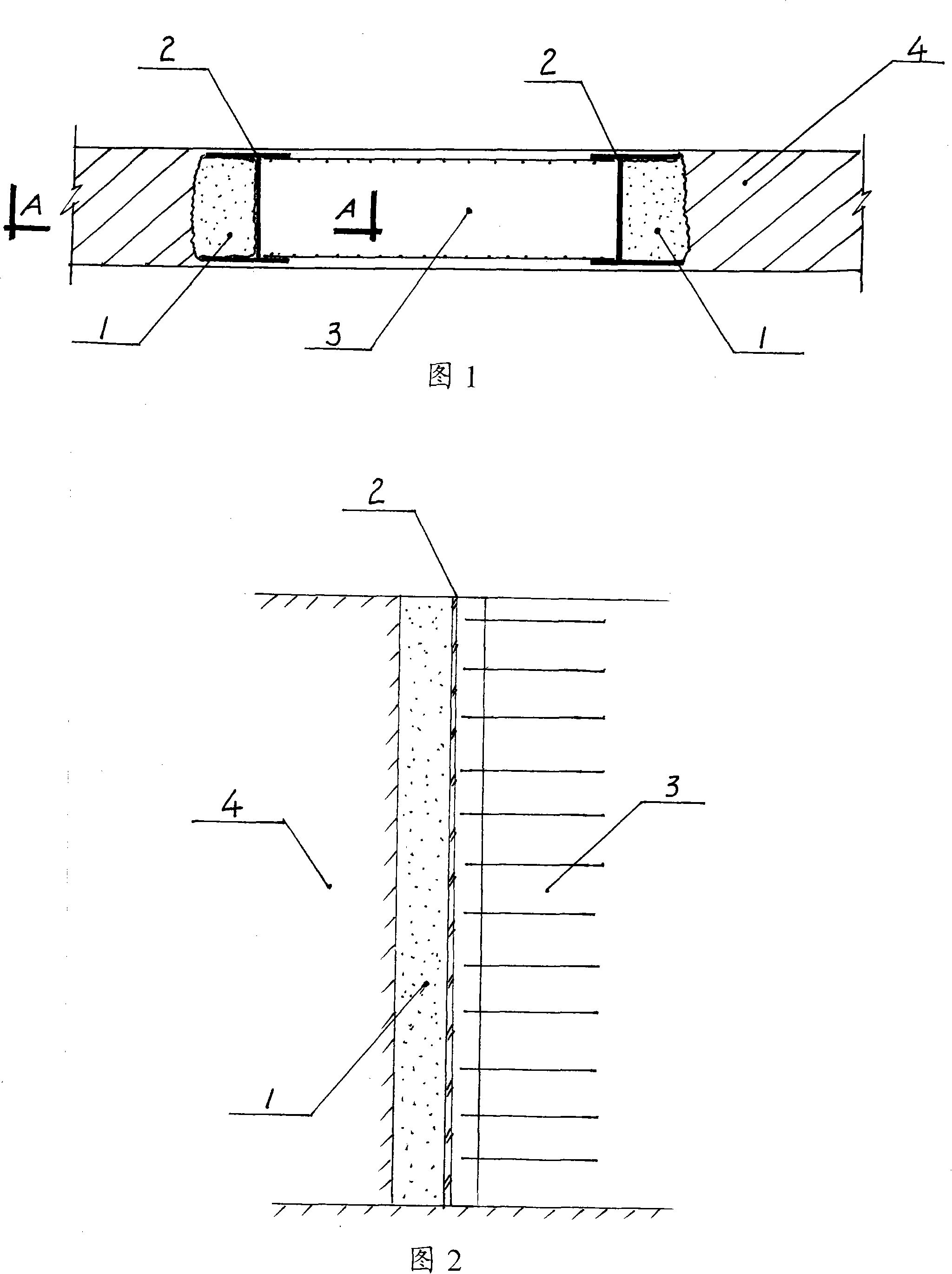

[0020] Embodiment 1: Referring to Fig. 1 and Fig. 2, this embodiment adopts an integral capsule body 1, and the filling in the capsule body 1 is gas, water or mud to form an air bag, water bag or mud bag for the I-shaped joint 2 The underground diaphragm wall is under construction. The capsule body 1 is installed between the joints 2 of the first-stage and second-stage grooves and the soil 4 of the second-stage groove. It can be installed into the groove section together with the diaphragm wall steel bars. It can be filled with fillers into the capsule body 1 first, and then the capsule body 1 can be put into the groove section; or the capsule body 1 can be put into the groove section first. , and then fill the capsule 1 with fluid fillings such as gas, water or mud, so that the capsule can be in contact with the inner wall of the joint 2 of the first-stage and second-stage grooves and the soil 4 of the second-stage groove, so as to prevent the concrete from flowing around to ...

