Super-deep diaphragm wall rigid connector comprehensive water stop system and construction method thereof

A technology of rigid joint and ground connection wall, which is applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of uneven settlement of surrounding ground, easy generation of quicksand, and unsmooth grouting, and achieves good application effect and technology. The effect of fewer links, lower requirements and lower construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

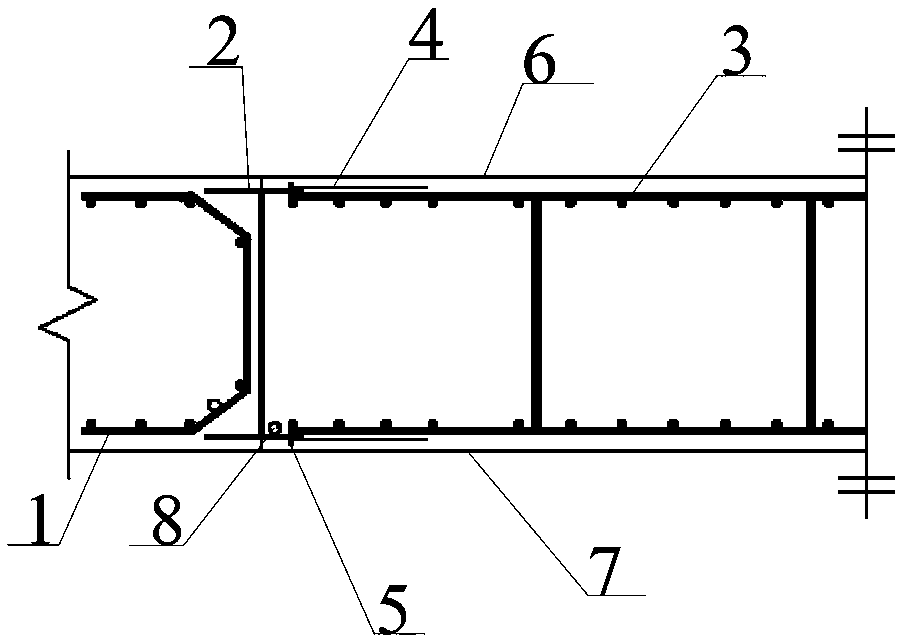

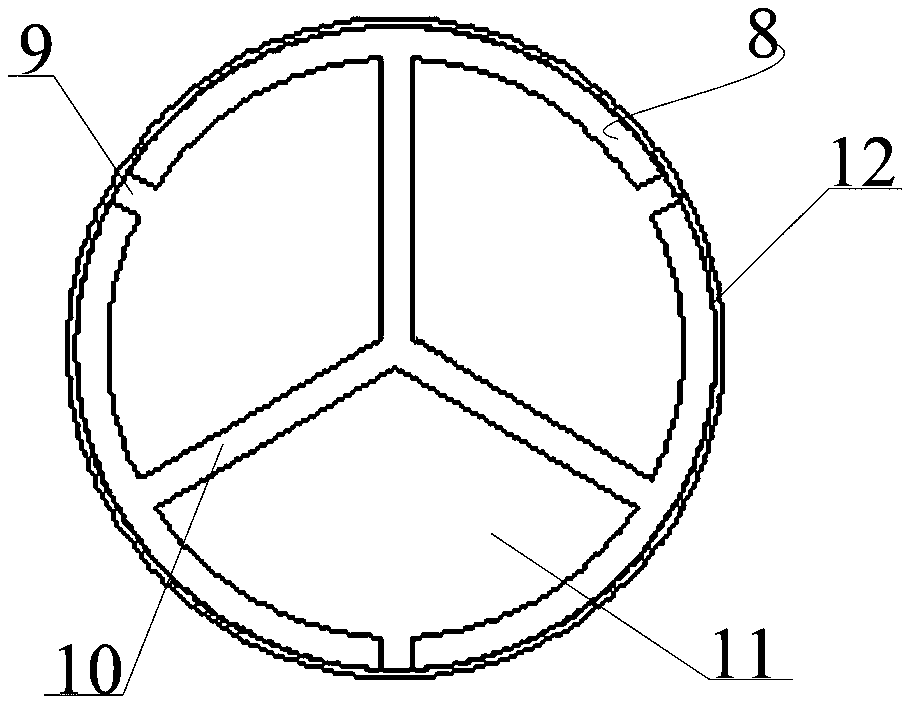

[0039]In this embodiment, the width of the flange of the I-beam joint is 350mm, and its bottom end is 500mm deeper than the bottom of the ground connection wall groove; the width of the grout-stop iron sheet is 500mm, and the thickness is 0.35mm; For the grouting pipe, the top of the pipe is 300mm higher than the top of the ground connection wall; the diameter of the grouting hole is 4mm, the distance below the groundwater level is 500mm, and the hole is wrapped with 2 layers of grout-stop tape with a width of 80mm. For the medium-fine sand mixed soil layer and the ultra-deep ground connection wall, micro-expansion ultra-fine cement slurry is used, the water-cement ratio is 0.7~0.8, and the grouting pressure is 0.4~1MPa. Compared with the joint water-stopping system of the ultra-deep ground-wall rigid joints or ordinary rigid joints combined with high-pressure rotary grouting piles, the construction cost of the ultra-deep ground-wall rigid joint comprehensive water-stop system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com