I-beam joint structure preventing flowing around body and water seeping of underground diaphragm wall and construction method thereof

An underground diaphragm wall and joint structure technology, which is applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of concrete bypass, incomplete cleaning of joints, easy water leakage at the joints of underground diaphragm walls, etc. The effect of preventing bypass and avoiding water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the content, features and effects of the present invention, the present invention will be described in detail with reference to the accompanying drawings and embodiments.

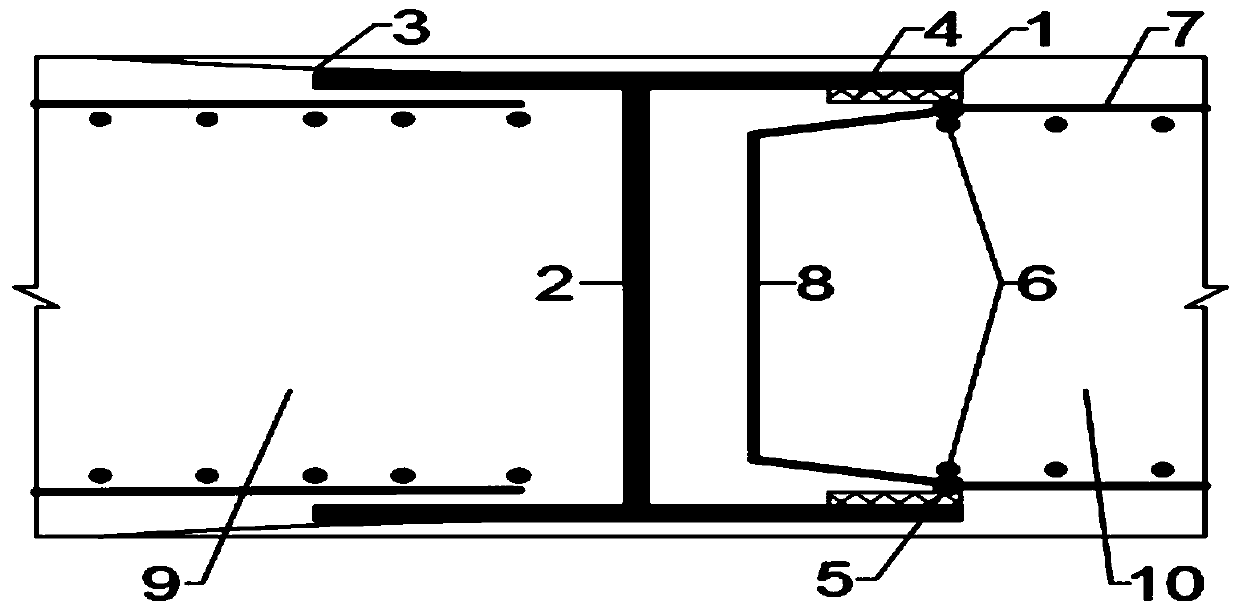

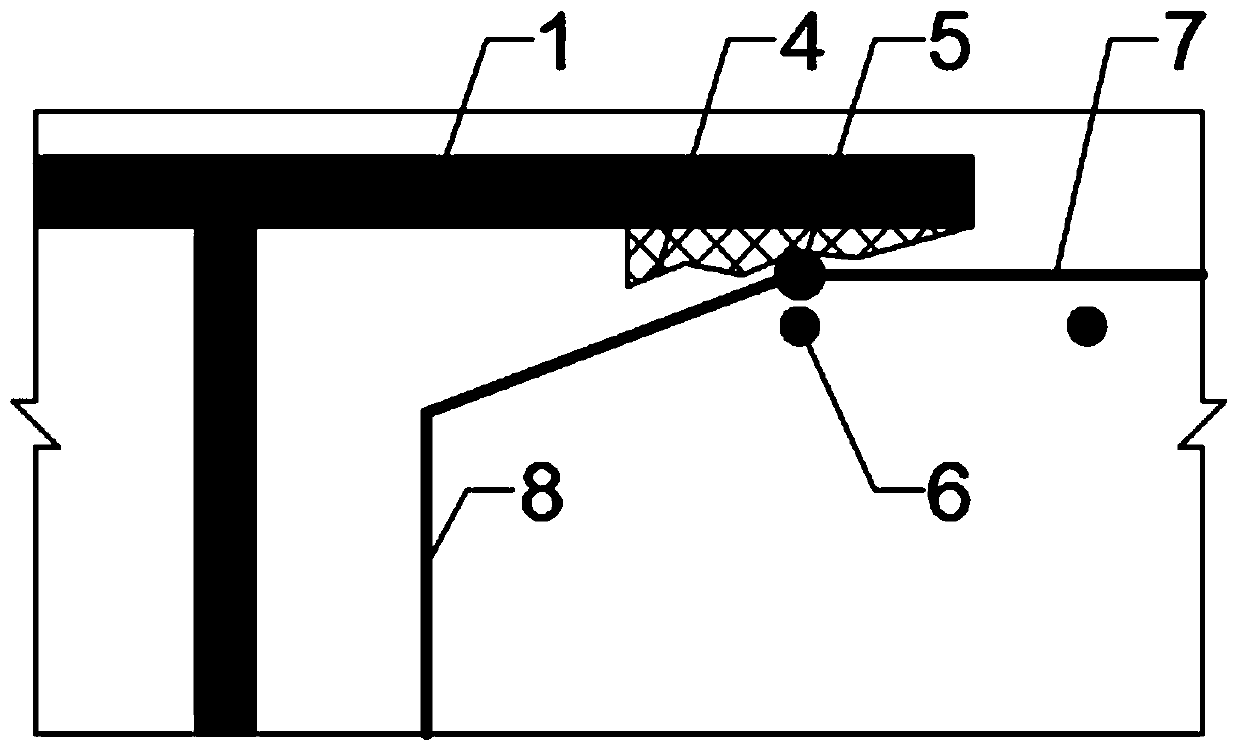

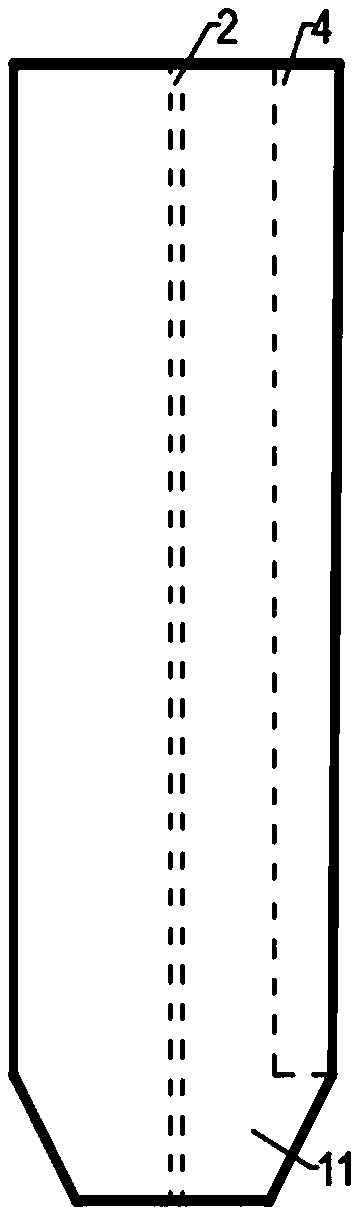

[0027] An underground diaphragm wall anti-circumvention and anti-seepage water I-shaped steel joint structure, wherein the joint structure is composed of I-shaped steel welded by two wing plate steels 1 and one web steel 2, anti-slip iron sheet 3, rubber The waterstop 4, the sealing vertical rib 5 at the corner of the steel cage end of the subsequent trough section, and the edge foot 11 at the bottom of the I-shaped steel joint are composed.

[0028] Such as figure 1 As shown, the inner side of the wing plate steel on one side of the I-beam is welded with the horizontally distributed ribs 7 of the reinforcement cage 9 of the previous groove section to form a whole, and the outer side of the wing plate steel on the side of the I-beam is respectively welded with the anti-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com