Embodiment 2

[0021] Embodiment 2: Referring to Fig. 1 and Fig. 3, this embodiment adopts a split-type capsule 1, which is composed of multiple capsules spliced together, and the filling in the capsule 1 is soil, sand or stone chips, which is used for the I-shaped joint 2 The underground diaphragm wall is under construction. The capsule body 1 is installed between the joint 2 of the first-stage and second-stage grooves and the soil 4 of the second-stage groove. Install the capsule body in 2. When installing the capsule body, fill the capsule body 1 with solid fillings such as earth, sand or stone chips; then put multiple capsule bodies 1 into the joint 2 so that the capsule body can be connected , The inner wall of the joint 2 of the second-stage tank is in contact to prevent the concrete from flowing around to the second-stage tank section.

Embodiment 3

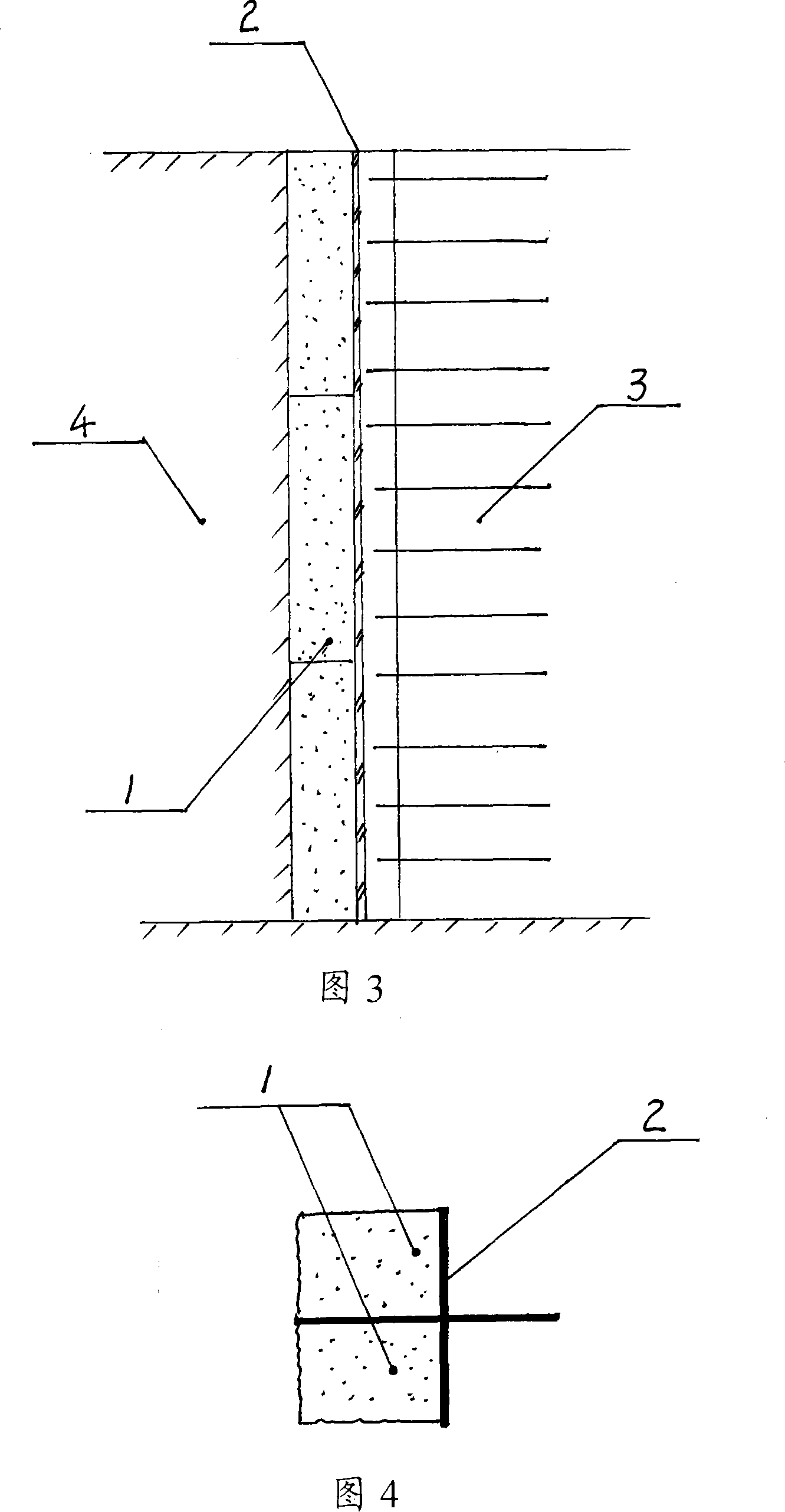

[0022] Embodiment 3: Referring to Fig. 4, the present embodiment adopts a split-type capsule 1, which is composed of two capsules, and the filling in the capsule 1 is gas, water or mud to form an air bag, water bag or mud bag for use in In the construction of the underground diaphragm wall of the cross-shaped joint 2, the capsule body 1 is installed between the joint 2 of the first-stage and second-stage troughs and the soil 4 of the second-stage trough, and the steel bars and joints of the first-stage trough section 3 are installed in the trough section The capsule body 1 has been installed in the joint 2 before, and installed in the groove section together with the continuous wall steel bars, the capsule body 1 can be filled with filling materials such as gas, water or mud first, or the capsule body 1 can be filled in the back Filling materials such as gas, water or mud. After being filled with fillers, the capsule body can be in contact with the inner wall of the joint 2 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com